Hi Carlos,

We have not deserted you, still here !

Just a bit quiet recently.

Maybe everyone is listening to their music

OR

wanting better speakers to go with the new amplifiers !

Hi dw1narso,

Input R relates mostly to the value of any input Resistors, so just look at the circuit diagram.

Carlos has explained how to calculate the input capacitor value for 20Hz roll-off.

If you want to build a Sub-bass amplifier, that is where I would go for a much lower roll off frequency and higher capacitor vaue, but the increased infra-bass output could then damage ordinary or full-range loudspeaker drivers, so the input capacitor value must be chosen accordingly.

Cheers .......... Graham.

Regarding queries about types of input capacitor, yes these can have an effect due to input transistor base current often not being in phase with input voltage.

A good non-electrolytic type should not give any problems, but, if the input R to ground is reduced then electrolytics paralleled with smaller Cs can be equally good.

We have not deserted you, still here !

Just a bit quiet recently.

Maybe everyone is listening to their music

OR

wanting better speakers to go with the new amplifiers !

Hi dw1narso,

Input R relates mostly to the value of any input Resistors, so just look at the circuit diagram.

Carlos has explained how to calculate the input capacitor value for 20Hz roll-off.

If you want to build a Sub-bass amplifier, that is where I would go for a much lower roll off frequency and higher capacitor vaue, but the increased infra-bass output could then damage ordinary or full-range loudspeaker drivers, so the input capacitor value must be chosen accordingly.

Cheers .......... Graham.

Regarding queries about types of input capacitor, yes these can have an effect due to input transistor base current often not being in phase with input voltage.

A good non-electrolytic type should not give any problems, but, if the input R to ground is reduced then electrolytics paralleled with smaller Cs can be equally good.

I am also listening music.... to be more precise.. watching DVD movies

Into the computer.

And the sound reproduced is beeing switched between Dx Standard and Dx Precision.

Interesting results.... Precision is better...but the advantage....hummm...the advantage is not so enormous.

Dx Standard has a very nice sonics.

Simple things sounds good.

regards,

Carlos

Into the computer.

And the sound reproduced is beeing switched between Dx Standard and Dx Precision.

Interesting results.... Precision is better...but the advantage....hummm...the advantage is not so enormous.

Dx Standard has a very nice sonics.

Simple things sounds good.

regards,

Carlos

Attachments

Caps again

Hi Carlos,

political correctness also counts ;-)

Anyway - I would still be happy to hear your judgement with respect to sound when replacing this cap by a short.

People care a lot about capacitors, and there is this fat electrolytic cap directly in the (feedback) signal path.

Nobody complains about it, even though any distortion introduced by this cap is fed back to the difference amplifier.

So I am wondering: Does this cap hurt or not?

- Maybe it introduces some distortion which actually sounds good?

Hhmm, I think I will give it a try once I have built this amp.

-----------

konkret

Hi Carlos,

political correctness also counts ;-)

Anyway - I would still be happy to hear your judgement with respect to sound when replacing this cap by a short.

People care a lot about capacitors, and there is this fat electrolytic cap directly in the (feedback) signal path.

Nobody complains about it, even though any distortion introduced by this cap is fed back to the difference amplifier.

So I am wondering: Does this cap hurt or not?

- Maybe it introduces some distortion which actually sounds good?

Hhmm, I think I will give it a try once I have built this amp.

-----------

konkret

Hi kronket,

You raise a valid point about possible distortion of the NFB divider capacitor being amplified by closed loop gain.

As you say this component is large and in series with 1k, though it might be cascaded with lower values to counter inductance. The component in the DX would also be unlikely to pass more than 0.5mA at maximum output, so it is hardly working 'hard'.

I would suggest that any distortion introduced here is going to be due to impedance at LF, with the resulting roll-off sounding benign.

I too would not like to run this kind of circuit without such a capacitor - too risky.

Cheers ...... Graham.

You raise a valid point about possible distortion of the NFB divider capacitor being amplified by closed loop gain.

As you say this component is large and in series with 1k, though it might be cascaded with lower values to counter inductance. The component in the DX would also be unlikely to pass more than 0.5mA at maximum output, so it is hardly working 'hard'.

I would suggest that any distortion introduced here is going to be due to impedance at LF, with the resulting roll-off sounding benign.

I too would not like to run this kind of circuit without such a capacitor - too risky.

Cheers ...... Graham.

Graham Maynard said:Hi kronket,

You raise a valid point about possible distortion of the NFB divider capacitor being amplified by closed loop gain.

