I have started to consider an improved replacement for my JBL 2226s (15" woofers for non JBL aficionados).

I would like to understand the internal details so I can make an informed choice, or even DIY some drivers with my lathe and mill.

Inevitably there's a mass of contradictory claims about the best way to make a driver.

My request for any references about transducer internals had 0 replies so I started to analyse it myself.

I re-invented a lot of stuff but have some ideas that I haven't seen published.

I still need to better understand eddy currents and third harmonic distortion.

Doug Button mentions this in one of his JAES papers but says the details are in a 1991 convention paper - "Design Parameters and Trade-offs in Large Diameter Transducers"

Any one know of a copy of this? I think the AES permits the publication of convention papers that are not available in the Journal.

Alternatively, does anyone have a better reference or want to discuss it here?

David

I would like to understand the internal details so I can make an informed choice, or even DIY some drivers with my lathe and mill.

Inevitably there's a mass of contradictory claims about the best way to make a driver.

My request for any references about transducer internals had 0 replies so I started to analyse it myself.

I re-invented a lot of stuff but have some ideas that I haven't seen published.

I still need to better understand eddy currents and third harmonic distortion.

Doug Button mentions this in one of his JAES papers but says the details are in a 1991 convention paper - "Design Parameters and Trade-offs in Large Diameter Transducers"

Any one know of a copy of this? I think the AES permits the publication of convention papers that are not available in the Journal.

Alternatively, does anyone have a better reference or want to discuss it here?

David

You need to be more specific as to what you want to use your 15" unit for.

Subwoofer? Or is it meant to go up to >100Hz?

Sealed Box? Ported? What size? Power Handling at LF?

I'm not sure it's sensible to try and 'improve' on a JBL bass unit. They were one of the last makers to switch to Ferrite magnets. They only did so when they came up with a Ferrite motor design which they felt minimized the disadvantages. It's rather more complex than anyone elses.

If you make your own motor system, you need to magnetise it. This is serious $$$ and hardware.

Practically all speaker motors are asymmetrical so if your unit has mainly 3rd harmonic, you are doing really well.

The motor is only 1 of a number of factors that determine THD in a bass unit. The surround & spider are also important and have to be matched to the motor for best THD.

When I left the civilised world at the end of the last Millenium, NeFeB magnets were awful .. especially their thermal performance. Their only advantage was small size & cheep.

Electric cars in the 21st century has changed things but I can't seem to find data on the new NeFeB magnets in the form that would be useful for design.

I'll see if I still have the JBL AES paper on their Ferrite motor design.

Subwoofer? Or is it meant to go up to >100Hz?

Sealed Box? Ported? What size? Power Handling at LF?

I'm not sure it's sensible to try and 'improve' on a JBL bass unit. They were one of the last makers to switch to Ferrite magnets. They only did so when they came up with a Ferrite motor design which they felt minimized the disadvantages. It's rather more complex than anyone elses.

If you make your own motor system, you need to magnetise it. This is serious $$$ and hardware.

Practically all speaker motors are asymmetrical so if your unit has mainly 3rd harmonic, you are doing really well.

The motor is only 1 of a number of factors that determine THD in a bass unit. The surround & spider are also important and have to be matched to the motor for best THD.

When I left the civilised world at the end of the last Millenium, NeFeB magnets were awful .. especially their thermal performance. Their only advantage was small size & cheep.

Electric cars in the 21st century has changed things but I can't seem to find data on the new NeFeB magnets in the form that would be useful for design.

I'll see if I still have the JBL AES paper on their Ferrite motor design.

You need to be more specific as to what you want to use your 15" unit for.

Subwoofer? Or is it meant to go up to >100Hz?

I want a more or less direct equivalent of a JBL 2226 except better

OK, that's fairly specific but only if you know the JBL part so I will lay out the details to save you a search.

The 2226 is a woofer that is efficient (97 dB @ 1 m 1 W) with plenty of power capacity (600 W AES nominal), low power compression and low distortion.

