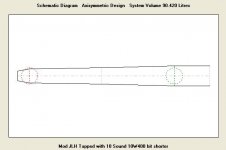

Ordered a pair of the 10W400 this week . Might have wait 3-4 weeks, so I'll get the cabinet plans sorted out .

If you run into any problems yell at me and I'll see what I can do to help. I think you will be pleasantly surprised by the results. I feel like I've got my best results with the wider bandwidth tapped horns. I speculate it is because you get more of the harmonics and overtones that are important to the overall texture of the bass. Kind of analogous to the harmonics of bass guitar being more import to tone than the fundamental. Keep us posted.

Rgs, JLH

If you run into any problems yell at me and I'll see what I can do to help. I think you will be pleasantly surprised by the results. I feel like I've got my best results with the wider bandwidth tapped horns. I speculate it is because you get more of the harmonics and overtones that are important to the overall texture of the bass. Kind of analogous to the harmonics of bass guitar being more import to tone than the fundamental. Keep us posted.

Rgs, JLH

Hi JLH

I don't want to hijack the thread, but I have one qustion for you John, that I hope you will respond to:

Being experienced with tapped horns, I wonder how you perceive the slam/punch of a tapped horn equipped with a single driver vs a vented cab with 2 x the same driver. (I know it's difficult to compare directly, because some driver are simply not usable in both confiurations - I just wanted to hear from someone who have tried both!)

Thanks!

Best regards

Peter

Hi JLH

I don't want to hijack the thread, but I have one qustion for you John, that I hope you will respond to:

Being experienced with tapped horns, I wonder how you perceive the slam/punch of a tapped horn equipped with a single driver vs a vented cab with 2 x the same driver. (I know it's difficult to compare directly, because some driver are simply not usable in both confiurations - I just wanted to hear from someone who have tried both!)

Thanks!

Best regards

Peter

That's really a apples to oranges comparison. The real problem is a lot of people associate the distortion in the midbass region with "punch". Much lower distortion or cleaner speakers are often thought to lack some "punch". However, you can measure them both and see the same SPL, but generally the vented cab will sound more punchy due to higher distortion. What I've found personally is when you reduce the distortion you lose some preceived punch, but you gain more detail and begin to hear more things in the recording that were previously masked. I also find the tapped horn generally has better tonal balance. The vented cab tends to be more of a one note bass machine. Just my thoughts.

Rgs, JLH

That's really a apples to oranges comparison. The real problem is a lot of people associate the distortion in the midbass region with "punch". Much lower distortion or cleaner speakers are often thought to lack some "punch". However, you can measure them both and see the same SPL, but generally the vented cab will sound more punchy due to higher distortion. What I've found personally is when you reduce the distortion you lose some preceived punch, but you gain more detail and begin to hear more things in the recording that were previously masked. I also find the tapped horn generally has better tonal balance. The vented cab tends to be more of a one note bass machine. Just my thoughts.

Rgs, JLH

Hi JLH,

Thanks for the reply! I quess I will simply have to compare the different system configurations directly in order to decide.

Best regards

Peter

Update

Take 2 -

Thanks to djk for the design. Great to see how helpful some of the DIY Audio people are , I'm a bit embarrassed to say the design has already reached an advanced state, with the speaker drivers ordered and the build layout finalised.

The design you showed has some problems that I found myself trying to acheive the original start intentions. It seems hard to get the area from eg. 100 to 150Hz flat if you try to get a roll-down from 100Hz to 35Hz. You always seem to get a dip above 100Hz in that case.

In the end I compromised my 35Hz target and also went for a flatter response, in order to get the best possible performance above 100Hz, which will help me to acheive the crossover to the 120-700Hz horn more successfully .

JLH , your comments are always very encouraging, I know your standards are high and this adds extra weight to the advice.

Increasing tone in every frequency band has a high priority for me . In my experience , extra tone always goes together with 'natural presence' and expanded soundstage . I'm now very keen to get the first unit built and do some listening .

Project is in full swing ( much quicker than my last one ) . This weekend, I drew out and finalised the construction details, mainly the top fold issues . I also drew up a cutting plan for a 4' x 8' sheet of 18mm MDF , which may get cut this week ( with luck ) by my wood supplier . I also made one base panel from 25mm ply .

