sts9fan said:would like to enABL a pair of 126E speakers I built.

FE126 benefits from the trifoil pattern... Details off of the Fostex driver page at my commercial site (links to 2 sets of forum posts)

dave.

So what has been done to this driver?

http://homepage.mac.com/tlinespeakers/FAL/images/FE127e-iso.jpg

Is that just the puzzlecoat? To you have one of those printable patterns as guides for the 126E?

http://homepage.mac.com/tlinespeakers/FAL/images/FE127e-iso.jpg

Is that just the puzzlecoat? To you have one of those printable patterns as guides for the 126E?

sts9fan said:So what has been done to this driver?

http://p10hifi.net/tlinespeakers/FAL/images/FE127e-iso.jpg

Is that just the puzzlecoat? To you have one of those printable patterns as guides for the 126E?

That driver is out-of-date, it is the old one. Althou way better than a stock driver the EnABLed version is WAY better yet... it does illustrate what the driver should look like before the EnABL is added... that has the trifoil pattern in damar + a coat (or 2 depending on how thinned) of puzzlekoat. EnABL pattern is added on top of this, then 3 coats of 50/50 gloss (only 1 on the dustcap)

dave

Hi Chris,

Welcome to our clan.

Attached is the pattern set for the 126/127 driver. One other thing you will need is a small amount of PVA. A droplet of this is applied on the center spot, on the center of the dome, before the Gloss coat conformal coating is applied, but after the pattern rings are applied.

Poly Vinyl Acrylic, Elmers White Glue, white craft glue, Parts Express surround to basket glue, these are all PVA.

Also, here is the link to the pictures of the step by step pattern process.

http://picasaweb.google.com/hpurvine/Fostex127ETreatment

Here for instructions and comments on the pattern application,

http://www.diyaudio.com/forums/showthread.php?postid=1224615#post1224615

Here for Gloss coat instructions

http://www.diyaudio.com/forums/showthread.php?postid=1225189#post1225189

And then visit the Hawthorne Audio site Mongo pointed you to in an earlier post, for general instructional comments on tools and preparations for patterning. A third tutorial on Gloss conformal coating will be posted in a day or two.

I don't know what Damar is either, it is part of Planet 10 Dave's pre treatment, and quite useful.

Have fun, be calm, and treat some cheap speakers first, just so you know how. It is a bit more subtle than it looks and pitfalls are covered in the Hawthorne site tutorials.

Bud

Welcome to our clan.

Attached is the pattern set for the 126/127 driver. One other thing you will need is a small amount of PVA. A droplet of this is applied on the center spot, on the center of the dome, before the Gloss coat conformal coating is applied, but after the pattern rings are applied.

Poly Vinyl Acrylic, Elmers White Glue, white craft glue, Parts Express surround to basket glue, these are all PVA.

Also, here is the link to the pictures of the step by step pattern process.

http://picasaweb.google.com/hpurvine/Fostex127ETreatment

Here for instructions and comments on the pattern application,

http://www.diyaudio.com/forums/showthread.php?postid=1224615#post1224615

Here for Gloss coat instructions

http://www.diyaudio.com/forums/showthread.php?postid=1225189#post1225189

And then visit the Hawthorne Audio site Mongo pointed you to in an earlier post, for general instructional comments on tools and preparations for patterning. A third tutorial on Gloss conformal coating will be posted in a day or two.

I don't know what Damar is either, it is part of Planet 10 Dave's pre treatment, and quite useful.

Have fun, be calm, and treat some cheap speakers first, just so you know how. It is a bit more subtle than it looks and pitfalls are covered in the Hawthorne site tutorials.

Bud

sts9fan said:what is damar? I don'tsee this mentioned in Bud's thread.

No you won't see it here. It is part of what i took from my old driver mods for the FE126/127. Using it to form the trifoil pattern helps supress to a certain degree the 2 big cone resonances in the 126/127.

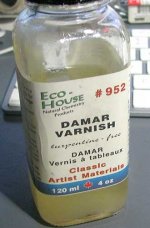

Damar is an artists varnish for coating oil paintings. A $10 bottle from the art supply store will last a lifetime.

dave

planet10 said:Here is a pic of the label from my bottle...still 2/3rds full after a couple hundred drivers (and a few spills)

dave

no, the red flag doesn't designate maple syrup content

DougL said:I was wondering if the treatment details had been worked out for the B200?

Double ring at the surround... a triple ring at the voice coil (because of the left overs from the dustcap), and 3 double rings on the phase plug plus the tip treatment.

1 coat puzzlekoat pre-coat, 3 50% gloss after.

