Art Ludwig's experiments.........

I didn't see his work posted, so........

http://www.silcom.com/~aludwig/Loudspeaker_construction.html#Creating_a_sound_sponge

GM

I didn't see his work posted, so........

http://www.silcom.com/~aludwig/Loudspeaker_construction.html#Creating_a_sound_sponge

GM

graaf said:

I understand. We can compare and come to conclusion that e.g. 18 mm plywood is better or worse than 18 mm MDF. Ok.

But what is the point of this comparison?

I know people that use 18 mm plywood but all people I know that use MDF use at leat 25 mm MDF, AT LEAST.

The point of the comparison was to show each materials resonant properties, with equal size panels under equal conditions.

And yes, many use just 18mm (3/4") stock to build speakers with, probably more than those that use 25mm (1").

planet10 said:

The wholw point of these forums is to share experience.

And you have no proof (and none could ever be offered -- a discussion of that pont in the thread this was split off from) that MDF is better or as good.

Many i have never met hold the same opinion as me... my feelings on boxes did not come about in isolation.

To share experience is one thing.

I've said it before - you, and a few others, express your opinion on the quality of MDF in no uncertain terms and it approaches bullying. You often imply that if one uses MDF they are settling for the worst possible choice, and it would be better not to build the box at all. This is the impression I get when I read your comments.

Your comments make it hard for someone who really doesn't know the difference (and plants the seeds of doubt in others that do) to feel good about what they have built.

A recent example: I was going to go back a take your post that sparked this side thread in the first place, but I see you have deleted it from the original thread and it's not in this one.

So from memory: you said, in reference to the kit proposed by gedlee, that

"there's not much sense shipping MDF across the country to be thrown in the bin"

That's a constructive comment.

I submit that much of your experience with the inferiority of MDF is a product of your own prejudice against it. You have tricked yourself into hearing a difference when none exists. Other example abound, such as (the big one) Enabl, damping of driver frames <6" in diameter, cables, caps and cabinet damping in general.

MDF is as good if not better than plywood for speaker box construction. This is a long establish fact. It has better damping properties than plywood, therefore less energy storage (a term that gets trotted out periodically as another of MDF's failings, which is completely untrue) as energy storage is another way of saying decay time. We can all plainly see, in the examples that you yourself referred to, that the decay time of plywood is longer.

Sonic qualities aside, MDF is not an ideal building product. I have decided to not use it, not only for speakers, but for anything else. A few good reasons:

It is heavy, needlessly so.

It too easily absorbs moisture, even when it is sealed.

It's dust from nearly all milling operations is insidious.

It's paintability is very good, but limited by the second factor (moisture). HDF provides a much better paint surface.

Re: Art Ludwig's experiments.........

Interesting page, I've never been through his entire site, thanks for the link.

One aspect of his testing that is lacking is that there will be two different vibrational mechanisms. One is covered in his test, the other is not. The one covered is the impact of air volume energy that will be any energy imparted to the air from the driver's rear side. The one not covered is the energy imparted into the front baffle by the direct contact of the driver mounting. Since most systems will have at a minimum either damping placed on the walls (ported) or fully stuffed (closed box), the impact of the two different mechanisms is also different.

The airborne energy can be largely damped with the resonances whose fundamental is related to the box dimensions being the major concern. I suspect that part of the reason that Ludwig was surprised at the energy measured at the corners was due to undamped airborne energy largely passing through the panel. This is energy simply passing through. It's the type of path that is why low bass passes so easily through walls in the home whereas higher frequencies are damped more easily. It's mostly normal to the walls in both. Much if not most of it is not the walls vibrating, the walls (and baffles) are simply somewhat transparent to energy transfer this way.

Of course, if the internal fundamental resonances related to the dimensions of the box also coincide with the unbraced dimensions for the panels, those panels may exacerbate those frequencies by resonating as well.

The part 2 of this is the energy imparted to a baffle by an attached driver. The origin of this is not one of energy passing through (a very large surface area for that case), it is much like a driver diaphragm. It's initially a transverse wave that is damped as the wave travels from driver to edge. The internal damping properties are probably of much more importance here. However, since the panel is so much stiffer than a diaphragm, there won't be much movement, so the spectrum will be a lot different for this. It is very much a bending wave condition. The stiffer the material, the less movement. Energizing a flat, uncut baffle with a rod connected to the panel would probably be the best way to test this, that would be interesting to see.