As you say this component is large and in series with 1k, though it might be cascaded with lower values to counter inductance. The component in the DX would also be unlikely to pass more than 0.5mA at maximum output, so it is hardly working 'hard'.

I would suggest that any distortion introduced here is going to be due to impedance at LF, with the resulting roll-off sounding benign.

I too would not like to run this kind of circuit without such a capacitor - too risky.

Cheers ...... Graham.

According to an old Wireless World article that I am trying to find, it's the leakage current that may cause distortion. When I find the article I will post.

Well boys, i have dismounted partially my laboratory... removed the bench

because i have bougth an old dinner table made with solid special wood...... wonderfull wood.

Because of that, i will have to sand it manually and for days to came.... a lot of dust in my home, reason why i removed all my precious things and had locked them all.

It is a good point.... distortions, caused by leakage or anything else is not an desirable effect...it is a defect!... and those things i do not want into our nice amplifier.

Soon..... or not too much soon.... 1 week, i will return to testings...and then we will listen with and without the capacitor, switching and for long time.... will try other values and some leakage will be "provided".... i will force a damage into an unit to have a evil leakage to listen to.

The wood, to be manually sanded, prepared and to receive sealant, varnish.... will be sanded once again after varnish to be receive the final layer.... i will be under the dust...out from electronics for a week i think.

Sorry for that.... any testings you can provide, studies, conclusions and fears about this subject is really very, very welcome.... i do not want errors and defects bothering Dx constructors...i want them happy, because this will make me happy too.

regards,

Carlos

because i have bougth an old dinner table made with solid special wood...... wonderfull wood.

Because of that, i will have to sand it manually and for days to came.... a lot of dust in my home, reason why i removed all my precious things and had locked them all.

It is a good point.... distortions, caused by leakage or anything else is not an desirable effect...it is a defect!... and those things i do not want into our nice amplifier.

Soon..... or not too much soon.... 1 week, i will return to testings...and then we will listen with and without the capacitor, switching and for long time.... will try other values and some leakage will be "provided".... i will force a damage into an unit to have a evil leakage to listen to.

The wood, to be manually sanded, prepared and to receive sealant, varnish.... will be sanded once again after varnish to be receive the final layer.... i will be under the dust...out from electronics for a week i think.

Sorry for that.... any testings you can provide, studies, conclusions and fears about this subject is really very, very welcome.... i do not want errors and defects bothering Dx constructors...i want them happy, because this will make me happy too.

regards,

Carlos

Attachments

Re: Well boys, i have dismounted partially my laboratory... removed the bench

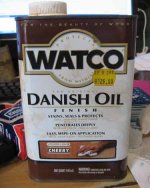

have you considered oiling instead of varnish?

I discovered Danish oil about 12years ago and would NEVER go back to varnish.

It's easier to apply, eaiser to repair, looks less artificial. Just nice in my view. It does not have that deep high gloss finish that many coats of varnish can give.

Try three coats, sanding with 320 grit glasspaper or garnetpaper between coats. If that's not good enough for you, then try upto 6coats of Danish oil, possibly going to 400grit for the last couple of coats. The oil, after leaving to set for a minimum of six hours, will clog the glasspaper, so keep turning/replacing it, and buy lots.

Sorry to all for being off topic.

Hi Carlos,destroyer X said:......dinner table made with solid special wood...... wonderfull wood.......................... to receive sealant, varnish.... will be sanded once again after varnish to be receive the final layer....

have you considered oiling instead of varnish?

I discovered Danish oil about 12years ago and would NEVER go back to varnish.

It's easier to apply, eaiser to repair, looks less artificial. Just nice in my view. It does not have that deep high gloss finish that many coats of varnish can give.

Try three coats, sanding with 320 grit glasspaper or garnetpaper between coats. If that's not good enough for you, then try upto 6coats of Danish oil, possibly going to 400grit for the last couple of coats. The oil, after leaving to set for a minimum of six hours, will clog the glasspaper, so keep turning/replacing it, and buy lots.

Sorry to all for being off topic.

Hi Carlos,

Nothing nicer than a nice piece of sealed/varnished natural wood to work on. Lots of thin layers applied and ultra-fine sanded to give a smooth finish.

Then to do any sharp/heavy work on it you can use a small rug or carpet tile with the fluffy pile side downwards protecting the suface, and tough back up to catch the sharp edges or drops of molten solder.

I remember when I varnished mine years ago, I sat back feeling all satisfied and poured myself a brandy - blimey, did the fumes mix with the spirit and make me tipsy or what !

Hi Harry,

Yes the leakage current and losses can cause distortion.

This is why non-electrolytic types are better for high impedance input circuitry, and cascaded quality electrolytics are better with low impedance circuitry.

