@hartgas, we are similar type of DIYers, just stick to plans and try to refrain from diversions. About the DAllASS III's WAF (Wife Acceptance Factor), they are rather LARGE speakers in both th visual and audio sense, so unless you have a large room to fill... again both visually and audio wise, best to opt for something smaller. The Dallas III plans can be found on www.fullrangedriver.com's gallery section. Good luck in your pursuit and keep us updated.

@David, I got some local plywood for the construction. A mold was created and the plys were glued in layers with the help of the mold. It was finally finished off with a birch veneer.

Update: the Corals are sitting pretty in my cupboard, have not found the time to install them in the Dallas III cabs as yet. I'll try to do it this weekend.

Cheers,

Jason

@David, I got some local plywood for the construction. A mold was created and the plys were glued in layers with the help of the mold. It was finally finished off with a birch veneer.

Update: the Corals are sitting pretty in my cupboard, have not found the time to install them in the Dallas III cabs as yet. I'll try to do it this weekend.

Cheers,

Jason

i just talked with my woodworking companion.

in the drawings of the dallas II we saw the thickness of the material is 14 mm

that seems very thin and flimsy to us.

is there any difference between plywood and solid wood? what about veneered MDF/HDF

@jason,

i saw on the design for the phy drivers, the OB's that mr salabert is using spruce instument wood and into some sort of sandwichfilled with sand. so instead of creating a dead box he is using thin wood and using the box as a resonator as done with musical instruments, any thought on that?

didn't you go for a thick baffle or is that integrated?

@ron

you said things developed from there and seems antiqutated, feel free to enlighten us.

thanks sofar with all the info

greetings

~joris

in the drawings of the dallas II we saw the thickness of the material is 14 mm

that seems very thin and flimsy to us.

is there any difference between plywood and solid wood? what about veneered MDF/HDF

@jason,

i saw on the design for the phy drivers, the OB's that mr salabert is using spruce instument wood and into some sort of sandwichfilled with sand. so instead of creating a dead box he is using thin wood and using the box as a resonator as done with musical instruments, any thought on that?

didn't you go for a thick baffle or is that integrated?

@ron

you said things developed from there and seems antiqutated, feel free to enlighten us.

thanks sofar with all the info

greetings

~joris

Yes. Depends on what type of wood.

People do seem to get obsessed over resonance. Remember, assuming the material is stiff enough for the purpose in hand, it doesn't matter if it rings like a bell if the natural resonance frequency of the panels is above the operational passband of the cabinet. That's why CRS is ideal for many cabinets. Personally, I don't like MDF / HDF. Not stiff enough, it kills you, and its resonant frequency is right where you don't want it, so you either need to use far more bracing than plywood requires, or double up the panels to push resonance down, below the cabinet's passband. Which has its own problems, like energy storage & slow decay time etc. Not good.

I'm not Ron, but his software & ability to plot wavefronts, and the different actions, has improved greatly since Dallas was designed (as if it wasn't good enough to start with) -current state of the art are his Austin enclosures.

People do seem to get obsessed over resonance. Remember, assuming the material is stiff enough for the purpose in hand, it doesn't matter if it rings like a bell if the natural resonance frequency of the panels is above the operational passband of the cabinet. That's why CRS is ideal for many cabinets. Personally, I don't like MDF / HDF. Not stiff enough, it kills you, and its resonant frequency is right where you don't want it, so you either need to use far more bracing than plywood requires, or double up the panels to push resonance down, below the cabinet's passband. Which has its own problems, like energy storage & slow decay time etc. Not good.

I'm not Ron, but his software & ability to plot wavefronts, and the different actions, has improved greatly since Dallas was designed (as if it wasn't good enough to start with) -current state of the art are his Austin enclosures.

you said things developed from there and seems antiqutated, feel free to enlighten us.

Well , first off a sound wave is spherical in nature, a wave travelling thru a medium is a very complex set of actions, there are energy exchanges (much beyond the inverse square law) that have to do with heat production or a transfer of one form of energy to another. As a wave encounters a reflection medium there is an exchange of energy, as it reflects the wave front changes shape. Its fairly endless.

I have some thoughts on the subject in the FR forum in the articles section. If you ever have insominia , please dont count sheep, just read my posts ( i hear they are reading my posts to patients in the hospital before an operation, cuts down on the cost of putting them out).

ron

Well , first off a sound wave is spherical in nature, a wave travelling thru a medium is a very complex set of actions, there are energy exchanges (much beyond the inverse square law) that have to do with heat production or a transfer of one form of energy to another. As a wave encounters a reflection medium there is an exchange of energy, as it reflects the wave front changes shape. Its fairly endless.