Despite it's impressive mass and decent Xmax (7.5mm) the Thiele/Small specs recommend it as a woofer rather than a subwoofer and a quick audition soon confirmed this so I have two JBL 2245 (18") as true subwoofers.

Since I have subwoofers I use the 2226 in a sealed box of around 4 cubic feet. This avoids any port resonances and sound leaks and provides an acoustic Linkwitz/Riley crossover to the subs. Also protects the 2226 from excessive excursion. It crosses to a compression driver at around 700 Hz.Sealed Box? Ported? What size? Power Handling at LF?

So it's your basic 15" + compression driver, just like a Geddes Summa or a JBL M2 studio monitor

Well, JBL did. The M2 uses a very nice 15" Dual Coil Differential while the top-of-the-line home unit is a 1501Al (15" too but not DCD, instead a massive Alnico with clever copper/steel pole pieces.)I'm not sure it's sensible to try and 'improve' on a JBL bass unit.

But they won't sell the 1501 to DIY builders, so I want to do better

Yes, they achieved excellent results.They were one of the last makers to switch to Ferrite magnets.

But I have looked at some of their papers and there are some shonky bits, they make mistakes like anyone so no reason I can't do better.

I think I will have to assemble a full powered Neo-Iron-Boron magnet.If you make your own motor system, you need to magnetise it. This is serious $$$ and hardware.

That won't be easy but should be possible, unlike with Alnico where it doesn't really work.

The DCD is push-pull so it takes care of 2nd harmonics, a clever trick.Practically all speaker motors are asymmetrical so if your unit has mainly 3rd harmonic...

This is where JBL and serious manufacturers have a head start on tinkerers like me. Maybe I will buy this as replacement parts.The motor is only 1 of a number of factors that determine THD in a bass unit. The surround & spider are also important and have to be matched to the motor for best THD.

The new stuff is excellent. Thermal performance has improved, better than ferrite. Still can't match Alnico.When I left the civilised world at the end of the last Millenium, NeFeB magnets were awful .. especially their thermal performance...

Thank you.I'll see if I still have the JBL AES paper on their Ferrite motor design.

Best wishes

David

Last edited:

You'll have to define 'better'.I want a more or less direct equivalent of a JBL 2226 except better

TS 'specs' are set by box size, LF cutoff & sensitivity. Choose any 2 (out of box size, LF cutoff & sensitivity) and the last is pre-determined.

Theoretical and Practical Aspects of Loudspeaker Bass Unit Design - Garner & Jackson

For the same sens, the smaller the box and higher the LF cutoff, the bigger the motor needs to be .. which may be counter intuitive for those not working with these beasts on a day to day basis.

It's a pity that Thiele & Small were Australian (Small by adoption) academic aboriginal elders so the TS specs don't really make sense ... especially if you design or make units. OK if you are a punter dreaming up a box for an existing unit

What's the subwoofer xover freq? Is it 2nd order or the dreaded 4th order LR?Since I have subwoofers I use the 2226 in a sealed box of around 4 cubic feet. This avoids any port resonances and sound leaks and provides an acoustic Linkwitz/Riley crossover to the subs. Also protects the 2226 from excessive excursion. It crosses to a compression driver at around 700 Hz.

700Hz is a problem for a 15" unit. You'll have problems with breakup regardless of your cone material.

I'd be interested in which shonky bits. No I'm not stirring. Really interested.But I have looked at some of their papers and there are some shonky bits, they make mistakes like anyone so no reason I can't do better.

That's not to say I advocate their deluxe gold plated methods. I like to spend money on stuff that actually sounds better.

But lower THD is good if it doesn't compromise other more audible stuff.

Don't under-estimate the forces in a large powered up speaker magnet and the tolerances you need while dealing with these forces.I think I will have to assemble a full powered Neo-Iron-Boron magnet.

That won't be easy but should be possible

.................

Got any links to data on these excellent NeFeB? I'm looking for families of BH curves with temperatureThe new stuff is excellent. Thermal performance has improved, better than ferrite. Still can't match Alnico.

