Hello again.

5 seconds?!

It may be true that I am little more impatient than you...

Can I ask about the bearings, how do you adjust the tension?

You can take a look at piezometers and accelrometers (gyroscopes?),

I bought these from seeedstore.com, but haven't comed around to do something useful with these. I have even thought to use a microphone, so please let us know how it'll go.

Hope this information helps.

I have postponed all that, I have too much to do, so a DIY DD TT may just be a dream.

So I'll buy a Technics instead, they're classics.

5 seconds?!

It may be true that I am little more impatient than you...

Can I ask about the bearings, how do you adjust the tension?

You can take a look at piezometers and accelrometers (gyroscopes?),

I bought these from seeedstore.com, but haven't comed around to do something useful with these. I have even thought to use a microphone, so please let us know how it'll go.

Hi-Fi News Test Record ; [url=http://www.needledoctor.com/Hi-Fi-News-Test-Record?sc=2&category=438 said:Hi-Fi News Test Record[/url] ]The two cartridge/arm resonance tests consist of test sweeps with pilot tones, and you'll actually see the arm misbehaving if there's any horrible mismatch in your set-up. The cartridge alignment test allows you to adjust the azimuth for minimum output, through a 300Hz vertical L-R signal at +6dB. Lastly, there's a track to show residual noise, consisting of unmodulated grooves. And this one will prove to be a real party trick if you use an idler-drive deck and none of your friends are willing to believe it's a quiet runner...

Hope this information helps.

I have postponed all that, I have too much to do, so a DIY DD TT may just be a dream.

So I'll buy a Technics instead, they're classics.

your tangential arm

Have you already tried increasing distance"D"? It seems the same design will work well, if "D" will be equal, or even longer than the arm own length (bearing to stylus distance).Hi Helmuth,

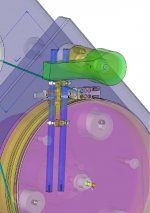

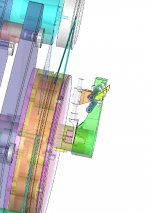

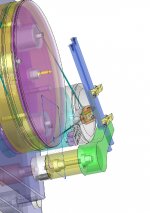

The only reason that I choose 2 linear bearings is to reduce the blocking cause (see photos). When you have a linear translation, you must take care of this relation: L>2,5D, more distance you have, better will be the translation, and of course you have double bearing torque, I hope the pulley and the weight will decrease this translation torque.

Hi Doomy,Hello again.

5 seconds?!

It may be true that I am little more impatient than you...

Can I ask about the bearings, how do you adjust the tension?

You can take a look at piezometers and accelrometers (gyroscopes?),

I bought these from seeedstore.com, but haven't comed around to do something useful with these. I have even thought to use a microphone, so please let us know how it'll go.

Hope this information helps.

I have postponed all that, I have too much to do, so a DIY DD TT may just be a dream.

So I'll buy a Technics instead, they're classics.

I have no tension on the bearings. The top bearing has 1 mm free in translation, so the whole platter can move vertically.

And thanks for the usufull links

In my case, I have L>3D. I didn't test longer one, cause I'm changing the system. Actually, I'm drawing a new arm, view to come.Have you already tried increasing distance"D"? It seems the same design will work well, if "D" will be equal, or even longer than the arm own length (bearing to stylus distance).

In fact, a linear bearing is not made for rotation, and I have drawn mine to also use it as so, up down the arm, and the blocking appears at this moment, The arm I made is also too long. I take attention to that you all had said to design the new tone arm. First drawings are about to be finished, so will post photos soon. THANKS.Sorry for a mistake I've made. Actually, I've meant distance "D", which is between the two bearings. Increasing it further, it is possible to exclude blocking.

Anyway, will wait for your next design to come.

On little wheels? Why not air linear bearings?

How about an active mechanism which actually DRIVES the arm (instead of low-friction). It shouldn't be too difficult to use a light source (perhaps laser) and light detectors to determine whether the arm is straight, and you could use mirrors to amplify the accuracy (simulating a very long light path).

