Oops! My bad, scrolled down too far...........

Yes, design for a bit higher Qt and use a cheap pot to dial in some series resistance to find out what size resistor or speaker wire size required to get the desired in room tonal response.

GM

Thanks GM. However I have no idea what that means

Is there a way to make the mid-bass speaker full range with minimal to no cross over and roll the tweeter in with minimal cross over too maybe higher in frequency?

I do also have an active cross over (SNAXO2-4) which I may use which is set up for Naim speakers which I no longer use.

The Coax speaker is quite heavy, not sure how applicable to foam core speakers they are though...

What kind of curve can be applied to a sheet of foam core?

Open cell or closed cell foam, which is more recommended foam core type here or does it matter at all?

It appears to be closed cell foam but they only sell it in this one variety. The foam is very stiff and brittle - not spongey like regular open cell foam. It feels like extruded polystyrene closed cell foam. It is same foam used for stiff white foam eating plates and bowls. Same company makes both - called thermoformed foam.

This is the exact manufacturer of the $1 foam core boards.

Foam Board

I have used home insulation XPS foam boards (Pink Owens Corning) with success. Stuff is thick though so more suited for larger speakers.

Last edited:

It appears to be closed cell foam but they only sell it in this one variety. The foam is very stiff and brittle - not spongey like regular open cell foam. It feels like expanded polystyrene closed cell foam. It is same foam used for stiff white foam eating plates and bowls. Same company makes both - called thermoformed foam.

This is the exact manufacturer of the $1 foam core boards.

Foam Board

I took seven minutes, no, six.

This exact manufacturer unfortunately is not available locally.

Locally we have easily available very rigid extruded polystyrene foam, normally used in insulations, so I'll go with it, if closed cell foam is recommended and rigidity is asked feature.

Thanks!

Last edited:

I bought some foam core while cruising through a dollar store and many months later got around to making a spiral cornu. Driver was a TB W4 616S. Drivers were donated by one of the diy Ottawa members. I brought the cornus to this past weekend's DIY Ottawa get together. Folks were surprised by the big sound the cornus produced. They did rattle a bit when pushed hard. They were powered by a vintage Kenwood KM206 150 watt/channel power amp.

for more pics see the following thread and post #116

http://www.diyaudio.com/forums/clubs-events/265017-diy-audio-ottawa-21-22-feb-2015-a-12.html

for more pics see the following thread and post #116

http://www.diyaudio.com/forums/clubs-events/265017-diy-audio-ottawa-21-22-feb-2015-a-12.html

Attachments

I bought some foam core while cruising through a dollar store and many months later got around to making a spiral cornu. Driver was a TB W4 616S. Drivers were donated by one of the diy Ottawa members. I brought the cornus to this past weekend's DIY Ottawa get together. Folks were surprised by the big sound the cornus produced. They did rattle a bit when pushed hard. They were powered by a vintage Kenwood KM206 150 watt/channel power amp.

for more pics see the following thread and post #116

http://www.diyaudio.com/forums/clubs-events/265017-diy-audio-ottawa-21-22-feb-2015-a-12.html

Nice work! I noticed that they have a rectangular aspect ratio of same as 20x30 DC board. Did you just stretch the perspective of the plan in one direction?

yes, I just extended the curves a bit. I used the full size of the foamcore boards 20"x30". If you look at the above photo enlarged you can see a diagonal shadow going towards the top left corner. I am so pleased that I may try 40"x40" next. 36" wide is the largest print I could get at the local print shop. 40" square is what I can comfortably get in the car. There was another pair of foam core at the event on the weekend. If you look at the second last photo where there is a group of people listening to a talk. Look at the right foam core speaker and you can just see the tops of a pair of palm sized foam cores on the table. We did not get a chance to listen to the tiny FC's.

Hi there,

I've just completed. a set of FC hypercubes with Visaton frs8-4's.

