Re: Re: Re: Re: Carbon fibre.

Dave's not here too (althou John was never immoralized by Tommy Chong)

dave

vincentrubble said:There seem to be alot of Johns around here

Dave's not here too (althou John was never immoralized by Tommy Chong)

dave

Re: Re: Re: Re: Carbon fibre.

Ok Vince.

You want everyone to agree with you? Or do you want objective opinions?

I don't bash for the sake of bashing.

I don't think there's any chance that you and I will be confused for each other.

vincentrubble said:

Thanks Dave. This was my line of thinking too. There seem to be alot of Johns around here so I will henceforth call myself Vince to avoid confusion.

Ok Vince.

You want everyone to agree with you? Or do you want objective opinions?

I don't bash for the sake of bashing.

I don't think there's any chance that you and I will be confused for each other.

Re: Re: Re: Re: Carbon fibre.

HDF is rigid on it's own. It will gain little from the formica layers.

Plywood and MDF are made for stability, solid wood is more sound.

vincentrubble said:

Why are the benefits negated? This whole principle combined with the extra strength added by having a variety of grain directions is the reason that many consider plywood to be structurally more sound than solid wood or mdf.

Thanks,

John

HDF is rigid on it's own. It will gain little from the formica layers.

Plywood and MDF are made for stability, solid wood is more sound.

Re: Re: Re: Carbon fibre.

No benefit for the size baffle he's refering to. Too much effort for little return. Not worth doing.

Not for "killing" resonance.

Wilson Benesch use of carbon fibre = marketing.

planet10 said:John is completely off-base if he thinks your technique won't have benefit.

No benefit for the size baffle he's refering to. Too much effort for little return. Not worth doing.

planet10 said:Using dissimilar thickness layers is a well recognized technique.[/B]

Not for "killing" resonance.

planet10 said:Not many. Carbon Fibre is a whole nother thing to fibreglass (akin to the difference between cardboard & MDF)... dramatically stiffer. Wilson Benesch use a lot of carbon fibre.

[/B]

Wilson Benesch use of carbon fibre = marketing.

What I'm going to suggest assumes 2 goals and I'd also guess this would probably be most applicable in an acoustic suspension design.

Goal 1) Prevent sound energy generated by the backwave of a driver from reaching the outer surface of the enclosure and thus radiating into the room.

Goal 2) Prevent sound waves from leaking back through the driver membrane and radiating into the room.

What about building a miniature anechoic chamber inside a fairly rigid and well braced enclosure made from baltic birch, mdf, whatever...? Would that science be scalable to work inside an enclosure at some level? Not suggesting it would be perfect but it may be an additive solution that would enhance the properties of the base material used in constructing the enclosure.

I'm thinking the triangular shapes could be manufactured from a non-exotic material. They'd need to store the sound energy and release it extremely slowly as heat. I think that is the basic principal in the full-sized chambers. Cork? Balsa? I guess you could use something like rigid fiberglass, but making all those--that is getting dangerously close to dollhouse territory.

This might also be like the box inside a box theory, but this inside box could have a vastly larger surface area exposed to the sound energy on the inside. Would that provide any benefit?

Goal 1) Prevent sound energy generated by the backwave of a driver from reaching the outer surface of the enclosure and thus radiating into the room.

Goal 2) Prevent sound waves from leaking back through the driver membrane and radiating into the room.

What about building a miniature anechoic chamber inside a fairly rigid and well braced enclosure made from baltic birch, mdf, whatever...? Would that science be scalable to work inside an enclosure at some level? Not suggesting it would be perfect but it may be an additive solution that would enhance the properties of the base material used in constructing the enclosure.

I'm thinking the triangular shapes could be manufactured from a non-exotic material. They'd need to store the sound energy and release it extremely slowly as heat. I think that is the basic principal in the full-sized chambers. Cork? Balsa? I guess you could use something like rigid fiberglass, but making all those--that is getting dangerously close to dollhouse territory.

This might also be like the box inside a box theory, but this inside box could have a vastly larger surface area exposed to the sound energy on the inside. Would that provide any benefit?

Attachments

Re: Re: Re: Re: Carbon fibre.

It not exactly a novel idea - MDF and particle board are of a similar structure. Denser on the outer than the inner. (goes back to the sandwich structure).

Is the intention to build the unit from cedar, then epoxy, or form the material first, then build the unit?

Would it be solid or a cross grain layered? How will the epoxy penetrate the wood, with pressure?

One problem with epoxy on bare wood is that the wood absords the solvent in the epoxy, leaving an unbalanced mix on the surface (one that is lacking in solvent will not cure properly).

