Even if it can be measured and calculated the question is can it be heard while the music is playing?

Yes. It is described in the technical reports.

Most modern cabinets are mdf. Its pretty solid and dense stuff. Is there any audible benefit in using other materials?

Yes. It is described in the technical reports.

We need to put two cabinets side by side, one made of brick (a solid material) and another with unbraced mdf, to decide this.

I wouldn't assume that a cabinet made of bricks doesn't vibrate...

I wouldn't assume that a cabinet made of bricks doesn't vibrate...

No you can assume its less than flimsy mdf. Have you tried it? If you made a cabinet which was 12 inch thick instead of 1 inch thick mdf, you would have no issues with vibration to worry about.

Hi,

I’ll try to explain the best I can my small contribution to acoustical behavior of loudspeakers I did a few years ago.

M

Thanks M, it is so rare to see really good data around here. From what I know your conclusions are spot on. Particularly the point about cross bracing. I have done this for a long time.

Some time ago I posted the cross brace recommendation here and got endless arguments about why it wouldn't work. Well it does work and it works very well.

I use CLD on the front baffle and the back panel, the two largest surfaces. Then the four largest surfaces are all linked together at their centers to the center of the cabinet with stiff oak posts. This simple technique is extremely effective at reducing all of the major LF modes in the cabinet. I now use CLD cross braces that I construct. The higher modes are dealt with by high damping, light, stiff panel material.

But again, job well done! Good to see some science around here for a change.

No you can assume its less than flimsy mdf. Have you tried it? If you made a cabinet which was 12 inch thick instead of 1 inch thick mdf, you would have no issues with vibration to worry about.

You forgot about the forklift required to move it. Is your doorway big enough to fit that?

Thanks M, it is so rare to see really good data around here. From what I know your conclusions are spot on. Particularly the point about cross bracing. I have done this for a long time.

:

Maybe I misunderstood but it sounds like he is in favor of triangle bracing over cross bracing. Linking corners to the opposing center of a panel.

Last edited:

That is a form of cross bracing in that the brace goes across the inside of the cabinet rather than just on one panel alone. The key is to use the counter opposed geometry of one panel to stiffen the other panel. There are many ways to do this. I have used the triangle method as well when I could not get a short brace straight across. Remember that for a given cross section, the shorter a brace is the stiffer it is.

There is no such thing as Perfect, regardless of cost. PeriodNo. You have to build the perfect room first. And then you would find the perfect position. The speakers would need to be built on location. Its not uncommon.

I know a guy, bit older than myself whom has lofty dreams like yours. Difference between you two isn't education, it's the Dream. His is perpetual motion. After hearing his ramblings for close to 40 years now, don't have much patients for him either. He also never bothered to read (READ!), learn the math, or take a scientific approach. Yet he goes on and on... sad really.

lilun said:do you like the united states mike? whats the advantages?

is it a free country? lot of opportunities?

Troll

Not sure I understand. Are you saying that you took a grid of 1500 measurements over the surface of your bookshelf speaker, used them as the velocity boundary conditions for a BEM simulation and it failed to predict the SPL in the far field?1. Simple vibration measurements cannot account for any precise acoustical results.

There no simple operator to transpose accelerometer out-put into dB SPL.

The geometry of pattern’s deformation is preponderant in is acoustic radiation of each resonance past the first one (some call that balloon mode).

That is not at all what he is saying. He is saying that there is no "simple" transform. Using one accelerometer on an enclosure wall tells you nothing about the sound that is radiated. Two might tell you more, three more yet, but it takes a lot of data and calculations to find a direct stable relationship.

Perhaps you reading is correct but that is not how I read the post. "Simple vibration measurements cannot account for any precise acoustical results." Had he said single and/or not described taking a set of simple(?) vibration measurements in the preceding paragraph I would not have posted. Mind you it seems a bit churlish criticising someone describing some real work given the OP of this thread.That is not at all what he is saying. He is saying that there is no "simple" transform. Using one accelerometer on an enclosure wall tells you nothing about the sound that is radiated. Two might tell you more, three more yet, but it takes a lot of data and calculations to find a direct stable relationship.