Found the thread yesterday afternoon, cut and assembled last night, sealed and installed drivers an hour ago. Listening to them now and I'm quite impressed, wife likes them too which is a bonus.

I'm looking for a small amp recommendation and some advice on finishing FC cabinets. I've been thinking of a decoupage style covering, maybe with sheet music and finished with an acrylic sealant. Any reason this may be a bad idea?

Also, many thanks to the OP and all here for the great ideas and dedication. I haven't contributed much but built several projects over the years from this site.

I'll try and post some pictures soon, before and after covering.

I've just completed. a set of FC hypercubes with Visaton frs8-4's.

Found the thread yesterday afternoon, cut and assembled last night, sealed and installed drivers an hour ago. Listening to them now and I'm quite impressed, wife likes them too which is a bonus.

I'm looking for a small amp recommendation and some advice on finishing FC cabinets. I've been thinking of a decoupage style covering, maybe with sheet music and finished with an acrylic sealant. Any reason this may be a bad idea?

Also, many thanks to the OP and all here for the great ideas and dedication. I haven't contributed much but built several projects over the years from this site.

I'll try and post some pictures soon, before and after covering.

i knew there would a mistake.

i'll watch for ~40mm pipes.

4.5in to 5in long?

oh no!

that doesn't fit the depth of the cabinet.

Have the vent down firing along length of MLTL, elevate the bottom off the floor by 2in and make 1.5in deep cutouts on the walls to allow the vent to escape. Much like the metronome design. You are basically making little 2in high legs from the sides. Or if you are "bent" on having it front firing, use a PVC elbow (pun intended).

