Hi all,

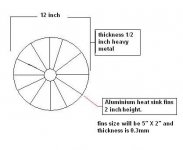

I want to make a heat sink just like this artistic type.

I need to know how much heat will dissipate using like this heat sink?

My ambient temp is 30c. The plate is circled 12inch-dia and ½ inch thickness metal. I will be using aluminum fins, which is each 5inch length X 2 inch to the air. Total fins is 12 pcs.

I don’t know how to calculate this.

Thank you

michael

I want to make a heat sink just like this artistic type.

I need to know how much heat will dissipate using like this heat sink?

My ambient temp is 30c. The plate is circled 12inch-dia and ½ inch thickness metal. I will be using aluminum fins, which is each 5inch length X 2 inch to the air. Total fins is 12 pcs.

I don’t know how to calculate this.

Thank you

michael

Attachments

There are quite a few manufacturers that already make cylinderical / spherical heatsinks, meaning a flat base with fins that stick up out of them. Could save you a lot of effort.

http://www.digit-life.com/articles/thermaltakevolcano2copperorb/index.html

http://www.frostytech.com/permalink.cfm?NewsID=63131

http://www.easycom.com.ua/data/cooler/81302330/img/4.jpg

http://www.cdrinfo.com/Sections/Reviews/Specific.aspx?ArticleId=14499

http://www.xbitlabs.com/articles/coolers/display/coolermaster-sphere_3.html

http://www.digit-life.com/articles/thermaltakevolcano2copperorb/index.html

http://www.frostytech.com/permalink.cfm?NewsID=63131

http://www.easycom.com.ua/data/cooler/81302330/img/4.jpg

http://www.cdrinfo.com/Sections/Reviews/Specific.aspx?ArticleId=14499

http://www.xbitlabs.com/articles/coolers/display/coolermaster-sphere_3.html

120 watts continuous power...so.... around 200 watts heat dissipation

As amplifiers usually work into average power...you can connect a 250 watts RMS into this heatsink.

But if you put it into the correct position.... horizontal, when your high is 2 inches and no obstructions bellow, or 4 inches cdistance from the heatsink to some solid object.

In my point of view will be good to an AB power amplifiers, pumping 120 watts RMS, continuous sinewave power into 1 Kilohertz.... or a 200 watts of consumption class A amplifier

regards,

Carlos

As amplifiers usually work into average power...you can connect a 250 watts RMS into this heatsink.

But if you put it into the correct position.... horizontal, when your high is 2 inches and no obstructions bellow, or 4 inches cdistance from the heatsink to some solid object.

In my point of view will be good to an AB power amplifiers, pumping 120 watts RMS, continuous sinewave power into 1 Kilohertz.... or a 200 watts of consumption class A amplifier

regards,

Carlos

Attachments

Hi DX,

waited for such a nice reply. you know what? it is actually for your turbo DX amp, preparing from now on. i will be making for three amps, mooly, aleph-3 (this two already made) and last is huge DX-turbo (waiting for final circuit design)... i am now designing a nice looks heat sink which will be placing on top of the amp and looks beautiful including blue led inside, looks even more beautiful as like you, it will be nice amp "DX turbo"....ha...ha....not prec-1 (ok). i will made own hand craft heat sink. as i know it will be good for 250w dissipate. its enough for one channel. good...news that i don't need to fight with heat sink. as this is the cheapest way to get huge heat sink.

i already bought two heavy circled plate with 1/2 inch thickness and for fins aluminium plate. They cut for me using leath mechine into nice circled.

Can i ask you on more question? if circle dia is 10 inch then how much heat will dissipate base on same design?

For DX-turbo each transistor will dissipate how much heat?

Thank you very,very much for your reply.

best regards

michael

waited for such a nice reply. you know what? it is actually for your turbo DX amp, preparing from now on. i will be making for three amps, mooly, aleph-3 (this two already made) and last is huge DX-turbo (waiting for final circuit design)... i am now designing a nice looks heat sink which will be placing on top of the amp and looks beautiful including blue led inside, looks even more beautiful as like you, it will be nice amp "DX turbo"....ha...ha....not prec-1 (ok). i will made own hand craft heat sink. as i know it will be good for 250w dissipate. its enough for one channel. good...news that i don't need to fight with heat sink. as this is the cheapest way to get huge heat sink.

i already bought two heavy circled plate with 1/2 inch thickness and for fins aluminium plate. They cut for me using leath mechine into nice circled.

