do not waste Hard disk computers, can be used for DIY tonearm.

Many HD which had been unused and I noticed there was something that could be used for our project is Bearing.

if we look at HD function to read the data on the disk rotating at 7200 rpm must be right, no mistakes and always accurate, just as we are doing now with our PC.

it takes part bearing of HD is excellent, should not be loose or wobbly.

why we do not try to recycle ... garbage ... go green IT.

unused HD:

The HD is already open.

I think this very good bearing...compact ,strongly and acurate ... but this motor have magnet inside.

I think this no matter because Schroerder's TA used magnet too

or our can take arm bearing :

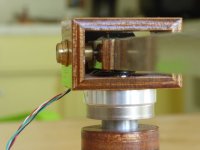

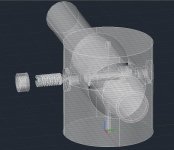

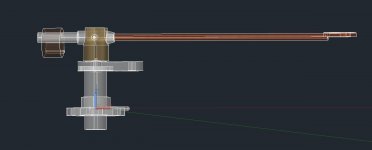

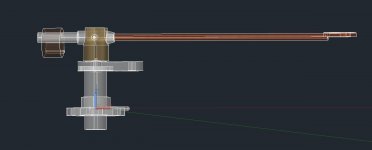

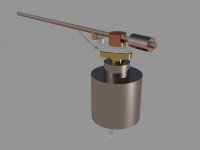

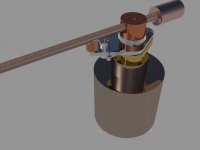

and drawing model DIY TA HD:

model used the HD arm bearing

Model used HD motor

just discus only

Many HD which had been unused and I noticed there was something that could be used for our project is Bearing.

if we look at HD function to read the data on the disk rotating at 7200 rpm must be right, no mistakes and always accurate, just as we are doing now with our PC.

it takes part bearing of HD is excellent, should not be loose or wobbly.

why we do not try to recycle ... garbage ... go green IT.

unused HD:

The HD is already open.

I think this very good bearing...compact ,strongly and acurate ... but this motor have magnet inside.

I think this no matter because Schroerder's TA used magnet too

or our can take arm bearing :

An externally hosted image should be here but it was not working when we last tested it.

and drawing model DIY TA HD:

model used the HD arm bearing

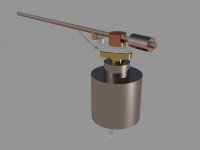

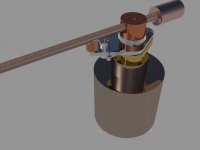

Model used HD motor

just discus only

Last edited:

Used arm bearing from HD

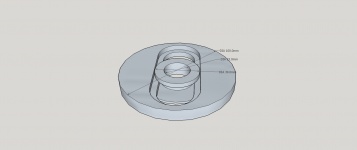

dimension draw

make a pivot pole. HD bearing is used as a buffer for horizontal movement.

Bearing of pivot rod use usual. our can use a part of tamiya or other. for vertical movement.

An externally hosted image should be here but it was not working when we last tested it.

dimension draw

make a pivot pole. HD bearing is used as a buffer for horizontal movement.

Bearing of pivot rod use usual. our can use a part of tamiya or other. for vertical movement.

Last edited:

suwaned,

The arm in the photo uses an HD bearing for the horizontal pivot and CD carrier bushings for the vertical. It works OK, but I prefer modern ceramic hybrid bearings.

Your 401 plinth in the other thread is beautiful. Congratulations.

The arm in the photo uses an HD bearing for the horizontal pivot and CD carrier bushings for the vertical. It works OK, but I prefer modern ceramic hybrid bearings.

Your 401 plinth in the other thread is beautiful. Congratulations.

Attachments

hello dtut,

I'm glad you shared DIY the HD bearing tonearm, very nice ... that has been working with the good. have a nice DIY TA

good idea used the modern ceramic hybrid bearings is good. low friction, our will looking for that for vertical bearing.

I have tried looking for.

Thank you for an appreciation for my new plinth.

my plinth have not already finishing. but only for tested because my the tonearm wire to short for new base. That DIY HD bearing tonearm too.

I'm glad you shared DIY the HD bearing tonearm, very nice ... that has been working with the good. have a nice DIY TA

good idea used the modern ceramic hybrid bearings is good. low friction, our will looking for that for vertical bearing.

I have tried looking for.

Thank you for an appreciation for my new plinth.

my plinth have not already finishing. but only for tested because my the tonearm wire to short for new base. That DIY HD bearing tonearm too.

This is pivot , my first project I had made separate :

An externally hosted image should be here but it was not working when we last tested it.

Very detailed work gentlemen.

But I'm wondering why Not simply adopt the Clever and V Good bearing that Nanook used/developed for his $2.19 Arm?

I tried both and I find the additional security of the hard disk motors reassuring and the sound slightly more 'solid' too. The ability of any of the usual linear trackers to become derailed rather bugs me too in spite of the way they sound.

Our 'spider' model overcomes this objection.

As an aside, if you want maximum freedom in the bearings you should use them upside down as they spin in the other direction and all the ones I have used have been much freer in that direction. Can't say I've noticed any difference in performance though

Very detailed work gentlemen.

But I'm wondering why Not simply adopt the Clever and V Good bearing that Nanook used/developed for his $2.19 Arm?

hi Bare,

My dream to get a long tonearm, as I have already tried to modify the techincs arm to replace the aluminum pipe to the wood. i have a problem and I think must to made DIY TA.