Of course there are SO MANY possibilities.

How about an active mechanism which actually DRIVES the arm (instead of low-friction). It shouldn't be too difficult to use a light source (perhaps laser) and light detectors to determine whether the arm is straight, and you could use mirrors to amplify the accuracy (simulating a very long light path).

Of course there are SO MANY possibilities.

needs to be 100% friction free

air does that

even a soft needle arm is able to move the arm from sided to side

maybe it would also be possible with magnetism, don't know

this constant arm moving from side to side isn't noticed so much with normal arms

but with a tangential you will notice this effect more

air does that

even a soft needle arm is able to move the arm from sided to side

maybe it would also be possible with magnetism, don't know

this constant arm moving from side to side isn't noticed so much with normal arms

but with a tangential you will notice this effect more

IMHO a good active system should be able to outperform anything else I can think of. Maybe study the Bang & Olufsen linear arms.

Had a Rabco and Harmon-Kardon Rabco (motorized roller with arm's wheels trailing like a wagon's rear wheels), and they were very sensitive to dust and dirt, and the arm intorduced some rumble of its own. For that matter, if you rotate the two rods in the previous model and change the wheel axles 90 degrees, the rear of that arm would self-align "frictionlessly".

Had a Rabco and Harmon-Kardon Rabco (motorized roller with arm's wheels trailing like a wagon's rear wheels), and they were very sensitive to dust and dirt, and the arm intorduced some rumble of its own. For that matter, if you rotate the two rods in the previous model and change the wheel axles 90 degrees, the rear of that arm would self-align "frictionlessly".

revox had a similar design.

dunno if it was active or not.

youtube link,

revox gramophone in action (Revox Plattenspieler in Aktion) - YouTube

dunno if it was active or not.

youtube link,

revox gramophone in action (Revox Plattenspieler in Aktion) - YouTube

regarding the B&O tangential arm

they had a second paralel arm with a strobo thing controlling the servo motor

and, I also think the actual tangential arm had a kittke free sideway play

this way its virtually free or decoupled from the mechanism/motor moving the arm

essentially you might look at it like a hybrid of a normal pivot hinged arm and a motor driven tangential sledge

maybe parts from a CD drive could be of use

they had a second paralel arm with a strobo thing controlling the servo motor

and, I also think the actual tangential arm had a kittke free sideway play

this way its virtually free or decoupled from the mechanism/motor moving the arm

essentially you might look at it like a hybrid of a normal pivot hinged arm and a motor driven tangential sledge

maybe parts from a CD drive could be of use

regarding the B&O tangential arm

they had a second paralel arm with a strobo thing controlling the servo motor

The second arm is only used to detect the size of the disc.

The servo is controlled by the movement of the tonearm. (It can freely move left and right)

At least on all types I have seen. (Beogram 6500, 5005, 4004)

Yes, the arm can pivot at its back "active" end, which is necessary to trigger the active motor to realign it tangentially. If executed well, it would just adjust the feed speed. Its offset-detecting light triggers can be exemely accurate if the defelction is amplified by a series of mirrors.

BTW I've always been relatively impressed w/ B&O cartridges too.

BTW I've always been relatively impressed w/ B&O cartridges too.

Yes, the arm can pivot at its back "active" end, which is necessary to trigger the active motor.......

ah, that's clever

reminds me, I noticed that CanaKit have various motor speed controller kits

but yeah, radial unipivot is more DIY 'friendly'

but after watching a documentary about top class German model builders, I would say anything is possible

Take a look

Optical Fibre Turntable for Archives Records - YouTube

It looks like the best tracker you can imagine. Exceeds the most demanding expectations. Honestly, I'm speechless...

Optical Fibre Turntable for Archives Records - YouTube

It looks like the best tracker you can imagine. Exceeds the most demanding expectations. Honestly, I'm speechless...

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- DIY Personal Turntable