14 in x 2 in deep should work. Just scale drawing.

X

Would I be pushing it if I tried to bump it up to the mini?

Are you saying a 4 driver Cornu with Synergy front horn? You will need channels to route back wave to Cornu center - a common box for all 4 drivers would work. A piezo or dome tweeter in middle will help cover highs lost by bandpassing fullrange drivers. Interesting...

Yes, the closer the TC's are to the throat the better of coarse. Depending on how much sensitivity you want a Vifa XT ring radiator might work at the throat? The Neo one (doesn't like low crossover points) or if there is room for a bigger one even better (doubt the room is there)... If you can get close enough for a high crossover point. It does respond very good to wave guides: http://www.diyaudio.com/forums/multi-way/241286-my-first-wave-guide-speaker-lots-pics.html

http://heissmann-acoustics.de/test-vifa-xt-300-xt25tg-waveguide-wg-300/

Last edited:

I've just purchase two 3" TB for my third project but, while waiting for the drives to arrive, I've started reading this thread and suddenly the project changed to a Cornu Spiral.

I would appreciate if someone could confirm if I've made the right choices and of materials and dimensions:

9mm ply wood

5mm foamboard

60cm box scaled from planet10 plan and about the height I'm lost...

I've read that the height should be the same as the driver diameter 3" aprox 7,6cm but also the throat area equal to the driver SD, if I scale the PDF to 60cm I get a throat width of 1,9 cm minus the 0,5 cm of foamboard 1,4cm so 32cm2/1,4CM/2=11,42cm this is a 50% increase, what I am doing wrong?

Here is the data for the driver:

DIAPHRAGM MTL Paper

SURROUND MTL Santoprene

NOMINAL IMPEDANCE 8 W

DCR IMPEDANCE 6.6 W

SENSITIVITY 1W/1m 87 dB

FREQUENCY RESPONSE 100 - 20K Hz

FREE AIR RESONANCE 100 Hz

VOICE COIL DIAMETER 20 mm

AIR GAP HEIGHT 6 mm

RATED POWER INPUT 15 W

MAXIMUM POWER INPUT 30 W

FORCE FACTOR, BL 3.3 TM

MAGNET WEIGHT (4 oz) 120 g

MOVING MASS 1.60 g

FERROFLUID ENHANCED No

SUSPENSION COMPLIANCE 1234 MN-1

EFFECTIVE PISTON AREA 0.0032 M2

Levc 0.3048 mH

Zo 67.6781 ohm

X-max 0.4 mm

Vas 1.8 Litr

Qts 0.64

Qms 6.59

Qes 0.71

Jorge

I would appreciate if someone could confirm if I've made the right choices and of materials and dimensions:

9mm ply wood

5mm foamboard

60cm box scaled from planet10 plan and about the height I'm lost...

I've read that the height should be the same as the driver diameter 3" aprox 7,6cm but also the throat area equal to the driver SD, if I scale the PDF to 60cm I get a throat width of 1,9 cm minus the 0,5 cm of foamboard 1,4cm so 32cm2/1,4CM/2=11,42cm this is a 50% increase, what I am doing wrong?

Here is the data for the driver:

