How do I stop the light leakage ?

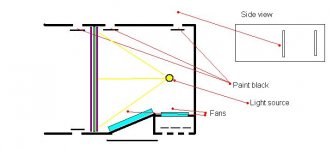

This is the most important thing if you want to have a movie experience with your diy-projector. The difficult thing is that you must not stop the air circulation. Most people just think: okej I just add some black airfilter that stops the light. Yes it does, but it also stop the most of the air. I did some test with my diy-projector and the absolute best way to solve it, is the way I show in the picture. This is how they do it in all stage and discolight equipments. It works extremly good no light leakage at all and it does not affect the cooling. And it´s very very simple to do.

This is the most important thing if you want to have a movie experience with your diy-projector. The difficult thing is that you must not stop the air circulation. Most people just think: okej I just add some black airfilter that stops the light. Yes it does, but it also stop the most of the air. I did some test with my diy-projector and the absolute best way to solve it, is the way I show in the picture. This is how they do it in all stage and discolight equipments. It works extremly good no light leakage at all and it does not affect the cooling. And it´s very very simple to do.

Attachments

How manny fans?

So how many fan's do you need?

I did some calculations a while ago and this was the result:

Ok let me first say, that this is a aproximation. The real stuff is mutch more complicated.

So we want to calculate how much flow our fan has to give when we use for example a 1000 watt halogene. So lets start.

What we want to calculate is the volume air per second we are gona need to cool the lamp. So we rewrite the equation into this:

We can now fill it in:

Let say that we lose 90% of our halogene light as heat so

Q=0,9 kW. Cp and the density of air we know. Let say that we want the temperature inside to be max. 40 C and the outside temperature is 20 C. So the temperature difference is 20 degrees.

So the flow we need is ~0,05 m^3/s that is ~90 CFM (cubic feet per minute)

This would be correct if there was no resistant to the flow, but we al know that this is not true. The resistant causes a higher pressure which causes a lower flow. (see fig)

So if you want to be safe, you have to at least double the needed CFM.

So in this case 2x90=180 CFM

A normal 60mmx60mm fan http://www.coolerguys.com/ProductDetails.aspx?productID=485 only moves ~18 CFM.

A 80mmx80mm fan does ~39 CFM

And the best i found was a 120mmx120mm fan with 78 CFM.

"Oh no problem! I just install three of them!!"

This is not true, 3 fans does not mean automaticly 3x the flow.

This depents if you place them in serie (so side by side) or in a push and pull situation. But to now which system to use can only be measured and not predicted.

So a 1000 watt halogene can be cooled but you are taking a big risk.

For more information:

http://www.comairrotron.com/engineering/airflow.htm

The next graph shows the relation of CFM against kW halogene.

Remember. To be save double the CFM value.

Ps. This is just a calculation in real live other factors as conduction and raddiation also take place, so some spots in the projector can still get a lot hotter.

I got now reaction then and i couldn't try it in reallife so it can be wrong, so be free to make your point

So how many fan's do you need?

I did some calculations a while ago and this was the result:

Ok let me first say, that this is a aproximation. The real stuff is mutch more complicated.

So we want to calculate how much flow our fan has to give when we use for example a 1000 watt halogene. So lets start.

An externally hosted image should be here but it was not working when we last tested it.

What we want to calculate is the volume air per second we are gona need to cool the lamp. So we rewrite the equation into this:

An externally hosted image should be here but it was not working when we last tested it.

We can now fill it in:

Let say that we lose 90% of our halogene light as heat so

Q=0,9 kW. Cp and the density of air we know. Let say that we want the temperature inside to be max. 40 C and the outside temperature is 20 C. So the temperature difference is 20 degrees.

So the flow we need is ~0,05 m^3/s that is ~90 CFM (cubic feet per minute)

This would be correct if there was no resistant to the flow, but we al know that this is not true. The resistant causes a higher pressure which causes a lower flow. (see fig)

An externally hosted image should be here but it was not working when we last tested it.

So if you want to be safe, you have to at least double the needed CFM.

So in this case 2x90=180 CFM

A normal 60mmx60mm fan http://www.coolerguys.com/ProductDetails.aspx?productID=485 only moves ~18 CFM.

A 80mmx80mm fan does ~39 CFM

And the best i found was a 120mmx120mm fan with 78 CFM.

"Oh no problem! I just install three of them!!"

This is not true, 3 fans does not mean automaticly 3x the flow.

This depents if you place them in serie (so side by side) or in a push and pull situation. But to now which system to use can only be measured and not predicted.

So a 1000 watt halogene can be cooled but you are taking a big risk.

For more information:

http://www.comairrotron.com/engineering/airflow.htm

The next graph shows the relation of CFM against kW halogene.

Remember. To be save double the CFM value.

An externally hosted image should be here but it was not working when we last tested it.