There are inexpensive devices intended to attach to and "make any surface into a speaker" (no one claims it to be a good speaker!). But it would seem that the best panel construction would be one that works poorly with such a device.

Has anyone tried comparing boxes of different construction and with no ports or driver holes, driven by one of these gizmos mounted on the inside of the front baffle? For equal drive level, meaaure SPL at the outside of the box (good=silent).

I never got around to trying it, maybe it's been done? (Or is it just a dumb idea. ..?)

Has anyone tried comparing boxes of different construction and with no ports or driver holes, driven by one of these gizmos mounted on the inside of the front baffle? For equal drive level, meaaure SPL at the outside of the box (good=silent).

I never got around to trying it, maybe it's been done? (Or is it just a dumb idea. ..?)

What a fascinating read! Lots to learn here.....If I may, has any data been collected on the sealed vs. ported enclosure? Yes I did get the point of the frequencies will be far outside any tuned ported enclosure but will there be any particular differing approach of the two?

Lots of data to absorb here, well worth several re-reads. Thanx!

______________________________________________________Rick.......

Lots of data to absorb here, well worth several re-reads. Thanx!

______________________________________________________Rick.......

Hi Dave, and Others

The BEM code gave the theoretical pressure output corresponding to the actual (measured) cabinet vibrations alone.

You can measure the driver response at several angles in the cabinet and then compare both (subtract the vibration’s theoretical pressure contributions is fun…)

The naughty modes are the ones that actually have a significant contribution, that’s the obvious answer…

Note to DIYers: unglued (just screwed) panels act like passive radiators with really significant output at some frequencies.

As you sais it is all very similar to cone resonances: some patterns look nasty but their contribution is insignificant because the different parts of the cone/panel cancel each other out.

Also some resonances radiate only off axis so you need actually need to measure and simulate on orbits.

Some say that the bigger the heavier the better, well think of a church bell: heavy and very stiff and very… good at radiating noise because the resonances are mostly damped through acoustic coupling which is poor as damping goes hence the long ringing.

Same goes with concrete towers: heavy stiff thick etc but also very good at transmitting the noise made by Mrs Robison (heels on the floor).

The issue as I said is that it is not trivial to estimate what will contribute to what, especially when the order of the mode is high.

So I would say that good practices should be to:

1. control the low order modes as much as possible with sensible braces linking vibrations nodes to anti-nodes

2. use stiff and light (that goes with thin in general) material this can be enhanced by constraining the walls (i.e. curving and/or put the in tension).

3. damp as much as you can with a constrained layer.

WRT the shape cylinders have a theoretical advantage (but construction is probably the limiting factor).

Force bent walls are good because the stiffness gain is high without adding thickness (i.e. weight) and as a bonus you may have better diffraction property

You can refer yourself to room acoustic for the ratios (long debate in itself) of the box dimensions that will both help with internal standing waves and

with the vibration of the cabinet walls provided that the material used in more or less uniform.

I did, using an inertial actuator bolted on a real woofer frame on a real cabinet. You could also use a modified butt-kicker but you need to decrease its own acoustic output.

This is quite obvious, you can easily recognize the music played through the cabinet…

You could just listen to the output of the laser vibrometer/accelerometer (did, I felt like a CIA agent…) or a stethoscope (did) but this give a wrong picture of the pressure radiated because all are in the very near field.

The information is too local so things might be worst than they really are a few meters away.

Of course if you have the real measurement you can use the BEM to calculate a transfer function at a virtual listening point and use it to do auralization, I did…

Pretty good indeed:

“Factor in the design of loudspeaker cabinets" H. D. Harwood, B. Sc. R. Mathews

H.D. Harwood - People - BBC R&D just browse the papers, they are well worth reading, BBC papers although from different era are still dealing with the same physics ;-)

And amongst many other accessible papers:

"Effect of panel damping on loudspeaker enclosure vibration" J. Backman

"The sound output of loudspeaker cabinet walls" D. A. Barlow

"Loudspeaker enclosure walls" P. W. Tappan

"The theory of loudspeaker cabinet resonances" J. K. Iverson

M

The BEM code gave the theoretical pressure output corresponding to the actual (measured) cabinet vibrations alone.

