Definitely 'outside the box' approach....

...it's a striking shape; very 'minimalist', which is hard to do. I applaud your craftsmanship, it's very well made for such a difficult design.

Yes, unfortunately, a lot of the design analysis of speakers has a tendency to be 'ancient'. Esp. with regard to omnis', which tended to be swept into the corner.

'Direct radiators and dipoles get all the attention! *whine* It's Not Fair!' *stamps feet, throws a tantrum*L*

Cell phone sound recordings are only slightly better than those with the typical camera. I'm vaguely considering a small digital recorder with a pair of mics....

...perhaps something like this (but I'd rather the mics be 'loose' instead of integral to the device):

Tascam DR-05X Portable Digital Recorder | Guitar Center

Price is reasonable....but like ones' cell, Don't Drop It....

Wonder if one could demo one....?

The B&W patent is definitely the one behind a few of their offerings....

*L* "What's old is new, yet again..."

Impressed by your carbon fibre work....real nice. I'm impatient to hear what my next group of cones perform like. I've been curious to hear the difference between the aluminum and the titanium. The latter is purported to be 'brighter'/'crisp' vs. the alum.

Not a surprise there, as it's harder/denser than the alum...and somewhat easier to handle and form into a cone...and doesn't dent as quickly...

Noticed you're using 'off the shelf' surrounds...I'm considering that, if I can find ones 'stiff enough' for my taste. Certainly less hassle....

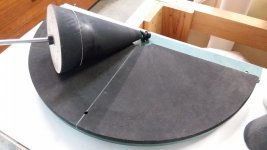

...and some pics...*S*

...it's a striking shape; very 'minimalist', which is hard to do. I applaud your craftsmanship, it's very well made for such a difficult design.

Yes, unfortunately, a lot of the design analysis of speakers has a tendency to be 'ancient'. Esp. with regard to omnis', which tended to be swept into the corner.

'Direct radiators and dipoles get all the attention! *whine* It's Not Fair!' *stamps feet, throws a tantrum*L*

Cell phone sound recordings are only slightly better than those with the typical camera. I'm vaguely considering a small digital recorder with a pair of mics....

...perhaps something like this (but I'd rather the mics be 'loose' instead of integral to the device):

Tascam DR-05X Portable Digital Recorder | Guitar Center

Price is reasonable....but like ones' cell, Don't Drop It....

Wonder if one could demo one....?

The B&W patent is definitely the one behind a few of their offerings....

*L* "What's old is new, yet again..."

Impressed by your carbon fibre work....real nice. I'm impatient to hear what my next group of cones perform like. I've been curious to hear the difference between the aluminum and the titanium. The latter is purported to be 'brighter'/'crisp' vs. the alum.

Not a surprise there, as it's harder/denser than the alum...and somewhat easier to handle and form into a cone...and doesn't dent as quickly...

Noticed you're using 'off the shelf' surrounds...I'm considering that, if I can find ones 'stiff enough' for my taste. Certainly less hassle....

...and some pics...*S*

P.P. C

(The cone with the white 'skirt' is a concept I want to try....a 2 mil alum cone 'insert' over a 5 mil 'skirt' with 3 'windows', bonded together. It'll either be a buzzy mess or ?.....we'll see...*G*0

The black cone shape is acoustic foam....shaped on the lathe with an electric carving knife, turning the lathe by hand. It takes a few go's to get the feel of making it work, but the hardest part is getting it to Stay on the face plate....

Inserting the foam cone into the metal cones' interior wipes out 'cone honk', which I've noted before...

....and a pair of prototypes.....the one on the shelf is one of my 'puter monitors, the other pair is nearly ready to be played to death....*L*

(The cone with the white 'skirt' is a concept I want to try....a 2 mil alum cone 'insert' over a 5 mil 'skirt' with 3 'windows', bonded together. It'll either be a buzzy mess or ?.....we'll see...*G*0

The black cone shape is acoustic foam....shaped on the lathe with an electric carving knife, turning the lathe by hand. It takes a few go's to get the feel of making it work, but the hardest part is getting it to Stay on the face plate....

Inserting the foam cone into the metal cones' interior wipes out 'cone honk', which I've noted before...