Ps. This is just a calculation in real live other factors as conduction and raddiation also take place, so some spots in the projector can still get a lot hotter.

I got now reaction then and i couldn't try it in reallife so it can be wrong, so be free to make your point

A 80mmx80mm fan does ~39 CFM

This depends on rpm, ive seen 80mm fans push out 80 cf/m and 120mm's push out 94cf/m, the cpu fan on my cpu pushes out 54cf/m and thats an 80mm, bear in mind the noise factor though, the higher rpm the noisier the fan will always be.

Heya multi, yeah i think a sticky it could be, it has got a pile of good info in here. There are a few others around way down the track thats got alot of good info, ill dig those out latter for ya and maybe they could be merged into 1 thread working on its topic ect. There is one hell of alot of good info in here, but its just down the track and all mixed up.

Trev

Trev

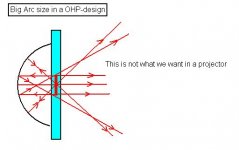

Arc Size

We all know that discharge lamps are the best for a good projector design, not much heat, excellent colortemp and long lifetime. But there is one thing that is not so very good with those lamps, the arcsize is alot bigger than the filament from a halogen lamp, a halogen lamp is a pointsource but a discharge lamp is not a real pointsource, this makes things more complicated when we use them in a projectordesign. Discharge lamps can also be a pointsource but you have to pay alot for that function.

Different discharge lamps:

HQI (MH,cdm) = Arcsize 9-12 mm, Cost $.

HTI = Arcsize 4-5 mm, Cost $$.

UHP = Arcsize 1 mm, Cost $$$.

Most people use the HQI-lamps as a lightsource to the DIY-projectors, because they are the cheapest discharge lamps, but

they are not a good pointsource, in a ohp-design with a big 15-17" tft panel you will not notice this problem, because you

don´t have to magnify the picturesource so very much. But the problem gets bigger with highresolution small tft panels that need more magnifying, the result will be a blurred projected picture. A bigger reflector and more distans to the fresnell helps a

bit. But for small tft-panels the best solution are small arc-size lamps or a HQI-lamp in a big Par-reflector design.

We all know that discharge lamps are the best for a good projector design, not much heat, excellent colortemp and long lifetime. But there is one thing that is not so very good with those lamps, the arcsize is alot bigger than the filament from a halogen lamp, a halogen lamp is a pointsource but a discharge lamp is not a real pointsource, this makes things more complicated when we use them in a projectordesign. Discharge lamps can also be a pointsource but you have to pay alot for that function.

Different discharge lamps:

HQI (MH,cdm) = Arcsize 9-12 mm, Cost $.

HTI = Arcsize 4-5 mm, Cost $$.

UHP = Arcsize 1 mm, Cost $$$.

Most people use the HQI-lamps as a lightsource to the DIY-projectors, because they are the cheapest discharge lamps, but

they are not a good pointsource, in a ohp-design with a big 15-17" tft panel you will not notice this problem, because you

don´t have to magnify the picturesource so very much. But the problem gets bigger with highresolution small tft panels that need more magnifying, the result will be a blurred projected picture. A bigger reflector and more distans to the fresnell helps a

bit. But for small tft-panels the best solution are small arc-size lamps or a HQI-lamp in a big Par-reflector design.

Attachments

Arc Size

The Par-reflector is the best design for a 1-ended lamp and more effective than the ohp-design, but you have to use a bigger reflector if you use a big arc-size lamp type HQI,MH or cdm-t to get a good result. A very good thing with the Par-reflector is that the arc-size don´t have any blur affect on the projected picture if you use a big reflector as the ohp-design has.

The Par-reflector is the best design for a 1-ended lamp and more effective than the ohp-design, but you have to use a bigger reflector if you use a big arc-size lamp type HQI,MH or cdm-t to get a good result. A very good thing with the Par-reflector is that the arc-size don´t have any blur affect on the projected picture if you use a big reflector as the ohp-design has.

Attachments

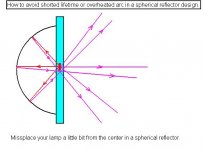

Missplace the lamp

The ohp-design is the most simple design to build but it has some disadvantage if it´s not build correct. Most people place the lamp in the center of the spherical reflector, but this wrong ! You must missplace it a little bit, otherwise you will shorten the lifttime of the lamp or it will be overheated, if you can´t missplace the lamp a little or you get blurness if you do that, you have to know that the lamps lifetime will maybe only be the half of what it should be.

The ohp-design is the most simple design to build but it has some disadvantage if it´s not build correct. Most people place the lamp in the center of the spherical reflector, but this wrong ! You must missplace it a little bit, otherwise you will shorten the lifttime of the lamp or it will be overheated, if you can´t missplace the lamp a little or you get blurness if you do that, you have to know that the lamps lifetime will maybe only be the half of what it should be.

