AndrewT 1

jcga 1

Ghianni 1

BlacK_Chicken 1

soongsc 2

Dieter12 1

kannan_s 1

Philipp23 1

mbrennwa 1

kevinkr 1

Mark Johnson 1

Microfast 1

jhenderson01075 1

cwtim01 1

diyaudnut 1

anatech 1

jan.didden 1

bk856er 1

PH104 1

nyt 1

jasse 1

jazid 1

etlasr 1

B&W_arthur 1

cddumat 1

Carl_Huff 1

AKN 1

Waltzingbear 1

Canvas 1

bmac_2780 1

casalobo 1

fonnesbek 1

lgo51 1

dennis h 1

duster1 1

PWatts 1

agdr 1

kasey197 1

PaulBC 1

CeeVee 1

NicMac 1

markus22ch 1

pete0 1

rephil 1

nlate 1

jwilhelm 1

total 47

jcga 1

Ghianni 1

BlacK_Chicken 1

soongsc 2

Dieter12 1

kannan_s 1

Philipp23 1

mbrennwa 1

kevinkr 1

Mark Johnson 1

Microfast 1

jhenderson01075 1

cwtim01 1

diyaudnut 1

anatech 1

jan.didden 1

bk856er 1

PH104 1

nyt 1

jasse 1

jazid 1

etlasr 1

B&W_arthur 1

cddumat 1

Carl_Huff 1

AKN 1

Waltzingbear 1

Canvas 1

bmac_2780 1

casalobo 1

fonnesbek 1

lgo51 1

dennis h 1

duster1 1

PWatts 1

agdr 1

kasey197 1

PaulBC 1

CeeVee 1

NicMac 1

markus22ch 1

pete0 1

rephil 1

nlate 1

jwilhelm 1

total 47

Hi soongsc,

I am very used to component level diagnostics and repair (then optimising if there is anything to optimize).

.... Hmmmm, certificates of calibration?

Hi Jens,

Without the full certification, I assume these units will be checked for some sort of calibration, right? Things like absolute level of signals might be generated at the QC station to assure that each unit is performing within published specs? Then the readings could be attached to a serial number as a record of performance that could then be available for down load for that particular serial number. I'm not asking for a full test instrument certificate of calibration (although that would be both useful and pretty cool!). Do you have an error budget worked out for these? (specification of the limits of accuracy) I only ask as the numbers I generate by using this instrument on other devices will have some level of accuracy associated with it. That way you could say that a device measured at such level, plus or minus x dB or mV or whatever. It might be useful to know how accurate a set frequency would be as well as this could affect a spot frequency reading as if you were adjusting a trap with a single tone injected.

All this might be completely irrelevant for someone just checking a quick repair. Although, it wouldn't hurt if they had some understanding that the numbers they are getting do have a tolerance, or range of values the actual signal might be at. The same issues surround every example of a DVM or VTVM (meters), or oscilloscope - especially an oscilloscope! A short passage explaining this in the user manual would be welcomed. That and an explanation of noise floors and the difficulty of taking readings down there. Just to keep people from expecting and assuming too much (or, welcome to my world).

I am not trying for "make work projects", but hobbyists generally are not well-versed in test equipment uncertainties. Some know as much as industry experts, but on average, they do not. The concept of noise in a measurement would also be a new concept for many. What do you think?

-Chris

I am very used to component level diagnostics and repair (then optimising if there is anything to optimize).

.... Hmmmm, certificates of calibration?

Hi Jens,

Without the full certification, I assume these units will be checked for some sort of calibration, right? Things like absolute level of signals might be generated at the QC station to assure that each unit is performing within published specs? Then the readings could be attached to a serial number as a record of performance that could then be available for down load for that particular serial number. I'm not asking for a full test instrument certificate of calibration (although that would be both useful and pretty cool!). Do you have an error budget worked out for these? (specification of the limits of accuracy) I only ask as the numbers I generate by using this instrument on other devices will have some level of accuracy associated with it. That way you could say that a device measured at such level, plus or minus x dB or mV or whatever. It might be useful to know how accurate a set frequency would be as well as this could affect a spot frequency reading as if you were adjusting a trap with a single tone injected.

All this might be completely irrelevant for someone just checking a quick repair. Although, it wouldn't hurt if they had some understanding that the numbers they are getting do have a tolerance, or range of values the actual signal might be at. The same issues surround every example of a DVM or VTVM (meters), or oscilloscope - especially an oscilloscope! A short passage explaining this in the user manual would be welcomed. That and an explanation of noise floors and the difficulty of taking readings down there. Just to keep people from expecting and assuming too much (or, welcome to my world).