Also not sure (from looking at the datasheets on the web) if the new NeFeB have similar thermal demagnetisation behaviour to the old ones.

If I was making a cost-no-object speaker, I'd use Alnico .. but on a plastic dome treble unit.

The hierarchy is Alnico, then SmCo .. then much further down the list, Ferrites and perhaps some of the new NeFeB.

I'd have to resurrect some Unobtainium dome & cone materials

and my bass would be Electrostatic

Last edited:

You'll have to define 'better'

Lower distortion and more efficient (for both the consequent reduction in thermal compression and a bit better for my environmental conscience).

I have done a back-of-envelope calculation and it looks like the efficiency could be doubled without too much trouble from unwanted saturation.

Haven't checked with Finite Element Magnetics but I think it's in the ballpark.

A DCD (push-pull) structure should reduce 2nd harmonic (Probably already inaudible levels but it can't hurt)

That leaves mainly third harmonic, discussed in the Button paper that I want.

Yes, if I ever actually make it then I will probably need to increase the box and/or raise the cross-over frequency.TS 'specs' are set by box size, LF cutoff & sensitivity. Choose any 2 (out of box size, LF cutoff & sensitivity) and the last is pre-determined.

66 Hz. 2nd order. The cut-off of the woofer is simply the natural roll-off of the sealed box, chosen to make the q = 0.5What's the subwoofer xover freq? Is it 2nd order or the dreaded 4th order LR?

The 2245 is capable of more so I have some freedom to optimise here.

The 2226 is pretty decent, JBL has published the curves.700Hz is a problem for a 15" unit. You'll have problems with breakup regardless of your cone material.

This is where the 15" starts to narrow and match the DI of the horn.

Pretty much standard practice for many systems from the M2 and Summa down.

I'm surprised by your comment, do you think this is a problem where "common wisdom" has a blind spot?

1. Common wisdom on ferrite problems seems to be incorrect.I'd be interested in which shonky bits...

2. The JBL Tech. note on the DCD drivers doesn't quite make sense.

It's been revised, presumably to fix it but the new one still doesn't quite make sense but in different places.

3. D.B Keele published a nice analysis of under versus over voice-coils

No one seems to have taken much notice.

I am aware that Geddes thinks low order distortion is already inaudible, so why bother.I like to spend money on stuff that actually sounds better.

But I think I can improve it without any downside so that's the plan.

Yes, scary but I can't see any reasonable alternative.Don't under-estimate the forces in a large powered up speaker magnet

I'll try to remember them.any links to data on these excellent NeFeB?

I believe this has been improved by addition of other rare earth elements.... if the new NeFeB have similar thermal demagnetisation behaviour to the old ones.

JBL chose Alnico for their top home system.The hierarchy is Alnico, then SmCo .. then much further down the list, Ferrites and perhaps some of the new NeFeB.

There's quite a bit of information about its internals on Audioheritage, the transducers forum contains internal company documents (by permission)

Alnico still has unmatched temperature resistance but the newer NeFeB looks pretty impressive.

I'd love to try a cone with modern composite materials.I'd have to resurrect some Unobtainium dome & cone materials

Should be possible to do low mass, stiff and well damped.

Would need some proper R and D, a Klippel system or similar.

Best wishes

David

Last edited:

Hummm... I'm scratching my head now i thought that AlNiCo magnets had a dismal thermal resistance compared to ferrite?...

i thought that AlNiCo magnets had a dismal thermal resistance compared to ferrite?...

JBL woofers are the most copied designs ever, and i think that if it would

be possible to improve them, it would have been done by now!. It's all

compromises, designing a one size fits all woofer is impossible, we have to live

with the crappy 2226 i guess ...

...

I think that Fostex and Audax both have nice JBL (replacements), and i doubt

anyone in his garage is going to do better in his lifetime

That being said, there are Mr. Heil's hiding and searching and being awesomely successfull .

.

JBL woofers are the most copied designs ever, and i think that if it would

be possible to improve them, it would have been done by now!. It's all

compromises, designing a one size fits all woofer is impossible, we have to live

with the crappy 2226 i guess

...

