Hi,

I am comparing the effects of having a regulated DC filament supply for my DIY preamp, loosely based on C22.

There are 5 tubes in this pre-amp. Three for audio and two for power supply.

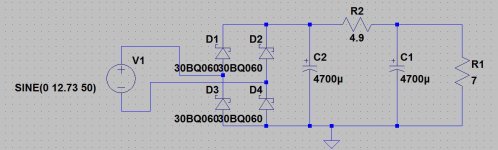

As I have 9Vac and 6Vac outputs from my transformer, I used the 9Vac supply for 3 ECC83s for audio and the 6Vac for two tubes in power supply. The schematic is attached.

The 7ohm is to represent a load of 0.9A for three filaments connected in parallel. I am using 6.3V filament supply and each filament current should be 300mA.

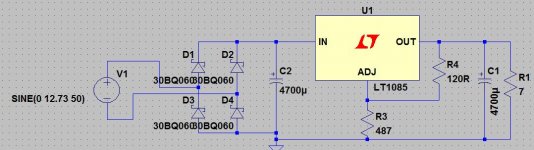

I like the effect from converting the filament supply from AC to DC. So thought I could improve by having the supply regulated for the 3 Audio ECC83. The schematic is also attached. I am using a ST LM317 instead of the LT1085.

The results of regulation using the ST LM317, to my surprise, is terrible! No life in the music any all. Very unmusical! Flat and mechanical sound.

Does any one have experience with DC filament supply to share?

If I can change the voltage regulator to LT1085, would it be better?

Or is there any topology of DC filament regulation that would yield good sound?

Please help.

I am comparing the effects of having a regulated DC filament supply for my DIY preamp, loosely based on C22.

There are 5 tubes in this pre-amp. Three for audio and two for power supply.

As I have 9Vac and 6Vac outputs from my transformer, I used the 9Vac supply for 3 ECC83s for audio and the 6Vac for two tubes in power supply. The schematic is attached.

The 7ohm is to represent a load of 0.9A for three filaments connected in parallel. I am using 6.3V filament supply and each filament current should be 300mA.

I like the effect from converting the filament supply from AC to DC. So thought I could improve by having the supply regulated for the 3 Audio ECC83. The schematic is also attached. I am using a ST LM317 instead of the LT1085.

The results of regulation using the ST LM317, to my surprise, is terrible! No life in the music any all. Very unmusical! Flat and mechanical sound.

Does any one have experience with DC filament supply to share?

If I can change the voltage regulator to LT1085, would it be better?

Or is there any topology of DC filament regulation that would yield good sound?

Please help.

Attachments

Hi,

I am comparing the effects of having a regulated DC filament supply for my DIY preamp, loosely based on C22.

There are 5 tubes in this pre-amp. Three for audio and two for power supply.

As I have 9Vac and 6Vac outputs from my transformer, I used the 9Vac supply for 3 ECC83s for audio and the 6Vac for two tubes in power supply. The schematic is attached.

The 7ohm is to represent a load of 0.9A for three filaments connected in parallel. I am using 6.3V filament supply and each filament current should be 300mA.

I like the effect from converting the filament supply from AC to DC. So thought I could improve by having the supply regulated for the 3 Audio ECC83. The schematic is also attached. I am using a ST LM317 instead of the LT1085.

The results of regulation using the ST LM317, to my surprise, is terrible! No life in the music any all. Very unmusical! Flat and mechanical sound.

Does any one have experience with DC filament supply to share?

If I can change the voltage regulator to LT1085, would it be better?

Or is there any topology of DC filament regulation that would yield good sound?

Please help.

I think you are hearing things. I just can't see how a heater can impact sound quality based on type of regulation, provided you have the correct voltage applied to the tubes.

Heaters bring the tube up to operational temperature, that is it. Using DC to drive the heaters only serves to cut potential hum.

For that matter, regulation will not buy you much with a constant load, which the heaters represent, except smaller capacitors and better efficiency of the power supply.