I am not trying for "make work projects", but hobbyists generally are not well-versed in test equipment uncertainties. Some know as much as industry experts, but on average, they do not. The concept of noise in a measurement would also be a new concept for many. What do you think?

-Chris

It seems to me some people are expecting lab level quality control. I looked at this project with acceptance that at this price, I am getting the functionality that provides good value assuming that we are going to hit the 50 mark. For the original price, I would love to have some better auto ranging input capability with the option to software select a specific range. If we start jumping to the hardware performance and quality issues, I would think it makes sense to make sure the software used meets similar standards. This really influences overall development efforts and cost. I am more than happy to accept the normal component inspection and test procedures just to make sure functionally it works. If occasionally I need performance certification level quality, then I would use an existing lab.

Lots of people like to rely on NDAs, it really means nothing unless the parties signing are expecting a market value much larger than what you have to pay lawyers. Proof of leakage path is also a very costly investigation.

Lots of people like to rely on NDAs, it really means nothing unless the parties signing are expecting a market value much larger than what you have to pay lawyers. Proof of leakage path is also a very costly investigation.

Last edited:

Autoranging and similar features should be under the control of the software in order to keep track of signal levels in the data acquisition and processing. I'll possibly implement this in MATAA for the Jensalyzer. No automagic hardware level switching for me please!It seems to me some people are expecting lab level quality control. I looked at this project with acceptance that at this price, I am getting the functionality that provides good value assuming that we are going to hit the 50 mark. For the original price, I would love to have some better auto ranging input capability with the option to software select a specific range. If we start jumping to the hardware performance and quality issues, I would think it makes sense to make sure the software used meets similar standards. This really influences overall development efforts and cost. I am more than happy to accept the normal component inspection and test procedures just to make sure functionally it works. If occasionally I need performance certification level quality, then I would use an existing lab.

Lots of people like to rely on NDAs, it really means nothing unless the parties signing are expecting a market value much larger than what you have to pay lawyers. Proof of leakage path is also a very costly investigation.

Gesendet von meinem D5803 mit Tapatalk

Why didn't you bring this up a year ago ???Hi soongsc,

I am very used to component level diagnostics and repair (then optimising if there is anything to optimize).

.... Hmmmm, certificates of calibration?

-Chris

It feels way to late now when it's production ready.

Save the requests for Jenzalyser v2.0 and let the production begin.

Hi Jeff,

Yes, you're right. The comments are too intertwined to separate and move to the other thread now.

Hi jasse,

As for cal and certs, I was hoping that QC records would suffice - in keeping with the first post Jens made. I would certainly not want to impose the use of a calibration laboratory as that would easily add a few hundred to the cost of each. A statement of the limit testing for QC would suffice, and the actual values would be bonus. I do realise this does add some extra work in recording those numbers. If the acceptance tests just used a go-no go type of test, actual values would not be taken. Too bad in that case.

A general statement which would be the same for each unit would help. It would indicate the centre values for each QC test and the limits for acceptance. Listing the make and model of the apparatus for that test would be helpful in assigning the uncertainties of the test. For the QC position, guard banding those tests would be wise to make sure you aren't passing units that could be out of tolerance.

I only suggest this assuming that each unit does undergo some kind of manufacturing quality control measurements. If they don't, I'm still in for the buy. I'm just not as confident of the results it gives. Quality control measurements taken and recorded is just good manufacturing practice so that you can see if the product is performing as it should, and that you don't have any components that are failing at their tolerances. Most manufacturing doesn't use incoming quality inspections, so you are only left with how the product is performing to signal problems. You want to catch this early to avoid massive rework at the end of the manufacturing process.

This is only because this product operates so close to the practical limits of performance.

-Chris

Yes, you're right. The comments are too intertwined to separate and move to the other thread now.

Hi jasse,

As for cal and certs, I was hoping that QC records would suffice - in keeping with the first post Jens made. I would certainly not want to impose the use of a calibration laboratory as that would easily add a few hundred to the cost of each. A statement of the limit testing for QC would suffice, and the actual values would be bonus. I do realise this does add some extra work in recording those numbers. If the acceptance tests just used a go-no go type of test, actual values would not be taken. Too bad in that case.

A general statement which would be the same for each unit would help. It would indicate the centre values for each QC test and the limits for acceptance. Listing the make and model of the apparatus for that test would be helpful in assigning the uncertainties of the test. For the QC position, guard banding those tests would be wise to make sure you aren't passing units that could be out of tolerance.