...I think that Fostex and Audax both have nice JBL (replacements), and i doubt

anyone in his garage is going to do better in his lifetime

That being said, there are Mr. Heil's hiding and searching and being awesomely successfull

Hummm... I'm scratching my head nowi thought that AlNiCo magnets had a dismal thermal resistance compared to ferrite?...

What happens with all magnetic materials is that the BH curve moves with temperature and the speaker loses sensitivity (They lose sensitivity for loadsa other reasons too).

Properly designed Alnico systems show the least change of all. SmCo about twice as bad.

These two are in a different league (at least 10x better) than anything else .. including the fancy new NeFeB that I've been able to see this Millenium.

But there is another important mechanism. The Permeance (operating point) of the magnet design has to remain above the 'knee' of the BH curve. If the BH knee moves past the Permeance due to temperature, the magnet will

demagnetise partially but permanently for all the magnet materials I've worked with. It's the biggest consideration in Ferrite & (old?) NeFeB magnet design.

It's not quite Curie point ... but related.

I can't figure out if da new supa dupa NeFeB materials also have this. Datasheets this Millenium seem to be more hype and less substance

Compression was a big thing in my previous life cos I was mainly involved with domestic speakers. Our small speakers had much less compression than our competitors and this is clearly heard in DBLTs.

__________________

Dave, I'm away from home and will write more when I can search my archives.

What happens with all magnetic materials is that the BH curve moves with temperature and the speaker loses sensitivity (They lose sensitivity for loadsa other reasons too)

The B temperature coefficient of the better NdFeB is less than 0.1% / K.

The temperature coefficient of resistivity of the voice coil is about 4 times that.

So the resistance increase dominates, even a perfect magnet would make little difference.

Just had a cute idea. Add a field coil and a temperature sensor, put current thru the coil not just to compensate for the magnet drop in field but for the voice coil increase in Re too. Constant (Bl)^2/Re.

No problem. In the meantime here's links to some Neo stuff that may be newer than when you last checked.Dave, I'm away from home and will write more when I can search my archives.

Temperature Ratings

Grades of Neodymium

Shows the two effects that you mentioned and clearly demonstrates the difference.

Yes, it's inherent to any ferromagnetic material I think.if da new supa dupa NeFeB materials also have this

JBL use an "SH" rated formulation and it's possible to do considerably better.

My idea is to use an external magnet and this should be better cooled than the typical internal Neo cylinder.

Best wishes

David

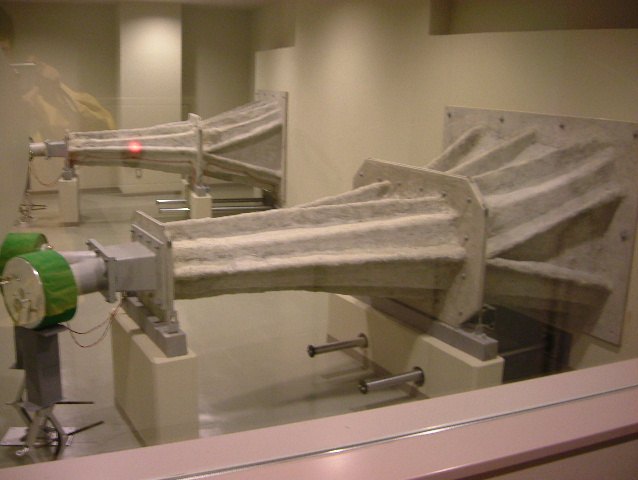

And finally a look inside JBL's studio monitor woofer, for your entertainment

http://www.audioheritage.org/vbulletin/showthread.php?33565-2216Nd

Last edited:

Dave Zan,

There are woofers that can better the JBL 2226, but nothing cheap. The Altec 515b is the best woofer ( 50hz-600hz ) I have heard--barring some of the exotic field coil woofers from Supravox or GOTO etc. The 515b ( from Great Plains Audio U.S.A. ) Has 14.750 gauss in the gap, light cone, BIG alnico magnet which makes it "faster" then any 15" driver I know. I too have a small machine shop, but making a better driver is not so easy and requires a complete redesign starting with the basket up. I don't want to reinvent the wheel, I rather spend my time listening to music, however I am interested in any modification / developments to improve drivers in general.