Can i ask you on more question? if circle dia is 10 inch then how much heat will dissipate base on same design?

For DX-turbo each transistor will dissipate how much heat?

Thank you very,very much for your reply.

best regards

michael

space2000 said:i am thinking to use 4 inch height 24 fins on this plate. just calculated and also center will be a fan.

how about that?

thanks.

I tend to use a heatsink with a reasonable speed fan(s) to help it along. This is why I use PC cases for my amplifiers as they have plenty of fan mountings on them already. I usually rip out the power supply innards and use the mains socket for my amp.

nigelwright7557 said:

I tend to use a heatsink with a reasonable speed fan(s) to help it along. This is why I use PC cases for my amplifiers as they have plenty of fan mountings on them already. I usually rip out the power supply innards and use the mains socket for my amp.

Thickness into your heatsinks just increase the heatsink mechanicall resistance

properties, cost and weigth... for heat transference (to the air) purposes, the important is the area in contact with the air... how big is the surface in contact with surrounding air to produce the heat changes, the heat transference... when the heat is lost from the heatsink and transfered to the air... the heat loss turns the heatsink more cool.

If you double your heigth, you will double your area... your heatsink will double its capacity to dissipate power.

The thickness causes a delay into the heat transference only... may be good to peaks of power, as it will absorb those surge moments of power in such a way the heat will not appear instantaneously into the heatsink surface...but will appear seconds after that... so...it will fool you... as the heat will not appear into the moment you are touching it, or measuring it to evaluate how hot it is... will be hot seconds after that.... the midnigth bass into your party will heat your heatsink internally and the heat will appear into the surface midnigth and 1 second past...just that.... the thickness does not increase the heatsink performance...just give it better look, a more respectable look, more weigth and strength...just that.

The amplifier is ready to go dear Space.... the pretty schematic not ready, but the schematic provided is the one... was assembled, tested, and it is playing wonderfull.

You need more condensers.... more...much more... electrolitic condensers to your supply, and a transformer that will give you around 70 volts (or more if you want).... a 50 plus 50 volts AC transformer, able to give you 10 plus 10 amperes... condensers to full power may be enormous... 25.000uf each rail minimum, and the best sittuation will be 50.000uf each rail (expensive...very expensive)

The amplifier is able to produce 45 volts of audio man!... a monster!.... this is more than 500 watts undistorted and twice of that distorted!

And using 3 ohms load it can produce much more than that.

It is a power machine... a speaker melter.... the thunderstorm generator... a killer amplifier...good for home demolition.

regards,

Carlos

properties, cost and weigth... for heat transference (to the air) purposes, the important is the area in contact with the air... how big is the surface in contact with surrounding air to produce the heat changes, the heat transference... when the heat is lost from the heatsink and transfered to the air... the heat loss turns the heatsink more cool.

If you double your heigth, you will double your area... your heatsink will double its capacity to dissipate power.

The thickness causes a delay into the heat transference only... may be good to peaks of power, as it will absorb those surge moments of power in such a way the heat will not appear instantaneously into the heatsink surface...but will appear seconds after that... so...it will fool you... as the heat will not appear into the moment you are touching it, or measuring it to evaluate how hot it is... will be hot seconds after that.... the midnigth bass into your party will heat your heatsink internally and the heat will appear into the surface midnigth and 1 second past...just that.... the thickness does not increase the heatsink performance...just give it better look, a more respectable look, more weigth and strength...just that.

The amplifier is ready to go dear Space.... the pretty schematic not ready, but the schematic provided is the one... was assembled, tested, and it is playing wonderfull.

You need more condensers.... more...much more... electrolitic condensers to your supply, and a transformer that will give you around 70 volts (or more if you want).... a 50 plus 50 volts AC transformer, able to give you 10 plus 10 amperes... condensers to full power may be enormous... 25.000uf each rail minimum, and the best sittuation will be 50.000uf each rail (expensive...very expensive)

The amplifier is able to produce 45 volts of audio man!... a monster!.... this is more than 500 watts undistorted and twice of that distorted!

And using 3 ohms load it can produce much more than that.