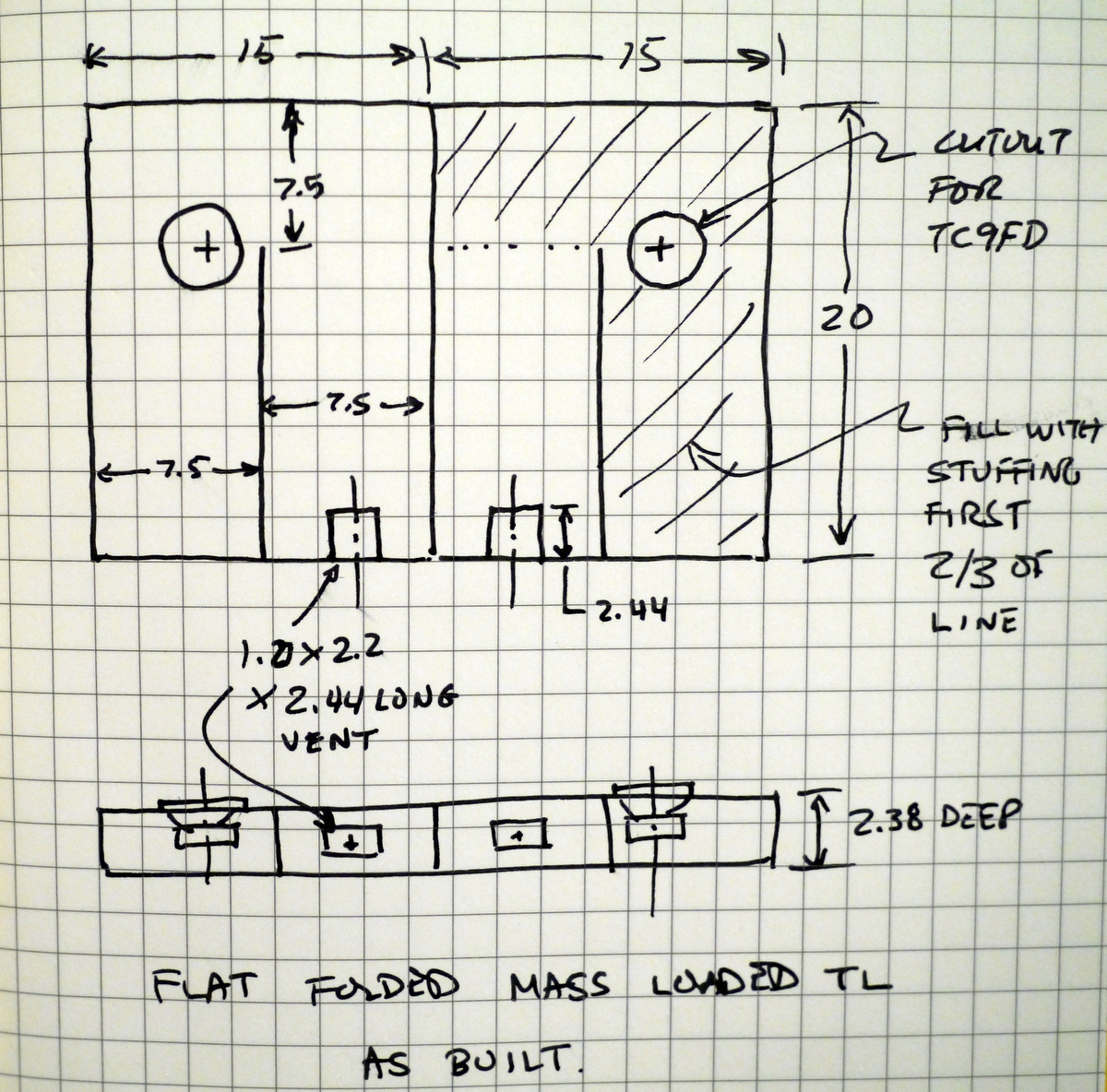

I'm building the wall-mltl for the TC9FD at this very moment.

I made the print this weekend onto a MDF-plate (it looks awesome!!!)

I fooled around with the geometry to keep the aspect ratio of the picture and still stay within the AMLTL logic.

In MLTL-language it turned out to have the following parameters:

L=103.2cm=40.6in

CSA=105.5cm^2=16.4in^2

I have PVC-pipe of which i thought it has 4cm inner diameter.

But i has only 3.5cm=1.38in.

I thought about 10cm of that would be ok.

Any suggestions how long that vent should be?

I'm building the wall-mltl for the TC9FD at this very moment.

I made the print this weekend onto a MDF-plate (it looks awesome!!!)

I fooled around with the geometry to keep the aspect ratio of the picture and still stay within the AMLTL logic.

In MLTL-language it turned out to have the following parameters:

L=103.2cm=40.6in

CSA=105.5cm^2=16.4in^2

I have PVC-pipe of which i thought it has 4cm inner diameter.

But i has only 3.5cm=1.38in.

I thought about 10cm of that would be ok.

Any suggestions how long that vent should be?

The length of port decreases as area decreases, to achieve the same tuning. With a diameter of 3.5cm, you are looking at a length of about 2.5 cm

I'm building the wall-mltl for the TC9FD at this very moment.

I made the print this weekend onto a MDF-plate (it looks awesome!!!)

I fooled around with the geometry to keep the aspect ratio of the picture and still stay within the AMLTL logic.

In MLTL-language it turned out to have the following parameters:

L=103.2cm=40.6in

CSA=105.5cm^2=16.4in^2

I have PVC-pipe of which i thought it has 4cm inner diameter.

But i has only 3.5cm=1.38in.

I thought about 10cm of that would be ok.

Any suggestions how long that vent should be?

Are you talking about this MLTL?

The vent CSA is 2.4 in^2 and you want to use a 1.38in inside dia round pipe? I would normally run a sim in Akabak and check but my computer is still down. Ignoring wall drag on pipe vs rectangular slot, the area and length are inversely proportional. So I estimate length of 1.38in dia pipe to be 1.66 in long for same tuning.

Foamcore Monster

I've been watching this thread since it started and wanted to share what I've been working on along the same lines, more or less. It's walnut door skin (1/8" plywood) laminated to polyurethane foam board.

