Relief

Thanks a lot Peter!

I had just signed off for the night at page 47 of the original thread...

I was thinking to revise my 'reading through the whole thread' estimate to two weeks minimum.

Now I better crack another small (ish) beer and have a look at the condensed thread.

PM heading your way soon about P.S. board/bits availabilty?

Cheers

Bill

Thanks a lot Peter!

I had just signed off for the night at page 47 of the original thread...

I was thinking to revise my 'reading through the whole thread' estimate to two weeks minimum.

Now I better crack another small (ish) beer and have a look at the condensed thread.

PM heading your way soon about P.S. board/bits availabilty?

Cheers

Bill

Did anyone have any luck using different pucks with their Shigaclone's? It's the one area I haven't addressed yet in my build and have a feeling getting rid of the magnetic clamp would be a good move. There was some DIY pucks produced back in the 2008 era of this thread, but I haven't seen it mentioned for a while. I'd spent the better part of the past year listening to my Mac Mini running into a Gigaworks 24/192 DAC using UTC output transformers. Going back to the Shigaclone - especially with one of Peter Daniel's superb chassis which I installed in June - I realised how much I'd missed the sound quality. If anyone knows of any pucks suitable for the Sanyo mechanism I'd love to purchase one.

Cheers,

- John

Cheers,

- John

Last edited:

I made some wooden ebony ones and am still using one. I think I sent ones to peter and m.massimo.

IIRC there was a small difference, but other things like the reclocking are more important IMHO.

I can post pics later of how to make the screw down spindle if.anyone is interested.

Fran

IIRC there was a small difference, but other things like the reclocking are more important IMHO.

I can post pics later of how to make the screw down spindle if.anyone is interested.

Fran

Hi Fran - would also like to see your pictures on how you made your screw-puck please.

I know Okapi had some lovely looking see-through yellow ones made from acrylic too, but I think there were problems with discs wobbling a little with them? They looked fantastic however. I'd love to get one made in frosted acrylic but I guess a CNC machined one-off would be pretty expensive?

Many thanks,

- John

I know Okapi had some lovely looking see-through yellow ones made from acrylic too, but I think there were problems with discs wobbling a little with them? They looked fantastic however. I'd love to get one made in frosted acrylic but I guess a CNC machined one-off would be pretty expensive?

Many thanks,

- John

Yeah - the issue with the okapi ones is that to do it right you need to part machine the platform first, then mount it on the motor shaft and then machine it true again. Likewise with the puck. I believe thats the way 47 labs do it.

So what did I do:

I used the original platform. I made a threaded spindle using some 6mm brass bar. I simply cut a 6mm thread on the bar and then used some sandpaper to bring the OD down to ~5.95 or so (some experimentation required). That will then push fit into the recess in the top of the existing platform.

After that, I took some ebony, turned it roughly, let it dry fully inside in the house, then went back and remachined it on a mandrel made to match the platform. I bored a 5.3mm hole, cut my M6 thread in it, then remachined it again.

Normally timber will move a bit, so it might be necessary to machine it again, but it should be stable after that. The beauty of this method is that you can try alu, acrylic, wood, brass whatever you like. And if you want to go back to magnetic puck, just pull out the brass insert.

Pics:

Fran

So what did I do:

I used the original platform. I made a threaded spindle using some 6mm brass bar. I simply cut a 6mm thread on the bar and then used some sandpaper to bring the OD down to ~5.95 or so (some experimentation required). That will then push fit into the recess in the top of the existing platform.

After that, I took some ebony, turned it roughly, let it dry fully inside in the house, then went back and remachined it on a mandrel made to match the platform. I bored a 5.3mm hole, cut my M6 thread in it, then remachined it again.

Normally timber will move a bit, so it might be necessary to machine it again, but it should be stable after that. The beauty of this method is that you can try alu, acrylic, wood, brass whatever you like. And if you want to go back to magnetic puck, just pull out the brass insert.

Pics:

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

Fran

I made some wooden ebony ones and am still using one. I think I sent ones to peter and m.massimo.