A third consideration, one I consider significant at least, is that when I'm listening to my speakers, I have the front baffle facing me with a small toe-out, so I see the inside facing side baffle at a high angle. This, being somewhat typical, means that the only significant baffle affecting the first arrival is the front baffle. The bottom (facing the floor, lots of change there), the sides, the top and the rear are all not having any impact on the first arrival. The result is that almost all of the output of these enter into perception as only reverberant room energy. This, to me, is the reason why I see far less importance in the material and the box. The room environment is much more of an influence and in fact, given that it can be altered for reflection/absorption so much that both a dead box and a lively box could possibly be made to sound very close in character if the room acoustics are adjusted for each one as long as the front baffle is constructed well. But compare two different boxes in the same room with no room change and the character should be different, how much will depend on the room's influence to begin with.

The primary issue as I see it is a heavy and/or well-braced front baffle with solid driver mounting. Of course, many will disagree, this is my reasoning. I'm in gedlee's camp on this one, the enclosure is grossly overrated.

Dave

GM said:I didn't see his work posted, so........

http://www.silcom.com/~aludwig/Loudspeaker_construction.html#Creating_a_sound_sponge

GM

Interesting page, I've never been through his entire site, thanks for the link.

One aspect of his testing that is lacking is that there will be two different vibrational mechanisms. One is covered in his test, the other is not. The one covered is the impact of air volume energy that will be any energy imparted to the air from the driver's rear side. The one not covered is the energy imparted into the front baffle by the direct contact of the driver mounting. Since most systems will have at a minimum either damping placed on the walls (ported) or fully stuffed (closed box), the impact of the two different mechanisms is also different.

The airborne energy can be largely damped with the resonances whose fundamental is related to the box dimensions being the major concern. I suspect that part of the reason that Ludwig was surprised at the energy measured at the corners was due to undamped airborne energy largely passing through the panel. This is energy simply passing through. It's the type of path that is why low bass passes so easily through walls in the home whereas higher frequencies are damped more easily. It's mostly normal to the walls in both. Much if not most of it is not the walls vibrating, the walls (and baffles) are simply somewhat transparent to energy transfer this way.

Of course, if the internal fundamental resonances related to the dimensions of the box also coincide with the unbraced dimensions for the panels, those panels may exacerbate those frequencies by resonating as well.

The part 2 of this is the energy imparted to a baffle by an attached driver. The origin of this is not one of energy passing through (a very large surface area for that case), it is much like a driver diaphragm. It's initially a transverse wave that is damped as the wave travels from driver to edge. The internal damping properties are probably of much more importance here. However, since the panel is so much stiffer than a diaphragm, there won't be much movement, so the spectrum will be a lot different for this. It is very much a bending wave condition. The stiffer the material, the less movement. Energizing a flat, uncut baffle with a rod connected to the panel would probably be the best way to test this, that would be interesting to see.

A third consideration, one I consider significant at least, is that when I'm listening to my speakers, I have the front baffle facing me with a small toe-out, so I see the inside facing side baffle at a high angle. This, being somewhat typical, means that the only significant baffle affecting the first arrival is the front baffle. The bottom (facing the floor, lots of change there), the sides, the top and the rear are all not having any impact on the first arrival. The result is that almost all of the output of these enter into perception as only reverberant room energy. This, to me, is the reason why I see far less importance in the material and the box. The room environment is much more of an influence and in fact, given that it can be altered for reflection/absorption so much that both a dead box and a lively box could possibly be made to sound very close in character if the room acoustics are adjusted for each one as long as the front baffle is constructed well. But compare two different boxes in the same room with no room change and the character should be different, how much will depend on the room's influence to begin with.

The primary issue as I see it is a heavy and/or well-braced front baffle with solid driver mounting. Of course, many will disagree, this is my reasoning. I'm in gedlee's camp on this one, the enclosure is grossly overrated.

Dave

MJL21193 said:To share experience is one thing.

I've said it before - you, and a few others, express your opinion on the quality of MDF in no uncertain terms and it approaches bullying. You often imply that if one uses MDF they are settling for the worst possible choice, and it would be better not to build the box at all. This is the impression I get when I read your comments.

