the LF and HF decoupling are on board to meet the very fastest of audio transient current demands.Which leads to the question - what would be the ideal choice for cap in that position? Also, would there be any benefit to having that pair of caps (the + and - rail) connected at the amp pcb's rail inputs? I.E., having it mounted physically as close as possible?

The main PSU smoothing is for VLF current demand and extra cabling inductance for a few inches of twisted 3core hardly makes any difference.

It can't be for 500ms !

The length of a whole half wave of mains power is either 10ms or 8.3ms.

The longest pulse while trying to charge the first C from the transformer is very roughly half of those time intervals, say 4 to 5ms.

Using PSUD, (and soft start) i can see a peak reached at 500ms (when charging 47mF from a 18v transfo) it is this peak (about twice the established ripple) i am speaking about

Edit:

It looks like the soft start introduces this peak

Last edited:

check the capacitor datasheet for one shot peak current limit. Can you estimate the duration of the current peak @ ~500ms?Using PSUD, (and soft start) i can see a peak reached at 500ms (when charging 47mF from a 18v transfo) it is this peak (about twice the established ripple)

a small and crazy snap-in

40V, 3800uf

and still doing 13.5A

Digi-Key - 495-3705-ND (Manufacturer - B41605A7388M002)

40V, 3800uf

and still doing 13.5A

Digi-Key - 495-3705-ND (Manufacturer - B41605A7388M002)

I thought I should follow my own advice and check Tinitus link he so kindly looked up for us.

I can't see any value specified for peak one shot current. There is not a defined symbol for that parameter.

T,

where does 13.5A comes from for ripple current?

I see 6.5A or 9.5A ripple capacity and when corrected for 100Hz this drops to ~4A.

On that basis 4//3900uF would give ~16A or 24A of continuous ripple capability.

I can't see any value specified for peak one shot current. There is not a defined symbol for that parameter.

T,

where does 13.5A comes from for ripple current?

I see 6.5A or 9.5A ripple capacity and when corrected for 100Hz this drops to ~4A.

On that basis 4//3900uF would give ~16A or 24A of continuous ripple capability.

Last edited:

I see 6.5A or 9.5A ripple capacity and when corrected for 100Hz this drops to ~4A.

On that basis 4//3900uF would give ~16A or 24A of continuous ripple capability.

ah, yes, too good to be true

appears to be different when going to manufactors spec sheet insted of digikey's

but still a tough little cap

but small, and too expencive then

thanks for correcting Andrew

I dont know why they have specced current at 10khz, when they do 100hz for others

gosh, they have some rated at 150gr, and 500.000 hours at 75gr

check the capacitor datasheet for one shot peak current limit. Can you estimate the duration of the current peak @ ~500ms?

They only mention max ripple / frequency without saying how long neither how much it can be outpassed.

On that basis 4//3900uF would give ~16A or 24A of continuous ripple capability.

yeah, and the silly thing is that a single "small" screw cap only slightly bigger will do just that, or wrong again

Digi-Key - 495-4220-ND (Manufacturer - B41456B7109M)

where does 13.5A comes from for ripple current?

I see 6.5A or 9.5A ripple capacity and when corrected for 100Hz this drops to ~4A.

hey Andrew, Im not arguing, but trying to understand

and theres an even tougher 55V, 17.5A, 125gr, though taken at 105gr

Digi-Key - 495-3701-ND (Manufacturer - B41605A0368M002)

but its a bit messey as this one isnt in the spec sheet either

but theres a similar one with same can size, but slightly more capacity

do I understand the frequency/current chart correctly, if I say that the 40V ø25mm can size derates with a 0.7 factor, and the 55V ø25x50mm derates with a 0.6 factor

btw, could you by mistake have taken the current rating at 125gr

the listed current seems to be at the 105gr rating, which is higher

man, that kind of heat is like steaming hot water

well, enough from me on that subject

looks to be a bit excessive though.

yeah, but as of now I have decided not waste more time, and not worry about it

"simple and easy" mostly works

Attachments

I am slightly afraid of how much it would cost

try to look up "United Chemi-Con", "chassis mount", at digikey

maybe not a Mallory, but affordable

this one looks interesting

http://search.digikey.com/scripts/DkSearch/dksus.dll?Detail&name=565-3298-ND

http://search.digikey.com/scripts/DkSearch/dksus.dll?Detail&name=E32D800HPC223MD80M-ND

I and others have been saying for a long time that the first cap in a CRC and CLC must have a very high ripple rating.

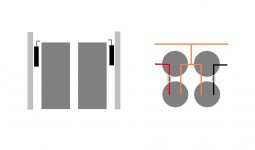

I have recommended that a bank of paralleled cheap caps are the most economic way of providing that ripple capability. The smoothing of rectified AC to DC is a continuous duty. In a high bias amplifier (eg ClassA) that is a high ripple current and continuous duty. The caps will heat up. Keep them in a cool environment, probably at the bottom of a well ventilated amplifier. Design to meet the duty.

I have recommended that a bank of paralleled cheap caps are the most economic way of providing that ripple capability. The smoothing of rectified AC to DC is a continuous duty. In a high bias amplifier (eg ClassA) that is a high ripple current and continuous duty. The caps will heat up. Keep them in a cool environment, probably at the bottom of a well ventilated amplifier. Design to meet the duty.

building your own super cell caps

it should be possible to stack multiple small caps, and cast them into solid blocks using a 2-component molding silicone, or whatever its called

might be very practical "building-blocks", and easy to handle

and as a positive side effect, I think such silicone rubber is resistant to heat

and ofcourse its electrically isolating

it should be possible to stack multiple small caps, and cast them into solid blocks using a 2-component molding silicone, or whatever its called

might be very practical "building-blocks", and easy to handle

and as a positive side effect, I think such silicone rubber is resistant to heat

and ofcourse its electrically isolating

@neutrality

make simulation with generic FW PSU and you'll know

I don't remember figures , or I'll write them

Generic FW PSU as per the F5 manual.

Below 0.4V peak-peak

- Home

- Amplifiers

- Pass Labs

- F5 power amplifier