Hi MaVo,

Many thanks for the feedback. From the tests I did originally, I thought that the System Design tool came up with the best overall compromise in terms of size (system volume) versus performance (efficiency, SPL response, diaphragm displacement, etc) - that is why I decided to use the word "optimum". In view of your comments however, perhaps I should reconsider this position .

.

That is great news, thanks for letting me know.

Kind regards,

David

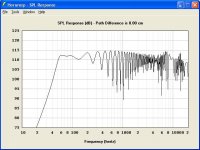

MaVo said:In your help file for the system design function, you write that it designs an optimum system for the given frequency range and driver. Now, I observed that the frequency response often has these little and regular peaks, while handmade designs can have a flatter frequency response within the same size restrictions.

Many thanks for the feedback. From the tests I did originally, I thought that the System Design tool came up with the best overall compromise in terms of size (system volume) versus performance (efficiency, SPL response, diaphragm displacement, etc) - that is why I decided to use the word "optimum". In view of your comments however, perhaps I should reconsider this position

MaVo said:Hornresp v20 looks like a great improvement, I got random crashes on my amd/winxp system with v19 and before, especially while running other software in the background, which seem to have stopped now.

That is great news, thanks for letting me know.

Kind regards,

David

Brett said:Did a couple of TH sims this morning and it all worked fine.

That sounds good, thanks Brett.

Kind regards,

David

brsanko said:Why does the combined response always drop off after 1khz?

Hi brsanko,

Mainly because the driver diaphragm is modelled as a rigid plane piston, and directivity effects are not taken into account. See Note 2 in the Hornresp Help file for further details.

Note however that it is theoretically possible to produce a more extended response - it all depends on the input parameter values.

Kind regards,

David

Attachments

defwing said:Seems to give same results on Windows Server 2008 64bit(Basically Vista) as 32bit XP so that part seems fine.

That is excellent news, thanks defwing.

Kind regards,

David

Hi David, concerning your automatic horn design tool:

I have been researching some old lab posts and discovered one in which Thomas Danley has written some numbers for an optimal driver for horn loading. Compared to the numbers your system design tool (from specifications) computes, his advice goes for heavier membranes, with a difference factor of about 2-3 times your numbers. Except this difference, the relationship of compression factor and frequency band with membrane weight and motor strength seem to follow the same guidelines in both your and his math. (for ease of use i ignore mms and mmd, since the difference is about 200-300%).

For a 15inch driver, 28-112hz, 1:1 compression, your model proposes a 65g membrane, while Tom would use 178g.

Here is the post i refer to: http://www.live-audio.com/messages/archive4/126294.html

Could you explain where this difference comes from? Well, i think you wont know his math, but maybe you could make a guess or give some hint how you arrive at these numbers?

I have been researching some old lab posts and discovered one in which Thomas Danley has written some numbers for an optimal driver for horn loading. Compared to the numbers your system design tool (from specifications) computes, his advice goes for heavier membranes, with a difference factor of about 2-3 times your numbers. Except this difference, the relationship of compression factor and frequency band with membrane weight and motor strength seem to follow the same guidelines in both your and his math. (for ease of use i ignore mms and mmd, since the difference is about 200-300%).

For a 15inch driver, 28-112hz, 1:1 compression, your model proposes a 65g membrane, while Tom would use 178g.

Here is the post i refer to: http://www.live-audio.com/messages/archive4/126294.html

Could you explain where this difference comes from? Well, i think you wont know his math, but maybe you could make a guess or give some hint how you arrive at these numbers?

Another dum basic question set from the maniac..

Marty.....Marty?

Marty.....Marty?

Sort of a repeat as I can't quite get a grip on these and am trying to figure out what I'm doing wrong.

If I have a tapped horn with S1=100 s2=200 s3=300 s4=400,

1) Is the baffle hole equal to s2?

2) How do I input a smaller baffle hole without affecting s2?

For example, 150.

3) Using a square for simplicity. I assume the horn construction

would be s1 at 10x10, s2 at 14.4x14.4, s3 17.3x17.3

with the driver centerd at the s2 position.

4) If 3 is correct, how would I introduce a V throat.

For example, one end of the driver area is a point or zero, the other end opens to the driver's width, the height is lets say 20cm.

Like the way the DT20's throat is. From the widest point it enters the rest of the horn.

5) Will Hornresp take the compression into account with the smaller driver baffle? (I know it does with smaller s2 vs s1.)

6) Since we build rectangular horns, would the standard for rectangular or square be a feasable option vs CON or EXP?

Or is there a conversion I have not found on line yet.

I ask this because building for size consideration requires a lot of exports to work with.

I know it sounds crazy but it might be nice to have the option to

use max spl in the tapped horn wizard based on preset by user

for wattage and xmax in the driver parameters. I found the max spl VERY usefull as I am working on PA boxes and the curves that worked best at full power looked strange at 2.85, but sounded better in the physical box than a flat at 2.85 std spl.

I need to go get some sleep. Been too obsessed with this, and driving hard for about two weeks non-stop, for good reason.

Marty.....Marty?

Marty.....Marty?Sort of a repeat as I can't quite get a grip on these and am trying to figure out what I'm doing wrong.

If I have a tapped horn with S1=100 s2=200 s3=300 s4=400,

1) Is the baffle hole equal to s2?

2) How do I input a smaller baffle hole without affecting s2?

For example, 150.