John - I agree with you. The level of bullying over MDF that is shown is not warranted by any real data, only subjective preference. And in none of these tests has anyone quantified the perceptual significance of any of this (except the uncontrolled tests of "I heard ..."). As I said, I found that none of it was very significant. Which is why I'm not going to argue the point. I am simply amazed by the level of argument of something that is in reality so insignificant. Far far more important than the material is the actual structural design - bracing etc. But thats pretty quantifiable engineering and not much fun to bash arround I suppose.

MJL21193 said:You have tricked yourself into hearing a difference when none exists.

Can't speak for Dave but they sure sound different to me, especially when you listen side by side.

MDF is as good if not better than plywood for speaker box construction. [/B]

I respectfully disagree, for the reasons you list.

I have decided to not use it, not only for speakers, but for anything else. A few good reasons: [/B]

Thanks, I think we know about those also. Just more reasons beyond the most important (sonic) to consider plywood if it's available and affordable. MDF if it's not. (actually I still have a soft spot for the sonic signature of K3. Don't shoot.

MJL21193 said:Your comments make it hard for someone who really doesn't know the difference (and plants the seeds of doubt in others that do) to feel good about what they have built.

It is for the people who haven't built a cabinet yet. The idea that MDF is a superior speaker material is, IMHO, a myth perpetrated by the industry because it is cheap. So pervasive that many in the industry believe it with no data to support it, just marketing handwaving. It is notable to see this slowly changing with a growing number of higher end speakers avoiding the use of MDF (B&W, Magico, Sonus Faber, Wilson, more...)

I am not after building just good speakers, i want to build great speakers, speakers that work well at bringng the emotion of the music to the listener. And all that within a frugal-phile(tm) philosophy.

A recent example: I was going to go back a take your post that sparked this side thread in the first place, but I see you have deleted it from the original thread and it's not in this one. So from memory: you said, in reference to the kit proposed by gedlee, that

"there's not much sense shipping MDF across the country to be thrown in the bin"

No need to speculate what the post said, here it is http://www.diyaudio.com/forums/showthread.php?postid=1487149#post1487149

And it is a description of exactly what i would do -- well not quite, it would go into the burn pile where thousands of other speaker boxes have met their end.

I am very interested in Dr Geddes speakers. He has an approach that i'd really like to hear -- i just wanted to make the point that, that is exactly what i'd do to the flat-pak cabinets.

I submit that much of your experience with the inferiority of MDF is a product of your own prejudice against it. You have tricked yourself into hearing a difference when none exists. Other example abound, such as (the big one) Enabl, damping of driver frames <6" in diameter, cables, caps and cabinet damping in general.

(Let's leave EnABL out of this -- not having heard a pair you are not in a position to comment)

You presume to tell me what i hear? Now i'd like to see you "prove" that

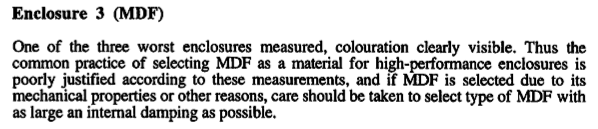

My dislike of MDF is based on real-world experience its direction driven by a lot of technical knowledge and applied physics, starting with that AES paper -- that to my extreme dissappointment at the time -- ranked MDF as the least suitable speaker building material. I could only console & rationalize that i was using HDF & not MDF.

MDF is as good if not better than plywood for speaker box construction. This is a long establish fact. It has better damping properties than plywood, therefore less energy storage (a term that gets trotted out periodically as another of MDF's failings, which is completely untrue) as energy storage is another way of saying decay time. We can all plainly see, in the examples that you yourself referred to, that the decay time of plywood is longer.

You can say that, yet with no data to support your position. You then go on to use data that contradicts your point to support it.

I have reposted that specific composite chart -- MDF vrs multi-ply from the Dutch site i linked above.

MDF has a large resonance @ ~250 Hz, ply a much lower & quicker decaying pair just either side. They both have a resonance at ~500 Hz with about the same initial magnitude, but the ply dissappears much quicker and with a quicker slope -- one will note that the MDF resonance pokes its head above the surface near the maximum time extent... it has a long shallow ridge of energy. Next 3, the magnitude of the ply is less and disappears quicker, then one unique to the MDF. Then another where they start about the same but the ply goes beneath the surface in about half the time. Then the one just above 1 k, ply starts lower but the MDF is quicker to below the surface, but the slopes are similar. This is where we have to note that the data Svante supplied indicates that the energy available to excite these resonances is inversly proportional to the frequency, so the most significant resonaces are the lower ones.