There are woofers that can better the JBL 2226, but nothing cheap. The Altec 515b is the best woofer ( 50hz-600hz ) I have heard--barring some of the exotic field coil woofers from Supravox or GOTO etc. The 515b ( from Great Plains Audio U.S.A. ) Has 14.750 gauss in the gap, light cone, BIG alnico magnet which makes it "faster" then any 15" driver I know. I too have a small machine shop, but making a better driver is not so easy and requires a complete redesign starting with the basket up. I don't want to reinvent the wheel, I rather spend my time listening to music, however I am interested in any modification / developments to improve drivers in general.

This figure is for the 'Intrinsic' curve, the Red curve in Grades of NeodymiumThe B temperature coefficient of the better NdFeB is less than 0.1% / K.

The relevant curve for sensitivity & compression is the 'Normal' Blue curve and that moves a lot more with temperature.

That's why I wanted to see a family of curves at various temperatures for each material.

But the NdFeB that Button uses in the 1991 paper is about twice as good as what I remember. Still a long way from Alnico & SmC

The 'knee' in the 'Normal' curve is at -950 kA/m so hardly visible. This says NdFeB magnets are very hard to demagnetise so you don't have to worry too much about setting Pe to avoid this.

Not quite 4x (see above) but you can deal with this a lot more simply by current drive and other techniques in my Powered Integrated Super Stuff techThe temperature coefficient of resistivity of the voice coil is about 4 times that.

So the resistance increase dominates, even a perfect magnet would make little difference.

Just had a cute idea. Add a field coil and a temperature sensor, put current thru the coil not just to compensate for the magnet drop in field but for the voice coil increase in Re too. Constant (Bl)^2/Re.

Reduces THD too.

Simpler would be to check the DC resistance by connecting the speaker as part of a DC bridge and adjusting the -ve output resistance of my Powered Integrated Super Sub bla bla

Note the heatsinking. A NdFeB motor should have enough heatsinking so its final size is the nearly same as the Alnico version to get rid of the same amount of heat and be at the same temp. But its thermal performance will be still worse cos the material.My idea is to use an external magnet and this should be better cooled than the typical internal Neo cylinder.

...

And finally a look inside JBL's studio monitor woofer, for your entertainment

2216Nd

BTW, this JBl 2216Nd beast is quite impressive. Is 2226 anything like it?

700Hz is a problem for a 15" unit. You'll have problems with breakup regardless of your cone material.

The 2226 is pretty decent, JBL has published the curves.

You'll have to ask for the their cones & surround then

______________

I can't help feeling that as your monster is for domestic use and not ear-bleeding levels, somewhat simpler methods for low THD and compression at the power levels you will use are appropriate.

The simplest is short coil in long gap as Don Keele suggests. Button points out some pros & cons.

I'm wary of using it in a small unit having been bitten by a production unit but a 15" bass unit should be OK.

And yes. Serious work on 'improving' a JBL 2226 for THD certainly needs some convenient way to measure Acoustic THD etc.

______________

My personal approach would be to use very crude methods to improve practical compression performance at the levels envisaged and use electronic trickery to further help this and to reduce THD.

Da JBL crowd would likely throw up their hands in horror

Last edited:

...The Altec 515b is the best woofer ( 50hz-600hz ) I have heard--

I have a soft spot for Altec, my first serious speaker was essentially a copy of the Voice Of The Theatre bass reflex/front loaded horn, cone mid on a self made horn and horn loaded tweeter.

But tech has improved since 1972 and now we can do a similar concept only better.

Aluminium ribbon, inside+outside voice coil wind, better coil former materials and better magnetic circuit.

But thanks for the reminder of my first, I feel quite sentimental.