If you really feel that the sound quality has changed, I would check the voltage to the heaters to make sure it is with specifications.

Stupid question : Have you measured true DC voltage with the simple CRC circuit and with the LM317 ? Maybe LM317 is not feeding a 6,3V supply to heaters

Yes, I have measured the voltage from the regulator.

I first played with 6.3Vdc

Then 6Vdc for a for a while.

They have the same characteristics. However, with 6Vdc, the sound is a bit dull compared to 6.3Vdc.

I think you are hearing things. I just can't see how a heater can impact sound quality based on type of regulation, provided you have the correct voltage applied to the tubes.

Heaters bring the tube up to operational temperature, that is it. Using DC to drive the heaters only serves to cut potential hum.

For that matter, regulation will not buy you much with a constant load, which the heaters represent, except smaller capacitors and better efficiency of the power supply.

If you really feel that the sound quality has changed, I would check the voltage to the heaters to make sure it is with specifications.

"DC to drive the heaters only serves to cut potential hum"

maybe the hum is always there, but we are unable to pin point it.

I have have much cleaner sound by converting from AC to DC filament supply.

'Flat and mechanical sound' could be the result of missing hum/buzz, if the original AC heaters were not wired correctly. Now you may be hearing the music as it is, without artificial aids.

Another possibility, assuming you are running the DC heater supply from the same secondary as you were previously using for AC, is that the extra load on the transformer has changed the shape of the primary current. This, perhaps combined with some HT PSU weakness, could result in a different amount of hum IM via that supply.

Or it could all be imagination.

The one thing which won't happen is that the valves themselves will notice the difference between AC and DC heaters: the heater-cathode system has far too long a thermal time constant for that.

Another possibility, assuming you are running the DC heater supply from the same secondary as you were previously using for AC, is that the extra load on the transformer has changed the shape of the primary current. This, perhaps combined with some HT PSU weakness, could result in a different amount of hum IM via that supply.

Or it could all be imagination.

The one thing which won't happen is that the valves themselves will notice the difference between AC and DC heaters: the heater-cathode system has far too long a thermal time constant for that.

If I read correctly :

-You tried DC heather supply vs. AC supply for heather with simple CRC network and you liked the result

- Then you tried an LM317 to provide regulated DC but results in a bad sounding mod

I will try , just to be sure is not pure fantasy , a selector to switch between the 2 DC supply , if you still notice difference i will check with a scope the DC output from the 317 .

As stated by DF96 the heater-cathode system has far too long a thermal time to notice difference between the 2 systems , and if TRUE RMS voltages are the same , i will check if LM317 is self-oscillating using a scope ...

-You tried DC heather supply vs. AC supply for heather with simple CRC network and you liked the result

- Then you tried an LM317 to provide regulated DC but results in a bad sounding mod

I will try , just to be sure is not pure fantasy , a selector to switch between the 2 DC supply , if you still notice difference i will check with a scope the DC output from the 317 .

As stated by DF96 the heater-cathode system has far too long a thermal time to notice difference between the 2 systems , and if TRUE RMS voltages are the same , i will check if LM317 is self-oscillating using a scope ...

humming sounds like "mmmmmm", and that is not life to me.....'Flat and mechanical sound' could be the result of missing hum/buzz,

The comparison is between an unregulated DC and Regulated DC via LM317. Not involving AC filament connection.'Another possibility, assuming you are running the DC heater supply from the same secondary as you were previously using for AC.

My father, 70+ year young, who is not into Audio can actually tell that regulation does not sound as good when listening out of my room.Or it could all be imagination.

I really do not know if the tubes know about the difference.The one thing which won't happen is that the valves themselves will notice the difference between AC and DC heaters: the heater-cathode system has far too long a thermal time constant for that.

i will check if LM317 is self-oscillating using a scope ...

Yes. I will check..

It sounds like there is something very wrong with the actual DC output. A flat 6.3 volt DC filament supply to a 12AX7 will always give better results in terms of hum etc. then a AC supply. But even the difference between AC and DC shouldn't be that audible with these kind of indirectly heated tubes.