If I could be so bold as to recomment another coating that is more stable than epoxy - polyurethane. It will not seperate, and be absorbed into the wood intact, even when thinned.

planet10 said:

You end up with a solid-plasticvery stiff outside skin with a highly damped interior, and the transition between the extremes is very chaotic.

Intelectually it seems a very good building material -- particularily for shapes. This is the proof of concept experiment.

It not exactly a novel idea - MDF and particle board are of a similar structure. Denser on the outer than the inner. (goes back to the sandwich structure).

Is the intention to build the unit from cedar, then epoxy, or form the material first, then build the unit?

Would it be solid or a cross grain layered? How will the epoxy penetrate the wood, with pressure?

One problem with epoxy on bare wood is that the wood absords the solvent in the epoxy, leaving an unbalanced mix on the surface (one that is lacking in solvent will not cure properly).

If I could be so bold as to recomment another coating that is more stable than epoxy - polyurethane. It will not seperate, and be absorbed into the wood intact, even when thinned.

Re: Re: Carbon fibre.

A broader definition of constrained layer is any layering of material with adjacent layers having different acoustic impedance.

dave

MJL21193 said:If you are thinking constrained layer damping, that's not it. Layers need a lossy medium between that will allow the inner layer to flex against the outer layer. Solid attachment means they will act as one.

A broader definition of constrained layer is any layering of material with adjacent layers having different acoustic impedance.

dave

Re: Re: Re: Re: Re: Carbon fibre.

I can tell you from practical results that you are mistaken.

dave

MJL21193 said:HDF is rigid on it's own. It will gain little from the formica layers.

I can tell you from practical results that you are mistaken.

dave

Re: Re: Re: Re: Re: Re: Carbon fibre.

As usual...

planet10 said:

I can tell you from practical results that you are mistaken.

As usual...

Re: Re: Re: Re: Carbon fibre.

Ever heard any of their speakers?

dave

MJL21193 said:Wilson Benesch use of carbon fibre = marketing.

Ever heard any of their speakers?

dave

Re: Re: Re: Re: Re: Carbon fibre.

I don't have to. You can't squeeze great sound out of carbon fiber - it's a building material. If the Wilson Benesch's sound sublime, it's not because they use carbon fiber.

planet10 said:

Ever heard any of their speakers?

I don't have to. You can't squeeze great sound out of carbon fiber - it's a building material. If the Wilson Benesch's sound sublime, it's not because they use carbon fiber.

Re: Re: Re: Re: Re: Carbon fibre.

Not novel at all... in MDF its purpose is to keep the material from falling apart.

dave

MJL21193 said:It not exactly a novel idea - MDF and particle board are of a similar structure.

Not novel at all... in MDF its purpose is to keep the material from falling apart.

dave

Re: Re: Re: Re: Re: Re: Carbon fibre.

Funny.

planet10 said:

..its purpose is to keep the material from falling apart.

Funny.

liasom said:

What about building a miniature anechoic chamber inside a fairly rigid and well braced enclosure made from baltic birch, mdf, whatever...? Would that science be scalable to work inside an enclosure at some level?

Would that provide any benefit?

Any type of vented speaker wouldn't benefit from total absorption of the back wave, as this is used for bass reinforement. A sealed box should be ok with it, but my own experience with stuffing in sealed boxes (which would be a close second to anechoic ) is that it can make the bass sound muffled. I prefer to cover the insides with rubber-backed commercial carpet. This carpet has good damping properties when adhered to the panels. The difference I hear with this is probably in the higher bass region - above 100Hz.

liasom said:Goal 1) Prevent sound energy generated by the backwave of a driver from reaching the outer surface of the enclosure and thus radiating into the room.

Goal 2) Prevent sound waves from leaking back through the driver membrane and radiating into the room.

