... It only works using magnetic repulsion. (I tried using attraction but this massively overdamped the system and resulted in worse overall friction than without it.)....

Using ball bearings less weight can hinder to win the stiction phase, which is the main problem whit such low speeds.

But attraction may be easier to build: a soft iron (not steel) V profile above and 3 adjustable magnets on a non recirculating balls carriage can achieve a perfectly constant flux along all rail length. We may even think a fully suspended system (upside down: magnetic attraction for mechanical grounding = adjustable negative weight + small carriage mass)

... I feel that improving mechanical grounding made much more difference than reducing friction....

quote completely

carlo

Using ball bearings less weight can hinder to win the stiction phase, which is the main problem whit such low speeds.

But attraction may be easier to build: a soft iron (not steel) V profile above and 3 adjustable magnets on a non recirculating balls carriage can achieve a perfectly constant flux along all rail length. We may even think a fully suspended system (upside down: magnetic attraction for mechanical grounding = adjustable negative weight + small carriage mass)

... I feel that improving mechanical grounding made much more difference than reducing friction....

quote completely

carlo

Last edited:

I still think repulsion is the way to go. Think of all those turntables with magnetic bearings. They all use repulsion. Repulsion didn't seem to add damping but attraction did. Also worth considering is that to use an upside down system the attraction has to have a greater force than the weight of the carriage where with repulsion the force has to be less than the weight of the carriage. The total amount of magnets for repulsion is of course much greater as you will need to have magnets along the entire length of the rail and not just on the carriage. Much more experimentation is required.

Niffy

Niffy

True what you say, even if the case of TTs seems rather different imho: to reduce the bearing noise of super massive platters, and often to get a significant decoupling too.

Anyway the only possible advantages could be:

uniform field: during the travel the magnets attract uniformly the rail (without its own field). An array of magnets can have the necessary uniform flux not to alter the carriage movement?

damping - this time the weight is subtracted from attraction, not added, and the difference may be brought to a minimum.

grounding becomes independent from the effective horizontal mass, and adjustable

In any case all this seems to me a superfluous complication, there is enough fun (or trouble) to build an acceptable carriage (and cables)

c

Anyway the only possible advantages could be:

uniform field: during the travel the magnets attract uniformly the rail (without its own field). An array of magnets can have the necessary uniform flux not to alter the carriage movement?

damping - this time the weight is subtracted from attraction, not added, and the difference may be brought to a minimum.

grounding becomes independent from the effective horizontal mass, and adjustable

In any case all this seems to me a superfluous complication, there is enough fun (or trouble) to build an acceptable carriage (and cables)

c

More Lil Casey

After several listening sessions with expensive MC carts, we tried some decent MMs. Finally I have borrowed the arm to listen it in my own system. After some Kamasutra with installing it on my reserve Braun belt drive turntable (heavily upgraded with 7 kilogramm platter) I tried Ortofon VMS20EO and Empire 888PE carts, and finally coreless MC cartridge of my own design. Surprizingly, Lil Casey sonic performance with high compliance Ortofon was excellent, and with Empire (888 is my favorite among MMs) it was even better. My own MC also sounds better, than on pivot arm (it is a heavy cart with low compliance and 3 gramm tracking weight). My unexpected conclusion: Lil Case works and sounds excellent with high and low compliance carts, and with both MCs and MMs. That is unusual and unexpacted.

Actually, nobody expected to hear VMS20 to perform as close to very expensive MCs, and it is a fact.

Walter

After several listening sessions with expensive MC carts, we tried some decent MMs. Finally I have borrowed the arm to listen it in my own system. After some Kamasutra with installing it on my reserve Braun belt drive turntable (heavily upgraded with 7 kilogramm platter) I tried Ortofon VMS20EO and Empire 888PE carts, and finally coreless MC cartridge of my own design. Surprizingly, Lil Casey sonic performance with high compliance Ortofon was excellent, and with Empire (888 is my favorite among MMs) it was even better. My own MC also sounds better, than on pivot arm (it is a heavy cart with low compliance and 3 gramm tracking weight). My unexpected conclusion: Lil Case works and sounds excellent with high and low compliance carts, and with both MCs and MMs. That is unusual and unexpacted.