I only suggest this assuming that each unit does undergo some kind of manufacturing quality control measurements. If they don't, I'm still in for the buy. I'm just not as confident of the results it gives. Quality control measurements taken and recorded is just good manufacturing practice so that you can see if the product is performing as it should, and that you don't have any components that are failing at their tolerances. Most manufacturing doesn't use incoming quality inspections, so you are only left with how the product is performing to signal problems. You want to catch this early to avoid massive rework at the end of the manufacturing process.

This is only because this product operates so close to the practical limits of performance.

-Chris

@etlasr

What level of information would you be looking for?

As a proposal I would say a circuit diagram, to the extent you are willing to reveal the circuitry, associated PCB component identifiers and possibly a few word on principle of operation, though that may be largely self evident from the circuit for those with a little bit of tech knowledge. Without that the alternative is to tediously reverse engineer the circuity from the PCB as I have done to resolve a fault on another expensive piece of test gear. It turned out to be no more than a dry joint and a malfunctioning PCB relay which I easily resolved once identified. Moving parts / relays always being a bit of a reliability driver. Of course the extent to which a home repair is possible on a software based product can be quite limited but having the basic info makes me (can't comment for others) feel as though I have a fighting chance of covering the basics before I resort to sending it back, especially if out of warranty and years down the line. Hope that helps clarify.

@anatech

The units will of course be checked and carefully adjusted before shipping. But for the GB there will not be a comprehensive report, showing the exact performance of that unit.

At least some of the tolerances are in the specification. E.g. the frequency will be within 30 ppm, unless the analyzer SW does not calculate it correctly.

@etlasr

I cannot promise that the schematics will be available at this point in time. I do intend to help the members here in case of problems. Hopefully it will never be needed, but of course you never know.

The units will of course be checked and carefully adjusted before shipping. But for the GB there will not be a comprehensive report, showing the exact performance of that unit.

At least some of the tolerances are in the specification. E.g. the frequency will be within 30 ppm, unless the analyzer SW does not calculate it correctly.

@etlasr

I cannot promise that the schematics will be available at this point in time. I do intend to help the members here in case of problems. Hopefully it will never be needed, but of course you never know.

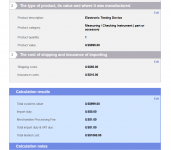

According to dutycalculator.com it is classified as an electronic testing device and the duty apparently is all of $1 from Denmark to the U.S.

I am nowhere close to confident that this is absolutely correct, but I can't recall ever paying a significant duty on imported electronics either.

As an aside I paid 6.5% duty and brokerage fees IIRC on custom transformers made in Belgium.

In any event I think it will be a small fraction of what the thing costs.

I am nowhere close to confident that this is absolutely correct, but I can't recall ever paying a significant duty on imported electronics either.

As an aside I paid 6.5% duty and brokerage fees IIRC on custom transformers made in Belgium.

In any event I think it will be a small fraction of what the thing costs.

Attachments

According to dutycalculator.com it is classified as an electronic testing device and the duty apparently is all of $1 from Denmark to the U.S.

I am nowhere close to confident that this is absolutely correct, but I can't recall ever paying a significant duty on imported electronics either.

As an aside I paid 6.5% duty and brokerage fees IIRC on custom transformers made in Belgium.

In any event I think it will be a small fraction of what the thing costs.

When i imported some amp modules and smps from Hypex, UPS collected around 5% import duty and when i filed CA taxes i had to pay another 2%

Use the postal service. It's very safe here and fair as far as duties and taxes. DHL, Fedex and especially UPS are terrible with brokerage charges. I have in the past paid more than a piece of equipment in brokerage and duties from UPS - I kid you not!

Let me put it another way ... Please, Please, Please, mail them to Canada!

-Chris

Let me put it another way ... Please, Please, Please, mail them to Canada!

-Chris

I'll take one unit too. I would rather use government to government official post offices vs. DHL, FedEx, UPS, etc. Strangely, when using the US Postal Service (USPS, i.e., US Gov.) they don't charge import taxes for years now for me on any packages coming from China, Europe, etc., regardless of cost, whereas UPS, FedEx, etc. seem to follow US Customs laws and charge an import fee. I have no idea why it is this way, (but I don't complain

I'll take one unit too. I would rather use government to government official post offices vs. DHL, FedEx, UPS, etc. Strangely, when using the US Postal Service (USPS, i.e., US Gov.) they don't charge import taxes for years now for me on any packages coming from China, Europe, etc., regardless of cost, whereas UPS, FedEx, etc. seem to follow US Customs laws and charge an import fee. I have no idea why it is this way, (but I don't complain

Add your name to the list in post #83 and reply. That should make you #48!

BK

- Status

- Not open for further replies.

- Home

- Group Buys

- GB for RTX6001 Audio Analyzer with AK5394A and AK4490