First thing I notice is the LM317 schematic. For max performance, both the LM317's in- and ouput should be bypassed with a small value foil cap (MKP, MKS, whatever) for shunting high frequency content. Datasheet states 100n@input and 1u@output.

- Have you measured the output voltage loaded or unloaded?

- Did you check the output with an oscilloscoop to check if it's flat?

- Did your new supply maybe cause noise in ground or a groundloop?

- Is the transformer up to the task?

First thing I notice is the LM317 schematic. For max performance, both the LM317's in- and ouput should be bypassed with a small value foil cap (MKP, MKS, whatever) for shunting high frequency content. Datasheet states 100n@input and 1u@output.

- Have you measured the output voltage loaded or unloaded?

- Did you check the output with an oscilloscoop to check if it's flat?

- Did your new supply maybe cause noise in ground or a groundloop?

- Is the transformer up to the task?

Last edited:

First thing I notice is the LM317 schematic. Both the LM317's in- and ouput should be bypassed with a small value foil cap (MKP, MKS, whatever) for shunting high frequency content. Datasheet states 100n@input and 1u@output.

- Have you measured the output voltage loaded or unloaded?

- Did you check the output with an oscilloscoop to check if it's flat?

- Did your new supply maybe cause noise in ground or a groundloop?

- Is the transformer up to the task?

I will try with bypassing.

and check voltage on the scope.

The 9Vac transformer is rated for 2A. I am drawing 0.9A. It worked with unregulated..

I think it should be up to the task.

Anyway

The 0.1uF cap at the input - "*Needed if device is more than 6 inches from filter capacitors."

The 1uF at the output - "†Optional—improves transient response."

I will try.....

If you are using AC on the heaters, the hum has at least two ways to enter the signal.

1) Through the grid, by induction of the magnetic field produced by the heater.

2) Through the cathode, due to Ckf and Rkf.

In an FFT, you can see two peaks, one at 50Hz (60Hz) and another at 100Hz (120Hz).

Many people like it a lot, and describes it as "Warmth", "Musicality", etc.

I do not want a "Sound" in my amps, that is why I use the cleanest possible DC.

This may sound "Sterile" or "Flat" but I like the term "Transparent"

The main disadvantage is that design flaws can not be masked with hum.

BTW. LM317 is a poor choice, try something better, with MOSFET transistors, low noise op amp, precision voltage reference, etc.

1) Through the grid, by induction of the magnetic field produced by the heater.

2) Through the cathode, due to Ckf and Rkf.

In an FFT, you can see two peaks, one at 50Hz (60Hz) and another at 100Hz (120Hz).

Many people like it a lot, and describes it as "Warmth", "Musicality", etc.

I do not want a "Sound" in my amps, that is why I use the cleanest possible DC.

This may sound "Sterile" or "Flat" but I like the term "Transparent"

The main disadvantage is that design flaws can not be masked with hum.

BTW. LM317 is a poor choice, try something better, with MOSFET transistors, low noise op amp, precision voltage reference, etc.

Last edited:

You are not the first to notice this. Marc Heijligers, Jos van Eijndhoven, Guido Tent and Henk Ten Pierick all engineers who work or worked at Philips Research found that all the different types of heating all sound different. They also have Audio as a hobby. Which pretty much disqualifies anything they say about audio! Even if they are trained engineers.he results of regulation using the ST LM317, to my surprise, is terrible! No life in the music any all. Very unmusical! Flat and mechanical sound.

There are ofcourse a hell of a lot of other folks who have reported on the lifeless sound of regulated dc in direct heated tubes.

Anecdotal info rates voltage regulated filaments as the worst sounding. Try current regulated filaments supplies.

Link to the Tentlabs doc.

http://www.tentlabs.com/Components/Tubeamp/Tubefilament/assets/Heatingmethods.pdf

Last edited:

For the moment, let's set credibility aside, and accept that the OP has actually heard a difference between the methods.

I imagine as many as 3 effects that might be in play.