I have some thoughts on the subject in the FR forum in the articles section. If you ever have insominia , please dont count sheep, just read my posts ( i hear they are reading my posts to patients in the hospital before an operation, cuts down on the cost of putting them out).

ron

ronc said:The Dallas was designed with my original programming, things have advanced from then.

As i look on it now its fairly antiquated.

ron

Does this mean we will see a Dallas IV anytime soon?

don9146 said:

Does this mean we will see a Dallas IV anytime soon?

I'm guessing that if/when it comes it will be A206.

dave

jasonlky said:@hartgas, we are similar type of DIYers, just stick to plans and try to refrain from diversions. About the DAllASS III's WAF (Wife Acceptance Factor), they are rather LARGE speakers in both th visual and audio sense, so unless you have a large room to fill... again both visually and audio wise, best to opt for something smaller. The Dallas III plans can be found on www.fullrangedriver.com's gallery section. Good luck in your pursuit and keep us updated.

@David, I got some local plywood for the construction. A mold was created and the plys were glued in layers with the help of the mold. It was finally finished off with a birch veneer.

Update: the Corals are sitting pretty in my cupboard, have not found the time to install them in the Dallas III cabs as yet. I'll try to do it this weekend.

Cheers,

Jason

hi Jason

how do the corals sound?

I'm guessing that if/when it comes it will be A206.

Right on! Slightly different expansion rates, a bit wider and will not need a SB(its sort of built in). Second pass showed a 34 hz bottom frequency, corner loaded. just working out the structural patterns. This will require external bracing stringers so WAF leaves the scene. Room should be on the larger volume. Flea amps would work very well.

I gave up on the Houston, it was just too complicated for a build.

Sorry i havent been more active, but the demands from work is very great.

ron

Right on! Slightly different expansion rates, a bit wider and will not need a SB(its sort of built in). Second pass showed a 34 hz bottom frequency, corner loaded. just working out the structural patterns. This will require external bracing stringers so WAF leaves the scene. Room should be on the larger volume. Flea amps would work very well.

I gave up on the Houston, it was just too complicated for a build.

Sorry i havent been more active, but the demands from work is very great.

ron

Coral 8A-40 tested in the Dallas III cabinets

Its time to breathe new life into this thread....

@Ron, I look forward to the next speaker design from you. I would certainly build it since I know what you are capable of.... In the mean time I have tried the resistors in series with the speakers and did not care for them. The 206 and Dallas III seem good enough without them. Thanks for the suggestion though. By the way with an air tight seal the speakers seem to breathe better down low.

Coral 8A-40

Well I have finally found some time to listen to the Coral 8A-40s that Yeo of diyparadisewas kind enough to lend me. The looong version can be found in my diy audio blog.

The short version....

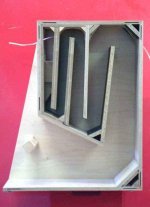

The Coral 8A-40 are very competent speakers but not enough to replace my Fostex FE206E. I understand that many here would disagree with me, Yeo especially but these are what my ears tell me. For the money, the Coral 8A-40 are truly unbeatable, that is if you can still find them. But for a few more dollar bills, the Fostex FE206E is better. Here a pic showing the magnets of both drivers, the FOstex FE206E is full 3 times larger and heavier than the Coral 8A-40.

Jason

ps - I managed a quick listen to Yeo's Hedlunds. They play LOUD and FAST!!! I am amazed at how well the Coral Beta 6 performed. The hedlunds look physically larger due to its height, but its a single fold design while the Dallas III is a double fold design, as such they are both very similar in size. And from what I can see the Hedlunds are a simpler build compared to my Dallas III simply because with the Hedlunds, there is only a single fold to contend with, while on the Dallas there are 2 folds to work on.

Its time to breathe new life into this thread....

@Ron, I look forward to the next speaker design from you. I would certainly build it since I know what you are capable of.... In the mean time I have tried the resistors in series with the speakers and did not care for them. The 206 and Dallas III seem good enough without them. Thanks for the suggestion though. By the way with an air tight seal the speakers seem to breathe better down low.

Coral 8A-40

Well I have finally found some time to listen to the Coral 8A-40s that Yeo of diyparadisewas kind enough to lend me. The looong version can be found in my diy audio blog.

The short version....

The Coral 8A-40 are very competent speakers but not enough to replace my Fostex FE206E. I understand that many here would disagree with me, Yeo especially but these are what my ears tell me. For the money, the Coral 8A-40 are truly unbeatable, that is if you can still find them. But for a few more dollar bills, the Fostex FE206E is better. Here a pic showing the magnets of both drivers, the FOstex FE206E is full 3 times larger and heavier than the Coral 8A-40.