You can measure the driver response at several angles in the cabinet and then compare both (subtract the vibration’s theoretical pressure contributions is fun…)

The naughty modes are the ones that actually have a significant contribution, that’s the obvious answer…

Note to DIYers: unglued (just screwed) panels act like passive radiators with really significant output at some frequencies.

As you sais it is all very similar to cone resonances: some patterns look nasty but their contribution is insignificant because the different parts of the cone/panel cancel each other out.

Also some resonances radiate only off axis so you need actually need to measure and simulate on orbits.

Some say that the bigger the heavier the better, well think of a church bell: heavy and very stiff and very… good at radiating noise because the resonances are mostly damped through acoustic coupling which is poor as damping goes hence the long ringing.

Same goes with concrete towers: heavy stiff thick etc but also very good at transmitting the noise made by Mrs Robison (heels on the floor).

The issue as I said is that it is not trivial to estimate what will contribute to what, especially when the order of the mode is high.

So I would say that good practices should be to:

1. control the low order modes as much as possible with sensible braces linking vibrations nodes to anti-nodes

2. use stiff and light (that goes with thin in general) material this can be enhanced by constraining the walls (i.e. curving and/or put the in tension).

3. damp as much as you can with a constrained layer.

WRT the shape cylinders have a theoretical advantage (but construction is probably the limiting factor).

Force bent walls are good because the stiffness gain is high without adding thickness (i.e. weight) and as a bonus you may have better diffraction property

You can refer yourself to room acoustic for the ratios (long debate in itself) of the box dimensions that will both help with internal standing waves and

with the vibration of the cabinet walls provided that the material used in more or less uniform.

If I could kill the direct radiation of a driver and listen to the cabinet output only (some have put two identical cabinets over both sides of a driver),

David

I did, using an inertial actuator bolted on a real woofer frame on a real cabinet. You could also use a modified butt-kicker but you need to decrease its own acoustic output.

This is quite obvious, you can easily recognize the music played through the cabinet…

You could just listen to the output of the laser vibrometer/accelerometer (did, I felt like a CIA agent…) or a stethoscope (did) but this give a wrong picture of the pressure radiated because all are in the very near field.

The information is too local so things might be worst than they really are a few meters away.

Of course if you have the real measurement you can use the BEM to calculate a transfer function at a virtual listening point and use it to do auralization, I did…

The Harwood study is still the most complete and on point look at that.

David

Pretty good indeed:

“Factor in the design of loudspeaker cabinets" H. D. Harwood, B. Sc. R. Mathews

H.D. Harwood - People - BBC R&D just browse the papers, they are well worth reading, BBC papers although from different era are still dealing with the same physics ;-)

And amongst many other accessible papers:

"Effect of panel damping on loudspeaker enclosure vibration" J. Backman

"The sound output of loudspeaker cabinet walls" D. A. Barlow

"Loudspeaker enclosure walls" P. W. Tappan

"The theory of loudspeaker cabinet resonances" J. K. Iverson

M

That is not at all what he is saying. He is saying that there is no "simple" transform. Using one accelerometer on an enclosure wall tells you nothing about the sound that is radiated. Two might tell you more, three more yet, but it takes a lot of data and calculations to find a direct stable relationship.

Precisely!

You can do the calculation and have a result as I did but look at the amount of work involved!

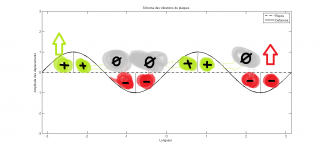

Saying something along the line of “the amplitude of the vibrations is high at this very spot (accelerometer location) therefore the pressure radiated by the whole cabinet MUST be high” is just wrong except for the very first modes or stupid design, look hereafter for an example of the latter ;-)

The results are far from being trivial. I give you two examples:

1. What happens if you put the accelerometer on the middle anti-node on the attached vibration pattern: big vibrations very small radiation.

2. When I did the first measurement with the cabinet back panel screwed and not glued, the amplitude of the vibration I measured was not large at all but the whole panel was uniformly moving.

However the panel surface area was several times that of the driver's: that made a very nice cardoid source!

