Hi Niffy, your input is very much appreciated, i hope with input from all those kind enough to respond to continue to improve this concept.

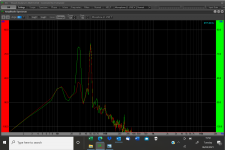

First in answer to your last question, i had previously found the motor seemed to have an input at 20-23Hz, and so now the motor pod is on a separate plinth from the deck and arm and i took these measurements again.

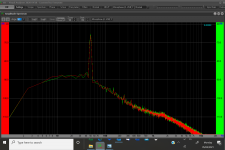

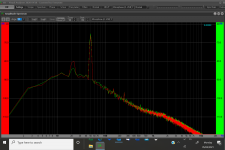

First 555 (stylus on record, motor switched off) shows the 50hz hum peak which seems to be how the ADC is wired because if i turn the volume up full when everything is set to play through the amp there is zero detectable hum at the speakers, and the bass has 250W a side to try and amplify that if it were there. it is picked up by the wiring which i have proven by shrouding it for a test but that isn't practical playing a record.

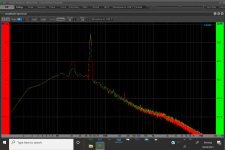

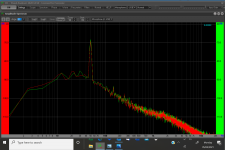

Then 544 is the motor switched on, one can see a peak still, maybe this is electro magnetic rather than mechanical as well?

First in answer to your last question, i had previously found the motor seemed to have an input at 20-23Hz, and so now the motor pod is on a separate plinth from the deck and arm and i took these measurements again.

First 555 (stylus on record, motor switched off) shows the 50hz hum peak which seems to be how the ADC is wired because if i turn the volume up full when everything is set to play through the amp there is zero detectable hum at the speakers, and the bass has 250W a side to try and amplify that if it were there. it is picked up by the wiring which i have proven by shrouding it for a test but that isn't practical playing a record.

Then 544 is the motor switched on, one can see a peak still, maybe this is electro magnetic rather than mechanical as well?

Attachments

Hi Mike,

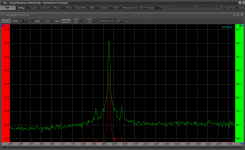

I notice in the 1kHz spectral post you have asymmetric sidebands. This is not good as it points to multiple sources of non-linearity. Pure amplitude modulation always results in symmetric sidebands. My first guess would be FM as well as AM.

I mentioned this for you keep an eye on as I don;t remember seeing this in your other plots.

I notice in the 1kHz spectral post you have asymmetric sidebands. This is not good as it points to multiple sources of non-linearity. Pure amplitude modulation always results in symmetric sidebands. My first guess would be FM as well as AM.

I mentioned this for you keep an eye on as I don;t remember seeing this in your other plots.

Hi Mike,

I notice in the 1kHz spectral post you have asymmetric sidebands. This is not good as it points to multiple sources of non-linearity. Pure amplitude modulation always results in symmetric sidebands. My first guess would be FM as well as AM.

I mentioned this for you keep an eye on as I don;t remember seeing this in your other plots.

Hi Warren, thanks, i am probably trying to do too many things at the same time, i find this sport engaging and get carried away!

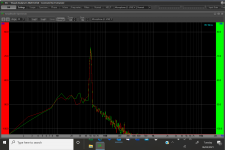

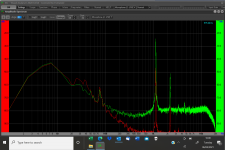

The latest looks as attached.

Now looking symmetrical to me but would be interested to know a little about FM and AM, how caused etc.............

M

ATM i find this set up measures similar but different, i cannot say better or worse but auto suggestion says it sounds better!

Attachments

Hi Mike,

The origin live pulley has a 7.5mm diameter crown (based on my OL motor) and a 300mm diameter platter. At 33-1/3rpm the motor is turning 22.2 times per second so it might be a motor issue after all. Try rerunning the test but with the deck running at 45rpm. If it is a motor issue then the peek should move to 30hz.

