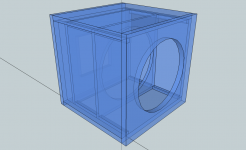

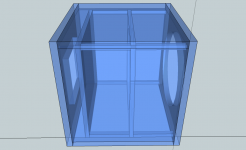

Bracing needs little bit more work. Chamber behind driver is bigger and needs more support. I made a mistake and the driver comes deeper than I thought.

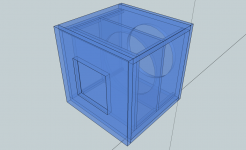

The actual volume is about 57L and acoustic volume is 68L. I will stuff it 24g/L of damping material which is alot and it will increase the volume plus 20% to 68L. Some may disagree with this but I want same output as in the sim of WinISD. Next choice is to make 500x500x500mm cube which would work even without stuffing. Actually I modelled it at first.

http://www.nousaine.com/pdfs/Box Stuffing.pdf has some info on stuffing subwoofers. On sealed box 24g/L is ok but with bass reflex maybe 12g/L.

The actual volume is about 57L and acoustic volume is 68L. I will stuff it 24g/L of damping material which is alot and it will increase the volume plus 20% to 68L. Some may disagree with this but I want same output as in the sim of WinISD. Next choice is to make 500x500x500mm cube which would work even without stuffing. Actually I modelled it at first.

http://www.nousaine.com/pdfs/Box Stuffing.pdf has some info on stuffing subwoofers. On sealed box 24g/L is ok but with bass reflex maybe 12g/L.

Hi.

I have a little bit of a problem now with materials. Maybe some expert in subwoofer box building will read this...

I asked prices from a carpenter and it seems a box from 26mm glued birch board is pretty expensive to make. I could get 19mm MDF box much cheaper.

Atleast there is two problems with MDF. One is finishing the surface so that it doesn't look ugly. Second is that it might resonate more and will the baffle hold togeather.

The driver will be placed a few millimeters deeper in baffle. Joints in box will be made with lamello.

Maybe a white or black paint job on surface and the baffle could be double?

I have a little bit of a problem now with materials. Maybe some expert in subwoofer box building will read this...

I asked prices from a carpenter and it seems a box from 26mm glued birch board is pretty expensive to make. I could get 19mm MDF box much cheaper.

Atleast there is two problems with MDF. One is finishing the surface so that it doesn't look ugly. Second is that it might resonate more and will the baffle hold togeather.

The driver will be placed a few millimeters deeper in baffle. Joints in box will be made with lamello.

Maybe a white or black paint job on surface and the baffle could be double?

Im not sure what you mean by "finishing", but it is easier to get a nice finish from mdf.

For hifi i think 19mm is a bit on the lean side, schould be at least 22mm.

Lamello is fine, use a lot of white glue (you have Cascol in Finland?)

A small tip: after aplying glue on mdf, put the bits together and wait a few minutes before putting pressure on the joints, this way you get a stronger joint because glue penetrate the flat hard layer.

Dag

For hifi i think 19mm is a bit on the lean side, schould be at least 22mm.

Lamello is fine, use a lot of white glue (you have Cascol in Finland?)

A small tip: after aplying glue on mdf, put the bits together and wait a few minutes before putting pressure on the joints, this way you get a stronger joint because glue penetrate the flat hard layer.

Dag

I decided to go for the 19mm MDF and double baffle. My "workshop" didn't have big enough space and tools for this project so the carpenter will assemble the enclosure. I just do sanding, paint job and installation. I'll have it in 2 weeks and then I get to do my work on it.

Hi vinodk,

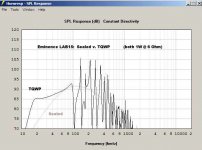

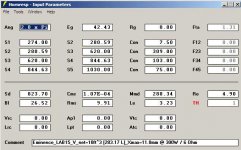

Do you already have the LAB15s? If not, I would advise to look at other drivers, e.g.: the Epic 12" that PE sells outperforms the LAB15 in a sealed HT application. Or go for a different enclosure, e.g.: a T-QWP looks promising for the LAB15

Regards,

Do you already have the LAB15s? If not, I would advise to look at other drivers, e.g.: the Epic 12" that PE sells outperforms the LAB15 in a sealed HT application. Or go for a different enclosure, e.g.: a T-QWP looks promising for the LAB15

Regards,

Attachments

Last edited:

For HT use and 20Hz I would go vented enclosure. At sealed enclosure F12=25Hz and max spl @20Hz=110dB(in room). A few designs from eminence -> http://www.eminence.com/pdf/LAB_15_cab.pdf

Hi vinodk,

T-QWP = tapped quarter wave pipe

T-TQWP = tapped tapered quarter wave pipe

These enclosure forms have been advocated in this forum by bjorno, and seem to result in home speakers of high quality. If you use the search you should be able to find any number of examples. Here is one:

http://www.diyaudio.com/forums/subw...band-w8q-1071f-8-x-12-box-reccomendation.html

Regards,

T-QWP = tapped quarter wave pipe

T-TQWP = tapped tapered quarter wave pipe

These enclosure forms have been advocated in this forum by bjorno, and seem to result in home speakers of high quality. If you use the search you should be able to find any number of examples. Here is one:

http://www.diyaudio.com/forums/subw...band-w8q-1071f-8-x-12-box-reccomendation.html

Regards,

Hi Veke 76,

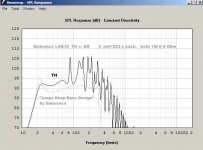

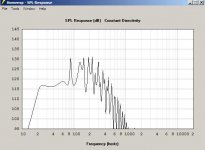

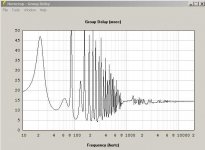

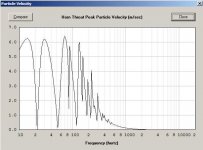

I think particle velocity is where the real advantage of the TH over the BR comes in:

Regards,

I think particle velocity is where the real advantage of the TH over the BR comes in:

Regards,

Attachments

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- Eminence LAB 15 + Hypex DS8.0 sealed box