Best wishes

David

No more than twice and typically a little less I think, but thanks for the comment, it's an easily overlooked point....The relevant curve for sensitivity & compression is the 'Normal' Blue curve and that moves a lot more with temperature.

I won't quibble whether that counts as a "lot", it's still half, or less, the resistivity variation.

The voice coil will inevitably run hotter than the magnet so that pushes the factor up a bit, "not quite 4x" sounds plausible to me.Not quite 4x (see above) but you can deal with this a lot more simply by current drive...

But current drive won't fix the reduction in Bl, need a temperature sensor for that.

Theoretically there should be a magnet temperature sensor AND current drive or voice coil resistance measurement.

Hardly worth the effort, my idea was just for fun.

An external magnet will be easier to keep cool and the time constant will be quite substantial which should reduce any audible effectNote the heatsink...But its thermal performance will be still worse cos the material.

In view of the dominance of the resistivity I don't think this is a real problem.

I am impressed by the 2216Nd too, that's part of the motivation and fun to explore the possibilities of a similar unit.BTW, this JBl 2216Nd beast is quite impressive. Is 2226 ...like it?

Unfortunately the 2226 in not very like it except in role, both hi-powered 15" woofers.

The 2226 is a classic extended coil with ferrite, not DCD and Neo.

There is more similar unit called the 2255, effectively a 2226 but Neo DCD.

Main benefit is that it's much less massive, important for professionals who have to move and fly them but less of concern to me.

Yes, I'm inclined to use a replacement cone and surround and just make a new magnet and perhaps have the VCs wound by OEM company, maybe Precision Econowind.You'll have to ask for the their cones & surround thenButton mentions some important points...

What does Button say?

Probably, it's partly a bit of fun to study the best....as your monster is for domestic use...somewhat simpler methods for low THD and compression at the power levels you will use are appropriate.

Need to explore the boundaries to know how far to push.

This is an important point.The simplest is short coil...as Don Keele

Don Keele does not analyse a "short coil". He keeps the coil the same and extends the field, which is different.

I came to the same conclusion that extended field looks simple and is potentially more efficient use of the magnet.

Nice to have your opinion that this is the way to do it.

What I have considered is a DCD with extended field - no one in the world does this AFAIK.

What bit you?Button points out some pros & cons.

I'm wary ... been bitten by a production unit

What does Button say this time?

Best wishes

David

Since you liked the 2216Nd, here's the top-of-line Alnico extended field to appreciate

http://www.audioheritage.org/vbulletin/showthread.php?33557-1501al-2

Note that the first cone breakup appears to be @ 1350 Hz.

About double my 700 Hz plan. (how about 666Hz since it's a beast of a speaker?)

Last edited:

The relevant curve for sensitivity & compression is the 'Normal' Blue curve and that moves a lot more with temperature.

Well, this is why I want to see, for each formulation, a family of 'Normal' BH curves at different temperature. IMHO, you don't have a handle on temperature sensitivity of a magnet system without this.No more than twice and typically a little less I think, but thanks for the comment, it's an easily overlooked point.

This Millenium, the makers have stopped publishing this info .. even for Ferrites.

You should certainly investigate electronic tricks to manage VC resistance.Theoretically there should be a magnet temperature sensor AND current drive or voice coil resistance measurement.

In the previous Millenium, it was hardly worth cooling magnets ... except for NdFeB

For the type of speakers I worked with, the biggest audible effect was NdFeB trebles sat on the poles of KEF UniQs

You'll have to ask for the their cones & surround then Button mentions some important points...

"In general a lightweight coil will decouple more violently and at a higher frequency"Yes, I'm inclined to use a replacement cone and surround and just make a new magnet and perhaps have the VCs wound by OEM company, maybe Precision Econowind.

What does Button say?

It's nomenclature. To me all coils shorter than the top plate are "short coil in long gap"Don Keele does not analyse a "short coil". He keeps the coil the same and extends the field, which is different.

I came to the same conclusion that extended field looks simple and is potentially more efficient use of the magnet.

It's actually more efficient use of the Cu .. but either way, it's good if you have loadsa $$$

The only short coil unit I've been involved with was an 20cm bass with 5mm pole for use up to 5kHz.What bit you?

