All valid but then you are basically changing everything. You can then remove the pots altogether and have a single optical encoder controlling MUSES chips with 0.25dB steps and 0.001 % THD setting the volume, the tone controls, etc. And you can introduce memory for saving different tone settings per input as well as gain to match input sources. Ofc with analog and digital on different PSUs and PCBs with the analog section isolated and shielded. And you get a completely new type of amp.I think that's only if you share a common PSU or even a common PCB. If (actually, when) I add a remote control feature to the amp, I'll definitely have a separate PSU for the digital circuit. And if I implement the digital pots, I'll have separate voltage regulator chips powering the analog and digital sides of the pot chips, independent of the supply rails which feed the analog electronics elsewhere.

Last edited:

Yes, all those are possible, but my intention is not to go that far, or anywhere close to it. I want a remote controlled volume, and this is the only part which is non-negotiable -- for me, that is. I want to do it with zero change to the existing circuits in Carl's PCBs, other than mounting the volume control pot off-board or replacing the pot with a digital pot.All valid but then you are basically changing everything. You can then remove the pots altogether and have a single optical encoder controlling MUSES chips with 0.25dB steps and 0.001 % THD setting the volume, the tone controls, etc. And you can introduce memory for saving different tone settings per input as well as gain to match input sources. Ofc with analog and digital on different PSUs and PCBs with the analog section isolated and shielded. And you get a completely new type of amp.

And FWIW, I dislike optical encoders. Even more so for volume controls, because they don't let me relate their angular displacement with volume setting.

But they give you 0.25db steps and perfect match between channels, not achievable even with the RK50.And FWIW, I dislike optical encoders. Even more so for volume controls, because they don't let me relate their angular displacement with volume setting.

And if you use with remote control anyway this is a no point.

But you are right on a simple motorized and remotely controlled volume pot.

A mechanical pot is an option only for headphone amps where you sit tied with a cable to the amp. All normal preamps should have remotely controlled volume, otherwise you can't sit and relax listening. And if you have to get up each time you need to change the volume, you'll end up replacing the amp sooner than later, regardless how good it is.

Yes, maybe this is why I am attracted to the idea of combining the ergonomics of a volume control pot and the accuracy, dust immunity, absence of crackling due to ageing, and channel balance of a digital pot.But they give you 0.25db steps and perfect match between channels, not achievable even with the RK50.

And if you use with remote control anyway this is a no point.

But if I am to be frank, I'll live with the channel imbalance of a stereo mechanical pot, as long as I get a motor and a remote to operate it.

Yes, I feel exactly this way too.A mechanical pot is an option only for headphone amps where you sit tied with a cable to the amp. All normal preamps should have remotely controlled volume, otherwise you can't sit and relax listening.

You miss the point of what I said above. In a high-end preamp, I would use a remote (IR, RS232 or TCP/IP) to control a MUSES chip that sets the volume. The optical encoder is used (as another control and) only if you want to turn the volume directly on the amp's faceplate (which on its turn controls the same MUSES chip setting the volume). For instance a Bourns optical encoder has a very nice tactile feel, pretty much matching a normal, old-style pot.Yes, maybe this is why I am attracted to the idea of combining the ergonomics of a volume control pot and the accuracy, dust immunity, absence of crackling due to ageing, and channel balance of a digital pot.Have a remote control setup which drives a motor pot, whose angular displacement is read by the uC through one of its ADC pins, and the uC then drives a digital pot.

What you describe above, "using a remote control to drive a motor pot whose angular displacement is read by the uC..." is basically nonsense.

I most certainly appear to be doing so.You miss the point of what I said above.

I can see you don't like it. I completely fail to see why it's nonsense.What you describe above, "using a remote control to drive a motor pot whose angular displacement is read by the uC..." is basically nonsense.

Anyway...

Cause then we would use a simple motorized analog potI can see you don't like it. I completely fail to see why it's nonsense.

Imo the thing to do, is start new threads for these different control options that you decide that you require for your purposes. If others want to join you on your quest fantastic, if know one wants to help or dislikes your choices you are in your own. Arguing in this thread services little purpose.

I can contribute if I want, I have made both types of designs and as I posted earlier I am willing to give you my code to use if you so desires or you can figure it out yourself, it is not that complicated, I managed to cobble it together

I’d rather hear what Carl has to say since it is his thread to begin with

I can contribute if I want, I have made both types of designs and as I posted earlier I am willing to give you my code to use if you so desires or you can figure it out yourself, it is not that complicated, I managed to cobble it together

I’d rather hear what Carl has to say since it is his thread to begin with

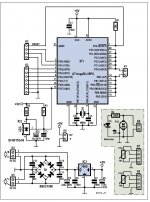

I don't really have a problem with the suggestions and debate. Everyone involved has the good intentions of adding value to the design as presented. As to what I am thinking about is to come forward with a simple add-on PCB that holds an Arduino NANO. that mcu will switch the IO and change the volume using an infrared remote control. the existing 5K linear volume pot will be replaced by motorized 5K Bourns linear pot. The main PCB has changed to make room for the motor assembly, but the analog circuit making up the preamp does not change at all The IO board does not change and the new digital lives totally separate from existing analog preamp.

Thoughts anyone?

Thoughts anyone?

Sorry for being a bit off-topic, but this is related to some posts above, re:motorized pots + PCB:

I have a bunch of such PCBs for a variety of potentiometers, prototypes from a developer working on a solution (for an ELMA "Relatt" relay attenuator of which I also happen to have a spare board w/o resistors)… If anyone is interested...