[1] starved cathode - where it simply isn't heated enough to abundantly provide electrons for nominal operation.

[2] induced hum 'bias' - where there is an essentially small A/C bias to the signal at 50/60 Hz, moving the signal constantly through different operating-points of the valves in the amplifying chain

[3] DC filament leakage - where some of the current (either in A/C or DC operation!) is making it onto the cathode, again changing the operating point of the tube.

Clearly #3 is a problem: no only would we not want to battle heater-to-cathode leakage generally, but also it wouldn't be reproducible from tube-to-tube, manufacturer-to-manuf, lot-to-lot, etc. Swapping 12AX7's might sound like an easy way to check this, but ... alas, even it isn't the issue, changing 12AX7s will introduce another assortment of new operating points and parameters. The only way to track this one down is with precision metrology - measuring the resistors on both cathode and plate to 4+ digits accuracy, then the voltages through the system. Leak can be found in the details of those last digits.

The #2 induced hum/bias stands out as being at least as likely as #1. So much of our perception of the quality of an audio system comes from parts of the music waveform that cross zero, and are bracketed by a few millivolts around zero. Moving the absolute average to a wider range 'cuz of the 50/60Hz A/C bias effect ... definitely makes a difference. The human ear is remarkable in being able to effortlessly tune out the 50/60 Hz tone while listening to music.

#1 / starved cathode is every likely a possibility too: most often a FWB-to-capacitor bank actually runs the operating voltage higher than "manufacturer spec", so generates a more enthusiastic cloud of electrons ... which obviously would have its own effect on the sound.

But the need for regulation of the DC? In an of itself, its hardly required at all, except merely to get the operating voltage to a known, safe, "in spec" range. If running the AX7's a little hot is the goal, then wire up the regulator to produce 7/14 volts. It won't be the regulator somehow influencing the sound as it will be setting your operating points where you're happiest - in real:world listening.

GoatGuy

I imagine as many as 3 effects that might be in play.

[1] starved cathode - where it simply isn't heated enough to abundantly provide electrons for nominal operation.

[2] induced hum 'bias' - where there is an essentially small A/C bias to the signal at 50/60 Hz, moving the signal constantly through different operating-points of the valves in the amplifying chain

[3] DC filament leakage - where some of the current (either in A/C or DC operation!) is making it onto the cathode, again changing the operating point of the tube.

Clearly #3 is a problem: no only would we not want to battle heater-to-cathode leakage generally, but also it wouldn't be reproducible from tube-to-tube, manufacturer-to-manuf, lot-to-lot, etc. Swapping 12AX7's might sound like an easy way to check this, but ... alas, even it isn't the issue, changing 12AX7s will introduce another assortment of new operating points and parameters. The only way to track this one down is with precision metrology - measuring the resistors on both cathode and plate to 4+ digits accuracy, then the voltages through the system. Leak can be found in the details of those last digits.

The #2 induced hum/bias stands out as being at least as likely as #1. So much of our perception of the quality of an audio system comes from parts of the music waveform that cross zero, and are bracketed by a few millivolts around zero. Moving the absolute average to a wider range 'cuz of the 50/60Hz A/C bias effect ... definitely makes a difference. The human ear is remarkable in being able to effortlessly tune out the 50/60 Hz tone while listening to music.

#1 / starved cathode is every likely a possibility too: most often a FWB-to-capacitor bank actually runs the operating voltage higher than "manufacturer spec", so generates a more enthusiastic cloud of electrons ... which obviously would have its own effect on the sound.

But the need for regulation of the DC? In an of itself, its hardly required at all, except merely to get the operating voltage to a known, safe, "in spec" range. If running the AX7's a little hot is the goal, then wire up the regulator to produce 7/14 volts. It won't be the regulator somehow influencing the sound as it will be setting your operating points where you're happiest - in real:world listening.