Actually, nobody expected to hear VMS20 to perform as close to very expensive MCs, and it is a fact.

Walter

Attachments

Beautiful version of the Lil Casey carbon - congratulations again E & W. Got some improvement from previous? Have you made some measures for frictions and eff masses? i'm really curios to learn something from-about your experience, plz post further details on building and setting.

Glad to know of your new tests (to hear a new item in our system is the only real way to compare) that confirm mine, and more my intentions (to design a linear for high compliance carts too).

I've tested with some aged mm - stanton - at - shure - and the dl103 on my setup (octal pre + 300b SE+ FE208 E sigma in it's BLH enclosure = not tubey at all, really sharp) and their individual personality was clearly evidenced. So now i'm tempted to buy an AT 120e to see how it tracks with 1,0 Vtf - 35 static compliance.

carlo

hope you'll have appreciated that it does'nt almost suffer the cables syndrome, the infamous linear nightmare, without ever skipping.

Much more than the sound, these are the real diyer satisfactions....

Glad to know of your new tests (to hear a new item in our system is the only real way to compare) that confirm mine, and more my intentions (to design a linear for high compliance carts too).

I've tested with some aged mm - stanton - at - shure - and the dl103 on my setup (octal pre + 300b SE+ FE208 E sigma in it's BLH enclosure = not tubey at all, really sharp) and their individual personality was clearly evidenced. So now i'm tempted to buy an AT 120e to see how it tracks with 1,0 Vtf - 35 static compliance.

carlo

hope you'll have appreciated that it does'nt almost suffer the cables syndrome, the infamous linear nightmare, without ever skipping.

Much more than the sound, these are the real diyer satisfactions....

Last edited:

Sorry 2a3set i have to repeat what said for the 3dToy (a printable PLT) on another thread. I am happy if other diyers will experience my design, perhaps trying to improve it by adding ideas and experience of their own. I'm happy even if some craftsmen will do something similar for one of his customers: it's important that artisans and repairers continue to exist.

But no group buy, no series production, no trade please.

I confess a subtle perfidy: this world, now abandoned by the great manufactures who did expensive research. is now full of people claiming themselves as genius simply for adding a tungsten weight or a cryogenic cable to a 50-year-old design.

So when I happen to find a little new thing and post it on diyAudio (it's not patented, but becomes public) I think: from now no one will sell it as if it's coming from his effort, his "secrets", telling lot of tales to his own exclusive advantage.

carlo

simply a diyer

But no group buy, no series production, no trade please.

I confess a subtle perfidy: this world, now abandoned by the great manufactures who did expensive research. is now full of people claiming themselves as genius simply for adding a tungsten weight or a cryogenic cable to a 50-year-old design.

So when I happen to find a little new thing and post it on diyAudio (it's not patented, but becomes public) I think: from now no one will sell it as if it's coming from his effort, his "secrets", telling lot of tales to his own exclusive advantage.

carlo

simply a diyer

More Lil Casey

Carlo, both metal and carbon arms perform more or less equal. I haven't measure friction and mass, but it has no issues with tracking. Ortofon VMS 20EO is of very high compliance, and with VTF of 1gramm it performs perfect. What amaizes me that there are no issues with horizontal tracking at all, and not even a trace of hum, despite considerable wire loop without shielding. Due to proper choice of wires and loop configuration by Eduard, of course.

There are some problems with tilting on badly warped records, and on them sometimes even skiping occures. I hope, next version will be non-tilting and also will allow use of proper clamp (reffered by Niffy).

Walter

Carlo, both metal and carbon arms perform more or less equal. I haven't measure friction and mass, but it has no issues with tracking. Ortofon VMS 20EO is of very high compliance, and with VTF of 1gramm it performs perfect. What amaizes me that there are no issues with horizontal tracking at all, and not even a trace of hum, despite considerable wire loop without shielding. Due to proper choice of wires and loop configuration by Eduard, of course.

There are some problems with tilting on badly warped records, and on them sometimes even skiping occures. I hope, next version will be non-tilting and also will allow use of proper clamp (reffered by Niffy).