IIRC there was a small difference, but other things like the reclocking are more important IMHO.

I can post pics later of how to make the screw down spindle if.anyone is interested.

Fran

Confirm and it works very very well.

Confirm and it works very very well.

Fran sent me one as well, and likewise I can confirm it works great. I've had no inclination to use the original or the expensive one I purchased that never ran true.

pucker job

Wooden puck looks great Fran.

I'm thinking to try something very simple using the flexible plastic magnetic sheet often used for sticking labels to metal shelves etc. Have to cut out a perfect disc shape which promises to be tricky . I'll post results, at least we can all have a laugh!

. I'll post results, at least we can all have a laugh!

The original puck could be cut back a lot which would reduce the rotational inertia of it, only the centre section actually touches the disc (unless it's a horribly warped disc). Might try that too...

A CEC belt drive top load transport I saw had a small puck about the size of yours Fran, it was quite heavy though.

Hmmm!

Cheers

Bill

Wooden puck looks great Fran.

I'm thinking to try something very simple using the flexible plastic magnetic sheet often used for sticking labels to metal shelves etc. Have to cut out a perfect disc shape which promises to be tricky

. I'll post results, at least we can all have a laugh!

. I'll post results, at least we can all have a laugh!The original puck could be cut back a lot which would reduce the rotational inertia of it, only the centre section actually touches the disc (unless it's a horribly warped disc). Might try that too...

A CEC belt drive top load transport I saw had a small puck about the size of yours Fran, it was quite heavy though.

Hmmm!

Cheers

Bill

Good to hear they're still working out OK.

But Kevin and Massimo: was there any difference heard?

Fran

Very subtle, but I thought I heard a small improvement overall. It just looks so much better and works great which is why I prefer it.

Overall as good as it is the Shigaclone is not a match for my TD-124 MKII..

Bad idea!

Hey top marks to Kevinkr you worked out how to mod a vintage analogue turntable to play redbook CD's?

I'm just joking...

Serious looking turntable! I'd be jealous if only I had kept any of my old vinyl.

'Bad Idea' title refers to my idea to use flexible magnetic sheet as a shigaclone puck, which was a non starter as ideas go... not enough gauss!

I made a rough one to check it out, but it didn't stick the CD down to the spindle platter well enough to read the table of contents.

For some reason I irrationally hate the abbreviation TOC!

Bill

Hey top marks to Kevinkr you worked out how to mod a vintage analogue turntable to play redbook CD's?

I'm just joking...

Serious looking turntable! I'd be jealous if only I had kept any of my old vinyl.

'Bad Idea' title refers to my idea to use flexible magnetic sheet as a shigaclone puck, which was a non starter as ideas go... not enough gauss!

I made a rough one to check it out, but it didn't stick the CD down to the spindle platter well enough to read the table of contents.

For some reason I irrationally hate the abbreviation TOC!

Bill

Last edited:

Hey Guys,

I am a newbe on this and would like to know if I can use Sharp QT-CH88X boom box transport

Can you post any pictures of the transport and the board underneath it?

Bill

Will this work?