Niffy

The origin live pulley has a 7.5mm diameter crown (based on my OL motor) and a 300mm diameter platter. At 33-1/3rpm the motor is turning 22.2 times per second so it might be a motor issue after all. Try rerunning the test but with the deck running at 45rpm. If it is a motor issue then the peek should move to 30hz.

Niffy

Welcome to the world of R&D, just make sure to change 1 thing at a time.

Frequency Modulation is like WOW where the F is varied, FM has deviation which is the amount in Hz that the F is varied.

AM is far more common in TT audio reproduction. The 2 frequencies you have 1KHz and 70Hz will naturally Amplitude modulate causing F1+F2 and F1-F2. So you have 1kHz-70Hz and 1kHz+70Hz thus upper and lower sidebands.

Frequency Modulation is like WOW where the F is varied, FM has deviation which is the amount in Hz that the F is varied.

AM is far more common in TT audio reproduction. The 2 frequencies you have 1KHz and 70Hz will naturally Amplitude modulate causing F1+F2 and F1-F2. So you have 1kHz-70Hz and 1kHz+70Hz thus upper and lower sidebands.

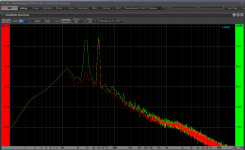

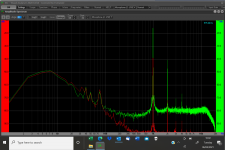

I re-ran the test Niffy, here you can see the peak at around 30Hz, so i bent down to the motor and can hear it buzz a little...........Hi Mike,

The origin live pulley has a 7.5mm diameter crown (based on my OL motor) and a 300mm diameter platter. At 33-1/3rpm the motor is turning 22.2 times per second so it might be a motor issue after all. Try rerunning the test but with the deck running at 45rpm. If it is a motor issue then the peek should move to 30hz.

Niffy

Attachments

I re-ran the test Niffy, here you can see the peak at around 30Hz, so i bent down to the motor and can hear it buzz a little...........

I read the instructions and adjusted the motor mount screws, 554 before, 557 after, i will check with a running set up but hope that's resolved

thanks again, mike

Attachments

Did you find if the two cylinders slide vertically to set height if you remove any grubscrews like Koldby suggested? - if you already have that then its a whole lot easier!!

From what I can see, it has NO adjustments there. That would have been to easy , lol

Things never work out that easy for me

Hi Mike,

I glad that you've found the source of that pesky 23hz bump. That this isn't an arm resonance issue would lend credence to my supposition that the little bump around the 10hz range is in fact the vertical resonance mode of the arm. 10hz is pretty much exactly where you want this to be so that is an excellent result.

The next peek at 50hz is likely to be mains noise being picked up by the tonearm wires. It does appear to be at a low level so hopefully isn't audible but any lowering of the noise floor is welcome.

Niffy

I glad that you've found the source of that pesky 23hz bump. That this isn't an arm resonance issue would lend credence to my supposition that the little bump around the 10hz range is in fact the vertical resonance mode of the arm. 10hz is pretty much exactly where you want this to be so that is an excellent result.

The next peek at 50hz is likely to be mains noise being picked up by the tonearm wires. It does appear to be at a low level so hopefully isn't audible but any lowering of the noise floor is welcome.

Niffy

It seems from the pics there are two sleeves one inside the other and that they are somehow held together, just find the fastenings?From what I can see, it has NO adjustments there. That would have been to easy , lol

Things never work out that easy for me

It is very useful to have guidance from those much more experienced and knowledgeable than me, so i will keep working on things and post the odd questions.Hi Mike,

I glad that you've found the source of that pesky 23hz bump. That this isn't an arm resonance issue would lend credence to my supposition that the little bump around the 10hz range is in fact the vertical resonance mode of the arm. 10hz is pretty much exactly where you want this to be so that is an excellent result.

The next peek at 50hz is likely to be mains noise being picked up by the tonearm wires. It does appear to be at a low level so hopefully isn't audible but any lowering of the noise floor is welcome.