DIAPHRAGM MTL Paper

SURROUND MTL Santoprene

NOMINAL IMPEDANCE 8 W

DCR IMPEDANCE 6.6 W

SENSITIVITY 1W/1m 87 dB

FREQUENCY RESPONSE 100 - 20K Hz

FREE AIR RESONANCE 100 Hz

VOICE COIL DIAMETER 20 mm

AIR GAP HEIGHT 6 mm

RATED POWER INPUT 15 W

MAXIMUM POWER INPUT 30 W

FORCE FACTOR, BL 3.3 TM

MAGNET WEIGHT (4 oz) 120 g

MOVING MASS 1.60 g

FERROFLUID ENHANCED No

SUSPENSION COMPLIANCE 1234 MN-1

EFFECTIVE PISTON AREA 0.0032 M2

Levc 0.3048 mH

Zo 67.6781 ohm

X-max 0.4 mm

Vas 1.8 Litr

Qts 0.64

Qms 6.59

Qes 0.71

Jorge

TB W3-594SB in Cornu

Jorge,

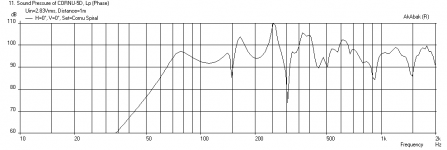

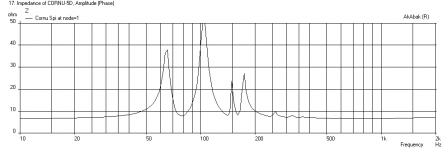

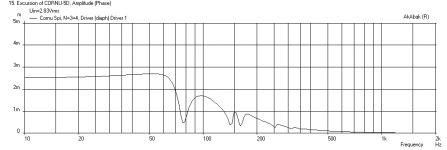

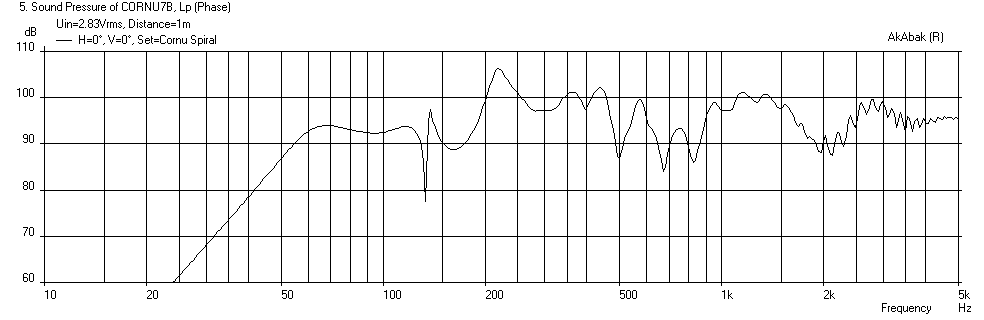

The whole trying to match Sd to the throat cross sectional area is all approximate anyway, you can be off by 2x and it is often just fine. In your case 1.4cm x 7.6cm x 2 = 21.3 cm and that is 65% of the driver Sd. A good value. I ran a simulation for the W3-594SB in Akabak (60 cm x 7.6cm deep) anyway so you can get a feel of how this will perform. It has good bass extension and sensitivity but you have to be careful about driving it hard as it exceeds xmax even at 1 watt. The xmax is only 0.4mm - I am sure that is not the physical damage limit but the limit for linear Bl operation.

Here is the SPL, impedance, and cone excursion at 2.83v, 1 meter.

60cm box scaled from planet10 plan and about the height I'm lost...

I've read that the height should be the same as the driver diameter 3" aprox 7,6cm but also the throat area equal to the driver SD, if I scale the PDF to 60cm I get a throat width of 1,9 cm minus the 0,5 cm of foamboard 1,4cm so 32cm2/1,4CM/2=11,42cm this is a 50% increase, what I am doing wrong?

Jorge

Jorge,

The whole trying to match Sd to the throat cross sectional area is all approximate anyway, you can be off by 2x and it is often just fine. In your case 1.4cm x 7.6cm x 2 = 21.3 cm and that is 65% of the driver Sd. A good value. I ran a simulation for the W3-594SB in Akabak (60 cm x 7.6cm deep) anyway so you can get a feel of how this will perform. It has good bass extension and sensitivity but you have to be careful about driving it hard as it exceeds xmax even at 1 watt. The xmax is only 0.4mm - I am sure that is not the physical damage limit but the limit for linear Bl operation.

Here is the SPL, impedance, and cone excursion at 2.83v, 1 meter.

Attachments

Are you saying a 4 driver Cornu with Synergy front horn? You will need channels to route back wave to Cornu center - a common box for all 4 drivers would work.