It is a power machine... a speaker melter.... the thunderstorm generator... a killer amplifier...good for home demolition.

regards,

Carlos

it doesn´t look that bad, but I didn´t catch how thick will the fins be?

Anyway, I think that the biggest concern is how do you want to attach the fins to the baseplate? You need to maintain the best thermal connection possible, and if you are about to use two rivets or screws it won´t help too much, because the fin will bend and the thermal contact will be good only near the screw.

I think you should better use something similar to passive cpu heatsinks, with more stacked fins and with for example two screws holding all the fins together.

Anyway, I think that the biggest concern is how do you want to attach the fins to the baseplate? You need to maintain the best thermal connection possible, and if you are about to use two rivets or screws it won´t help too much, because the fin will bend and the thermal contact will be good only near the screw.

I think you should better use something similar to passive cpu heatsinks, with more stacked fins and with for example two screws holding all the fins together.

No,destroyer X said:..........If you double your heigth, you will double your area... your heatsink will double its capacity to dissipate power.........

double the height may achieve about 40% more dissipation capacity.

Double the width and ensure that the remote corners operate at the same temperature as the corners of the half width version will give about double the dissipation capacity.

Re: Beautifull.... very nice heatsink.

I use PC fans on my amps.

If you use one then go for a higher current fan as they blow quite a bit more air through.

I have one fan sucking air into the PC case at one end and another blowing it out at the other corner, works a treat.

destroyer X said:

Will you use a fan blower into it?

Helps a lot.

regards,

Carlos

I use PC fans on my amps.

If you use one then go for a higher current fan as they blow quite a bit more air through.

I have one fan sucking air into the PC case at one end and another blowing it out at the other corner, works a treat.

Yes... fan solves the problem related the correct position to convection cooling

See the sketch attached.

Into the correct position, cooling is easy to one side, and bad to the other side.

Into the Vertical position, you have good air flow to both sides...BUT..... there are turbulences..the air goes up and face hot air from the top turning there...this opposes some resistance to air flow, and use to reduce a little the heatsink capacity....maybe 20 or 30 percent...i do not know exactly.

When you double your heatsink size, you will double the heat transference capacity if you have a good position, the correct convection position OR, if you use a fan.

Using a fan, it will dominate the "air pressure around the fins, and them, turbulences or not will make the heatsink much more efficient.

The fan produces noises... and vibrations... so, must be mounted over rubber pads (soft foam rubber) and can use a chip to reduce the voltage.... if you have 12 to 25 volts you can connect one LM7808 and you will have lower voltage, the fan will produce less air flow but will work silent.... reduce voltage till 7 volts...less than that turns the fan unstable... i like to use 8, or 9 volts.... well, this is personal.... i do not like the fan noises...others do not bother with that, some folks listen so high volumes that cannot listen any fan blower operating.

regards,

Carlos

See the sketch attached.

Into the correct position, cooling is easy to one side, and bad to the other side.

Into the Vertical position, you have good air flow to both sides...BUT..... there are turbulences..the air goes up and face hot air from the top turning there...this opposes some resistance to air flow, and use to reduce a little the heatsink capacity....maybe 20 or 30 percent...i do not know exactly.

When you double your heatsink size, you will double the heat transference capacity if you have a good position, the correct convection position OR, if you use a fan.

Using a fan, it will dominate the "air pressure around the fins, and them, turbulences or not will make the heatsink much more efficient.

The fan produces noises... and vibrations... so, must be mounted over rubber pads (soft foam rubber) and can use a chip to reduce the voltage.... if you have 12 to 25 volts you can connect one LM7808 and you will have lower voltage, the fan will produce less air flow but will work silent.... reduce voltage till 7 volts...less than that turns the fan unstable... i like to use 8, or 9 volts.... well, this is personal.... i do not like the fan noises...others do not bother with that, some folks listen so high volumes that cannot listen any fan blower operating.

regards,

Carlos

Attachments

No, they still won't.space2000 said:hi,

i already bought heat sink compound for attaching the fins. so the fins will be attach 100% with the plate...

The pressure will not be the same on the whole surface.

How thick are the fins?

And how do you plan to attach the transistors?

I am afraid cubic, Kubbek, may be rigth

Those fins, those metal blades are normally soldered using electrical fusion into some contact points... alike automobile chassis soldering... hard solder, metal melts into some poins...then the heat transference from the base to the fins are better.