The bias and loading aspects of any test for measuring electrolytic performance is important. Also in audio, electrolytics tend to be in series with resistors which limit any capacitor induced variation, so measured test results might not be directly applicable to real-world audio results.

I get quite fed up with some who have read such reports and say you must not use electrolytics in audio. Electrolytics are no worse than transformers !!!! Either of these components can be used quite acceptably if the designer knows what they are doing.

I have run amplifier circuits both with and without capacitors specifically to listen for capacitor induced distortion, and where the capacitors are suitably matched to circuit resistances and impedances I simply could not hear whether they were switched in or out of circuit.

And so, because of the protection they offer to irrepairable loudspeakers, I still choose to use them.

Cheers ........ Graham.

Nothing nicer than a nice piece of sealed/varnished natural wood to work on. Lots of thin layers applied and ultra-fine sanded to give a smooth finish.

Then to do any sharp/heavy work on it you can use a small rug or carpet tile with the fluffy pile side downwards protecting the suface, and tough back up to catch the sharp edges or drops of molten solder.

I remember when I varnished mine years ago, I sat back feeling all satisfied and poured myself a brandy - blimey, did the fumes mix with the spirit and make me tipsy or what !

Hi Harry,

Yes the leakage current and losses can cause distortion.

This is why non-electrolytic types are better for high impedance input circuitry, and cascaded quality electrolytics are better with low impedance circuitry.

The bias and loading aspects of any test for measuring electrolytic performance is important. Also in audio, electrolytics tend to be in series with resistors which limit any capacitor induced variation, so measured test results might not be directly applicable to real-world audio results.

I get quite fed up with some who have read such reports and say you must not use electrolytics in audio. Electrolytics are no worse than transformers !!!! Either of these components can be used quite acceptably if the designer knows what they are doing.

I have run amplifier circuits both with and without capacitors specifically to listen for capacitor induced distortion, and where the capacitors are suitably matched to circuit resistances and impedances I simply could not hear whether they were switched in or out of circuit.

And so, because of the protection they offer to irrepairable loudspeakers, I still choose to use them.

Cheers ........ Graham.

A little of topic folks...just a moment, as Andrew has nice informs to me

This table was receiving rain....near the place people constructed things...cement and concrete was over and down.

Yesterday, me and my daugther made a cleaning on it...was soap and watter...and the effect when the surface was wet was very nice...i suppose the same effect with the Danish oil you are telling about.

The problem... i do not know nothing about this oil... is this Mineral or vegetable oil?.... what is the colour of it?.... tell me if it dries when time passes..... will the table be oiled?... say.... some cloth passed over the dried surface will be dirty, oiled or something alike...has it strong smell?

I cannot imagine.... tell me something.... how they produce the oil?... is it from some vegetable grain...some extracted thing from seeds.

It may be a better idea...this varnish turns bad when receive watter...so....not good to dinner table surface...it is a strong block of nice wood.... very strong...very old.... the wood may have more than 250 years old.

regards,

Carlos

This table was receiving rain....near the place people constructed things...cement and concrete was over and down.

Yesterday, me and my daugther made a cleaning on it...was soap and watter...and the effect when the surface was wet was very nice...i suppose the same effect with the Danish oil you are telling about.

The problem... i do not know nothing about this oil... is this Mineral or vegetable oil?.... what is the colour of it?.... tell me if it dries when time passes..... will the table be oiled?... say.... some cloth passed over the dried surface will be dirty, oiled or something alike...has it strong smell?

I cannot imagine.... tell me something.... how they produce the oil?... is it from some vegetable grain...some extracted thing from seeds.

It may be a better idea...this varnish turns bad when receive watter...so....not good to dinner table surface...it is a strong block of nice wood.... very strong...very old.... the wood may have more than 250 years old.

regards,

Carlos

Attachments

Hi Carlos, the Danish oil dries in the wood, and will not leave things oily once dry (about a day).. you get it in almost clear and dyed versions.... I have a can of cherry coloured oil.

It gives off no strong smells... very easy to work with indoors, althouh it contains toxic components... i.e. don't drink it.

Real danish oil is just a polymerized linseed oil, but the stuff you normally buy has the toxic additives.

It givesa nice satin finish. Beautifull for indoors, but not strong enough for outdoors...

The only thing I like better is 2 part gloss polyurethane, but that gives a plastic look, not suitable for that table.

It gives off no strong smells... very easy to work with indoors, althouh it contains toxic components... i.e. don't drink it.

Real danish oil is just a polymerized linseed oil, but the stuff you normally buy has the toxic additives.