That also why I do not give much attention to Stereophile data, IMO best intention wrong realization.

I doubt that a laser vibrometer is something that can be afforded by many (audio) companies although it does speeds up the work dramatically to an industry compliant speed (design -> check -> improve -> check etc.)

For expensive high-end speaker it is OK to do it to make sure that your mega bucks cabinet (B&W does it) is working as you think it is but for entry level stuff better follow good practices...

M

Attachments

Last edited:

No you can assume its less than flimsy mdf. Have you tried it? If you made a cabinet which was 12 inch thick instead of 1 inch thick mdf, you would have no issues with vibration to worry about.

No, you can't assume that. Look at the BBC report, or at Barlows paper (i think it was there). They measured the vibration of panels with different thickness, and they all vibrated with the same amplitude - just at different frequencies. I know, this sounds strange, but it is perfectly according to theory.

And it's the same if you use other materials than wood. Aluminum, for example, is stiffer and denser (?) than MDF, but it still vibrates very strong. The walls of one speaker I once build from a aluminum profile was vibrating so strong that the sound output of the walls was clearly visible in the frequency response.

The higher the thickness there's another thing you have to take into account: the theory (2x the thickness -> 8x the stiffness) holds only for thin panels. A 12" thick panel is not thin any more (compared to usual speaker sizes). So there will be other effects.

As above, the Harwood papers specifically states that thicker material radiates as much as thinner, so increased cost and weight for no benefit.

Good to read Maiky76's contribution. A later variant of the BBC mini-monitor - Jim Rogers's JR149 - used a curved, aluminium cabinet with damping to reduce the output from the enclosure. It got good reviews at the time. I presume the BBC didn't run with it as their results were good enough for use.

Good to read Maiky76's contribution. A later variant of the BBC mini-monitor - Jim Rogers's JR149 - used a curved, aluminium cabinet with damping to reduce the output from the enclosure. It got good reviews at the time. I presume the BBC didn't run with it as their results were good enough for use.

Good reading for sure. Still don't see anything that has been proved or rather improved other than material science coming up with better materials to work with over the last 30 years.

Constrained layer dampening is part of my current design. Just exactly how am unsure of atm, but do have a clue (not my first rodeo). What is cost effective/ available are the key points I'm looking at currently. The design as of now will use sono tubes for the sub/bass TL section. Not single tube, but 3 layers. Each of these are physically (mechanically) constrained with a dampening layer between them (2 ie XoXoX). Or (lol) two + two mechanical constrained layers and a single dampened constrained layer eg XXoXX. Do believe the former is the route I will be taking.

Also note that tho the TL is made with tubes, they are cut up and only form part of the enclosure.

The baffle is 4 layers with two constrained layers isolating the above from the baffle which is acoustic suspension. MTMWW(W(W)) if I can find the space (volume) for the third driver or for that matter a forth, tho I doubt this possibility. Is becoming increasingly hard just adding a third.

Why it is so bloody hard to find thin material to work with in the US is beyond me. Especially in Florida, everything must be imported from either the NE or the west coast where they haven't cut down all the bloody trees yet or europe where I can find everything I would need. Go figure

Constrained layer dampening is part of my current design. Just exactly how am unsure of atm, but do have a clue (not my first rodeo). What is cost effective/ available are the key points I'm looking at currently. The design as of now will use sono tubes for the sub/bass TL section. Not single tube, but 3 layers. Each of these are physically (mechanically) constrained with a dampening layer between them (2 ie XoXoX). Or (lol) two + two mechanical constrained layers and a single dampened constrained layer eg XXoXX. Do believe the former is the route I will be taking.

Also note that tho the TL is made with tubes, they are cut up and only form part of the enclosure.

The baffle is 4 layers with two constrained layers isolating the above from the baffle which is acoustic suspension. MTMWW(W(W)) if I can find the space (volume) for the third driver or for that matter a forth, tho I doubt this possibility. Is becoming increasingly hard just adding a third.

Why it is so bloody hard to find thin material to work with in the US is beyond me. Especially in Florida, everything must be imported from either the NE or the west coast where they haven't cut down all the bloody trees yet or europe where I can find everything I would need. Go figure

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- how much cabinet sound