Has anyone implemented opposed force cancellation woofer mounting? It is something I want to try. I feel I have explored the limits of box bracing and damping and want to give the force cancelling technique a go. I have a real time spectrum analyser and plan to purchase a 3-axis accelerometer. The principle is attractive but I suspect successful implementation is not that easy. First thoughts are linking the magnets with threaded rod with an adjuster and optimising the tension for minimum box excitation. Some have suggested a resilient pad between magnets but this would surely conflict with the principle. Any hands on experience would be appreciated.

Hi,

used two drivers simply mounted in opposite in a concrete globe (You can see it on my website), no braces or other fancy stuff, just screwed them to the 'baffle'.

At demos I balance a glass of water on top and also ask listeners to touch the globe. Well, the glass never falls off, nor does the water surface jitter like in Jurassic Park. And the testers always take a second look to see the membranes wobble, cause they are so surprised they can't feel any vibration at all.

When the casing isn't as inert itself then bracing or other means of direct connection of the drivers should succeed.

In general the principle works well and even the simplest implementations proove the conceptual advantages.

jauu

Calvin

used two drivers simply mounted in opposite in a concrete globe (You can see it on my website), no braces or other fancy stuff, just screwed them to the 'baffle'.

At demos I balance a glass of water on top and also ask listeners to touch the globe. Well, the glass never falls off, nor does the water surface jitter like in Jurassic Park. And the testers always take a second look to see the membranes wobble, cause they are so surprised they can't feel any vibration at all.

When the casing isn't as inert itself then bracing or other means of direct connection of the drivers should succeed.

In general the principle works well and even the simplest implementations proove the conceptual advantages.

jauu

Calvin

used two drivers simply mounted in opposite in a concrete globe (You can see it on my website), no braces or other fancy stuff, just screwed them to the 'baffle'.

Isn't your concrete construction of the main contributor to the lack of vibration? The B&W subwoofer PV1D

PV1D Subwoofer | Bowers & Wilkins

also has a spherical cabinet but since it is aluminium they do brace the drivers. In fact, they resiliently mount the drivers so the cabinet makes no contribution to the force cancelling. With conventional cabinet construction I think the opposed drivers have to be braced. How best to do this is what I am seeking.

First thoughts are linking the magnets with threaded rod with an adjuster and optimising the tension for minimum box excitation.

Do you mean bolting together or bracing apart? The best way to do this is to have them touching preferably at three points.

Isn't your concrete construction of the main contributor to the lack of vibration?

Yes, but the fact that they are opposed will have a significant impact. Also, the air inside will couple to the cabinet but by how much depends on what kind of enclosure you are planning

As far as force cancellation is concerned, I don't think it matters if the connection is in tension or compression. The reaction forces will always be equal and opposite in direction and as such should cancel. Of course this is in theory. Any lack of symmetry will throw things out fractionally. I tend to prefer tension rod since this will contribute to box strength and counter inflation (with a sealed box). I am considering long threaded rod passing through the bolt holes of both woofers from one side to the other. This will put the reaction forces right at the baffles where it is needed rather than on the magnet structure. Compression is easier to achieve though.Do you mean bolting together or bracing apart?

So, not linking the magnets like you initially said? That's why I was wondering how you were planning to do it. I like your idea of bolting at the baffle, but I would be concerned about putting force on the baskets. All the examples I've seen have coupled the magnets, I think this is the better solution, and you could have some mild decoupling at the baffle, in fact I think you'll find that will be necessary. You are not going to get total cancellation, and then the baffle would be the best place to "loose" the difference I think

I will try both tensioning at the baffle, (which should be easier provided I can get the threaded rod at the right length) and also magnet compression bracing. I will compare and post the results. Should add to the limited info available to the DIYer. I seem to recall a cylindrical coupling of the driver magnets but can't recall where I came across this. I think plastic plumbing 100mm diameter was used. The cylinder was perforated to equalise pressure.So, not linking the magnets like you initially said? That's why I was wondering how you were planning to do it. I like your idea of bolting at the baffle, but I would be concerned about putting force on the baskets. All the examples I've seen have coupled the magnets, I think this is the better solution, and you could have some mild decoupling at the baffle, in fact I think you'll find that will be necessary. You are not going to get total cancellation, and then the baffle would be the best place to "loose" the difference I think

Yes, please keep us posted, I for one will be interested to see how you get on. I think from your initial post you suspect it will not be as easy in practice as it sounds, it will be almost impossible I think to have tight coupling at both the magnet and the baffle, this is why I ended up using shims between the magnets in my experiment. Good luck

I just finished a dual opposed design for Parts Express using Dayton LS10-44 drivers and powered by a Behringer nu1000dsp. I don't have an accelerometer available. So my findings are just "seat of the pants". Literally, i sat on the enclosure There is a 1.5" thick window brace that connects the other 4 walls. By the feel test, there is really no cabinet vibration. And it really does sound fantastic.

There is a 1.5" thick window brace that connects the other 4 walls. By the feel test, there is really no cabinet vibration. And it really does sound fantastic.

An externally hosted image should be here but it was not working when we last tested it.

Yes, that's similar to what I am considering. Thanks.Found this pic when looking for info about the JBL triple chamber subs. Not sure if it's from an original or a copy though....

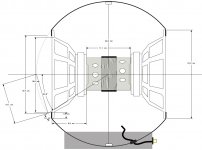

Its very efficient and highly recommended. I made these. Playing full force one cant feel a thing touching the bowl. A spherical enclosure is the most efficient as there will be no vibration due to pressure inside cabinet. A box will still "bulge"- a sphere in metal cant bulge  The drawing don't reflect full out the build. Magnets are glued together via a piece of pipe.

The drawing don't reflect full out the build. Magnets are glued together via a piece of pipe.

Attachments

Last edited:

at sub frequencies the box panel resonances can be pushed well above the pass band with cross bracing

and at sub frequencies everything is a fractional wavelength - so what do people think they are fixing re "sound"?

I suppose "rattle", and other nonlinear contact/support issues may like force cancellation but it really should't be expected to be a 1st order audible improvement

and at sub frequencies everything is a fractional wavelength - so what do people think they are fixing re "sound"?

I suppose "rattle", and other nonlinear contact/support issues may like force cancellation but it really should't be expected to be a 1st order audible improvement

Is that sealed? Glued, good idea

Sealed and glued. Only used glue to build it actually

//

I have gone to extremes with bracing but I can still feel vibration with fingertips and the box "walks" on a hard floor. The box is 90 litres internal volume so is not small. I feel a force cancelling opposed woofer design can improve the performance audibly. It will be used in a music system not for home theatre.at sub frequencies the box panel resonances can be pushed well above the pass band with cross bracing

and at sub frequencies everything is a fractional wavelength - so what do people think they are fixing re "sound"?

I suppose "rattle", and other nonlinear contact/support issues may like force cancellation but it really should't be expected to be a 1st order audible improvement

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- Force cancellation woofers