An externally hosted image should be here but it was not working when we last tested it.

Jason

ps - I managed a quick listen to Yeo's Hedlunds. They play LOUD and FAST!!! I am amazed at how well the Coral Beta 6 performed. The hedlunds look physically larger due to its height, but its a single fold design while the Dallas III is a double fold design, as such they are both very similar in size. And from what I can see the Hedlunds are a simpler build compared to my Dallas III simply because with the Hedlunds, there is only a single fold to contend with, while on the Dallas there are 2 folds to work on.

And from what I can see the Hedlunds are a simpler build compared to my Dallas III simply because with the Hedlunds, there is only a single fold to contend with, while on the Dallas there are 2 folds to work on.

If you look at a true horn profile its a inconstant change(M factor) in area as the wave expands. Due to the fact that DIYers would have trouble making curves all i did was to break up the curves to point expansions. 3 sections gave me greater control over the expansion rates than 2. If you want simple then use a BIB, to me if properly designed so that there is no direct reflection back to the mouth and an outboard filter chamber is used and there is a greater final end expansion then it will outperform the Hedlunds by a great margin and be a much more simple build. Trust me, it will go lower with less distortion and be the same relative height.

ron

If you look at a true horn profile its a inconstant change(M factor) in area as the wave expands. Due to the fact that DIYers would have trouble making curves all i did was to break up the curves to point expansions. 3 sections gave me greater control over the expansion rates than 2. If you want simple then use a BIB, to me if properly designed so that there is no direct reflection back to the mouth and an outboard filter chamber is used and there is a greater final end expansion then it will outperform the Hedlunds by a great margin and be a much more simple build. Trust me, it will go lower with less distortion and be the same relative height.

ron

ronc said:I'm guessing that if/when it comes it will be A206.

Right on! Slightly different expansion rates, a bit wider and will not need a SB(its sort of built in). Second pass showed a 34 hz bottom frequency, corner loaded. just working out the structural patterns. This will require external bracing stringers so WAF leaves the scene. Room should be on the larger volume. Flea amps would work very well.

ron

Hiya Ron.... This design that you are currently working sounds real interesting, a 34Hz bottom end is not to be messed around with. Just as I was ticking off my checklist, I came accross corner loading. I do have a very large bedroom to fill, problem is corners are very far apart, what do your sims tell you about rear wall loading?

ronc said:If you look at a true horn profile its a inconstant change(M factor) in area as the wave expands. Due to the fact that DIYers would have trouble making curves all i did was to break up the curves to point expansions. 3 sections gave me greater control over the expansion rates than 2. If you want simple then use a BIB, to me if properly designed so that there is no direct reflection back to the mouth and an outboard filter chamber is used and there is a greater final end expansion then it will outperform the Hedlunds by a great margin and be a much more simple build. Trust me, it will go lower with less distortion and be the same relative height.

ron

I did consider building a BIB before I settled on the Dallas III, but was caught up by its inherent ripple effects and the requirement for corner loading. I obviouly did not know how to properly design one, so BIBs went out the window...

Jason

I have kinda lost interest in Big BLHs. Complexity/cost/size is the sticker. Trying to make a single driver BLH (despite the enclosure size) is a series of comprimses.

I have been very impressed with Martins 2 way OBs. I do like the OB sound,however they lack the bottom end of either a properly designed BLH or a woofer.

IMHO a BVR suppling up to 240 Hz and either an OB or horn/waveguide from there to the top is a good answer. The OB/BVR is a very simple/cost effective build and for normal listening SPLs will perform in an adequate manner. Many many builds are established around this principal like Basszilla,Altec Mdl 14/19 (except they use a compression driver/horn and XO in the critical range) ect. ect. The BVR IMO is the best comprimise of a BLH and a BR, extended BW and a simple build. Just add an OB for the upper range (horn/waveguide if so inclined or have the talent) and be done with it. Bi amp and you will have a system that will be hard to outperform and be very cost efficent.

ron

I have been very impressed with Martins 2 way OBs. I do like the OB sound,however they lack the bottom end of either a properly designed BLH or a woofer.