Walter

Walter, what you say (tracking on warps) is precisely why the carbon version was made: the first version tracked very well on eccentricities, but badly on steep warps. The second is oK; the lighter the better: a vert. mass near as possible to the horizontal one is the key to.

If you still have problems work carefully on the weight, removing all the possible material, and on the bearings: the pentips work well, but due the rail length must be tightened to get no play, jewels would be better for sure - 8 ball bearings are too many, 4 would be enough. Meanwhile remove all the lubrication.

Now I'm working on the last problem, the carriage tilt: once the mini CW is set it doesn't give problems, but if it weren't at all would be even better, and the sound could also gain in focusing.

This solution (attachment) with the carriage on bicones (#2952) could maybe work, but I won't get my hands on it without having a 10x10 carbon profile, otherwise instead of going further it would go back

ciao - carlo

If you still have problems work carefully on the weight, removing all the possible material, and on the bearings: the pentips work well, but due the rail length must be tightened to get no play, jewels would be better for sure - 8 ball bearings are too many, 4 would be enough. Meanwhile remove all the lubrication.

Now I'm working on the last problem, the carriage tilt: once the mini CW is set it doesn't give problems, but if it weren't at all would be even better, and the sound could also gain in focusing.

This solution (attachment) with the carriage on bicones (#2952) could maybe work, but I won't get my hands on it without having a 10x10 carbon profile, otherwise instead of going further it would go back

ciao - carlo

Attachments

Last edited:

more:

cables: maybe such thin cables allow very tight twisted pairs, then no hum. In the first arm I passed the cables as drawn, and as you did, but their pushing moved the carriage raised up for positioning, now on the second they come directly out of the parallelogram, making two spiral loops. Far better

c2

cables: maybe such thin cables allow very tight twisted pairs, then no hum. In the first arm I passed the cables as drawn, and as you did, but their pushing moved the carriage raised up for positioning, now on the second they come directly out of the parallelogram, making two spiral loops. Far better

c2

VTF

Carlo, we've encoutered a problem with uneven VTF. It gradually decreases as the stylus goes from first to last groove, and difference is about 35%. Parallelogramm should not behave this way. Any ideas why it does? I have my own idea why, but your opinion , please?

As to the cables, yes they are thin twisted ones, you are right.

Walter

P.S. Get rid of the tilt should be substancial improvement.

Carlo, we've encoutered a problem with uneven VTF. It gradually decreases as the stylus goes from first to last groove, and difference is about 35%. Parallelogramm should not behave this way. Any ideas why it does? I have my own idea why, but your opinion , please?

As to the cables, yes they are thin twisted ones, you are right.

Walter

P.S. Get rid of the tilt should be substancial improvement.

Last edited:

I never noticed it, because I always measured the VTF only in the center, as with any arm. Now I'll check.

The only reason that comes to mind is that the rail is not perfectly leveled and parallel to the disk. This is extremely important, that's why I designed a levelable base, like I did for the Rabbit PLT.

If the parallelogram has too friction, the increasing distance of the rail from the disk can lift the carriage, unloading part of the VTF.

These were the measures of stiction on my arms

MK2 carbon - horizontal movement - stiction F = 1.63 mN - MK1 was stiction F = 1.41 mN

MK2 carbon - vertical movement - stiction F = 2.01 mN - MK1 - stiction F = 4.87 mN

on the carbon the advantage is evident, on the previous the measure was excessive. I believe that a 10-15% VTF variation on warps is rather normal with any arm

Carriage tilting: as I said on a post the dynamic setting must be meticulous (that is, boring), but once in place I had no more problems. As said, for steadier results align the half of the cantilever to the rail center and adjust the rail with respect to the spindle to avoid any overhang.

So if you don't spend your time changing cartridges, it's a flaw that one can happily survive.

ciao - carlo

do this test: play a record with minimal warp, ad look carefully the parallelogram movement (a laser level may help) It must follow every movement flawlessly and immediately. If not, you're still in trouble.

The only reason that comes to mind is that the rail is not perfectly leveled and parallel to the disk. This is extremely important, that's why I designed a levelable base, like I did for the Rabbit PLT.

If the parallelogram has too friction, the increasing distance of the rail from the disk can lift the carriage, unloading part of the VTF.