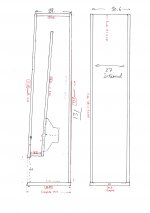

Briefly, the form of this speaker will be a pillar about 130cm height , 33cm deep and 30cm wide. These are outside dimensions . The mouth is 19.3 x 27 cm . Above the mouth, the front baffle slopes back a bit - 2.4 degrees - to a slightly smaller top area ( about 29 x 30 cm ) . This is due to the four-section horn expansion, which is necked-down a bit at the halfway point . It's rather similar to JLH's 40Hz unit, except for the sloping front , and I'm going to make the base panel removeable to get access to the driver, rather than having a rear-access panel .

I will try to scan a picture of the layout in next 2-3 days .

At this rate, I will be waiting for the drivers ...

MJ

Take 2 -

Thanks to djk for the design. Great to see how helpful some of the DIY Audio people are , I'm a bit embarrassed to say the design has already reached an advanced state, with the speaker drivers ordered and the build layout finalised.

The design you showed has some problems that I found myself trying to acheive the original start intentions. It seems hard to get the area from eg. 100 to 150Hz flat if you try to get a roll-down from 100Hz to 35Hz. You always seem to get a dip above 100Hz in that case.

In the end I compromised my 35Hz target and also went for a flatter response, in order to get the best possible performance above 100Hz, which will help me to acheive the crossover to the 120-700Hz horn more successfully .

JLH , your comments are always very encouraging, I know your standards are high and this adds extra weight to the advice.

Increasing tone in every frequency band has a high priority for me . In my experience , extra tone always goes together with 'natural presence' and expanded soundstage . I'm now very keen to get the first unit built and do some listening .

Project is in full swing ( much quicker than my last one ) . This weekend, I drew out and finalised the construction details, mainly the top fold issues . I also drew up a cutting plan for a 4' x 8' sheet of 18mm MDF , which may get cut this week ( with luck ) by my wood supplier . I also made one base panel from 25mm ply .

Briefly, the form of this speaker will be a pillar about 130cm height , 33cm deep and 30cm wide. These are outside dimensions . The mouth is 19.3 x 27 cm . Above the mouth, the front baffle slopes back a bit - 2.4 degrees - to a slightly smaller top area ( about 29 x 30 cm ) . This is due to the four-section horn expansion, which is necked-down a bit at the halfway point . It's rather similar to JLH's 40Hz unit, except for the sloping front , and I'm going to make the base panel removeable to get access to the driver, rather than having a rear-access panel .

I will try to scan a picture of the layout in next 2-3 days .

At this rate, I will be waiting for the drivers ...

MJ

Just as a reference point for others (since you design is fixed), the crossover design can complement the roll-off of the cabinet.

In other designs I have used a low-pass filter with a high Q to achieve a LR24 transfer function (6dB down at the crossover point). In the case of the first out-of-band peak in the TH, either a damped 1/4W stub or an electronic zero (notch) will be needed. This can extend the usable bandwidth about a half octave or so.

http://i56.photobucket.com/albums/g196/dkleitsch/dts20inside.jpg

Stubs in a Danley design.

In other designs I have used a low-pass filter with a high Q to achieve a LR24 transfer function (6dB down at the crossover point). In the case of the first out-of-band peak in the TH, either a damped 1/4W stub or an electronic zero (notch) will be needed. This can extend the usable bandwidth about a half octave or so.

http://i56.photobucket.com/albums/g196/dkleitsch/dts20inside.jpg

Stubs in a Danley design.

Stubs

Hi djk

That's an interesting pic, and I've seen it before, it's starting to make a bit more sense, but I'll fire out a couple of Qs :

(i) Are the pipes tapping into the extreme throat end of the taper ?

(ii) Are these just resonant pipes with a 1/4W length chosen to reduce the first 'problem' peak, which in my case would be around 160-170Hz ?

or (iii) do they duct air from the throat into the second part of the line to cause some other effect on the horn loading ?

This is very timely information anyway . Anything to reduce the burden of electronic correction is v.important in my books .

Now, 1/4W at 170Hz is ...50cm .. hmmmm

Hi djk

That's an interesting pic, and I've seen it before, it's starting to make a bit more sense, but I'll fire out a couple of Qs :

(i) Are the pipes tapping into the extreme throat end of the taper ?

(ii) Are these just resonant pipes with a 1/4W length chosen to reduce the first 'problem' peak, which in my case would be around 160-170Hz ?

or (iii) do they duct air from the throat into the second part of the line to cause some other effect on the horn loading ?

This is very timely information anyway . Anything to reduce the burden of electronic correction is v.important in my books .

Now, 1/4W at 170Hz is ...50cm .. hmmmm

jpeg of the proposed build , from some old-school sketching I did at the weekend .