There's no rule that a Cornu Horn has to have 4 channels per driver. For example, you could sub-divide the central chamber into 4, and place 4 smaller drivers, one in each section. In the case of the Synergy, you could construct a spiral path horn for each of the 4 drivers with the mouths exiting around the edges of the Synergy horn.

There's no rule that a Cornu Horn has to have 4 channels per driver.

OK, I'm jumping on the picky wagon here Don. A Cornu or any version of it has one driver and 2 sets of horns of unequal length in a squared off spiral. Anything else and it gets it's own name. Lots of possibilities with spiral horns and I think that's what you meant. Bose has a patent on a 2 spiral horn and there is a plan here for a 6 spiral. Heck some dummy even bent the spiral into a Penthorn and still wants to be included in the group. Can you believe some people?

So is the 2" HiWave BMR12 driver too small for the mini?

A 2 in driver is too small for a 20 in mini. Go with 14 in x 2 in and you should be good.

Cornu Spiral stuffing?

I am close to finishing my CNC plywood and bendy MDF 32" x 32" Cornu spirals, at least the insides.

I designed my own continuously curved horn profiles in 3D animation software, the CNC cut tracks through a 1/2" plywood center plane, then bent 3/8" bendy MDF into these tracks, and covered with birch veneer. Has been an enormous amount of work. I wish I had known about the foam core option when I started. I could have made a series of prototypes and dialed in the best design. I am worried from reading parts of this thread that mine are too big and will have too much bass. The horns are about 8 feet long when unwrapped. At their inner end, at the narrowest, the horns are about 1.5" tall by 1.25" wide.

The last step will be to run them through a 5' wide belt sander at a local shop, so the tops and bottoms of all the spirals will be perfectly flat and parallel.

Still need to glue the fronts and backs on (also 1/2" birch ply)which I doubt will be easy. Planning to do one side at a time with heavy weights to clamp the sandwich. I am actually thinking I will put a small bead of silicone caulk on the spirals and then bolt the sandwich together temporarily to hear how they sound more quickly.

What is recommended to stuff inside the chamber behind the driver? I have Fostex FE126E units, but if people have suggestions for better drivers (planet 10?) I am all ears.

Is it necessary to put stuffing of some kind in the chamber behind the driver? Lambswool or something? This material will not be easily changed one they are glued together so another reason to temp clamp them first.

What materials to have on hand to try as stuffing? Is stuffing truly needed? What affect does the stuffing have?

Colin

I am close to finishing my CNC plywood and bendy MDF 32" x 32" Cornu spirals, at least the insides.

I designed my own continuously curved horn profiles in 3D animation software, the CNC cut tracks through a 1/2" plywood center plane, then bent 3/8" bendy MDF into these tracks, and covered with birch veneer. Has been an enormous amount of work. I wish I had known about the foam core option when I started. I could have made a series of prototypes and dialed in the best design. I am worried from reading parts of this thread that mine are too big and will have too much bass. The horns are about 8 feet long when unwrapped. At their inner end, at the narrowest, the horns are about 1.5" tall by 1.25" wide.

The last step will be to run them through a 5' wide belt sander at a local shop, so the tops and bottoms of all the spirals will be perfectly flat and parallel.

Still need to glue the fronts and backs on (also 1/2" birch ply)which I doubt will be easy. Planning to do one side at a time with heavy weights to clamp the sandwich. I am actually thinking I will put a small bead of silicone caulk on the spirals and then bolt the sandwich together temporarily to hear how they sound more quickly.

What is recommended to stuff inside the chamber behind the driver? I have Fostex FE126E units, but if people have suggestions for better drivers (planet 10?) I am all ears.

Is it necessary to put stuffing of some kind in the chamber behind the driver? Lambswool or something? This material will not be easily changed one they are glued together so another reason to temp clamp them first.

What materials to have on hand to try as stuffing? Is stuffing truly needed? What affect does the stuffing have?