It givesa nice satin finish. Beautifull for indoors, but not strong enough for outdoors...

The only thing I like better is 2 part gloss polyurethane, but that gives a plastic look, not suitable for that table.

Hi,

when manufacturers of Danish oil are prepared to publish the secret recipes for their version of the oil it usually specifies Tung oil as the main constituent. I think it's mostly based on vegetable oils.

The first couple of coats sink into the wood. the later coats fill the grain structure. The oil sets in contact with the air and wood.

But do allow at least 6hours before rubbing down.

At two coats the finish is almost matt, three or four coats is satin to semi-gloss, five or six coats is becoming quite glossy with a well filled grain.

Be careful with the oiled rags. They can spontaneously combust.

It does darken the wood slightly and some woods continue to darken with light exposure/age.

It is not as light as laquer nor shellac based sealers, which tend to be very pale.

when manufacturers of Danish oil are prepared to publish the secret recipes for their version of the oil it usually specifies Tung oil as the main constituent. I think it's mostly based on vegetable oils.

The first couple of coats sink into the wood. the later coats fill the grain structure. The oil sets in contact with the air and wood.

But do allow at least 6hours before rubbing down.

At two coats the finish is almost matt, three or four coats is satin to semi-gloss, five or six coats is becoming quite glossy with a well filled grain.

Be careful with the oiled rags. They can spontaneously combust.

It does darken the wood slightly and some woods continue to darken with light exposure/age.

It is not as light as laquer nor shellac based sealers, which tend to be very pale.

Is this oil by any chance a wood sealer?

On several wood pieces I made myself, what I used, instead of varnish, was diluted wood sealer, which I applied with a rag.

As I do not like shiny wood or didn't want it to darken the very clear wood I was using (called ivory in Brazil), I went in with several coats.

Any varnish or oil should be applied after this sealer, which should then require less coats and would darken the wood in a lesser degree.

Tung based products are certainly oily, and should be applied after the sealer. Also in very thin coats.

I wonder if this Danish oil is available in this country.

On several wood pieces I made myself, what I used, instead of varnish, was diluted wood sealer, which I applied with a rag.

As I do not like shiny wood or didn't want it to darken the very clear wood I was using (called ivory in Brazil), I went in with several coats.

Any varnish or oil should be applied after this sealer, which should then require less coats and would darken the wood in a lesser degree.

Tung based products are certainly oily, and should be applied after the sealer. Also in very thin coats.

I wonder if this Danish oil is available in this country.

Hi,

I have never tried Danish oil over shellac based wood sealer.

Doing this may interfere with the setting ability of the oil. The Shellac will virtually stop the oil penetrating the wood necessary for the set.

Danish oil is a sealer. It makes the surface impervious to water. The oil does NOT flake off like varnish if water gets through any surface imperfections. The oil penetrates the wood rather than lying ON the surface. It does not raise the grain like varnish or water does and thus minimises the rubbing down after the first coat.

It resists grubby finger marks, can be buffed up, takes a silicone polish if desired. Worth a try on scrap/underside to see if it gives what is wanted.

I have never tried Danish oil over shellac based wood sealer.

Doing this may interfere with the setting ability of the oil. The Shellac will virtually stop the oil penetrating the wood necessary for the set.

Danish oil is a sealer. It makes the surface impervious to water. The oil does NOT flake off like varnish if water gets through any surface imperfections. The oil penetrates the wood rather than lying ON the surface. It does not raise the grain like varnish or water does and thus minimises the rubbing down after the first coat.

It resists grubby finger marks, can be buffed up, takes a silicone polish if desired. Worth a try on scrap/underside to see if it gives what is wanted.

Translation for Carlos

Tio Carlos

Here is the Brazilian portuguese adaptation:

"Já que estou de mal humor (ou de saco cheio, ou sem vontade), vou mais é trabalhar."

Regarding your package, I will replace the marshmallows you suggested with additional multi-color heatshirink and some other interesting things from my parts collection (thanks eBay). Since I will mail it after going through the "policia federal", you will not incurr any fees.

Cheers!

-------------------------------------------------destroyer X said:

I tried to translated it literally... i have used google for that...but do not make sense to me.... i would like to know to smile, as usually you have nice kiddings with me.

Tio Carlos

Here is the Brazilian portuguese adaptation:

"Já que estou de mal humor (ou de saco cheio, ou sem vontade), vou mais é trabalhar."

Regarding your package, I will replace the marshmallows you suggested with additional multi-color heatshirink and some other interesting things from my parts collection (thanks eBay). Since I will mail it after going through the "policia federal", you will not incurr any fees.

Cheers!