Looks good to me. I like the fact that the woofer is well protected inside the horn. It should last forever. Nice work.

Rgs, JLH

P.S. Make sure the hole cutout for the woofer is the full diameter of the cone.

Details

Ha ha , yes JLH I saw the problems one guy had with the half-sized aperture .

Hoping to get the main pieces tomorrow and make a start .

Details - intending to put some small corner 'fillers' at the top fold and one larger angle in the lower back corner. The volume has been calc-ed to suit .

Not sure about :

(i) whether to put a layer of wool felt ( 10mm thick ) at the upper fold to reduce any upper-bass or lower-mid hollowness

(ii) whether to put some texture ( eg sawdust in varnish ) on the walls of the horn before I seal it up .

Advice useful .

Looks like djk did a hit-and-run on the 1/4W stubs, not sure whether to allow contingency for that or not . 'Not' if I don't know how to do it !

MJ

Ha ha , yes JLH I saw the problems one guy had with the half-sized aperture .

Hoping to get the main pieces tomorrow and make a start .

Details - intending to put some small corner 'fillers' at the top fold and one larger angle in the lower back corner. The volume has been calc-ed to suit .

Not sure about :

(i) whether to put a layer of wool felt ( 10mm thick ) at the upper fold to reduce any upper-bass or lower-mid hollowness

(ii) whether to put some texture ( eg sawdust in varnish ) on the walls of the horn before I seal it up .

Advice useful .

Looks like djk did a hit-and-run on the 1/4W stubs, not sure whether to allow contingency for that or not . 'Not' if I don't know how to do it !

MJ

(i) whether to put a layer of wool felt ( 10mm thick ) at the upper fold to reduce any upper-bass or lower-mid hollowness

(ii) whether to put some texture ( eg sawdust in varnish ) on the walls of the horn before I seal it up .

I've used poly batting material stapled to the walls before. There is a fine balance to how much. You don't want to go nuts with it. Probably 2 feet in the throat near where woofer is mounted and nothing else. I wouldn't mess with putting it at the fold.

Texturing the inside of the horn shouldn't do much considering the wavelenghts we are talking about. I would not bother with it.

Rgs, JLH

Progress

One pic of construction as of this afternoon . Some parts glued-together , others just prepared . Going very well, helped by the fact my timber supplier cut the pieces to about +/-0.5mm accuracy !

I may be held up quite a bit now by lack of drivers, because I wasn't confident to cut all the fixing holes without marking-through from the real speaker . That means I also can't fit the internal panel yet . I will work on some details ( baseplates ) and source the remaining wood I need to make the 2nd unit .

Might need your contribution on a ~120-700 bass/mid horn JLH , I'll raise a thread on Multi-Way section some time soon . Have been talking to Lars about the best way of simulating SPL correctly -

High Efficiency Speaker Asylum - Final debate on 120-700 Hyperbolic with B&C 8PE21 - IslandPink - March 03, 2011 at 12:23:09

MJ

One pic of construction as of this afternoon . Some parts glued-together , others just prepared . Going very well, helped by the fact my timber supplier cut the pieces to about +/-0.5mm accuracy !

I may be held up quite a bit now by lack of drivers, because I wasn't confident to cut all the fixing holes without marking-through from the real speaker . That means I also can't fit the internal panel yet . I will work on some details ( baseplates ) and source the remaining wood I need to make the 2nd unit .

Might need your contribution on a ~120-700 bass/mid horn JLH , I'll raise a thread on Multi-Way section some time soon . Have been talking to Lars about the best way of simulating SPL correctly -

High Efficiency Speaker Asylum - Final debate on 120-700 Hyperbolic with B&C 8PE21 - IslandPink - March 03, 2011 at 12:23:09

MJ

Attachments

Throat packing

Still waiting for the drivers ...

So, I've been working on details, and getting pieces done for unit 2 .

Shown here is how I've decided to squeeze-down the beginning of the throat volume as per the model . I haven't acheived quite 120cm^2 but it's about 150 now. This piece of wood is incidentally cut from the front panel of the abandoned Onken project !

Still waiting for the drivers ...

So, I've been working on details, and getting pieces done for unit 2 .

Shown here is how I've decided to squeeze-down the beginning of the throat volume as per the model . I haven't acheived quite 120cm^2 but it's about 150 now. This piece of wood is incidentally cut from the front panel of the abandoned Onken project !

Attachments

Sometimes I really hate computers.

I hate them all the time, but try Alt+0176 = ° for degree symbol next time.

GM

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- Ideas on 35-150(?) HiFi Tapped Horn