Attachments

FYI,

don't do Big Arc size in big parallel reflector (Mathias post #73 dwg 1), unless you have a perfect reflector to produce parallel light, I tested it before and got uneven light beam.

Mathias,

"Most people place the lamp in the center of the spherical reflector, but this wrong !"

is this for MH lamp too? because it doesn't have filament, it just has a small tube with chemical filled inside. For Halogen lamp, yes , it blew just for 10 hours use, at least it happen to me.

don't do Big Arc size in big parallel reflector (Mathias post #73 dwg 1), unless you have a perfect reflector to produce parallel light, I tested it before and got uneven light beam.

Mathias,

"Most people place the lamp in the center of the spherical reflector, but this wrong !"

is this for MH lamp too? because it doesn't have filament, it just has a small tube with chemical filled inside. For Halogen lamp, yes , it blew just for 10 hours use, at least it happen to me.

You will always get more or less uneven light beam from a Par-reflector, if you use it close to the target, that is why you should use condensors in a such design, all Pro-projectors use condensors after the Par-reflector. But a big reflector with a big arc-size is a must if you want any parallel light at all. With "big arc-size" I don´t mean 40mm or so, more like 10-20mm.

I mean both halogen and MH, but I know it´s harder to missplace a MH-lamp, but the thing is that the lamp gets hotter than it should be in a spherical reflector design even a "small tube with chemical" gets hotter. How much this affect the lifetime of a MH-lamp is hard to say but it gets shorter. The thing you can do to avoid this is to use forced cooling on the lamp and many projectors use that.

I mean both halogen and MH, but I know it´s harder to missplace a MH-lamp, but the thing is that the lamp gets hotter than it should be in a spherical reflector design even a "small tube with chemical" gets hotter. How much this affect the lifetime of a MH-lamp is hard to say but it gets shorter. The thing you can do to avoid this is to use forced cooling on the lamp and many projectors use that.

I´m no expert in cooling, but I know that most pro-projector have two fans one that pull the cool air into the case and one that pull the hot air out from the case, the one that pull the hot air out from the case is always placed near the lamp, so the lamp will probably be cooled with hot air like bobharry said.

I did a different spherical reflector design a while ago, I used a dichroic reflector instead of the normal "soup laddel" reflector, in that way I don´t bounce back the heat to the lamp, only the light, notice that I use a normal magnifying glass as a condensor, not heat proof. The design worked very good and I had no problem with the heat. I know that the reflector is a little to small, but it was only a test setup and you can get a bigger dichroic reflector.

I did a different spherical reflector design a while ago, I used a dichroic reflector instead of the normal "soup laddel" reflector, in that way I don´t bounce back the heat to the lamp, only the light, notice that I use a normal magnifying glass as a condensor, not heat proof. The design worked very good and I had no problem with the heat. I know that the reflector is a little to small, but it was only a test setup and you can get a bigger dichroic reflector.

Attachments

Mathias nice work, im working on somthing at the moment thats very much the same as a eliptical reflector, when i get the parts i need ill post it up, in my tersting on a prototype i saw a masive increase in light both on the cdm-t and the 250w, the increse on the 250w was so much that it was as bright if not brighter then beforcades 400w. The only problem? heat! no probs for the bulb as they are tested and run at 650deg c in the factory, thats the outer shell case, but for the poor old condenser, well they dont like it weather its mounted loose or tight agains any plate lol. its just too much heat for the glass so ill have to find a very high temp grade of glass or make a baracade inbetween the lamp and condenser with temperd glass or ir filter.

Guys your prety much right all of you on the warm air on the bulb, 2 reasons they have the bulbs this way, 1 running a bulb too cold will change its colour temp and reduce its life, it will also reduce the light output, 2 for the obvious, boomba, the best way to run any bulb especially halogen is hot, they are designed to run hot and thats the way they are designed to stay, if you run them too cold you will have unwanted results. The things to mainly keep cool is the condenser and the reflector and this must be done with warm air and not cold, cold air will cause fractures not only in a glass reflector but also a condenser, trust me, ive tried it.

Trev

Guys your prety much right all of you on the warm air on the bulb, 2 reasons they have the bulbs this way, 1 running a bulb too cold will change its colour temp and reduce its life, it will also reduce the light output, 2 for the obvious, boomba, the best way to run any bulb especially halogen is hot, they are designed to run hot and thats the way they are designed to stay, if you run them too cold you will have unwanted results. The things to mainly keep cool is the condenser and the reflector and this must be done with warm air and not cold, cold air will cause fractures not only in a glass reflector but also a condenser, trust me, ive tried it.

Trev

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- General Interest

- Everything Else

- The Moving Image

- Optics

- DIY-Projector Plans and theory collection !!