GoatGuy

what is the deal of using AC on indirect filaments?

if using quality tubes and good circuit, you should not hear any hum.

with LM317 you create even more heat (diodes,IC) .. low efficiency

if you used instead a switching regulator with good filtered output (LM2576ADJ_HV), -you will have hi efficiency and possibility to use any input voltage up to 50V (and stay cool)

(and stay cool)

if using quality tubes and good circuit, you should not hear any hum.

with LM317 you create even more heat (diodes,IC) .. low efficiency

if you used instead a switching regulator with good filtered output (LM2576ADJ_HV), -you will have hi efficiency and possibility to use any input voltage up to 50V

Last edited:

Trust your ears. Despite the naysayers, I have always found a significant difference in sound when changing the type of heater supply for indirectly heated tubes. Of course, this is assuming the voltage is correct.

My experience is a bit different from yours though in that I have always found an AC supply to sound best, followed by unregulated DC and with voltage-regulated DC in last place. I am pretty sure we are hearing similar things though because I would use similar language to describe DC supplies generally----flat, mechanical, unmusical, uninvolving----all those subjective phrases that drive engineers crazy. I have given up trying to understand what accounts for the sonic changes and just go with what sounds best (to me).

My experience is a bit different from yours though in that I have always found an AC supply to sound best, followed by unregulated DC and with voltage-regulated DC in last place. I am pretty sure we are hearing similar things though because I would use similar language to describe DC supplies generally----flat, mechanical, unmusical, uninvolving----all those subjective phrases that drive engineers crazy. I have given up trying to understand what accounts for the sonic changes and just go with what sounds best (to me).

Hi,

I am comparing the effects of having a regulated DC filament supply for my DIY preamp, loosely based on C22.

There are 5 tubes in this pre-amp. Three for audio and two for power supply.

As I have 9Vac and 6Vac outputs from my transformer, I used the 9Vac supply for 3 ECC83s for audio and the 6Vac for two tubes in power supply. The schematic is attached.

The 7ohm is to represent a load of 0.9A for three filaments connected in parallel. I am using 6.3V filament supply and each filament current should be 300mA.

I like the effect from converting the filament supply from AC to DC. So thought I could improve by having the supply regulated for the 3 Audio ECC83. The schematic is also attached. I am using a ST LM317 instead of the LT1085.

The results of regulation using the ST LM317, to my surprise, is terrible! No life in the music any all. Very unmusical! Flat and mechanical sound.

Does any one have experience with DC filament supply to share?

If I can change the voltage regulator to LT1085, would it be better?

Or is there any topology of DC filament regulation that would yield good sound?

Please help.

This has been discussed a lot in other threads. Probably not such a popular topic now, early AudioAsylum has lots of posts and before that the Joe List (if you can find any traces of it online now) It was regarded by many as common knowledge that voltage regulation sounded poor and current regulation was better - on DHT's as well as IDHTs. Some insist that AC is the only way to fly. The fact is that everybody has different ears and if you hear a difference you shouldn't give in to an engineer's prompt that there's nothing there to hear.

I ran Voltage regulated IDHT's something like ten years ago and thought they sucked as well, but the while the overall world of sound is vast and multifaceted, we are usually seeking improvements in a specific way. I might come back to Vregs in a different context some day and think they are a boon to all human kind.

I've seen a good number of audio ee's over the years who gave somebody a hard time for thinking they could hear a difference from a given circuit component only to come back a year or two later advocating the same component for the same reason. Some are honest about it and some very often don't seem to remember that they thought differently once upon a time. I'd say trust your ears , but keep open to noticing your own biases.

If the DC/AC heater exploration is new to you you should probably cast your net a little wider at first anyway. I would probably try the LT108_ as current regulator. For more info there is probably still reference to Tom Ronan's Ronan reg online somewhere - essentially an LT108_ as Vreg followed by another as Current reg. You can just use the LT108_ current regulator by itself if you like. You might try a separate reg for each tube. There should be lot's of references and a few people promoting their own designs online. Rod Coleman's is good for DHT's, maybe he has something for IDHT's . I dunno. Experiment !

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Tubes / Valves

- Effect of Regulated DC Filament Supply