Good decision Duda... very good... heatshrink tubes...coloured...nice!

Boys.... i see how Europe is beautifull related those things to paint..... USA too has all those things, as also Canada...but here....i am trying to imagine what oil will be good.

Oleo de Rícino

Oleo de Banana

Oleo de Mamona

This Danish oil can picture will be very helpfull to understand more about.

People use automobile oil.... the dirty black one, having carbon, to paint the wood that supports, hold, the ceiling.... the ceiling's wooden frame.... protection against time and small animals... turn waterproof too...but really smelly.

Well... thank you all.... Duda, Carlmart, AndrewT, Nordic, Graham, and all folks that contribute.

I thank you very much....and i suggest to return to the amplifier subject folks.... we dive deep into the off topic....please, let's return and thank you very much.

I am still sanding till i will study that Danish oil and will colect informations into the local shops.

To Harry3 my regards.... i love Aussies.... KonKret, my regards too...you are very clever.

Dear Graham... i also love those varnishes.... shine finishment... sanded and another layer...and sanded once again... and another layer.... but, i have a 10 years old lovely daugther... the varnish i have here, the one is fast to dry, if you forget a glass with cold watter inside, in the other day, a white circle will be into the varnish surface.... others i have here, Sparlack and other Navy material, smells a lot and delay too much to dry.

regards,

Carlos

Boys.... i see how Europe is beautifull related those things to paint..... USA too has all those things, as also Canada...but here....i am trying to imagine what oil will be good.

Oleo de Rícino

Oleo de Banana

Oleo de Mamona

This Danish oil can picture will be very helpfull to understand more about.

People use automobile oil.... the dirty black one, having carbon, to paint the wood that supports, hold, the ceiling.... the ceiling's wooden frame.... protection against time and small animals... turn waterproof too...but really smelly.

Well... thank you all.... Duda, Carlmart, AndrewT, Nordic, Graham, and all folks that contribute.

I thank you very much....and i suggest to return to the amplifier subject folks.... we dive deep into the off topic....please, let's return and thank you very much.

I am still sanding till i will study that Danish oil and will colect informations into the local shops.

To Harry3 my regards.... i love Aussies.... KonKret, my regards too...you are very clever.

Dear Graham... i also love those varnishes.... shine finishment... sanded and another layer...and sanded once again... and another layer.... but, i have a 10 years old lovely daugther... the varnish i have here, the one is fast to dry, if you forget a glass with cold watter inside, in the other day, a white circle will be into the varnish surface.... others i have here, Sparlack and other Navy material, smells a lot and delay too much to dry.

regards,

Carlos

Attachments

Well Carlos,

If you want to really do a lot of work, but have the finest, deepest looking finish, look up "French Polish". Not the most practical finish, as it is softer than modern finishes, but it it made up of many thin layers, so it looks very deep.

Pure tung oil is another choice. It's not a glossy finish and is a little more time consuming to apply than products like the Danish Oil, but it's more resistant to discoloring from sun exposure and once it cures, it's resistant to strong solvents. Gives a nice natural look. You can apply modern finishes over it once it has cured.

Finally, there is wax. A nice carnuba wax finish has a very natural look and feels very nice to the touch. Not shiny, but calm. It will resist water spills, as long as they are wiped up within a few minutes. Easy to reapply or restore. Only problem is that other finishes cannot be applied later unless you completely strip off the wax with solvent. So test a little area on the bottom side first. In fact, I would do a small test of each of the finishes you consider on a small spot on the bottom of the table. Don't just look at them, feel them too.

Sheldon

If you want to really do a lot of work, but have the finest, deepest looking finish, look up "French Polish". Not the most practical finish, as it is softer than modern finishes, but it it made up of many thin layers, so it looks very deep.

Pure tung oil is another choice. It's not a glossy finish and is a little more time consuming to apply than products like the Danish Oil, but it's more resistant to discoloring from sun exposure and once it cures, it's resistant to strong solvents. Gives a nice natural look. You can apply modern finishes over it once it has cured.

Finally, there is wax. A nice carnuba wax finish has a very natural look and feels very nice to the touch. Not shiny, but calm. It will resist water spills, as long as they are wiped up within a few minutes. Easy to reapply or restore. Only problem is that other finishes cannot be applied later unless you completely strip off the wax with solvent. So test a little area on the bottom side first. In fact, I would do a small test of each of the finishes you consider on a small spot on the bottom of the table. Don't just look at them, feel them too.

Sheldon

- Status

- Not open for further replies.

- Home

- Amplifiers

- Solid State

- Destroyer x Amplifier...Dx amp...my amplifier