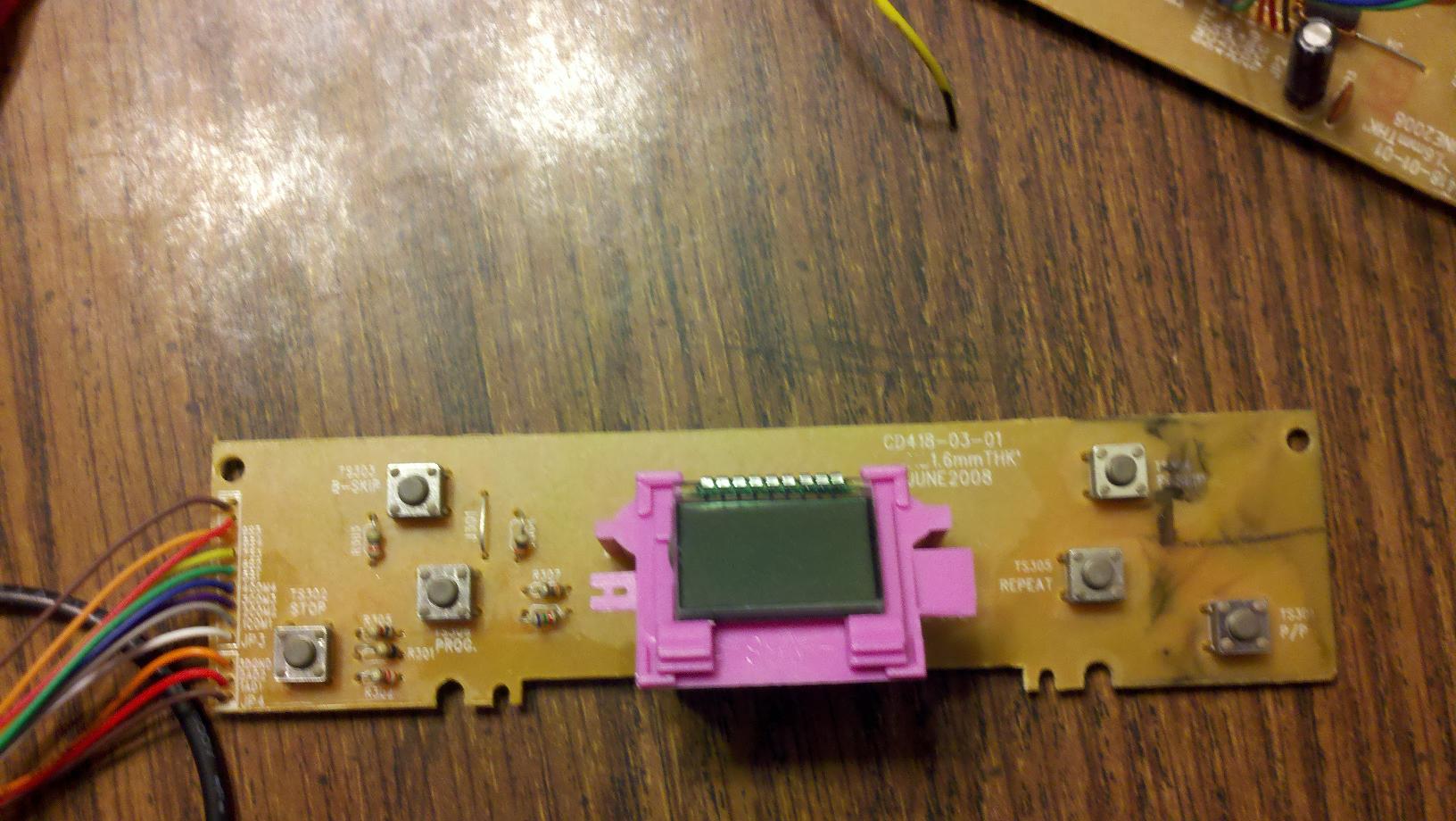

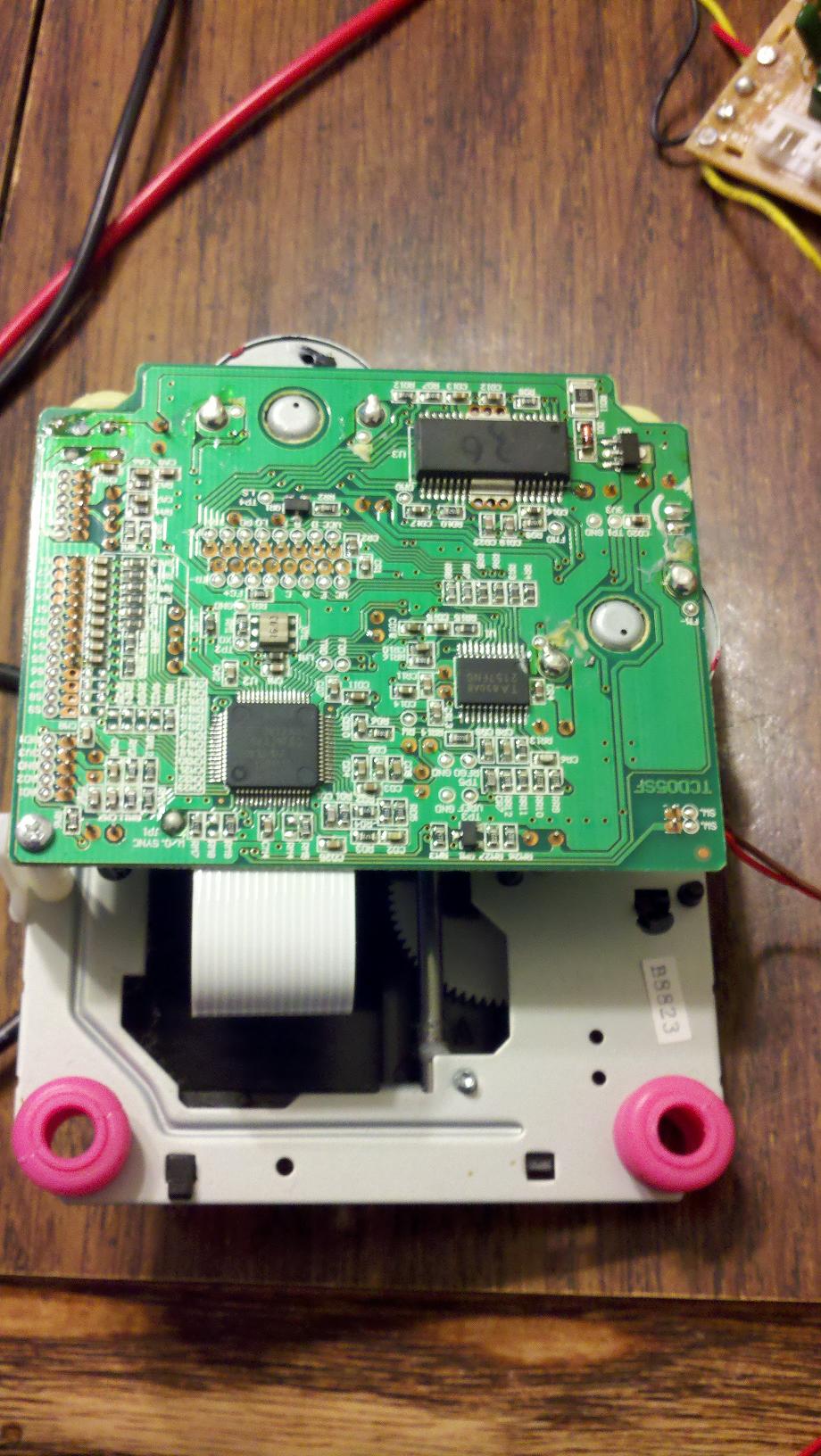

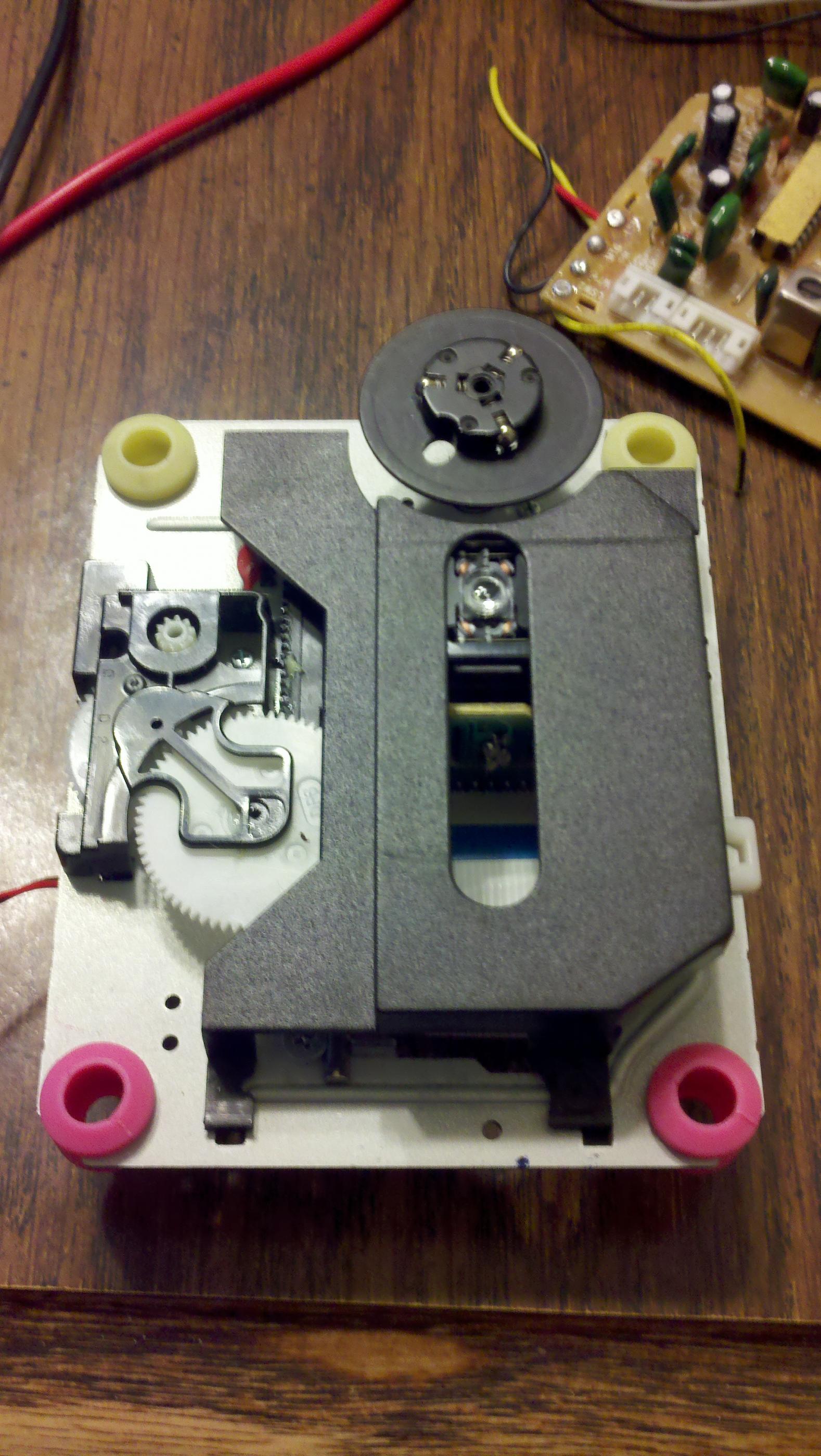

This cd unit is from a cheap boombox player my daughter had. The tray mechanism broke, and we replaced her's, but I thought I could have a bit of fun with this one. I have it running on the parts alone, and the transport is getting 9V so I assume the Shig PS should work fine. The link below is to the pdf of the chip specs (TC94A29FAG). I am not an engineer, so I can't really tell if I can get a digital output from it. It has a 1 bit DAC in the chip, but that isn't nearly good enough. I already have a chassis in the works, but if this doesnt work I can always use it for something else.

Pictures:

Chip PDF http://www.datasheetcatalog.org/datasheet/toshiba/4225.pdf

Thanks, James

This cd unit is from a cheap boombox player my daughter had. The tray mechanism broke, and we replaced her's, but I thought I could have a bit of fun with this one. I have it running on the parts alone, and the transport is getting 9V so I assume the Shig PS should work fine. The link below is to the pdf of the chip specs (TC94A29FAG). I am not an engineer, so I can't really tell if I can get a digital output from it. It has a 1 bit DAC in the chip, but that isn't nearly good enough. I already have a chassis in the works, but if this doesnt work I can always use it for something else.

Pictures:

Chip PDF http://www.datasheetcatalog.org/datasheet/toshiba/4225.pdf

Thanks, James

Attachments

- Home

- Source & Line

- Digital Source

- Finally, an affordable CD Transport: the Shigaclone story