Why do you have to drill the magnet? The string doesn't have to pass thru the magnet. Unless I am seeing this wrong. The magnets have a gap between them. The string stops above the upper magnet. Othewrwise if the string went all the way thru the magnets what do you need the magnets for? And making a hole is easy. EDM it. Right tool for the job.Hi

...the interview in hifi+...

The Nd magnet is an extremely hard material; trying to drill a tiny hole in it and get rid of the swarf material (which is strongly attracted back to the block) is a nightmare. Took him about 8 hours to go a few mm IIRC...

Will try and dig out the magazine and see exactly what he had to say.

Why not try drilling a tiny hole in a cheap ferrite magnet and see how you get on with that?

cheers

cv

I built mine similar to a design that I found online, it works fine.

Attachments

First effort from a while ago, but the principle is the same and it does work. Even though I wouldn't allow it in the same room with the beautiful Schoeder clones in this thread, it has the advantage of being build-able with a drill press and hand tools. The inner spring is missing. Your proposed materials should work well. I found that a pin to keep the carrier from turning is helpful.

Doug

Doug

Attachments

Last edited:

That version is widely available online still..I built mine similar to a design that I found online, it works fine.

https://www.ebay.com/itm/2246200835...LjUeFnofyxRzdA9wI%3D|ampid:PL_CLK|clp:2563228

Other types are also available ...

https://www.ebay.com/itm/185404827893?var=693194360721

Last edited:

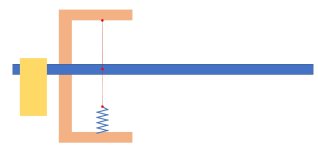

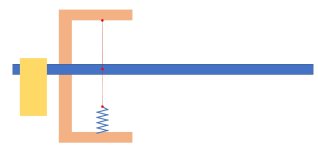

Hi everyone here. I just found this thread and was impressed by all the hard work you did. I must admit I haven't read all 1500+ posts, and maybe my question has been already answered, but I'll ask it anyway: Why all the effort of dealing with magnets? The role of the attracting magnets is to keep a vertical fishing line under tension. Why can't this be achieved using a spring???

Hi,

I have made for myself a clone of the Original TA and I do not have all the mentioned problems such as lack of precise positioning, own resonants frequency. Regarding the resonant frequency, every TA has its own depending on the material of the TA s wand and type of construction as well. I would dare to say that magnets work in a pretty different way comparing to the AM system with spring and is not a matter of charming at all.

However to reach a good result it took me few attempt.......

I think Frank Schroedoer TA is a great TA and the world wide credit he has obtained confirm it.

However, would be interested to see your development with the spring....... and of course the results.

Rgds

Adelmo

I have made for myself a clone of the Original TA and I do not have all the mentioned problems such as lack of precise positioning, own resonants frequency. Regarding the resonant frequency, every TA has its own depending on the material of the TA s wand and type of construction as well. I would dare to say that magnets work in a pretty different way comparing to the AM system with spring and is not a matter of charming at all.

However to reach a good result it took me few attempt.......

I think Frank Schroedoer TA is a great TA and the world wide credit he has obtained confirm it.

However, would be interested to see your development with the spring....... and of course the results.

Rgds

Adelmo

Last edited:

In fact I think the magnets solution was preferred not because their charm, but because it allows the magnet end of the string rotate freely, thus helping the anti-skating function of the string. A wire rigidly mounted at both ends (the spring can ultimately be removed altogether) makes the wire much stiffer in terms of torsion.

Unipivot, yes. Repelling, no. The TA is suspended by attraction to the top magnet and attracted by a bottom magnet just as much as needed to maintain a correct azimuth. It's genius idea. No friction, no bearing chatter, just free movement! I had a close look at the few YT movies covering this TA and I think the anti-skating is also magnetic, although in one of the movies one dealer claimed anti-skating is done by the audio cables, which is laughable for a $20K TA

$20K TA

Seriously ? $20k. ?

That is an obscene price for a flawed design. The fool who pays that price without being fully aware of the problems with it deserves to have their money taken from them.

Herr Schroeder will make them three tone arms for that price I would imagine ....and they would work properly.

Having run my clone now for quite some time I know that , if I had the money , I would put my name down for a proper Schroeder made Schroeder in a heart beat.

( roll on that lottery win !!! )

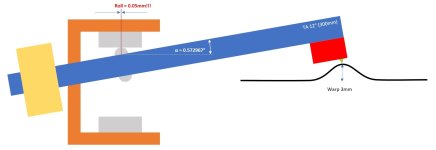

My dear, I understand your concern and theoretically, at least, you are absolutely correct. BUT! In real life, engineering design in general, and tonearm design specifically, is an endless chain of approximations and tradeoffs, the most obvious being the huge 2.5 degrees tracking error of the pivoted tonearms.The tonearm rolls on the upper bearing when vertically moving.

Not good.

My engineering background doesn't allow me to buy into hypes, no matter if positive or negative, before crunching the numbers.

And here are the numbers. The roll you mentioned is a mere 0.05mm. Please keep in mind that the width of our hair is more than double at 0.12mm!

And to be honest, I doubt that even a high end turntable setup by trained professionals using the manufacturer's protractor could attain such precision of the spindle-pivot distance in the first place!

Of course the drawing is not to scale and hugely exaggerated in order to make that roll visible.

Hi, please allow me to correct my previous statement. That price is for the whole Triangleart reference turntable (including the Osiris TA).Seriously ? $20k. ?

- Home

- Source & Line

- Analogue Source

- DIY Schroeder Tonearm???