This way, the better you could make, will not have perfect contact from the base to the fins.... thermical contact needs metal surface contact... a very flat surface into the fins to match the aluminium base (disc)... the thermal grease will help, but may not be perfect.

Try, for instance, insert a sheet of paper between the fins base and the disc...if enters...then the mechanical contact is not good, and as a result the termical transference will not be good too.

I hope not, but this pretty heatsink may be frustrating, i hope my fears do not have confirmation.

Good luck dear Space... nice artistic work... i am not sure it will work fine as a good heatsink.

regards,

Carlos

Those fins, those metal blades are normally soldered using electrical fusion into some contact points... alike automobile chassis soldering... hard solder, metal melts into some poins...then the heat transference from the base to the fins are better.

This way, the better you could make, will not have perfect contact from the base to the fins.... thermical contact needs metal surface contact... a very flat surface into the fins to match the aluminium base (disc)... the thermal grease will help, but may not be perfect.

Try, for instance, insert a sheet of paper between the fins base and the disc...if enters...then the mechanical contact is not good, and as a result the termical transference will not be good too.

I hope not, but this pretty heatsink may be frustrating, i hope my fears do not have confirmation.

Good luck dear Space... nice artistic work... i am not sure it will work fine as a good heatsink.

regards,

Carlos

dear dx and all,

when i was designing the heat sink i already thought about the contact and found there is two effective way to solve it. one is to solder it properly and another is to use heat compound pest attach under the fins surface properly then i will be 100% total contact with the plate. all we need is to contact with plate that will help to travel the heat from one to another. I already bought the heat compounds, wow its expensive, 25g is $5.50. i bought two tube for now see how much it will require. heat tollarence is -50c to 200c. so its just nice to use. i will be putting it later on.

now can have comments pls...need more discussion.

best regards

michael

when i was designing the heat sink i already thought about the contact and found there is two effective way to solve it. one is to solder it properly and another is to use heat compound pest attach under the fins surface properly then i will be 100% total contact with the plate. all we need is to contact with plate that will help to travel the heat from one to another. I already bought the heat compounds, wow its expensive, 25g is $5.50. i bought two tube for now see how much it will require. heat tollarence is -50c to 200c. so its just nice to use. i will be putting it later on.

now can have comments pls...need more discussion.

best regards

michael

I hope will work fine.... depending how you have bent the fins

and that bent area of contact..the size of this contact area...from the fins to the base disc...if very flat piece of bent material may work fine... i hope so.

The excess of heat compound can be removed with a cloth, or a cotton swab... a cotton piece into a wood, dampened with petrol solvent....but in the reality the need of this grease is a very small ammount...just to cover the aluminium with a very thin layer..both sides must receive some grease...spread with your fingers...and latter remove the excess.

I hope will work fine...beautifull artistic work, and a new option to people do by themselves.... a Do it Yourself work... perfect for our forum... excelent for our people.... i hope works fine.

I mean.... the grease does not need to paint the aluminium white colour.... just a little will fill the microscopic gaps into the metal structure.... the result may be ligth gray, not the aluminium original colour but not needed to be entirelly white.... a thin layer.. almost white, not completelly white may work and will save expensive thermical grease beeing wasted.... people use too much..they confuse this with toothpaste..ahahahaha!

regards,

Carlos

and that bent area of contact..the size of this contact area...from the fins to the base disc...if very flat piece of bent material may work fine... i hope so.

The excess of heat compound can be removed with a cloth, or a cotton swab... a cotton piece into a wood, dampened with petrol solvent....but in the reality the need of this grease is a very small ammount...just to cover the aluminium with a very thin layer..both sides must receive some grease...spread with your fingers...and latter remove the excess.

I hope will work fine...beautifull artistic work, and a new option to people do by themselves.... a Do it Yourself work... perfect for our forum... excelent for our people.... i hope works fine.

I mean.... the grease does not need to paint the aluminium white colour.... just a little will fill the microscopic gaps into the metal structure.... the result may be ligth gray, not the aluminium original colour but not needed to be entirelly white.... a thin layer.. almost white, not completelly white may work and will save expensive thermical grease beeing wasted.... people use too much..they confuse this with toothpaste..ahahahaha!

regards,

Carlos

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Solid State

- heat sink design, pls help