The stuff is quite light and stiff. Panels have a pine frame and are edge banded so they look great.

The lineup is an Electrovoice EVM15B an Eminence ASD1001 on a Selenium horn with a potato masher lens and a Beyma bullet tweeter.

It turned out to be a pretty deep throated beast. The finish is 5 or so coats of amber shellac and 2 coats of clear poly urethane.

I've been watching this thread since it started and wanted to share what I've been working on along the same lines, more or less. It's walnut door skin (1/8" plywood) laminated to polyurethane foam board.

The stuff is quite light and stiff. Panels have a pine frame and are edge banded so they look great.

The lineup is an Electrovoice EVM15B an Eminence ASD1001 on a Selenium horn with a potato masher lens and a Beyma bullet tweeter.

It turned out to be a pretty deep throated beast. The finish is 5 or so coats of amber shellac and 2 coats of clear poly urethane.

hi mlise - is that the "pea-shooter" horn Selenium (and now, PRV) used to make things look flat on the top? how did you fabricate a lens? (I think I see an acoustic lens) - is your foam board like the usual pink stuff? - that's a powerful looking system yet very traditional !

aw - the $4.99 horn I'm talking about must be a defective copy - mine had thread match problems too

http://www.parts-express.com/prv-audio-wg-14-25-1-45-x-45-abs-waveguide-1-3-8-18--294-2841

aw - the $4.99 horn I'm talking about must be a defective copy - mine had thread match problems too

http://www.parts-express.com/prv-audio-wg-14-25-1-45-x-45-abs-waveguide-1-3-8-18--294-2841

Last edited:

for more pics see the following thread and post #116

http://www.diyaudio.com/forums/clubs-events/265017-diy-audio-ottawa-21-22-feb-2015-a-12.html

Nice work on the foam-core Cornus!

However, I'm more interested in the little bookshelves with the 3.5" Kevlar cone Tymphany drivers, visible between the Cornus in the same pic. Could you throw some light on the design, specs, performance of those bookshelves?

Selenium HL14-25 1" Exponential Horn 45x45 1-3/8"-18 TPI is the horn I have. Six bucks, I had to try it. It could strip paint off the floor right in front, but a step to the left and there's nothing. The lens works great to spread out the sound. It's rings of 1/8" masonite and fly screen with holes cut. The lens in the picture is the second attempt and looks way better then the first, but the first works way better. more thinner layers are the trick. The pictured lens is heavy duty screen and foam tape. The first was cheap screen applied with spray adhesive.

The foam is the fiberglass reinforced polyurethane from Home Depot. HD only has 2'X2' pieces of the Owens Corning stuff. The 4'X8' sheets are less uniform and you have to peel off the paper from the outsides. The pink stuff would be much better if you could get full sheets. Something 3/4" would be ideal. I made a frame of 1"X3" pine with pocket hole screws and glued the 1/8" ply on both sides, cut out one side and glued in the foam with polyurethane glue and glued back the cut out piece with PU glue. The glue foams up and will bulge the panels unless it's clamped between 2X thick plywood pieces. When it's dry, trim the edges and apply iron on edge banding.

The foam is the fiberglass reinforced polyurethane from Home Depot. HD only has 2'X2' pieces of the Owens Corning stuff. The 4'X8' sheets are less uniform and you have to peel off the paper from the outsides. The pink stuff would be much better if you could get full sheets. Something 3/4" would be ideal. I made a frame of 1"X3" pine with pocket hole screws and glued the 1/8" ply on both sides, cut out one side and glued in the foam with polyurethane glue and glued back the cut out piece with PU glue. The glue foams up and will bulge the panels unless it's clamped between 2X thick plywood pieces. When it's dry, trim the edges and apply iron on edge banding.

Last edited:

- Home

- Loudspeakers

- Full Range

- Foam Core Board Speaker Enclosures?