....and a pair of prototypes.....the one on the shelf is one of my 'puter monitors, the other pair is nearly ready to be played to death....*L*

Attachments

Last edited:

Thanks, ABJ....and a big 👏👍 to Thomas as well...*VBS* I'm impressed by his venture and speaker, a nice blend of Walsh & transmission line 'sculpture' (calling it an 'enclosure' doesn't seem right nor appropo)...

I find the application of his driver choice and the means of support fascinating. No 'exterior support' or 'framework' to intrude on the cones' radiation pattern.

In the pdfs' attached, he's applying a DML driver; these typically are adhered with VHB film tape. Strong stuff....I use it to 'close' the seams on my cones.

Once applied and joined, it's 'over'; you don't get a 2nd chance to redo the seam without destroying the cone....

A thought on a next version (isn't there always one in mind?...I thought so... DIY is like that...*G*) is using a version that's screw mounted if available.

DIY is like that...*G*) is using a version that's screw mounted if available.

The reason I suggest this; the pair of my speakers shown on my workbench use a two-way driver with the original center tweeter removed. This left a center hole through the magnet structure, also centered on the voice coil.

Sized for a #10 or 5mm machine screw, one could have a mechanical joint at a very critical point. Not that VHB 'gives up' easy, but it's still a small contact point....

Just saying.... There is the issue of the metal basket of that sort of driver, and what to do with it....🙄

I'm still wrestling with that conundrum as well...a 'custom inverted basket' would do the trick, but not $ feasible at this time....*shrug*G*

*L* They may not be 'pretty'....but they do work.

I find the application of his driver choice and the means of support fascinating. No 'exterior support' or 'framework' to intrude on the cones' radiation pattern.

In the pdfs' attached, he's applying a DML driver; these typically are adhered with VHB film tape. Strong stuff....I use it to 'close' the seams on my cones.

Once applied and joined, it's 'over'; you don't get a 2nd chance to redo the seam without destroying the cone....

A thought on a next version (isn't there always one in mind?...I thought so...

The reason I suggest this; the pair of my speakers shown on my workbench use a two-way driver with the original center tweeter removed. This left a center hole through the magnet structure, also centered on the voice coil.

Sized for a #10 or 5mm machine screw, one could have a mechanical joint at a very critical point. Not that VHB 'gives up' easy, but it's still a small contact point....

Just saying.... There is the issue of the metal basket of that sort of driver, and what to do with it....🙄

I'm still wrestling with that conundrum as well...a 'custom inverted basket' would do the trick, but not $ feasible at this time....*shrug*G*

*L* They may not be 'pretty'....but they do work.

Thanks!

I like the Ti cones seriously good looking! Will be intresting to see How they perform.

A couple of comments.

I actually remove the tape on the exciter and use loctite super glue as it allows an easier removal if needed.

Yes I’m using foam surround with low compliance as it gives the best sound. I’ve tried rubber surround which gives a more ”ringning” sound and more distortion.

The foam insert is an intresting idé I’ll try it.

One very critical point in this design is the alignment between the voice coil former and the membrane. It needs to be perfectly in line.Any miss-allignment Will generate distortion. This is the reason why I made number of the jigs to assure this.

Why not just remove the basket with a hacksaw?

Thomas

I like the Ti cones seriously good looking! Will be intresting to see How they perform.

A couple of comments.

I actually remove the tape on the exciter and use loctite super glue as it allows an easier removal if needed.

Yes I’m using foam surround with low compliance as it gives the best sound. I’ve tried rubber surround which gives a more ”ringning” sound and more distortion.

The foam insert is an intresting idé I’ll try it.

One very critical point in this design is the alignment between the voice coil former and the membrane. It needs to be perfectly in line.Any miss-allignment Will generate distortion. This is the reason why I made number of the jigs to assure this.

Why not just remove the basket with a hacksaw?

Thomas

Life During Wartime...

...fighting the 'invisible enemy'....the only thing The Chump has said that is True....*sigh* When we need a Leader....we've got a Lead Weight...😒

Your're welcome. *S* Credit to where it's deserved....👍

Loctite is better, yes....but I still have reservations re super glues in some applications. A matter of preferences vs. paranoias I guess...

Looking forward to bench racing the Ti vs. Al myself, which is why I always 'do' pairs. And, Yes, surround>cone>voice coil alignment/height is a hard trick to pull off. Remembering to put in And pull out voice coil spacers before 'n after assembly is a must. Learned the hard way with both; the second is easy to fix...