I have a bunch of such PCBs for a variety of potentiometers, prototypes from a developer working on a solution (for an ELMA "Relatt" relay attenuator of which I also happen to have a spare board w/o resistors)… If anyone is interested...

Attachments

This is not as obvious as you say. My Cyrus 8 amp uses a motor pot, but it is used to sense the angular displacement and the final volume control is done in solid state. The LCDuino system too does the same thing. And a lot of audiophile DIY builders believe that the 0.5dB typical channel imbalance is unacceptable, therefore they want a digital pot for the actual attenuation.Cause then we would use a simple motorized analog pot

So, in answer to your comment, no, many DIYers won't use a simple motorized analog pot directly. Of course, you can call all of them nonsense.

I already suggested a MUSES chip with 0.25dB step for a digital high-end solution. This is used in the Pass X-32 preamp as well. If I would introduce all the hassle of digital, then get all the pros it can give you as well.This is not as obvious as you say. My Cyrus 8 amp uses a motor pot, but it is used to sense the angular displacement and the final volume control is done in solid state. The LCDuino system too does the same thing. And a lot of audiophile DIY builders believe that the 0.5dB typical channel imbalance is unacceptable, therefore they want a digital pot for the actual attenuation.

But for a cheaper all-analog amp, I would just get a TKD pot, the 4CP-2500 for instance, it is a step up from the RK27 and not too expensive as well.

I guess the question is are you building a 1k or 10k amp.

But in general I agree with you that the LCDuino is a nice solution.

I guess all of us in this thread want all the features and characteristics of this specific all-analog Self-Didden-Huff preamp, with the convenience of remote controlled volume, and some of us are sensitive to the channel imbalance and dust related crackling of a mechanical pot.I already suggested a MUSES chip with 0.25dB step for a digital high-end solution. This is used in the Pass X-32 preamp as well. If I would introduce all the hassle of digital, then get all the pros it can give you as well.

But for a cheaper all-analog amp, I would just get a TKD pot, the 4CP-2500 for instance, it is a step up from the RK27 and not too expensive as well.

Here are my fpd files. The 1U/10mm build in post 1967 was done with these. A few notes before you dive in and use them:Thank you for offering this. I would be interested in the updated file.

The rear panel is a perfect fit for the PCB and connectors. I would nevertheless advise a bit of patience and "tack" the connectors to the PCB with a single solder point, then fit it all to the back panel, then go back and solder all the connectors in the PCB. It is too easy without a reference to not seat the connectors fully and then it becomes a real struggle.

The front panel tolerances around the bushings are fairly tight, but they fit fine. This was to avoid tolerance stack up and rubbing knobs since the knobs are countersunk.

Note that I sourced a different in/out switch with longer bushing and toggle to avoid a countersink. If you go with the standard switch and 10mm panel you will likely need to add a countersink to that hole to make it work.

I found that knobs can vary considerably (up to 0.5mm) vs. nominal spec'd diameter, so if you go with counterbored knobs then you may want to source yours first and measure them before you commit to making the panel.

The anti-rotation bore for the Lorlin switch on the back side is not present - I did that one by hand.

It was a great, fun project and I would highly recommend it! I find it very useful for tweaking tone to volume levels.

Best,

Mike

Attachments

As a follow up to my fpd post above I just checked my front panel and the bushing centers are within 0.5mm of Carl's drawing above. So perhaps some small adjustments are in order but nevertheless it does work.

Best,

Mike

For those of you that are interested in a remote controlled volume, I now have main PCBs that are intended for use with the BOURNS 5K motorized pot.

BOURNS #PRM162-K415K-502B1 motorized pot, in stock at Mousers USA.

The revised PCB is identical electrically to the non-motorized version.

PLEASE NOTE: This is a modified main PCB that accepts the described motorized pot. The processor board and Infra-Red receiver are not included.

Please message me if you are interested in this new PCB.

BOURNS #PRM162-K415K-502B1 motorized pot, in stock at Mousers USA.

The revised PCB is identical electrically to the non-motorized version.

PLEASE NOTE: This is a modified main PCB that accepts the described motorized pot. The processor board and Infra-Red receiver are not included.

Please message me if you are interested in this new PCB.

For those of you that are interested in a remote controlled volume, I now have main PCBs that are intended for use with the BOURNS 5K motorized pot.

BOURNS #PRM162-K415K-502B1 motorized pot, in stock at Mousers USA.

This is awesome.

What would be the centre-to-centre distance between the volume pot and the pot next to it? And do you have any idea of how much higher the axis of the motor pot is compared to the other pots?

The dimensions affecting the front panel remain the same. Any successful front panel design that worked for the 'non-motorized' version will work for this version. The PCB is the same depth. However the width has been extended 5mm. A 5mm change in the PCB width should not affect any chassis requirements.

If I'm understanding you right, we can now buy any remote-controlled-motor-pot kit or module from anywhere, desolder the motor pot which is part of that module, extend the two wires which went to the old motor pot's motor so that they now stretch to your Bourns pot's motor leads, and then we're good to go. The electrical drive currents, speeds, etc, which drive one motor pot should be pretty much the same for another, right?The dimensions affecting the front panel remain the same. Any successful front panel design that worked for the 'non-motorized' version will work for this version. The PCB is the same depth. However the width has been extended 5mm. A 5mm change in the PCB width should not affect any chassis requirements.

View attachment 1034228

- Home

- Source & Line

- Analog Line Level

- Doug Self Preamp from Linear Audio #5