Colin

Colin,

Sounds like an awesome project. Please show is some photos! 32 inches produces deep bass and the amplitude is somewhat controlled by how tall your channels are. It sounds like you are running 3 in wide channels with both sides so you may be just fine. Did you follow the Cornu plan or did you make your own? If you followed plan I can run a simulation for you. I would go with a bigger driver if you went with 32 inch. Maybe TB W5-1611 - that sims rather nicely. You generally need stuffing at least in main chamber. Use poly fill pillow stuffing, lambs wool, rock wool, fiberglass, they all work to reduce high freq from leaking out and they smooth the response. You can tie string around a wad of stuffing that goes in throat. Pull string out to adjust. Sounds very ambitious and I look forward to hearing your first sound reports.

X

Sounds like an awesome project. Please show is some photos! 32 inches produces deep bass and the amplitude is somewhat controlled by how tall your channels are. It sounds like you are running 3 in wide channels with both sides so you may be just fine. Did you follow the Cornu plan or did you make your own? If you followed plan I can run a simulation for you. I would go with a bigger driver if you went with 32 inch. Maybe TB W5-1611 - that sims rather nicely. You generally need stuffing at least in main chamber. Use poly fill pillow stuffing, lambs wool, rock wool, fiberglass, they all work to reduce high freq from leaking out and they smooth the response. You can tie string around a wad of stuffing that goes in throat. Pull string out to adjust. Sounds very ambitious and I look forward to hearing your first sound reports.

X

I made my own plan for the spirals using 3D animation software.

I more or less matches the original Cornu Copy diagram posted by the guy from Quebec, but does not have any corners - continuously expanding always curved horns - there are 8 total, 4 on each side of the center divider. Two on each side are split about half way along into two, as in the original design I copied.

I can try to find a way to post the pattern.

Pictures after the belt sander!

Like all projects, no matter how carefully thought through, I want to make another pair knowing what I know now from building the first set.

Colin

I more or less matches the original Cornu Copy diagram posted by the guy from Quebec, but does not have any corners - continuously expanding always curved horns - there are 8 total, 4 on each side of the center divider. Two on each side are split about half way along into two, as in the original design I copied.

I can try to find a way to post the pattern.

Pictures after the belt sander!

Like all projects, no matter how carefully thought through, I want to make another pair knowing what I know now from building the first set.

Colin

X -

Thanks for the supportive thoughts. When I run them through the 5' belt sander, obviously the horns will get shorter, or shallower looking at them from the front.

I was planning to sand them down the minimum amount needed to make the top surfaces of the spirals flat and all parallel.

Is this right, or would a shallower section be better? I would guess the expected height of each will be 1.5" max, and at the inside the horns are about 1.25" wide, and 32" at the outside, and about 96" long.

They might look nicer and weigh a lot less if they are thinner, like 1" each. Don't forget there are two layers of horns, so if I have two layers of horns each 1" thick, with 3 layers of 0.5" plywood in the middle, front, and back, the whole thing will be 3.5" thick if I sand them down to 1" each side, or 4.5" thick if I leave them ~1.5" each.

CG

Thanks for the supportive thoughts. When I run them through the 5' belt sander, obviously the horns will get shorter, or shallower looking at them from the front.

I was planning to sand them down the minimum amount needed to make the top surfaces of the spirals flat and all parallel.

Is this right, or would a shallower section be better? I would guess the expected height of each will be 1.5" max, and at the inside the horns are about 1.25" wide, and 32" at the outside, and about 96" long.

They might look nicer and weigh a lot less if they are thinner, like 1" each. Don't forget there are two layers of horns, so if I have two layers of horns each 1" thick, with 3 layers of 0.5" plywood in the middle, front, and back, the whole thing will be 3.5" thick if I sand them down to 1" each side, or 4.5" thick if I leave them ~1.5" each.

CG

That looks like the original Cornu without any corners. I did something similar with my 14 inch one. A simulation using the standard geometry will probably give you a close approximation. I would try to keep the 1.5 in depth x 2. If you make it too thin it may not sound good for a 4 or 5 on driver.