For such a small unit, a short coil has to be quite fragile. Remember, my expertise is making cheapo systems which sound better than gold-plated stuff like JBLs.

The unit did all the expected good stuff but was unreliable.

A 15" unit like the JBLs would get away from the fragile coils

This reminds me of 2 important design features you should incorporate in your 'improved' 2226.Since you liked the 2216Nd, here's the top-of-line Alnico extended field to appreciate

1501al-2

- IMHO, double suspensions are mandatory for this type of unit

- I don't think the JBLs have this but having Al or Cu in close proximity to the coil makes a big difference in VC temperature. Button mentions Al rings above & below the top plate. I extended the Al chassis to come close to the coil.

Even an Al disc on top of the pole helps.

You need to try & see.

Will discuss more tomorrow but a few points

What is your experience for this?

Very nice, inductance is very stable as well as some thermal benefits.

Best wishes

David

I plan on this, but perhaps for different reasons....

- IMHO, double suspensions are mandatory for this type of unit

What is your experience for this?

Did you look carefully at the cross section? Many copper disks (well, anuli if you're pedantic) incorporated into the pole piece.

- I don't think the JBLs have this...

Very nice, inductance is very stable as well as some thermal benefits.

Best wishes

David

Last edited:

The only short coil unit I've been involved with was an 20cm bass with 5mm pole for use up to 5kHz.

IMHO, double suspensions are mandatory for this type of unit

The double suspensions prevent the assembly from rocking. With single suspensions, a roll surround provides little centring action. If you look at the Klippel curves for static restoring force for these large JBLs, you'll see that the units work (sorta low THD) well into the region where the suspension and surround start limiting.I plan on this, but perhaps for different reasons.

What is your experience for this?

There's a balance between the 'static' non-linearities and the dynamic tendency of a 'long coil' to jump out of the gap and there's a non-intuitive situation when making the suspension/surround limit earlier reduces THD at high levels.

But in these units, a lot of effort has been taken to reduce the effects that make the coil jump out so its uncharted stuff for me.

Suspensions will usually still centre under this type of stress but not surrounds (unless you use EVIL corrugated paper cone edges

Those rings have no effect on VC heating as the heat still has to go through the steel. They stabilise the inductance which is one of the 'coil jumping out' factors.Did you look carefully at the cross section? Many copper disks (well, anuli if you're pedantic) incorporated into the pole piece.

Very nice, inductance is very stable as well as some thermal benefits.

In 1501AL, the biggest factor might be using an Al VC former (not clear on their datasheet) AND the holes. A fibreglass or Nomex former with high temperature glue, allows you to quote higher powers .. but compression is MUCH higher. Button sorta mentions this.

______________________

My contention (tested mainly on 8" & smaller units) is that you get more audible benefits (in DBLTs bla bla) from dealing with compression due to VC heating than fancy magnet structures to reduce THD.

I've had a few successful forays into big spl country but as we could never compete with JBL's "hand-carved from solid $$$ Unobtainium by virgins" stuff, we achieved better results by other means.

eg It's a myth that ported systems have more excursion than sealed boxes. Properly designed ported systems have less excursion at the same spls.

Electronic trickery gives you HUGE advantages. This Millenium, I'm surprised that Harman & Genelec, in their powered speakers haven't taken full advantage of this.

But it saves my lawyers contacting them for infringing my Powered Integrated Super Sub tech.

Few catch-up questions and comments.

The numbers I have show NdFeB about twice as bad as SmCo, which is about what one would expect from the respective Curie points.

Also noticed that Button quotes the "intrinsic" temperature coefficient, as I did

You don't like 4th order? I have 2nd so I don't take it personally but curious about your reasons.

Button's paper shows the TDS waterfalls for various 15" drivers.

The 2226 is example "I" and the TDS is exemplary, best driver there.

Many of the others would indeed have problems.

I actually did wonder about this.

I plan to use a spider at each end of the VC, this should be optimal to keep it collinear, yes?