These were the measures of stiction on my arms

MK2 carbon - horizontal movement - stiction F = 1.63 mN - MK1 was stiction F = 1.41 mN

MK2 carbon - vertical movement - stiction F = 2.01 mN - MK1 - stiction F = 4.87 mN

on the carbon the advantage is evident, on the previous the measure was excessive. I believe that a 10-15% VTF variation on warps is rather normal with any arm

Carriage tilting: as I said on a post the dynamic setting must be meticulous (that is, boring), but once in place I had no more problems. As said, for steadier results align the half of the cantilever to the rail center and adjust the rail with respect to the spindle to avoid any overhang.

So if you don't spend your time changing cartridges, it's a flaw that one can happily survive.

ciao - carlo

do this test: play a record with minimal warp, ad look carefully the parallelogram movement (a laser level may help) It must follow every movement flawlessly and immediately. If not, you're still in trouble.

Last edited:

Walter, knowing your skill the thing worried me, so yesterday after dinner I wanted to check the VTF problem.

I placed the arm on the testing turntable which allows the fastest settings, and leveled it the best I could (using a bubble level and the movement of the carriage itself, which is even more sensible)

Weight on the middle 1,96 gr (+- equal to what set on the other TT) - weight on outer 1,73 - weight on inner 2.12.

Different, damn **!!** But different also from your. (increasing instead of decreasing)

Another source of doubt was about the cart movement and his variable support, but the problem shouldn't be there, if I'm not mistaken. (attachment)

Since in my testing turntable there is a micrometric adjustment for the arm base (on LC carbon the leveling base in quite uncomfortable, larger and better that on the MK1), I tried to set it while controlling the digital scale: magic! an immediate and significant VTF change. This seems to confirm yesterday thoughts

You and Eduard have found the more precise way to level the arm (constant VTF measurements). Quite easy too. Now measures are almost uniform, thxs

carlo

What is your hypothesis?

I placed the arm on the testing turntable which allows the fastest settings, and leveled it the best I could (using a bubble level and the movement of the carriage itself, which is even more sensible)

Weight on the middle 1,96 gr (+- equal to what set on the other TT) - weight on outer 1,73 - weight on inner 2.12.

Different, damn **!!** But different also from your. (increasing instead of decreasing)

Another source of doubt was about the cart movement and his variable support, but the problem shouldn't be there, if I'm not mistaken. (attachment)

Since in my testing turntable there is a micrometric adjustment for the arm base (on LC carbon the leveling base in quite uncomfortable, larger and better that on the MK1), I tried to set it while controlling the digital scale: magic! an immediate and significant VTF change. This seems to confirm yesterday thoughts

You and Eduard have found the more precise way to level the arm (constant VTF measurements). Quite easy too. Now measures are almost uniform, thxs

carlo

What is your hypothesis?

Attachments

Last edited:

variable VTF

Hi, Carlo. I'm pretty sure that problem is in Roberval balance, and not in leveling or friction. If we compare Lil Casey with wooden model (which has true Roberval balance, and so the balance can not be changed by shifting counterweight, nor by shifting another weight), we may see that right half of Lil Casey is the same, but the left half is mechanically different (it has no vertical bar connected to both horizontal ones), and so it isn't true parallelogramm, despite it looks very similar to it. That is the reason, why we may balance Lil Casey by shifting its counterweight, but from the other hand it causes said problem while cartridge travels horizontally. If we change configuration back to Roberval, VTF will be constant all the way. However, it will require another method to counterbalance the arm. Not a big problem.

Hi, Carlo. I'm pretty sure that problem is in Roberval balance, and not in leveling or friction. If we compare Lil Casey with wooden model (which has true Roberval balance, and so the balance can not be changed by shifting counterweight, nor by shifting another weight), we may see that right half of Lil Casey is the same, but the left half is mechanically different (it has no vertical bar connected to both horizontal ones), and so it isn't true parallelogramm, despite it looks very similar to it. That is the reason, why we may balance Lil Casey by shifting its counterweight, but from the other hand it causes said problem while cartridge travels horizontally. If we change configuration back to Roberval, VTF will be constant all the way. However, it will require another method to counterbalance the arm. Not a big problem.

