Peter Daniel said:As to bending, don't have any experience with that, and I don't think it will be easy, if possible at all.

Would probably make it milky if I could do it. Better off to glue the pieces (baffle to bottom)

MJL21193 said:

Dave, you are the MAN! I'm thinking I'll use my Vifa PL18 and have the box~ 15 litres. Sides, front/back 10 x 12 inches; top/bottom 10 x 10.

Email cost of postage and how I will pay you.

I will be away for a week starting next week, so I'm looking forward to doing this when I return. Should be enlightening.

No braces... those are pretty large unbraced spans...

dave

Peter Daniel said:Hi Dave,

I'm not sure how it relates to your particular bracing, but I tried to use a support bracket with Fertins and it didn't work well.

I was a bit dissapointed as I thought that would be an improvement, but it wasn't; it sounds better without magnet supported in a back. The baffle is made out of 3" acrylic and mounted inside a stud wall with cavities filled with sand.

I'd say all bets are off until you open up that tunnel uou have it mounted in... if it is 3" think and the driver hole is 7" then the rear opening should be approaching 13" in diameter.

Your brace is also just holding it to the baffle and not to the rest of the structure (in this case your house.

dave

planet10 said:

No braces... those are pretty large unbraced spans...

dave

No braces, I want the panels to resonate. After first tests I will reduce box size and test again with a smaller driver.

planet10 said:I'd say all bets are off until you open up that tunnel uou have it mounted in... if it is 3" think and the driver hole is 7" then the rear opening should be approaching 13" in diameter.

Your brace is also just holding it to the baffle and not to the rest of the structure (in this case your house.

The baffle itself is 12" square and it's pressure fitted between stud's frame so it could be regarded as part of the house. I still need to insert a box filled with sand on top, but somehow it was never my priority.

Though it may look like a tunnel, it doesn't feel like, besides, I did increase the opposite side dia. to 9", that all what seemed to be reasonable without compromising rigidity.

Still, tunnel or not tunnel, the sound with a bracket lost microdynamics and became "dull"

Peter Daniel said:

Still, tunnel or not tunnel, the sound with a bracket lost microdynamics and became "dull"

Bracing the magnet assembly on a large driver makes sense. I'm a firm believer. Bracing a small one is probably not needed, especially if the magnet is larger. Added mass plus shorter basket spans make a stable unit.

planet10 said:

We might have enuff 12mm scraps to cut the bits for your box (we are trying to standardize on 15mm so we can buy a lift at a time) Given how cheap Canada Post is that might be the most efficient way to get the BB (ie we give you the pieces you pay the post)

dave

Dave, I will pick up full sheet today. It's only $26.15 for the 1/2" and what I don't use will not go to waste.

Thanks for the offer though.

John

MJL21193 said:[Dave, I will pick up full sheet today. It's only $26.15 for the 1/2" and what I don't use will not go to waste.

That is the kind of price you get buying an entire lift at wholesale.

Are we talking the same stuff? Baltic Birch -- a full sheet is 60"x60".

Any substitute needs to be void free. We aren't talking just any plywood.

dave

planet10 said:

That is the kind of price you get buying an entire lift at wholesale.

Are we talking the same stuff? Baltic Birch -- a full sheet is 60"x60".

Any substitute needs to be void free. We aren't talking just any plywood.

The $26.15 is the price quoted to me over the phone. $39.15 for 3/4 inch. I'm sorry Dave, but you have to realize that I live in the industrial heartland of Canada, not out on the fringe like you British Columbians.

It was my intention to pick it up today after a meeting I had in the area. The meeting dragged on and didn't exactly go my way. Traffic was heavy, so I just came home. See how work can be unhealthy for a hobby?

It is, from the guy on the phone's description real baltic birch plywood. 5' x 5' sheet, lots of plys.

I'll find out for sure tomorrow. They open at 7 am, I will make a detour on my way to work and get it.

planet10 said:

That is the kind of price you get buying an entire lift at wholesale.

Are we talking the same stuff? Baltic Birch -- a full sheet is 60"x60".

$26.10 is what I paid. 9 ply baltic birch plywood.

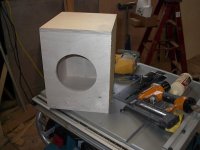

I have just came in from my shop where I was playing with it. I have built the first enclosure for the resonance test, and had enough left over to start a small pair to replace my rear surrounds.

I will admit it's more pleasant to work with than MDF, dust is sweeter.