Best wishes

David

...Alnico systems show the least... SmCo about twice as bad.

These two...(at least 10x better) than ...the fancy new NeFeB that I've been able to see this Millenium.

The numbers I have show NdFeB about twice as bad as SmCo, which is about what one would expect from the respective Curie points.

Also noticed that Button quotes the "intrinsic" temperature coefficient, as I did

...What's the subwoofer xover freq? Is it 2nd order or the dreaded 4th order LR?

You don't like 4th order? I have 2nd so I don't take it personally but curious about your reasons.

700Hz is a problem for a 15" unit. You'll have problems with breakup

Button's paper shows the TDS waterfalls for various 15" drivers.

The 2226 is example "I" and the TDS is exemplary, best driver there.

Many of the others would indeed have problems.

Du.uuh! Of course this should be "25mm pole".

I actually did wonder about this.

The double suspensions prevent the assembly from rock...

I plan to use a spider at each end of the VC, this should be optimal to keep it collinear, yes?

Best wishes

David

It's really all pie-in-the-sky for me until I see a family of 'normal' BH curves at different temps.The numbers I have show NdFeB about twice as bad as SmCo, which is about what one would expect from the respective Curie points.

Also noticed that Button quotes the "intrinsic" temperature coefficient, as I did

Come to think of it, Button's paper is 1991. I must have looked at the same formulations as he did. The first serious 'widespread' use of NdFeB was in the KEF UniQs from that time.

Just stirring.You don't like 4th order? I have 2nd so I don't take it personally but curious about your reasons.

But for a measure of protection, you might want to go 3rd order. On the other hand as it is a 15" supa gold plated unit used in a domestic environment, it may not be worth it. IMveryHO, 4th is overly complex.

Excuse me ROTFL. I've been looking at TDS type stuff a bit longer than JBL.Button's paper shows the TDS waterfalls for various 15" drivers.

The 2226 is example "I" and the TDS is exemplary, best driver there.

Many of the others would indeed have problems.

Fryer & Millward is a PAFplot after Peter Fryer. The most useful but you need a good anechoic. It's the only one that shows sensible LF info.

A TDS waterfall is a KEFplot (CDS) Berman & Fincham

There's also a JAPplot Suzuki et al which is really just another view of the same info as a KEFplot.

But there's even earlier stuff used by the BBC that Peter introduced at Wharfedale in the 70's.

21st century digits make 'waterfalls' a mandatory bell/whistle in all acoustic measurement packages but that doesn't mean that their interpretation is easy. John Atkinson at Stereophile probably looks at more waterfalls than anyone else in the known universe ... but I remember sitting down with him and explaining some of the gotchas in the last Millenium.

I'm wanking about this cos this is a 1st order attribute and ranks with frequency response as a measurement which tells us whether a speaker sounds good .. when interpreted properly

_____________________________

For the rest of Button 1991 ...

- Only one unit has an Al coil former so they have all gone for high quoted power handling instead of trying for less compression.

- Many including 2226 have straight sided cones which will have fairly nasty breakup.

- Reference 4 is by Dr. Don Barlow, who designed the LEAK sandwich cones. He was a true polymath and I was privileged to have met him and have read his Engineering Memos.

- There's two papers by Mark Gander & one by Henricksen in the Bibliography which are worth getting. IIRC, they were both JBL. Still surprised I didn't know of Button

This is ideal but just having 2 spiders separated by a 1cm plastic ring sorta like JBL 1501al is good enough.I plan to use a spider at each end of the VC, this should be optimal to keep it collinear, yes?

JBL woofers are the most copied designs ever, and i think that if it would

be possible to improve them, it would have been done by now!

they did.

years ago -

https://en.wikipedia.org/wiki/Gauss_Speaker_Company

TAD

j/k

``````````````````````````

and there are these -

i forget which model, one of the goto unit woofers weighs 95 pounds -

and the compression driver woofers, even more ...

http://audio-lab-tnk2.sakura.ne.jp/

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Efficient direct-radiator/woofer: optimization