Attachments

Last edited:

Walter, what you say is interesting but in my opinion not correct: at least not for the variation of the VTF during tracing.

Let's go back to the beginning:

A - we have a rail along which travels the carriage, then a moving center of gravity: a parallelogram scale is insensitive to the shifting of weights on the plates. That's the reason why I used it.

B - On the other "plate" we have instead a fixed Cw, so there is no need for the parallegram. That's the reason why I abolished it (together with its 2 or 4 bearings).

That half behaves like a normal pivoted one: the inclination causes a very slight approach to the fulcrum of the CW center of gravity, with variations of the recall quite negligible for the angles found due to warps or disks of different thicknesses. Using long levers I would have less inclination and therefore less variations, but also a greater weight of the mobile masses, which instead has very harmful effects.

On a leveled rail (constant distance from the disk) during the tracing the carriage slides without weight variations seen from the scale, so the parallelogram remains completely still, as you can see by moving the carriage not touching the disk sirface.

Without inclinations of the parallelogram there can be no variations of the recall of the CW, and therefore of the VTF.

On a slanted rail (variable distance from the disk) the carriage lifts from the rail, increasing his VTF with the part of his weight no more supported by the rail: an ideal parallelogram should restore the distance immediately, but a real one has some stiction that brakes the action: the variations of VTF found on mine are strangely similar to the 200 mg stiction I had previously measured.

In reality I believe that, since perfect discs do not exist, everything moves continuously and acts in a friction regime that is much more favorable, with VTF variations similar to the great majority of TA.

carlo

hoping I was able to explain this in english

Let's go back to the beginning:

A - we have a rail along which travels the carriage, then a moving center of gravity: a parallelogram scale is insensitive to the shifting of weights on the plates. That's the reason why I used it.

B - On the other "plate" we have instead a fixed Cw, so there is no need for the parallegram. That's the reason why I abolished it (together with its 2 or 4 bearings).

That half behaves like a normal pivoted one: the inclination causes a very slight approach to the fulcrum of the CW center of gravity, with variations of the recall quite negligible for the angles found due to warps or disks of different thicknesses. Using long levers I would have less inclination and therefore less variations, but also a greater weight of the mobile masses, which instead has very harmful effects.

On a leveled rail (constant distance from the disk) during the tracing the carriage slides without weight variations seen from the scale, so the parallelogram remains completely still, as you can see by moving the carriage not touching the disk sirface.

Without inclinations of the parallelogram there can be no variations of the recall of the CW, and therefore of the VTF.

On a slanted rail (variable distance from the disk) the carriage lifts from the rail, increasing his VTF with the part of his weight no more supported by the rail: an ideal parallelogram should restore the distance immediately, but a real one has some stiction that brakes the action: the variations of VTF found on mine are strangely similar to the 200 mg stiction I had previously measured.

In reality I believe that, since perfect discs do not exist, everything moves continuously and acts in a friction regime that is much more favorable, with VTF variations similar to the great majority of TA.

carlo

hoping I was able to explain this in english

Last edited:

VTF

Carlo, I've measured VTF with digital scale on flat immovable record, and also on platter mat without record, moving scale gradually to center. I was really surprized to see VTF variations on different diameters. Starting 3,5 gramm on first groove, going down to 2gramm on last one. Seems too much for small inclination, even if it remains (arm rail and platter cheked by bulb levels). Stylus was placed onto immovable scale for every measurement.

Anyway, if you still have that wooden model, it is easy to check my assumptions experimentally. I would like to do it myself, but I don't have a model yet. Maybe I'll make one for that purpose, as well as to check my variant of spring and counterweight arrangement. Will take time.

I'm not like Sir Isaac Newton in mechanics, so there is a probability I'm wrong, but I suppose it is rather small.

Walter

Carlo, I've measured VTF with digital scale on flat immovable record, and also on platter mat without record, moving scale gradually to center. I was really surprized to see VTF variations on different diameters. Starting 3,5 gramm on first groove, going down to 2gramm on last one. Seems too much for small inclination, even if it remains (arm rail and platter cheked by bulb levels). Stylus was placed onto immovable scale for every measurement.