Here's a pic of the first box:

Attachments

MJL21193 said

OK, I guess you guys deserve some compensation for having to live that far from the ocean; but $40 a sheet for 3/4" BB - I too am envious.

Aengus

The $26.15 is the price quoted to me over the phone. $39.15 for 3/4 inch. I'm sorry Dave, but you have to realize that I live in the industrial heartland of Canada, not out on the fringe like you British Columbians.

OK, I guess you guys deserve some compensation for having to live that far from the ocean; but $40 a sheet for 3/4" BB - I too am envious.

Aengus

The redbud are in full bloom...thunderstorms rolled across Kentucky this evening...heralding the arrival of a cold front...redbud winter...Thank God for the light show with a sound track...stirs the soul...

Dave et al,

I've given some thought to a holey baffle...have a pair roughed up...need to ask: What is the proportion of hole to solid?

Also, I'm considering the use of a ~3/16" felt to wrap the holey baffle with. I feel that since it is the first surface "seen" by the backwave that it needs some treatment. My thoughts are to roundover the holes and stop the felt short...not to constrict the holes. I ask your comments.

Baffles are glued up, sanded, ready to route the recesses. The bookmatch line will bisect the offset tweeter.

Dave et al,

I've given some thought to a holey baffle...have a pair roughed up...need to ask: What is the proportion of hole to solid?

Also, I'm considering the use of a ~3/16" felt to wrap the holey baffle with. I feel that since it is the first surface "seen" by the backwave that it needs some treatment. My thoughts are to roundover the holes and stop the felt short...not to constrict the holes. I ask your comments.

Baffles are glued up, sanded, ready to route the recesses. The bookmatch line will bisect the offset tweeter.

Ed Lafontaine said:I've given some thought to a holey baffle...have a pair roughed up...need to ask: What is the proportion of hole to solid?

I'd guess 30-40% holes... sometimes hard to get that high.

Also, I'm considering the use of a ~3/16" felt to wrap the holey baffle with. I feel that since it is the first surface "seen" by the backwave that it needs some treatment. My thoughts are to roundover the holes and stop the felt short...not to constrict the holes.

Pretty much what we do... the frequencies of interest to the holes won't see the felt, the ones you want to kill so they don't reflect will be killeed more effectively in the air trap between the 2 surfaces (ie just felt the whole thing (or at least the part near the driver -- that is all we usually do)

dave

Ed Lafontaine said:

I've given some thought to a holey baffle...have a pair roughed up...need to ask: What is the proportion of hole to solid?

Having just finished a few of these holes myself, I can say it's pretty tedious. Not sure if rounding over the edge of the holes is beneficial.

Ed, your avatar and a few of your words suggest that you might have a scatter gun handy to make quick work of them holes

you might have a scatter gun handy

Mongo is a hunter/gatherer who can't reach too high on the tree. He has collected an assortment of larger spade bits and holes saws up to 4 1/4" that aid in the task.

I need to get the camera from my wife.

Corian for front baffles, etc.

Where do you get Corian milled? Ie: so that it could be routed out for flush mounting drivers, putting a slight round over on the sides, etc. Does anyone know of a company that does Corian work for anything other than countertops? I was thinking a Corian for my front baffle. Perhaps I should just stick to using BB with veneer overtop.

Vince

MJL21193 said:

Are you refering to the steel? I would actually be interested in building a speaker from steel, but I,m not convinced the results would be any better. It's expensive, heavy and requires skills to work with that the average woodworker doesn't have (no matter how many episodes of Monster Garage you've watched.).

You want stiffness, do what Wilson audio does - use Corian. Now that's something I'd like to try. I've worked with it before (counter top obviously) It glues together, and the glue joins the parts and leaves no seam. Very heavy, very strong.

Where do you get Corian milled? Ie: so that it could be routed out for flush mounting drivers, putting a slight round over on the sides, etc. Does anyone know of a company that does Corian work for anything other than countertops? I was thinking a Corian for my front baffle. Perhaps I should just stick to using BB with veneer overtop.

Vince

Re: Corian for front baffles, etc.

Corian can be worked with standard wood working tools - routers, saws. It's real hard plastic.

vincentrubble said:

Where do you get Corian milled? Ie: so that it could be routed out for flush mounting drivers, putting a slight round over on the sides, etc. Does anyone know of a company that does Corian work for anything other than countertops? I was thinking a Corian for my front baffle. Perhaps I should just stick to using BB with veneer overtop.

Vince

Corian can be worked with standard wood working tools - routers, saws. It's real hard plastic.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Design & Build

- Construction Tips

- Discussion on what materials to build speakers out of