In my first work this, later i wanted to make a simple to use HD bearing arm which I think is very good because there is no movement, but I have difficulty when making the pivot for vertical movement. So I tried to make a little complex.

sorry i do not understand about the Clever and V Good bearing, next i will learn about that.

regards

ed

I have already upload video , how are the pivot spinning?

It is stability

[Diy HD bearing tonearm - YouTube]. https://m.youtube.com/watch?v=8jtaDzs4cnE

It is stability

[Diy HD bearing tonearm - YouTube]. https://m.youtube.com/watch?v=8jtaDzs4cnE

Last edited:

how long distance of pivot to spindel ideal?

After the pivot was completed. I have to determine long distance of P to S.

I choose a long distance aproximal 16.5", because i think with the long arm can get little tracking error / more linier path of circle.

And what is the ideal? I don't know. Because how long the distance of arm used when to made the vinyl. It is must same. That complicated for accepted many kind of the records.

After the pivot was completed. I have to determine long distance of P to S.

I choose a long distance aproximal 16.5", because i think with the long arm can get little tracking error / more linier path of circle.

And what is the ideal? I don't know. Because how long the distance of arm used when to made the vinyl. It is must same. That complicated for accepted many kind of the records.

The cutter has a servo driven tangential arm. It were ideal to have the same at playback, but the biggest problem here is to follow the groove that has variable pitch. There is an inherent offset error that has to be corrected by a servo or by mechanical means.Because how long the distance of arm used when to made the vinyl. It is must same.

Ed, I'm really impressed with the work on your arm..

I'm working on a project called 3R. Reclaim-Rework-Relisten

Pic one is a JVC drop in.. Pic 2 is Consonance Droplet.

Also reusing the Spindle, motor and platter from a Yamaha YP450 to use with a single arm..

Going to try out some plinths made with great Canadian maple

For me finding good ARMs at a good price is a dilemma.. Yamaha parts are pretty good but original arm is not that good..

Can you make me an arm to try out? I can send Pm to discuss? Price etc?

I'm working on a project called 3R. Reclaim-Rework-Relisten

Pic one is a JVC drop in.. Pic 2 is Consonance Droplet.

Also reusing the Spindle, motor and platter from a Yamaha YP450 to use with a single arm..

Going to try out some plinths made with great Canadian maple

For me finding good ARMs at a good price is a dilemma.. Yamaha parts are pretty good but original arm is not that good..

Can you make me an arm to try out? I can send Pm to discuss? Price etc?

Attachments

Ed, I'm really impressed with the work on your arm..

I'm working on a project called 3R. Reclaim-Rework-Relisten

Pic one is a JVC drop in.. Pic 2 is Consonance Droplet.

Also reusing the Spindle, motor and platter from a Yamaha YP450 to use with a single arm..

Going to try out some plinths made with great Canadian maple

For me finding good ARMs at a good price is a dilemma.. Yamaha parts are pretty good but original arm is not that good..

Can you make me an arm to try out? I can send Pm to discuss? Price etc?

hello Joel,

i have seen your Project , your two DIY R3 turntable and new plint very nice and good job. your have done painted white color a great.

i have not tried any part of the TT for rebuilt excepted arm. Next time I will to do like you.

i have experience to founded good arm like your , i looking for good arm is over price for me. small budget..

and soo i starting explored to how build of the tonearm by self. 1 year i have do it.

Actualy

i'm not confidence to myself for share about the DIY TA. but i 'm willing to share my experience and hope all friends can give me feedback and advice to me.

i'm not confidence to myself for share about the DIY TA. but i 'm willing to share my experience and hope all friends can give me feedback and advice to me.Thank you very much to you for appreciation for my DIY TA. this supported for me. I make it for my self and i have not desire to commercial.

i have just shared. please don' say price.....

I hope all friends not consider high expectation for me because i'm an amateur and not an expert. I just curious and hobby.

i will a little told about me, i'am a Dentist and the practice and teaching at academy of dental technique (learn for make a denture). my main job,

i have a great interest and enthusiastic in the DIY audio. for my hobby.

i think i was wrong to be a dentist.

and my buddy "Joel" , i apologize, i'm not professional, but i will share my experience and help what i can do it for you, and our can discus about the DIY a long Tonearm.

Hi again Ed and thanks for all of your TA details buddy..

The distance between us is a little far but maybe a trade at some point.. Plinth in exchange for a tonearm maybe Just hobby ideas..

Just hobby ideas..

Your Dentist skills must be Awesome!

The paint on my table is done by the same guy who applied the Piano finish on all the Energy Veritas speakers.. The table is sprayed but not made into piano finish but Planning to make one without the grooves then he can do piano..

Talk to you later.. Outdoor project is waiting for me..

Keep posting.. Really enjoy it..

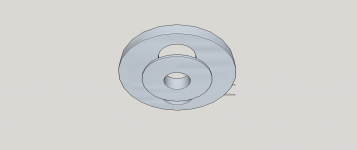

Here is idea I had for arm board for Rb300 threaded style arm mounts.. The center piece is solid and user drill for the arm.. The bottom washer compresses against the main piece..

Joel

The distance between us is a little far but maybe a trade at some point.. Plinth in exchange for a tonearm maybe

Your Dentist skills must be Awesome!

The paint on my table is done by the same guy who applied the Piano finish on all the Energy Veritas speakers.. The table is sprayed but not made into piano finish but Planning to make one without the grooves then he can do piano..

Talk to you later.. Outdoor project is waiting for me..

Keep posting.. Really enjoy it..

Here is idea I had for arm board for Rb300 threaded style arm mounts.. The center piece is solid and user drill for the arm.. The bottom washer compresses against the main piece..

Joel

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- DIY Tonearm from part HD computers, why not..?