Anyway, if you still have that wooden model, it is easy to check my assumptions experimentally. I would like to do it myself, but I don't have a model yet. Maybe I'll make one for that purpose, as well as to check my variant of spring and counterweight arrangement. Will take time.

I'm not like Sir Isaac Newton in mechanics, so there is a probability I'm wrong, but I suppose it is rather small.

Walter

Last edited:

I'm not like Sir Isaac Newton in mechanics, so there is a probability I'm wrong, but I suppose it is rather small.

Walter

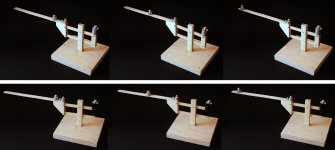

Nor do I ! - after having posted the first hypothesis of the parallelogram #2384, I finally found the solution #2435 only after spending a lot of time playing with the mock up.

I found it (in pieces) for these new photos (attachment): hope convincing - but do the same test with your arm, which is much more accurate.

Briefly it behaves like a hybrid steelyard, on one side there is a plate on which you can move the center of gravity without changing the weight seen by the scale, on the other a rod with a fixed (adjustable)weight to balance it.

Carlo, I've measured VTF with digital scale on an immovable record, I was really surprised to see VTF variations on different diameters.

That's what I did too, finding myself surprising VTF differences. #3015**

But then I adjusted the rail leveling micrometrically, while checking the variations on the digital scale, finally getting a uniform VTF (only 3-4 mg of difference) over the entire carriage displacement. It's now clear that with the level you cannot make a fairly accurate set up. I advise you to do the same.

I believe that by working together (all those willing to try a radial rail) we can bring the Lil Casey to be an everyday tonearm, compact, easy and comfortable to use, and probably better than many others.

carlo

** after those measures do you understand why I don't take particular account of listening tests? I've never heard an audiophile say: "My left channel sounds worse than the right one ..." Although it's practically impossible to get them sounding the same

Walter

Nor do I ! - after having posted the first hypothesis of the parallelogram #2384, I finally found the solution #2435 only after spending a lot of time playing with the mock up.

I found it (in pieces) for these new photos (attachment): hope convincing - but do the same test with your arm, which is much more accurate.

Briefly it behaves like a hybrid steelyard, on one side there is a plate on which you can move the center of gravity without changing the weight seen by the scale, on the other a rod with a fixed (adjustable)weight to balance it.

Carlo, I've measured VTF with digital scale on an immovable record, I was really surprised to see VTF variations on different diameters.

That's what I did too, finding myself surprising VTF differences. #3015**

But then I adjusted the rail leveling micrometrically, while checking the variations on the digital scale, finally getting a uniform VTF (only 3-4 mg of difference) over the entire carriage displacement. It's now clear that with the level you cannot make a fairly accurate set up. I advise you to do the same.

I believe that by working together (all those willing to try a radial rail) we can bring the Lil Casey to be an everyday tonearm, compact, easy and comfortable to use, and probably better than many others.

carlo

** after those measures do you understand why I don't take particular account of listening tests? I've never heard an audiophile say: "My left channel sounds worse than the right one ..." Although it's practically impossible to get them sounding the same

Attachments

Hi Walter, Carlo,

You'll notice in Walters picture of the Roberval balance #3016 that when the load on the two sides is equal the balance is level and when the load is different it isn't. It would seem to follow that if the two sides are made to be at different levels, varying height due to warps, then the load will be different. This could explain why you are getting a variation in tracking force with VTA. I know that the lil casey isn't a true Roberval balance but as long as the counterweight stub is roughly horizontal and the pivot is at the same level as the center of mass of the weight it should operate as if it was.

Niffy

You'll notice in Walters picture of the Roberval balance #3016 that when the load on the two sides is equal the balance is level and when the load is different it isn't. It would seem to follow that if the two sides are made to be at different levels, varying height due to warps, then the load will be different. This could explain why you are getting a variation in tracking force with VTA. I know that the lil casey isn't a true Roberval balance but as long as the counterweight stub is roughly horizontal and the pivot is at the same level as the center of mass of the weight it should operate as if it was.

Niffy

- Home

- Source & Line

- Analogue Source

- DIY linear tonearm