Thanks for that xrk971. It looks like I will have to try one of these with the open baffles I am making. The Eminence Beta 15s run out of xmax pretty quickly below about 60 - 70Hz. I bought the ff225WKs to use as upper base to mids but I really only need two for that so the other two can go in a Karlsonator and give some punch to the lower base which will enable me to run my two subs at lower frequency than I planned to do. That's the theory anyway!!! It will probably give me some options as to where in the room I place the Karlsonator and the subs as well.

jamikl

jamikl

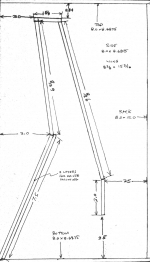

Karlsonator 0.53X Plans Adapted for Foam Core

Here are the plans for Karlsonator especially adapted to utilize only 2 sheets of standard 20 in x 30 in 3/16 in thick foam core sheets per speaker. Make 2 x 30 in long strips of 8.0 in wide sections from a sheet and cut most of the pieces from those two strips. The speaker cabinet is 8.0 inches wide internally. You will also need some in 8-11/16 wide strips for the side panels ans top and bottom from the second sheet. The back is 8 x 15 in even, and the wing panel is 8-3/8 x 15-3/16 in. The slot on the wing starts at 3/8 in wide and 3 in from the end. You can pretty much hand draw the curved arc like I did, or scale my drawing up to full size. It is not critical.

Follow the photos I posted of the build to see where to add bracing - it needs a lot of it. Basically, you need to add bracing to keep the middle divider attached to the back wall and the top and bottom attached to the divider. Otherwise, these large panels will bend and breathe in and out with sound pressure. I use moderate stuffing from the closed end to the bottom turn, with decreasing density as I get closer to the turn. Adjust to taste through driver cutout.

The Karlson aperture or wing is attached to the box with drywall screws onto a stack of 3 layers of foam core blocks (3/4 in x 1 in x 3 layers) glued together and affixed to the inside edge of the box. You will find that 3 layers provides ample purchase for the drywall screws to hold. The TC9FD drivers are held in place with drywall screws through 2 layers of foam core and it works fine.

Start by drawing the plan onto one of the side panels. Use that to start gluing the pieces in place. Notice that the double layer panel for the drivers is offset to sit flush at an angle on the bottom and to provide a notch for the top panel to sit in before gluing. The top vent piece is 1-5/8 in long as it is kind of blurry in the scan. As you glue each piece with hot melt, use a 90 deg piece of foam core as a gauge to rest the part being glued to ensure it is true and square before the glue sets. Once you have all the internal pieces glued on and sealed with a fillet of hot glue, add the struts and bracing. The glue on the top and bottom and back panel. The add 3 of 4 pieces of bracing between the top and the vent shelf. Then glue the blocks to secure the wing with screws. Now is a good test to listen to it with and without the wing to see what a difference the Karlson aperture makes.

Have fun and make sure you take pictures. Good luck!

Where can we find the plans X? Thanks

Here are the plans for Karlsonator especially adapted to utilize only 2 sheets of standard 20 in x 30 in 3/16 in thick foam core sheets per speaker. Make 2 x 30 in long strips of 8.0 in wide sections from a sheet and cut most of the pieces from those two strips. The speaker cabinet is 8.0 inches wide internally. You will also need some in 8-11/16 wide strips for the side panels ans top and bottom from the second sheet. The back is 8 x 15 in even, and the wing panel is 8-3/8 x 15-3/16 in. The slot on the wing starts at 3/8 in wide and 3 in from the end. You can pretty much hand draw the curved arc like I did, or scale my drawing up to full size. It is not critical.

Follow the photos I posted of the build to see where to add bracing - it needs a lot of it. Basically, you need to add bracing to keep the middle divider attached to the back wall and the top and bottom attached to the divider. Otherwise, these large panels will bend and breathe in and out with sound pressure. I use moderate stuffing from the closed end to the bottom turn, with decreasing density as I get closer to the turn. Adjust to taste through driver cutout.

The Karlson aperture or wing is attached to the box with drywall screws onto a stack of 3 layers of foam core blocks (3/4 in x 1 in x 3 layers) glued together and affixed to the inside edge of the box. You will find that 3 layers provides ample purchase for the drywall screws to hold. The TC9FD drivers are held in place with drywall screws through 2 layers of foam core and it works fine.

Start by drawing the plan onto one of the side panels. Use that to start gluing the pieces in place. Notice that the double layer panel for the drivers is offset to sit flush at an angle on the bottom and to provide a notch for the top panel to sit in before gluing. The top vent piece is 1-5/8 in long as it is kind of blurry in the scan. As you glue each piece with hot melt, use a 90 deg piece of foam core as a gauge to rest the part being glued to ensure it is true and square before the glue sets. Once you have all the internal pieces glued on and sealed with a fillet of hot glue, add the struts and bracing. The glue on the top and bottom and back panel. The add 3 of 4 pieces of bracing between the top and the vent shelf. Then glue the blocks to secure the wing with screws. Now is a good test to listen to it with and without the wing to see what a difference the Karlson aperture makes.

Have fun and make sure you take pictures. Good luck!

Attachments

THANK YOU

XRK You are an amazing man. You've really started something here. I've made 3 sets of Cornu's and given two away. They sound good with those $6 amps from ebay. I can't wait to start on these. It will take longer than most as I'm booked

solid through Sept. with my live sound gig's. I'll get pictures this time.

Thanks again excellent work.

Howie

XRK You are an amazing man. You've really started something here. I've made 3 sets of Cornu's and given two away. They sound good with those $6 amps from ebay. I can't wait to start on these. It will take longer than most as I'm booked

solid through Sept. with my live sound gig's. I'll get pictures this time.