So not only does this say that ply is less resonant (and in particular when you factor in where it counts), but it is better damped,

It should be noted that both the Dutch site, & Ludwig's* work point to the best performance from more complex panels than just "naked" MDF or ply.

*(As dlr pointed out, Ludwig's work does not address the most significant source of energy available to excite resonances -- structure borne.)

dave

Attachments

planet10 said:

It is for the people who haven't built a cabinet yet. The idea that MDF is a superior speaker material is, IMHO, a myth perpetrated by the industry because it is cheap.

well, MDF is at least easy to work with which is a great thing from perspective of "the people who haven't built a cabinet yet"

perhaps MDF is not "superior" but it is also not "inferior" PER SE

Isn't it "HOW You use it" that really counts rather then just "WHAT You use" (MDF or plywood or...)

and I REALLY would like to know what would be the advantage of using e.g. "2x18 plywood with bracing" over "3x18 MDF"

because I would like to have better DIY speakers

I am very interested in everything significantly measurably better than my 3x18 MDF

give me the data please

best,

graaf

graaf said:perhaps MDF is not "superior" but it is also not "inferior" PER SE

Isn't it "HOW You use it" that really counts rather then just "WHAT You use" (MDF or plywood or...)

In some senses maybe... execution is VERY important, but materials play a role too. And i prefer elegance to brute force -- and in this case i think that brute force introduces its own problems.

I am very interested in everything significantly measurably better than my 3x18 MDF

give me the data please

Measurements you'll have to supply yourself... there is so much we can't yet measure, and interpretation is so important that it can be used as a design tool.

As to the 3x18mm box, i'd be willing to tackle a better sounding box, but i'd need to know more about how you executed your build.

dave

planet10 said:

As to the 3x18mm box, i'd be willing to tackle a better sounding box, but i'd need to know more about how you executed your build.

this is how I did it - the front and back is about 50 mm

the side walls are just 25 mm thick

Attachments

gedlee said:

John - I agree with you...

Far far more important than the material is the actual structural design - bracing etc.

That's something else that's refreshing - having someone agree with me.

That's the drum I've been beating: build it properly and it doesn't make a difference what it's made out of. Obviously, there is a list of equivalent materials that are suitable for this. MDF is definitely one.

Cal Weldon said:

Can't speak for Dave...

Circle of influence. (see post#56 above)

I dont see any sense in those very thick front baffles...in order to let the driver breathe you have to route most of it away again...good bracing in the corners with thick wood works just as good

Make the rest of the enclosure thicker, thats much more effective than a thick front...optimum front would be aluminium

Those who have tried both MDF and plywood wont use nothing but ply...and those who claim MDF to be equal or even better havent tried nothing but MDF...just wondering

Personally I dont care much one way or the other, but if plywood didnt cost more and was easy available in good quality, I would definately use ply...but good quality ply is expencive as hell , and hard to get hold of

Make the rest of the enclosure thicker, thats much more effective than a thick front...optimum front would be aluminium

Those who have tried both MDF and plywood wont use nothing but ply...and those who claim MDF to be equal or even better havent tried nothing but MDF...just wondering

Personally I dont care much one way or the other, but if plywood didnt cost more and was easy available in good quality, I would definately use ply...but good quality ply is expencive as hell , and hard to get hold of

planet10 said:

It is for the people who haven't built a cabinet yet. The idea that MDF is a superior speaker material is, IMHO, a myth perpetrated by the industry because it is cheap. So pervasive that many in the industry believe it with no data to support it, just marketing handwaving. It is notable to see this slowly changing with a growing number of higher end speakers avoiding the use of MDF (B&W, Magico, Sonus Faber, Wilson, more...)

Exactly. Misinforming the rookies and planting seeds of doubt in others.

I have news for you: the MDF industry is not resting it's fortune on speaker cabinet production. I don't know the figures, but I'm willing to bet it's a very minuscule amount of MDF's total production goes to speakers. Maybe .0001%?

Here's my take on why these companies you list are changing the material they use: first and foremost - marketing. Also, for one of the same reason I stopped using it - for a long lasting ultra high gloss finish, MDF will not stand up.

planet10 said:

I am not after building just good speakers, i want to build great speakers, speakers that work well at bringng the emotion of the music to the listener. And all that within a frugal-phile(tm) philosophy.