3) Using a square for simplicity. I assume the horn construction

would be s1 at 10x10, s2 at 14.4x14.4, s3 17.3x17.3

with the driver centerd at the s2 position.

4) If 3 is correct, how would I introduce a V throat.

For example, one end of the driver area is a point or zero, the other end opens to the driver's width, the height is lets say 20cm.

Like the way the DT20's throat is. From the widest point it enters the rest of the horn.

5) Will Hornresp take the compression into account with the smaller driver baffle? (I know it does with smaller s2 vs s1.)

6) Since we build rectangular horns, would the standard for rectangular or square be a feasable option vs CON or EXP?

Or is there a conversion I have not found on line yet.

I ask this because building for size consideration requires a lot of exports to work with.

I know it sounds crazy but it might be nice to have the option to

use max spl in the tapped horn wizard based on preset by user

for wattage and xmax in the driver parameters. I found the max spl VERY usefull as I am working on PA boxes and the curves that worked best at full power looked strange at 2.85, but sounded better in the physical box than a flat at 2.85 std spl.

I need to go get some sleep. Been too obsessed with this, and driving hard for about two weeks non-stop, for good reason.

G'day MaVo

I believe the basic math used in Tom's program comes from:

http://users.ece.gatech.edu/~mleach/papers/HornPaper/HornPaper.pdf

It's not too hard making up an Excel Spreadsheet to implement these equations. Apparently most of Tom's horns were derived using the Leach model.

It has worked for me too.

Cheers

William Cowan

I believe the basic math used in Tom's program comes from:

http://users.ece.gatech.edu/~mleach/papers/HornPaper/HornPaper.pdf

It's not too hard making up an Excel Spreadsheet to implement these equations. Apparently most of Tom's horns were derived using the Leach model.

It has worked for me too.

Cheers

William Cowan

MaVo said:Compared to the numbers your system design tool (from specifications) computes, his advice goes for heavier membranes, with a difference factor of about 2-3 times your numbers.

For a 15inch driver, 28-112hz, 1:1 compression, your model proposes a 65g membrane, while Tom would use 178g.

Could you explain where this difference comes from?

Hi MaVo,

Sorry, but I have no idea how Tom arrives at his Mmd value.

Are his numbers consistent with those generated by the "Leach model" William refers to? I think you will find that the Hornresp results are pretty close to the ones calculated using Leach methodology.

What happens to the predicted SPL response when the Hornresp-suggested Mmd value of 65g is changed to Tom’s value of 178g? I suspect that the high frequency roll-off point may be somewhat lower.

Kind regards,

David

Hi screamerusa,

In the current version of Hornresp, the area of the baffle hole opening into the throat side of the tapped horn equals Sd if there is no throat chamber, or Atc if a throat chamber has been specified.

Changing the value of Sd or Atc has no effect on the value of S2. Hornresp Version 20.10 will enable you to specify a baffle hole different in area from either Sd or Atc. I hope to release the new software sometime within the next two weeks, if everything goes according to plan.

Correct, except that S2 = 14.14 x 14.14 .

.

You would need to set S1 = 0.01, and adjust the values of S2, S3, etc accordingly.

Yes.

Sorry, I'm not sure what you mean .

.

I will include the option in Version 20.10.

Kind regards,

David

screamersusa said:If I have a tapped horn with S1=100 s2=200 s3=300 s4=400,

1) Is the baffle hole equal to s2?

In the current version of Hornresp, the area of the baffle hole opening into the throat side of the tapped horn equals Sd if there is no throat chamber, or Atc if a throat chamber has been specified.

screamersusa said:2) How do I input a smaller baffle hole without affecting s2? For example, 150.

Changing the value of Sd or Atc has no effect on the value of S2. Hornresp Version 20.10 will enable you to specify a baffle hole different in area from either Sd or Atc. I hope to release the new software sometime within the next two weeks, if everything goes according to plan.

screamersusa said:3) Using a square for simplicity. I assume the horn construction would be s1 at 10x10, s2 at 14.4x14.4, s3 17.3x17.3 with the driver centerd at the s2 position.

Correct, except that S2 = 14.14 x 14.14

screamersusa said:4) If 3 is correct, how would I introduce a V throat.

You would need to set S1 = 0.01, and adjust the values of S2, S3, etc accordingly.

screamersusa said:5) Will Hornresp take the compression into account with the smaller driver baffle? (I know it does with smaller s2 vs s1.)

Yes.

screamersusa said:6) Since we build rectangular horns, would the standard for rectangular or square be a feasable option vs CON or EXP?

Sorry, I'm not sure what you mean

screamersusa said:I know it sounds crazy but it might be nice to have the option to use max spl in the tapped horn wizard based on preset by user for wattage and xmax in the driver parameters.

I will include the option in Version 20.10.

Kind regards,

David

brsanko said:In otherwords the parameters don't tell hornresp that there is a whizzer cone?

Hi brsanko,

That is correct.

Kind regards,

David

Hi,

I just downloaded the latest Hornresp, and have some difficulty creating the model. In the help file it tells you to when you have L12 in focus you can type H, L, O, etc to get the type of flare you want. However, when I do this, nothing happens.

Appreciate some help. The attached pic shows where I'm at.

I just downloaded the latest Hornresp, and have some difficulty creating the model. In the help file it tells you to when you have L12 in focus you can type H, L, O, etc to get the type of flare you want. However, when I do this, nothing happens.

Appreciate some help. The attached pic shows where I'm at.

Attachments

- Home

- Loudspeakers

- Subwoofers

- Hornresp