Foam vs. rubber surrounds...I want to try both. Since I'm working towards 'throttling' the lower bass by cone size with and an active Xover (handing it over to a sub, esp. with smaller cones), the rubber may work better....

Yes, try a foam cone within the driven cone...to my ears, it 'cleans up' the response without degrading overall performance. Size it to the same general shape of the cone, and mount it so there's a +/- 1 cm. space between cone surfaces...

Another thing to play with is that gap....I'll bet lunch + beer that a calibrated mic and a waterfall display will exhibit Something Happens....

The 'honk' of the cone, when listened to without an....'cavity' (that works; beats 'enclosure', since there's none...) beneath it goes away...

The two smaller 'prototype' unit pairs literally have no cavity. Their bases are sealed at their bottoms, an experiment with 'acoustic suspension'. With a smaller driver, it seems to give them 'punch' for their size (13 cm. tall x 7.5 cm. bottom dia. x 2.5 cm. dia. @ the v.c., 75 deg. slope).

That pair (used for my 'puter monitors) are mated to a small Sony self-powered sub. Tiny HF Walsh tweets with foam cones, simple cap xover....

Junk drivers all, driven by a Phillips 'desk-top' stereo with a 'sub-out'.

I can play them to max volume to 'clip'...haven't been able to break them yet...*L*

Removing a basket with a hacksaw is easy, yes....dealing with the little metal sawdust bits around a strong magnet, no so much...

I've a couple of 'dead' drivers that I'm planning to Frankenstein though....see if I can cut the 'arms' of the basket accurately enough to flip the cut off basket surround and re-attach it.....

Plan B consists of 'hydraulic coercion'....which with an expensive driver would be a Leap of Faith, for sure....*L*

Oh....Acoustic Foam.....through a 'fabric shop' in CA, I was able to get 2 blocks 12"x12"x6" post-paid no tax for 20 USD; cheapest source for me.

Cuts on a bandsaw into blocks. Don't try cutting cones that way if you value your fingers....

I 'rough-cut' pyramids, and used my lathe manually with an electric carving knife. Mounting the foam to a face plate is a good trick in itself to make it stay put....

Anyway....stay healthy, and keep in contact.

This is the fun part; better is when we're done... )

)

Cheers, J

...fighting the 'invisible enemy'....the only thing The Chump has said that is True....*sigh* When we need a Leader....we've got a Lead Weight...😒

Your're welcome. *S* Credit to where it's deserved....👍

Loctite is better, yes....but I still have reservations re super glues in some applications. A matter of preferences vs. paranoias I guess...

Looking forward to bench racing the Ti vs. Al myself, which is why I always 'do' pairs. And, Yes, surround>cone>voice coil alignment/height is a hard trick to pull off. Remembering to put in And pull out voice coil spacers before 'n after assembly is a must. Learned the hard way with both; the second is easy to fix...

Foam vs. rubber surrounds...I want to try both. Since I'm working towards 'throttling' the lower bass by cone size with and an active Xover (handing it over to a sub, esp. with smaller cones), the rubber may work better....

Yes, try a foam cone within the driven cone...to my ears, it 'cleans up' the response without degrading overall performance. Size it to the same general shape of the cone, and mount it so there's a +/- 1 cm. space between cone surfaces...

Another thing to play with is that gap....I'll bet lunch + beer that a calibrated mic and a waterfall display will exhibit Something Happens....

The 'honk' of the cone, when listened to without an....'cavity' (that works; beats 'enclosure', since there's none...) beneath it goes away...

The two smaller 'prototype' unit pairs literally have no cavity. Their bases are sealed at their bottoms, an experiment with 'acoustic suspension'. With a smaller driver, it seems to give them 'punch' for their size (13 cm. tall x 7.5 cm. bottom dia. x 2.5 cm. dia. @ the v.c., 75 deg. slope).

That pair (used for my 'puter monitors) are mated to a small Sony self-powered sub. Tiny HF Walsh tweets with foam cones, simple cap xover....

Junk drivers all, driven by a Phillips 'desk-top' stereo with a 'sub-out'.

I can play them to max volume to 'clip'...haven't been able to break them yet...*L*

Removing a basket with a hacksaw is easy, yes....dealing with the little metal sawdust bits around a strong magnet, no so much...

