Hot CL 60 thermistor in the Ac input line

I follow the power supply schematic in the manual but use 160000uF of line filtering from a 500W transformer.

i notice that in use the thermistor is very hot to touch.

With the Ac input switch off, I can only touch it for about 5 seconds.

I am aware that the thermistor should not be touched when the power supply is switched on as it is carrying live current

Is this normal?

kp93300

I follow the power supply schematic in the manual but use 160000uF of line filtering from a 500W transformer.

i notice that in use the thermistor is very hot to touch.

With the Ac input switch off, I can only touch it for about 5 seconds.

I am aware that the thermistor should not be touched when the power supply is switched on as it is carrying live current

Is this normal?

kp93300

ac line thermistor

This is the thermistor that I use

GE SENSING / THERMOMETRICS - CL-60 - THERMISTOR, SERIES CL

Farnell order code Order Code: 1653469

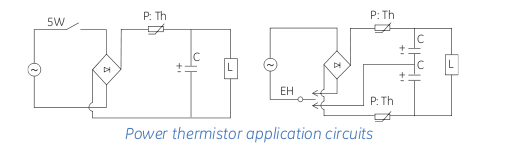

The application circuit from the manual is attached.

i notice that the thermistor is in the secondary circuit . F5 manual use the thermistor in the primary circuit.

Is this difference significant ?

Sorry my knowledge of electronic is basic.

kp93300

This is the thermistor that I use

GE SENSING / THERMOMETRICS - CL-60 - THERMISTOR, SERIES CL

Farnell order code Order Code: 1653469

The application circuit from the manual is attached.

i notice that the thermistor is in the secondary circuit . F5 manual use the thermistor in the primary circuit.

Is this difference significant ?

Sorry my knowledge of electronic is basic.

kp93300

Attachments

Thermistor temperature is proportional to the heat it dissipates.

At a 1.25A current level it dissipates ~1.7W heat, at 2.5A some 2.75W.

At 3.75A it's 3.65W and the maximum it handles is 4.5W at 5A average.

In a monoblock F5 at the primary side, a CL60 would dissipate less than 1W.

Connected at the secondary side, dissipation is much higher and temperature of the thermistor would be too hot for the touch.

Placing it right in front of 160.000uF (or 80.000uF) is not the wisest thing to do.

Read the CL60 line in Fig1 of the CL datasheet : www.thermometrics.com/assets/images/cl.pdf

At a 1.25A current level it dissipates ~1.7W heat, at 2.5A some 2.75W.

At 3.75A it's 3.65W and the maximum it handles is 4.5W at 5A average.

In a monoblock F5 at the primary side, a CL60 would dissipate less than 1W.

Connected at the secondary side, dissipation is much higher and temperature of the thermistor would be too hot for the touch.

Placing it right in front of 160.000uF (or 80.000uF) is not the wisest thing to do.

Read the CL60 line in Fig1 of the CL datasheet : www.thermometrics.com/assets/images/cl.pdf

Last edited:

Soon 2 Monoblocks F5 balanced finish.

(Variant of EUVL: Toshiba Transistor, U 16V, bias 2A).

The PSU I used (Monoblocks):

2x12V/625W TOROIDY trasformer;

8 MUR3060;

4X47000/40V (FTcap) - 2 x 0,15R/50W - 4x47000/40V (FTcap).

Theoretically should have voltage 16V, but practically are 13.75 V. ..

Amplifier will function normally with this tension?

On the same transformer and voltage I 2x18V.

Can I use 22..24V voltage for the balanced version of EUVL?

In this case a bias of 1.6 A would be OK?

Or be smaller?

The heatsink is 400x160x83mm (Monoblocks)

Thanks,

Vitalica

(Variant of EUVL: Toshiba Transistor, U 16V, bias 2A).

The PSU I used (Monoblocks):

2x12V/625W TOROIDY trasformer;

8 MUR3060;

4X47000/40V (FTcap) - 2 x 0,15R/50W - 4x47000/40V (FTcap).

Theoretically should have voltage 16V, but practically are 13.75 V. ..

Amplifier will function normally with this tension?

On the same transformer and voltage I 2x18V.

Can I use 22..24V voltage for the balanced version of EUVL?

In this case a bias of 1.6 A would be OK?

Or be smaller?

The heatsink is 400x160x83mm (Monoblocks)

Thanks,

Vitalica

Hello kp93300,

It's best to bypass that thermistor with a relay a few seconds after startup.

This way it can cool down and function again as soft start.

If it stays in the circuit it remains hot and its resistance low, it won't work again as soft start if you quickly on-off-on the amp.

Also put the thermistor before the transformer (on the mains).

See my post for more info: F5 finished

Regards,

Danny

It's best to bypass that thermistor with a relay a few seconds after startup.

This way it can cool down and function again as soft start.

If it stays in the circuit it remains hot and its resistance low, it won't work again as soft start if you quickly on-off-on the amp.

Also put the thermistor before the transformer (on the mains).

See my post for more info: F5 finished

Regards,

Danny

A thermistor of a different color.............

Once the amp is at operating temperature how do the thermistors (TH1/TH2) stabilize the bias setting?

How do/does this work while playing music, I do understand that some of that power that was turning into heat is now turning into music. Do they have an effect at that point?

I'm on the smaller side of acceptable for heatsinks, so I'm wondering if they would help or hurt this situation at all.

Once the amp is at operating temperature how do the thermistors (TH1/TH2) stabilize the bias setting?

How do/does this work while playing music, I do understand that some of that power that was turning into heat is now turning into music. Do they have an effect at that point?

I'm on the smaller side of acceptable for heatsinks, so I'm wondering if they would help or hurt this situation at all.

