I just picked up an EV Sentry IV and the HF horn, ST350, has an open voice coil.

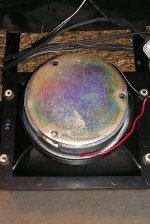

I found a YouTube video but it shows a square magnet with four screws. Mine is round with three screws that holds the back cover on.

With the back off, I can see the magnet and plates on both sides but nothing is loose and I don't want to start prying things apart.

Maybe it's just stuck together? Any help would be appreciated.

Thanks in advance.

I found a YouTube video but it shows a square magnet with four screws. Mine is round with three screws that holds the back cover on.

With the back off, I can see the magnet and plates on both sides but nothing is loose and I don't want to start prying things apart.

Maybe it's just stuck together? Any help would be appreciated.

Thanks in advance.

Thanks zeonriderObviously I didn't search long enough

15. sec.

The only diaphragm worth buying is the Klipsch K77 diaphragm.

Klipsch La Scala Factory K 77 F Tweeter Horn Diaphragm Faceplate Assembly 127126 | eBay

You will need to remove the new diaphragm from its plastic carrier before you install it in yours. This is hard to do.

All others have no high end, and no low end (I'm not kidding you).

Klipsch La Scala Factory K 77 F Tweeter Horn Diaphragm Faceplate Assembly 127126 | eBay

You will need to remove the new diaphragm from its plastic carrier before you install it in yours. This is hard to do.

All others have no high end, and no low end (I'm not kidding you).

Although the video shows the magnet structure coming off relatively easily, mine isn't. To the point that the anodized plates (pole pieces?) start to pull away from the magnet.

The inside plate is recessed into a cup formed by the rest of the horn and therefore can't be pried up. It looks there s a rubber o-ring like seal and I'm thinking that this has attached itself to the magnet structure :-( Any ideas how to get this apart?

The inside plate is recessed into a cup formed by the rest of the horn and therefore can't be pried up. It looks there s a rubber o-ring like seal and I'm thinking that this has attached itself to the magnet structure :-( Any ideas how to get this apart?

If so, just how "hard" is it to remove the diaphragm from the carrier? 1hr, 3hrs?

Pictures

"do you think the Klipsch "diaphragm face place assembly" is better than the equivalent one for the 350?"

They are not interchangeable, so the question makes no sense.

"If so, just how "hard" is it to remove the diaphragm from the carrier? "

5 minute job.

Just don't break the aluminum lead-out wire.

If you shift the magnet during disassembley, it's not easily repaired, and I would probably toss it and get another used one.

They are not interchangeable, so the question makes no sense.

"If so, just how "hard" is it to remove the diaphragm from the carrier? "

5 minute job.

Just don't break the aluminum lead-out wire.

If you shift the magnet during disassembley, it's not easily repaired, and I would probably toss it and get another used one.

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- EV ST350 HF horn repair