Thanks again excellent work.

Howie

Darkstar,

Thank you for the kind words and glad to hear that the Cornu was so much fun for you. As I was listening to these mini Karlsonators belting out some pretty loud clean music, I couldn't help but think that these would be great little stage monitors as they aim up and sit on the floor, and they play quite loud for their size. Not rock concert levels by any means but great for a home jam session with your friends when you need a little box that sounds great. I am really having a blast listening to them in pseudo 'mono' mode and think it will be a great little unobtrusive background 'radio' as you can set this up in a corner or wall out of the way and it will play beautiful sounding radio or background music that sounds good from almost anywhere. As I said, it sounds good even almost 90 deg off axis. Can't wait to hear these in stereo...

I think you will have a lot of fun with these if you enjoyed the Cornu. Very easy to build and probably makes a great and unique gift.

Looking forward to seeing your build.

Thank you for the kind words and glad to hear that the Cornu was so much fun for you. As I was listening to these mini Karlsonators belting out some pretty loud clean music, I couldn't help but think that these would be great little stage monitors as they aim up and sit on the floor, and they play quite loud for their size. Not rock concert levels by any means but great for a home jam session with your friends when you need a little box that sounds great. I am really having a blast listening to them in pseudo 'mono' mode and think it will be a great little unobtrusive background 'radio' as you can set this up in a corner or wall out of the way and it will play beautiful sounding radio or background music that sounds good from almost anywhere. As I said, it sounds good even almost 90 deg off axis. Can't wait to hear these in stereo...

I think you will have a lot of fun with these if you enjoyed the Cornu. Very easy to build and probably makes a great and unique gift.

Looking forward to seeing your build.

I laminated 4 sheets of the plastic faced foamcore together last night- never again- it was slipping and sliding all over the place! I was fighting the glue....

I'll give letting the PVA cure up for a little bit before combining sheets a try- and I'll use a roller, next time.

I'll give letting the PVA cure up for a little bit before combining sheets a try- and I'll use a roller, next time.

I must admit that I'm a bit skeptical wrt the claimed off axis behavior. A lens with such a wide gab shouldn't be able to affect the upper registers that much and the smaller gab would create some nasty resonance?

Any chance of you doing a measurement?

And also a more detailed description of the sound would be nice. Pros and cons and comparisons to other designs with the same drivers.

But anyway, thanks again for you work and sharing it.

Any chance of you doing a measurement?

And also a more detailed description of the sound would be nice. Pros and cons and comparisons to other designs with the same drivers.

But anyway, thanks again for you work and sharing it.

Last edited:

What about a diluted solution of of a high strength wood glue like Gorilla applied with an old Windex/Fantastic or home spray bottle?

The Preval reusable sprawer can also be used with water based shellac.

The Preval reusable sprawer can also be used with water based shellac.

Last edited:

Certainly an option bob- my experience trying to use weighting to get the PVA to work, however, indicates to me that I need initial tack- something wood glue doesn't "do" well. I need to be able to put weighting on the top piece so as to get good joining around the edges, without the two surfaces forming a liquid bearing. The smooth plastic surfaces are what make this challenging- the plasticized surfaces are stronger than the normal paper, by a good amount, but they mean very little surface friction under clamping force.

Another option is a frame in which the clamping is done but I'd prefer not to have to do that as the sheets are fairly big.

Another option is a frame in which the clamping is done but I'd prefer not to have to do that as the sheets are fairly big.

I must admit that I'm a bit skeptical wrt the claimed off axis behavior. A lens with such a wide gab shouldn't be able to affect the upper registers that much and the smaller gab would create some nasty resonance?

Any chance of you doing a measurement?

And also a more detailed description of the sound would be nice. Pros and cons and comparisons to other designs with the same drivers.

But anyway, thanks again for you work and sharing it.

Of course it doesn't sound as good as on-axis (at higher freq), but I noticed that it is clearly better than my usual speaker with just a bare direct radiator. The mids and bass were still pretty good and from a "radio for background" music application, I meant it sounded pretty good. Measurement will require me to get a longer cable for the pc to amp and mic.

Now I'm not sure what sheets you are using. Is it a 1/4" with plastic instead of paper, or the thick pink stuff I used for the Dec horn? I ended up stripping all the film to get a more secure grab on the foam - using hot glue.

Attachments

Jamikl,

I scaled all dimensions evenly. That's about 37 in tall if I remember correctly. A large cabinet but it will be unique in its ability to throw a solid flat bass shelf down to 30 Hz. I look forward to seeing your build. Due to its size, I assume you will be making this out of plywood and not foam core? I suppose one could make it out of that 3/4 in XPS sheathing insulation foam with sufficient bracing.

Good luck!

X

I scaled all dimensions evenly. That's about 37 in tall if I remember correctly. A large cabinet but it will be unique in its ability to throw a solid flat bass shelf down to 30 Hz. I look forward to seeing your build. Due to its size, I assume you will be making this out of plywood and not foam core? I suppose one could make it out of that 3/4 in XPS sheathing insulation foam with sufficient bracing.

Good luck!

X

Mini Karlsonator (0.53X) with Dual TC9FD's Thread

For those of you interested in building the mini Karlsonator with the Vifas, I started a new thread here: http://www.diyaudio.com/forums/full-range/239338-mini-karlsonator-0-53x-dual-tc9fds.html#post3564364

For those of you interested in building the mini Karlsonator with the Vifas, I started a new thread here: http://www.diyaudio.com/forums/full-range/239338-mini-karlsonator-0-53x-dual-tc9fds.html#post3564364

- Home

- Loudspeakers

- Full Range

- Foam Core Board Speaker Enclosures?