Last edited:

My understanding: during warmup the thermistors are high resistance so they allow the outputs to reach operating temp quickly. Once warmed up, they reduce the bias (reduced resistance) and allow the amplifier to stay at a stable operating temperature and bias. I guess there is some delta depending on how far they are from the outputs etc.

at first start up from cold the temp comp thermistors are also cold. The have high resistance.

The thermistors are in parallel to the bias setting resistors.

The high resistance cold thermistor hardly changes the effective bias resistor value and this sets the gate source voltage (Vgs) applied to the output FETs.

As the heatsink heats up, the thermistor also heats up and it's resistance drops.

This reduces the effective bias resistance and thus reduces the Vgs of the output FET. Less bias current.

If the sink cools a little, lower ambient temperature, or a door/window left open, then the thermistor cools slightly and increases Vgs again. More bias current.

This is a feedback system that attempts to minimise the variation in heatsink temperature with changes in operating conditions.

The thermistors are in parallel to the bias setting resistors.

The high resistance cold thermistor hardly changes the effective bias resistor value and this sets the gate source voltage (Vgs) applied to the output FETs.

As the heatsink heats up, the thermistor also heats up and it's resistance drops.

This reduces the effective bias resistance and thus reduces the Vgs of the output FET. Less bias current.

If the sink cools a little, lower ambient temperature, or a door/window left open, then the thermistor cools slightly and increases Vgs again. More bias current.

This is a feedback system that attempts to minimise the variation in heatsink temperature with changes in operating conditions.

the thermistor feedback is very slow, many seconds of time constant, maybe minutes.

It will not be audible from millisecond to millisecond, nor even from second to second.

However, it achieves this stabilisation by changing the Vgs for different operating conditions.

It is quite likely that the amp will have a different bias current when the ambient conditions are different. This may be audible from morning to evening, or day to day, or season to season. It will depend on how sensitive the amplifier sound is, to changes in bias current.

It will not be audible from millisecond to millisecond, nor even from second to second.

However, it achieves this stabilisation by changing the Vgs for different operating conditions.

It is quite likely that the amp will have a different bias current when the ambient conditions are different. This may be audible from morning to evening, or day to day, or season to season. It will depend on how sensitive the amplifier sound is, to changes in bias current.

the thermistor feedback is very slow, many seconds of time constant, maybe minutes.

It will not be audible from millisecond to millisecond, nor even from second to second.

However, it achieves this stabilisation by changing the Vgs for different operating conditions.

It is quite likely that the amp will have a different bias current when the ambient conditions are different. This may be audible from morning to evening, or day to day, or season to season. It will depend on how sensitive the amplifier sound is, to changes in bias current.

Some have built the F5 without the thermal tracking and current limiting and say it's better sounding. I wonder how much of that difference is related to the thermal tracking and how much is the current foldback circuit.

at first start up from cold the temp comp thermistors are also cold. The have high resistance.

The thermistors are in parallel to the bias setting resistors.

The high resistance cold thermistor hardly changes the effective bias resistor value and this sets the gate source voltage (Vgs) applied to the output FETs.

As the heatsink heats up, the thermistor also heats up and it's resistance drops.

This reduces the effective bias resistance and thus reduces the Vgs of the output FET. Less bias current.

If the sink cools a little, lower ambient temperature, or a door/window left open, then the thermistor cools slightly and increases Vgs again. More bias current.

This is a feedback system that attempts to minimise the variation in heatsink temperature with changes in operating conditions.

That's what I was looking for, how, if in fact it does influence bias during actual operation. I understand the start up/warm up thermistor function.

My heatsinks run very hot, I can only touch them for 4-5 seconds, I guess I'm not missing anything not having used them????

My build seems to warm up fine and hold steady bias.

Some have built the F5 without the thermal tracking and current limiting and say it's better sounding. I wonder how much of that difference is related to the thermal tracking and how much is the current foldback circuit.

I have built mine without the thermal compensation and current limiting as well. I had no intention of using the current limiting but I misplaced the thermistors and was debating on whether or not to include them so............

My main concern is the heat, I don't know if the heatsinks I'm using are big enough.

My heatsinks run very hot, I can only touch them for 4-5 seconds, I guess I'm not missing anything not having used them????

Try again

Im sure you can make the 6 seconds needed

Anyway, might be worth to consider how accurate measurements really are

I suppose you measure voltage drop, and not actual current flow

CL 60 thermistor

Thank all for the replies.

I have the thermistor behind a soft start board that i bought from Connexelectronic.This is on the primary side of the transformer.

i have used this set up for the past one month .

I check that the maximum operating temperature of the CL 60 is 175 deg c .

I think CL 60 will be ok

I might try danny's soft start circuit one of this days.

BTW, my current set up with the F5, OB5 from GR research, Promitheus DAC and AMC CD 6 player as transport is the best in my 20 over years of hi fi journey.

This set up is good in all aspects and I think I am spending too much time listening to music !

thanks again to all the helpful people.

kp93300

Thank all for the replies.

I have the thermistor behind a soft start board that i bought from Connexelectronic.This is on the primary side of the transformer.

i have used this set up for the past one month .

I check that the maximum operating temperature of the CL 60 is 175 deg c .

I think CL 60 will be ok

I might try danny's soft start circuit one of this days.

BTW, my current set up with the F5, OB5 from GR research, Promitheus DAC and AMC CD 6 player as transport is the best in my 20 over years of hi fi journey.

This set up is good in all aspects and I think I am spending too much time listening to music !

thanks again to all the helpful people.

kp93300

- Home

- Amplifiers

- Pass Labs

- F5 power amplifier