IMHO a BVR suppling up to 240 Hz and either an OB or horn/waveguide from there to the top is a good answer. The OB/BVR is a very simple/cost effective build and for normal listening SPLs will perform in an adequate manner. Many many builds are established around this principal like Basszilla,Altec Mdl 14/19 (except they use a compression driver/horn and XO in the critical range) ect. ect. The BVR IMO is the best comprimise of a BLH and a BR, extended BW and a simple build. Just add an OB for the upper range (horn/waveguide if so inclined or have the talent) and be done with it. Bi amp and you will have a system that will be hard to outperform and be very cost efficent.

ron

Yeah, I came to this conclusion back in '67 and never looked back. All my simple pipe horn builds were strictly woofer horns, though XO's could be as high as 500 Hz. In Nov. '69 I experienced bi-amping, active XOs combined with acceptable performance SS power and how to do CD horn EQ, so bye-bye expensive PIA tube systems. In June '70 I learned about separate subs systems, so for me the 'circle' was complete until digital delay and most recently, 80 Hz Unity concept horns, reducing the 'circle' back to a nominally two way system.

GM

GM

Yeah, I came to this conclusion back in '67 and never looked back

I am slow Greg, (a Texan) so it takes me longer.

Yeah. That's why I've ended up trying to simplify everything as far as I possibly can of late. The more complicated things get, the more variables there are. And more to go wrong.

Thus my (actually my Mentor) motto "the hardest thing you can do is to make something simple".

I have learned that in industrial design that simple is better. Once you start to make something complicated that unknown variables enter and the system becomes unstable. Too many engineers depend on correction or control by computers. To the young today its easier to correct for design flaws by puter correction rather than design correctly in the first place. When i first entered the field all we had was analog, yes we had to work harder to find an answer but there are still systems in use that i designed over 30 years ago. All this sums up to what i learned from my mentor.

1. Make it simple.

2. Make it cost effective.

3. Make it easy to build.

4. Make it easy to operate.

5. Make it reliable.

ron

I am slow Greg, (a Texan) so it takes me longer.

Yeah. That's why I've ended up trying to simplify everything as far as I possibly can of late. The more complicated things get, the more variables there are. And more to go wrong.

Thus my (actually my Mentor) motto "the hardest thing you can do is to make something simple".

I have learned that in industrial design that simple is better. Once you start to make something complicated that unknown variables enter and the system becomes unstable. Too many engineers depend on correction or control by computers. To the young today its easier to correct for design flaws by puter correction rather than design correctly in the first place. When i first entered the field all we had was analog, yes we had to work harder to find an answer but there are still systems in use that i designed over 30 years ago. All this sums up to what i learned from my mentor.

1. Make it simple.

2. Make it cost effective.

3. Make it easy to build.

4. Make it easy to operate.

5. Make it reliable.

ron

very good I agree complet:

"I have learned that in industrial design that simple is better. Once you start to make something complicated that unknown variables enter and the system becomes unstable. Too many engineers depend on correction or control by computers. To the young today its easier to correct for design flaws by puter correction rather than design correctly in the first place. When i first entered the field all we had was analog, yes we had to work harder to find an answer but there are still systems in use that i designed over 30 years ago. All this sums up to what i learned from my mentor.

1. Make it simple.

2. Make it cost effective.

3. Make it easy to build.

4. Make it easy to operate.

5. Make it reliable."

"I have learned that in industrial design that simple is better. Once you start to make something complicated that unknown variables enter and the system becomes unstable. Too many engineers depend on correction or control by computers. To the young today its easier to correct for design flaws by puter correction rather than design correctly in the first place. When i first entered the field all we had was analog, yes we had to work harder to find an answer but there are still systems in use that i designed over 30 years ago. All this sums up to what i learned from my mentor.

1. Make it simple.

2. Make it cost effective.

3. Make it easy to build.

4. Make it easy to operate.

5. Make it reliable."

Attachments

BLH

I thought the single driver concept was pretty simple. Complexity and comprimises is the designers problem. As far as construction, once I got the full size drawing made[ and accurate] the work of cutting and glueing wasn't too bad. A lot of work really, but the reward was there in the end.

Ron, i wish you'd get back to the 206 Austin and turn it loose on us. The 166 A is fine speaker design..The instruments sound correct and the lower end is presented like a finely carved statue. We do our part, you do yours. Times a wasting.

Bob

I thought the single driver concept was pretty simple. Complexity and comprimises is the designers problem. As far as construction, once I got the full size drawing made[ and accurate] the work of cutting and glueing wasn't too bad. A lot of work really, but the reward was there in the end.

Ron, i wish you'd get back to the 206 Austin and turn it loose on us. The 166 A is fine speaker design..The instruments sound correct and the lower end is presented like a finely carved statue. We do our part, you do yours. Times a wasting.

Bob

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- DIY Back Loaded Horn - Dallas III for Fostex 206E