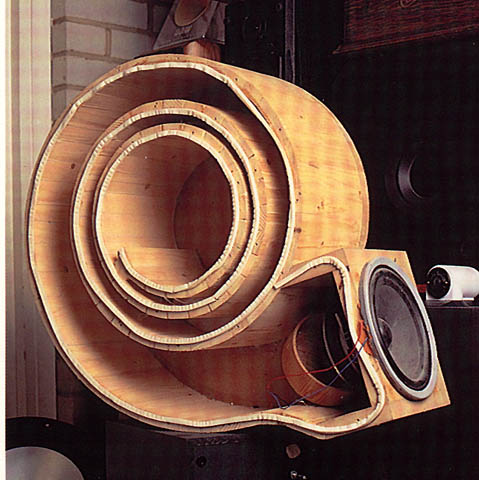

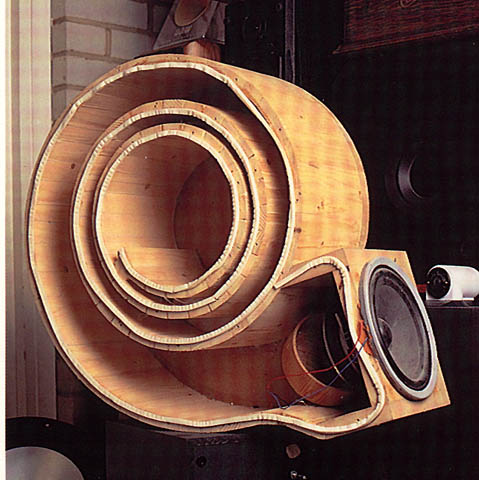

Pretty much B&W's goals when working on the Nautilus....

dave

I can attest to the effectiveness of double walled boxes and horns filled with sand. Having heard, or rather not heard a few, I can tell you that they work great. Very little if any resonance on the outside walls. The same should be true for the inside wall, too. But super heavy and hard to make. Yes indeed.

Very dense marine grade plywood is also another material I've had great success with. Not light either, and not cheap. But very neutral. No box sound.

It would be nice to know how Meyer Sound build their PA boxes. They are extremely well damped. You can thump them or dolly them over rough floors, they don't make a sound. Looks like 3/4" plywood, very dense. One would guess they use very good bracing, too. Whatever it is, it works.

Very dense marine grade plywood is also another material I've had great success with. Not light either, and not cheap. But very neutral. No box sound.

It would be nice to know how Meyer Sound build their PA boxes. They are extremely well damped. You can thump them or dolly them over rough floors, they don't make a sound. Looks like 3/4" plywood, very dense. One would guess they use very good bracing, too. Whatever it is, it works.

planet10 said:

Pretty much B&W's goals when working on the Nautilus....

dave

Oh...man...I bet somebody stayed up ALL NIGHT building that!

MJL21193 said:A sealed box should be ok with it, but my own experience with stuffing in sealed boxes (which would be a close second to anechoic ) is that it can make the bass sound muffled. I prefer to cover the insides with rubber-backed commercial carpet. This carpet has good damping properties when adhered to the panels. The difference I hear with this is probably in the higher bass region - above 100Hz.

I've also heard the muffled sound to varying degrees in stuffed enclosures. That is why I'm thinking to find a way to entirely get rid of stuffing, foam, carpet, etc. in a box shaped sealed enclosure. I have a project in the works requiring small sealed enclosures and am going to try a semi-anechoic idea on a test enclosure. My plan is to make the shapes less deep than those used in the big chambers (see graphic, like on the right side) and to either glue the shapes on only 3 sides--back, bottom, and either left or right or to place them less densely so as to cover about 40%-50% of the interior surface. Probably the latter approach since it might slightly help dampen panel resonances with a bunch of small "braces". I suppose the challenge is to find the right balance. It is so easy to over-dampen an acoustic suspension design. Still investigating to find an appropriate material though.

I figure it's worth a try.

Attachments

You might like to try a method that Dave Berriman used in several of his designs - a sandwich (3) of hardboard stuck together with Evostick and with the rough surface towards the drive units. These were very effective.

Talking of whom, does anyone have a copy of Hi Fi News and Record Review with the article on building his floorstander (DB8 I think) circa 1998. I got a mention in the article but made the mistake of lending my copy to a friend and I never got it back.

Talking of whom, does anyone have a copy of Hi Fi News and Record Review with the article on building his floorstander (DB8 I think) circa 1998. I got a mention in the article but made the mistake of lending my copy to a friend and I never got it back.

liasom said:

My plan is to make the shapes less deep than those used in the big chambers (see graphic, like on the right side) and to either glue the shapes on only 3 sides--back, bottom, and either left or right or to place them less densely so as to cover about 40%-50% of the interior surface.

I figure it's worth a try.

NOW you have my interest. The idea is taking shape in my head.

A multitude of triangular prisms cut from MDF, glued to the inside panels, in sets of 4. Then a set perpendicular to the first, and so on in a checkerboard pattern.

I wonder how effective it would be? Would certainly strengthen the box panels also.

I have a sealed pair that I'm currently working on that I might try this method. My original plan was to for a constrained layer with the 5/8" MDF on the inside and 1/2" veneered particleboard on the outside with silicone rubber as the adhesive. Then rubber back carpet on the inside to reduce and disperse standing waves.

VERY worth a try.

Thanks.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Design & Build

- Construction Tips

- Discussion on what materials to build speakers out of