Bud gets a hold of one he may detail it slightly differently. Drivers now on a boat to Jakarta,

dave

Attachments

Dave,

I think that what you have on the ship bound B200's is the correct thing to do. These additional interim rings I have cautioned everyone about, with respect to the Hemp FR8 are showing some difficult characteristics. Difficult enough that I am going to hang on to the FR8 drivers for a bit more experimentation.

When I first applied the mid cone and mid whizzer rings, the sonic character changed markedly. Much less tolerance for harsh and nasal sounds. Paradoxically, the amount of detail and musical nuance is definitely greater than with the single sets of rings at start and finish of the cones, or triple set in the B200's case and others.

I am going to have to purchase and sacrifice some inexpensive cones to figure out what the odd harsh character is. Sounded almost like what you would expect to hear, from looking at Soongsc CSD plot, for the pattern that fully dissipated the nodal standing wave ringing. But, it was also tantalizingly more capable. The Gloss smoothed that harshness away, with just a slight edge showing occasionally.

I continued to use musically more dense test material, though still pretty smooth in nature, and was satisfied that I was on to something very useful. Then Tate, from the Hawthorne Audio forum, stopped by, bringing a collection of much more raucous, hard edged music, on Red Book CD only, with unknown quality in transfer. Still, a more benign EnABL pattern would not have stumbled here. I also use Red Book during the last phase of treating something new, I just hadn't done that yet.

This music definitely woke up the harsh side of things, so I am glad he came and brought what he did. I want to reinforce a warning about these new mid rings, DON"T USE THEM.... just yet.

Meanwhile, back with the 200B's. Doug, If Dave is satisfied with the quality from the treatment he performed, I am quite confident I would end up with the same patterns in the same places, so, go for it.

Bud

I think that what you have on the ship bound B200's is the correct thing to do. These additional interim rings I have cautioned everyone about, with respect to the Hemp FR8 are showing some difficult characteristics. Difficult enough that I am going to hang on to the FR8 drivers for a bit more experimentation.

When I first applied the mid cone and mid whizzer rings, the sonic character changed markedly. Much less tolerance for harsh and nasal sounds. Paradoxically, the amount of detail and musical nuance is definitely greater than with the single sets of rings at start and finish of the cones, or triple set in the B200's case and others.

I am going to have to purchase and sacrifice some inexpensive cones to figure out what the odd harsh character is. Sounded almost like what you would expect to hear, from looking at Soongsc CSD plot, for the pattern that fully dissipated the nodal standing wave ringing. But, it was also tantalizingly more capable. The Gloss smoothed that harshness away, with just a slight edge showing occasionally.

I continued to use musically more dense test material, though still pretty smooth in nature, and was satisfied that I was on to something very useful. Then Tate, from the Hawthorne Audio forum, stopped by, bringing a collection of much more raucous, hard edged music, on Red Book CD only, with unknown quality in transfer. Still, a more benign EnABL pattern would not have stumbled here. I also use Red Book during the last phase of treating something new, I just hadn't done that yet.

This music definitely woke up the harsh side of things, so I am glad he came and brought what he did. I want to reinforce a warning about these new mid rings, DON"T USE THEM.... just yet.

Meanwhile, back with the 200B's. Doug, If Dave is satisfied with the quality from the treatment he performed, I am quite confident I would end up with the same patterns in the same places, so, go for it.

Bud

About the B200, what do you think of the rubber gasket at the edge of the surround? There was some discussion earlier about Raleigh waves at the stepped edge on the Hemp 4.5 drivers and some were trimming these off. Is there enough of a step here to cause problems?

I was curious and found that mine would peel off pretty easy and was thinking of replacing them with a flatter felt ring.

Thanks,

Scott

I was curious and found that mine would peel off pretty easy and was thinking of replacing them with a flatter felt ring.

Thanks,

Scott

scottw said:About the B200, what do you think of the rubber gasket at the edge of the surround? There was some discussion earlier about Raleigh waves at the stepped edge on the Hemp 4.5 drivers and some were trimming these off. Is there enough of a step here to cause problems?

The ring on the B200s is quite innocuous... probabaly less troublsome on than the HA 4.5c one is after you've peeled it off.

Note: this is the latest version of the B200 with the terminals together on one side.

dave

I agree. You might paint it with a full strength gloss coat, after the driver is in a baffle. Might also put an EnaBL pattern out at the edge of the mounting flange, and then gloss coat it.The ring on the B200s is quite innocuous

These two will have some effect upon dispersion and will aid in integration with a baffle, but are not a necessity. If you also treat the baffle to EnABL, then this ring set will become more useful.

Not uncommon to put a set of rings on the baffle, just beyond the mounting plate of the driver too. Really just depends upon how wide a dispersion pattern the driver throws and whether you are getting a persistent beaming of upper frequencies, from the center area of the driver.

Bud

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- EnABL Processes