Marketing.

tinitus said:Those who have tried both MDF and plywood wont use nothing but ply...and those who claim MDF to be equal or even better havent tried nothing but MDF...just wondering

Personally I dont care much one way or the other, but if plywood didnt cost more and was easy available in good quality, I would definately use ply...but good quality ply is expencive as hell , and hard to get hold of

I've used both and still do use both, the material is just not that important acoustically. I really don't like finishing plywood, it is a real pain. Give me MDF anytime for finishing - once you learn how to seal it first and then paint because I only use water based finishes.

But cutting MDF - what a pain! The dust is disgusting. Is there an ideal - NOO! But with the cost of MDF vs "good" plywood, its no contest for me. If a customer wants to pay the extra for plywood, I don't care.

Sorry Dave, I couldn't find it.planet10 said:

No need to speculate what the post said, here it is

planet10 said:

You can say that, yet with no data to support your position. You then go on to use data that contradicts your point to support it.

I have reposted that specific composite chart -- MDF vrs multi-ply from the german site i linked above.

That composite chart you made is not correct. Either look at the ones on the actual site again, or take a look at the ones below, which I copied direct from there and present here unaltered (except for the labels I added).

It can be clearly seen that the materials are virtually identical, with nearly the same resonance and the same decay. Any difference that you can pick out from these charts is not audible. Not at all, by any human.

You say there is so much we can't measure. What we can't accurately measure is the brains ability to deceive, especially where hearing and strong convictions are involved.

Attachments

MJL21193 said:Misinforming the rookies and planting seeds of doubt in others.

Or informing the rookies of the misinformation. Everytime i plant a seed of doubt i feel i am doing a public service. There are enuff naysayers that the smart ones will look at the data and arguments and make a choice based on their own preferred set of compromises.

the MDF industry is not resting it's fortune on speaker cabinet production

I was talking about the loudspeaker manufacturing industry. Just as been expressed in just the last few posts, they like it because it is cheap, & cheap to finish.

Not the paper i was looking for, but makes me smile (Note: he wasn't very complimentary of any materials used "naked" -- i can only console myself in that my use of plywood is part of a carefully conceived construction that makes its properties work to my advantage, ie a lot of care is taken in the execution)

101 AES Convention Juha Backman

dave

Attachments

planet10 said:

Or informing the rookies of the misinformation.

I was talking about the loudspeaker manufacturing industry. Just as been expressed in just the last few posts, they like it because it is cheap, & cheap to finish.

101 AES Convention Juha Backman

dave

I'm not going to get into the "informing rookies" thing. Browbeating is more like it.

This paper you found is conclusive evidence? The Dutch site you linked for the measurements was proof enough, no?

The loudspeaker manufacturers? They want to fool the public?

Cheap it may be, but it's not as cheap to finish well. And the biggest problem: it doesn't stay finished. Hairline cracks can (will) form at the seems, The surface will change and start to slightly texture. These are problems that show up on a perfectly reflective finish when the substrate is not perfectly stable.

When you sell speakers for $100,000 plus, you can afford good materials (for finishing). Keep the returns and warranty costs down.

Attachments

MJL21193 said:That composite chart you made is not correct. Either look at the ones on the actual site again

I went back & double checked... the composite chart is correct. I would never use any of these materials without bracing, the chart is image 9 & 10, modestly braced MDF vrs modestly braced birch ply (both 18mm). Execution is important.

dave

graaf said:

this is how I did it - the front and back is about 50 mm

the side walls are just 25 mm thick

As has been pointed out, you are going to have big "oil can" resonance issues with that baffle.

Much better to use a thin baffle (Al is good), and brace things up.

dave

planet10 said:

I went back & double checked... the composite chart is correct. I would never use any of these materials without bracing, the chart is image 9 & 10, modestly braced MDF vrs modestly braced birch ply (both 18mm). Execution is important.

dave

Braced? With what? How was it braced? How was the brace fastened? See the questions that need to be answered to properly evaluate the results?

I like to look at the raw product, without treatment. This always gives a better idea.

Still, there is not much of a difference between the two, and it's doubtful that the differences picked up on with the test gear would be audible.

It's too bad that you live so far away Dave, I could challenge you to a listening test. Put your money where your mouth is sort of thing. I would be more than happy to build two exactly identical speakers of your design (no, not one of those frugil phool "horns").

Shut me up forever if you could tell the difference.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Discussion arising from Geddes loudspeaker