Inform me

I am very intressed im spiral horn but theres a lot of pages (114) to read . What i vant to now is the maths behind spiral horns. The only "paper" i found was on http://www.cornu.purespace.de/flat1.htm.

I am very intressed im spiral horn but theres a lot of pages (114) to read . What i vant to now is the maths behind spiral horns. The only "paper" i found was on http://www.cornu.purespace.de/flat1.htm.

The Cornu speaker doesn't use a true Cornu spiral function. If you want to creat a spiral based on mathematical function, the throat will be very small. I show this in post 331 where the curves are calculated in closed form functions in Mathcad.

http://www.diyaudio.com/forums/full-range/225622-ever-think-building-cornu-spiral-horn-now-you-can-34.html#post3314105

Hope this helps.

X

should I consider changing drivers to the Tang Band W4-1879 4"

for some reason, even though the appearance goes against my audio engineering brain's instincts, the little slotted copper plug in the middle looks cool to me, at least unusual, and a bit techy.

What would the impact be of this driver over the ones I already bought (FE126E)? Or should I get Planet 10 Enabled ones instead (more $$, but I want my speakers to be the best possible and right the first time).

I will likely put the 126Es into some foam core ones for use in my office.

I kind of want to try some Foamcore Swans.

CG

for some reason, even though the appearance goes against my audio engineering brain's instincts, the little slotted copper plug in the middle looks cool to me, at least unusual, and a bit techy.

What would the impact be of this driver over the ones I already bought (FE126E)? Or should I get Planet 10 Enabled ones instead (more $$, but I want my speakers to be the best possible and right the first time).

I will likely put the 126Es into some foam core ones for use in my office.

I kind of want to try some Foamcore Swans.

CG

should I consider changing drivers to the Tang Band W4-1879 4"

for some reason, even though the appearance goes against my audio engineering brain's instincts, the little slotted copper plug in the middle looks cool to me, at least unusual, and a bit techy.

What would the impact be of this driver over the ones I already bought (FE126E)? Or should I get Planet 10 Enabled ones instead (more $$, but I want my speakers to be the best possible and right the first time).

I will likely put the 126Es into some foam core ones for use in my office.

I kind of want to try some Foamcore Swans.

CG

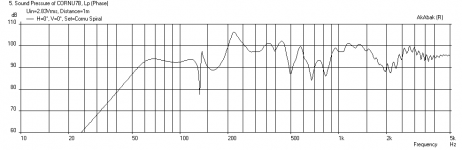

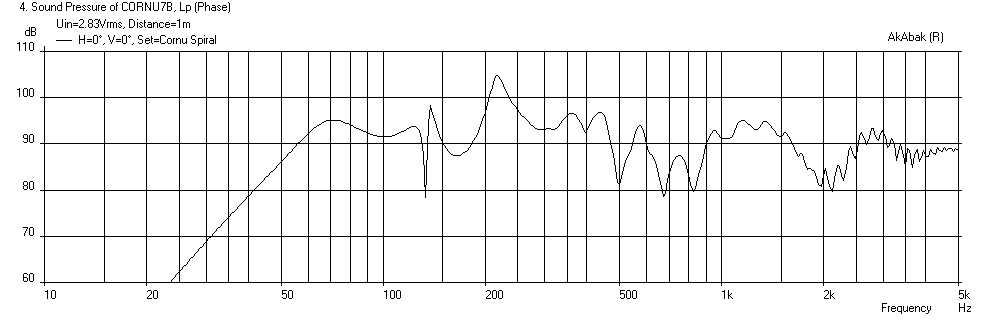

Both of these drivers will work pretty well in a 27.6 in x 4.5 in deep Cornu. Here are the sims for the FE126EN vs the W4-1879. The Tang Band seems like it will be more balanced as the high end on the Fostex is greater. The Fostex has very small xmax so you will probably get more satisfying bass from the Tang Band.

FE126EN

W4-1879

Attachments

- Home

- Loudspeakers

- Full Range

- Ever think of building a Cornu Spiral horn? Now you can!