Niffy

Ideas on what to focus on next and how, much appreciated, thanks, mike

Last edited:

Hi Mike,

The origin live pulley has a 7.5mm diameter crown (based on my OL motor) and a 300mm diameter platter. At 33-1/3rpm the motor is turning 22.2 times per second so it might be a motor issue after all. Try rerunning the test but with the deck running at 45rpm. If it is a motor issue then the peek should move to 30hz.

Niffy

Earlier it was shown that if the speed was changed to 45 rpm, the 23Hz went away

Hi Karsten, You are correct as well, I know, i did the test and I missed the diagnosis, I didn’t think to look at the motor to solve it, I looked at the transmission path.Sorry didn´t see the follow up on that. Same conclusion as earlier. The 23 Hz is from the motor/pully arrangement.

What i find almost unbelievable is that i split the plinth so that the motor (or so i thought!!) couldn't possibly send its vibrations through..........

So, at the moment, because of that

• the motor is in its pod, that OL engineered carefully

• that sits on 4 layers of MLV,

• that sits on chip board,

• that sits on an inner tube

• that sits on MDF

• that sits on 1 layer MLV

• that sits on a beech block

• that sits on MLV

• that sits on the metal wall shelf

• that shelf also goes under the TT

• above which is layers of MLV

• above which are steel balls and cups and chipboard

• another MLV

• another beech block

• above which the TT isolations

• and then the TT.

How on earth does the now tiny motor noise go through all those?!

More interestingly, how do I simply stop it……..

What layer simply stops 22Hz…….because the assembly above does not………

M

Hi Mike,

Remove the belt and rest the stylus on a non-revolving record and switch the motor on. If you can no longer detect the 22hz signal then the vibration won't be being transmitted via the motor/deck support. It will be being transmitted via the belt. You may find that adjusting the belt tension (slackening it?) may help.

I used an Origin Live belt for many years, they are notably better than those supplied by many manufacturers. I did however improve on the OL flat belt with the use of three separate 1.5mm round section nitrile belts. My drive system and bearing are highly unusual so it is more likely that the improvement was due to improvements in belt routing rather than belt material.

Niffy

Remove the belt and rest the stylus on a non-revolving record and switch the motor on. If you can no longer detect the 22hz signal then the vibration won't be being transmitted via the motor/deck support. It will be being transmitted via the belt. You may find that adjusting the belt tension (slackening it?) may help.

I used an Origin Live belt for many years, they are notably better than those supplied by many manufacturers. I did however improve on the OL flat belt with the use of three separate 1.5mm round section nitrile belts. My drive system and bearing are highly unusual so it is more likely that the improvement was due to improvements in belt routing rather than belt material.

Niffy

Last edited:

Hi Mike

Would you be able to try a differently compliant cart to see if you can get that 10Hz to move somewhere we can see it better?

Hi 2wice, thanks for your interest, this is the one and only cartridge, its a low compliance Rega Ania......

After i have done the belt experiments and removed as much of that peak as possible, i will try again to demonstrate moving the resonance for interest,

Mike

Hi 2wice, thanks for your interest, this is the one and only cartridge, its a low compliance Rega Ania......

After i have done the belt experiments and removed as much of that peak as possible, i will try again to demonstrate moving the resonance for interest,

Mike

Thank you

Hi Mike,

Remove the belt and rest the stylus on a non-revolving record and switch the motor on. If you can no longer detect the 22hz signal then the vibration won't be being transmitted via the motor/deck support.

Niffy

And you could also take the belt off and rotate the platter to 33.3 RPM by hand look for the 23 Hz peak. Rumble from the bearing, maybe?

Hi Gents,

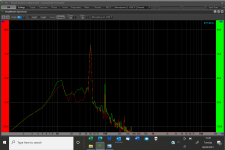

I dont seem to be getting completely consistent results, but here attached

1. Belt off, motor off 562

2. Belt off motor on 33 563

3. Belt off motor on 45 564

4. Belt off driven by hand 569

5. Belt on motor on 570

Overall it now seems the 22 is mostly gone, but the equivalent from 45 is horrible.......

M

Attachments

- Home

- Source & Line

- Analogue Source

- DIY linear tonearm