I've a couple of 'dead' drivers that I'm planning to Frankenstein though....see if I can cut the 'arms' of the basket accurately enough to flip the cut off basket surround and re-attach it.....

Plan B consists of 'hydraulic coercion'....which with an expensive driver would be a Leap of Faith, for sure....*L*

Oh....Acoustic Foam.....through a 'fabric shop' in CA, I was able to get 2 blocks 12"x12"x6" post-paid no tax for 20 USD; cheapest source for me.

Cuts on a bandsaw into blocks. Don't try cutting cones that way if you value your fingers....

I 'rough-cut' pyramids, and used my lathe manually with an electric carving knife. Mounting the foam to a face plate is a good trick in itself to make it stay put....

Anyway....stay healthy, and keep in contact.

This is the fun part; better is when we're done...

Cheers, J

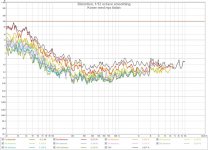

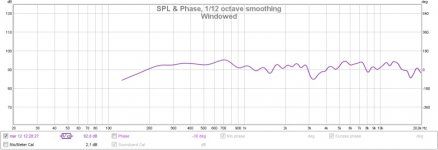

Measurements

I have Done some simple measurements (indoor) using REW.

Frequency response and distortion.

The frequency response is Windowed which means that the response under 150Hz is irrelevant. Measuring with pink noice indiciets that they play down to approx. 67-70Hz. i.e. they need support from a couple of sub woofers...

I have Done some simple measurements (indoor) using REW.

Frequency response and distortion.

The frequency response is Windowed which means that the response under 150Hz is irrelevant. Measuring with pink noice indiciets that they play down to approx. 67-70Hz. i.e. they need support from a couple of sub woofers...

Attachments

Looking Good....

..Thomas! I agree with ABJensen and you, a sub will 'fill in' the bottom hz for you.

I run a sub with mine....crossover freq varies with the size of the drivers...

The smaller ones obviously cross higher than the larger, which I suspect are close in base diameter to yours...

*G* Let the graphs and your ears be your guides...taking into account the room they're in, of course.

Have a good Sunday and stay healthy...

Jerry

..Thomas! I agree with ABJensen and you, a sub will 'fill in' the bottom hz for you.

I run a sub with mine....crossover freq varies with the size of the drivers...

The smaller ones obviously cross higher than the larger, which I suspect are close in base diameter to yours...

*G* Let the graphs and your ears be your guides...taking into account the room they're in, of course.

Have a good Sunday and stay healthy...

Jerry

Yes, I Agree they need the support from woofers.

I have been experimenting with all sorts of woofers closed box, bas reflex, open baffle, H-baffle and infinite baffle. Reason being that it has been seriously hard to integrate.

I have found that the best alternative is the infinite baffle. However that is bit hard to implement...so I ended up with a sort of H-baffle.

I have also been experimenting with cross-over freq. I’m currently using 250 LR24.

Have very good Sunday!

Thomas

I have been experimenting with all sorts of woofers closed box, bas reflex, open baffle, H-baffle and infinite baffle. Reason being that it has been seriously hard to integrate.

I have found that the best alternative is the infinite baffle. However that is bit hard to implement...so I ended up with a sort of H-baffle.

I have also been experimenting with cross-over freq. I’m currently using 250 LR24.

Have very good Sunday!

Thomas

Hello,

New on this link I coming over from the DML side. I ave been working on a Walsh driver in the 3D modeling world and now have it printing it out now. The speaker includes a 8" down firing woofer and is ported at the bottom. The physical dimensions are 300mm x 300mm x 915mm for the woofer enclosure with the 200 mm Walsh driver on top. I am driving the Woofer and Walsh driver with an two way active cross over and seperate amps for both driver.

Cheers,

Steve

New on this link I coming over from the DML side. I ave been working on a Walsh driver in the 3D modeling world and now have it printing it out now. The speaker includes a 8" down firing woofer and is ported at the bottom. The physical dimensions are 300mm x 300mm x 915mm for the woofer enclosure with the 200 mm Walsh driver on top. I am driving the Woofer and Walsh driver with an two way active cross over and seperate amps for both driver.

Cheers,

Steve

- Home

- Loudspeakers

- Planars & Exotics

- DIY Walsh driver revisited