Vinyl-Addict said:

Doug, You can get a rough estimate of the repelling force by dividing the pull force by 3. IOW, 36lbs pull force will repel a 12 pound load with about 1/8" gap. This is just an estimate.

You really should experiment by building a model or jig to figure this out since it is very hard to get it right the first time.

I would avoid using a series of small disc magnets due to the cogging effect. Ring magnets are the best choice.

As was previously mentioned, precision is key when it comes to positioning the magnets, both concentricity and parallelism are of prime importance to the success of your project.

FWIW, I'm using ring magnets with 180 pounds pull force in my magnetic bearing. The platter weighs 50 pounds.

I was going by what he said here. Says divide them by 3. Thats 38.34 lbs of repel so maybe it is a bit to much. I'm still a bit confused on how to figure out how much pull force I would need. I'm glad I wouldn't need those if thats true because the others are a lot cheaper. Maybe these would be better http://www.magnet4less.com/product_info.php?cPath=1_13&products_id=322 according to his calculations that would give 28.67 lbs of repel force.

I don't really know - the maths of this issue is not my strong point . However, going by what 'Vinyl-Addict' posted the second magnets you linked to do seem a better match.

Bearing (no pun intended) in mind I've built assemblies which use cylinder (disc) magnets for both parts of the bearing and examples that use a ring magnet for one section, I feel pretty firm in my belief that, if one section is a ring magnet, cogging is not an issue. However, my soution was specificaly designed to work with the much lower mass of my platter. Viny-addict has built something much closer to what you are intending.

Bearing (no pun intended) in mind I've built assemblies which use cylinder (disc) magnets for both parts of the bearing and examples that use a ring magnet for one section, I feel pretty firm in my belief that, if one section is a ring magnet, cogging is not an issue. However, my soution was specificaly designed to work with the much lower mass of my platter. Viny-addict has built something much closer to what you are intending.

Dougie085 said:

I was going by what he said here. Says divide them by 3. Thats 38.34 lbs of repel so maybe it is a bit to much. I'm still a bit confused on how to figure out how much pull force I would need. I'm glad I wouldn't need those if thats true because the others are a lot cheaper. Maybe these would be better http://www.magnet4less.com/product_info.php?cPath=1_13&products_id=322 according to his calculations that would give 28.67 lbs of repel force.

Doug, You need to know exactly what the weight of the platter is. I suggest building it first, then weigh it and then order magnets. You need to be able to design the upper and lower bearing housing around the size of the magnets since you will probqbly be bonding the magnets at those locations.

Everything involved in the assembly, from where the magnets are bonded and located will affect the end result. My platter is 70mm thick. I originally had an acrylic platter but built another platter that is a 3 layer design of Aluminum/Delrin/Aluminum. I added a lot of mass to the outside perimeter to make the total weight 47 pounds.

As I previously stated, divide the "pull force" by 3. The pull force is always given but you seldom if ever are given the repelling force of magnets. This will get you in the ball park but you should seriously consider building a test jig before finalizing machining of the bearing so you get the proper gap between upper & lower bearing assemblies. This is not an easy thing to get right the first time.

planarboy said:ive been thinking my riaa stage lately is letting me down, but it probably is.

Ebay special...yaqin 12b tube preamp with phono stage, very noisy, pretty ordinary.

People have suggested to me to get graham slee, but i might just watch this thread and copy what doug ends up doing.

I just arranged to buy one of these for the requisite $285 it seems to go for. I'm looking to pick it up on Monday, on a business trip to Toronto,as the ebay seller is in the Toronto (Ontario, Canada) area.

I'm looking to find a decent chassis to start with with respects to modification.

I'm looking to start at a fairly low price ..with a decent chassis, and basic circuit...and then move it up in quality. The Yaqin is a stab in the dark.

This may end up being a modified Yaqin product for OEM base use and course...modified .., rebranded...then resale.

I'd have Yaqin make me new faceplate, of course. I'd like to use the Ming Da stuff, but it's quite expensive to start with.

Too many choices!

I've also floated around the idea of having the guys on the board cobble together a circuit and then label it on the board as 'product of the DIYAuadio.com crew', and then donate some cash to the board for each one sold. Help the board out, kinda thing. I mean, all doors are open here. I'm just trying to figure out which one to walk through.

Building one from scratch is also not something I'm looking to do right now, which a design coming from here would need take, as a route.

I'm smart enough to stick to my strength, which is modding gear, not designing circuits. Which is why I have to start with an existing product. I'd start with Ongaku level stuff..but that can be bit insulting to the designers, and not too many sales at that level.

A friend has four of the Blue Note units floating around his store, he's sending me one, it should be here tomorrow. I'm going to hack it to pieces to see what it does when it's taught to sit up and beg and bark.

According to that friend I've already pushed a modded $200 unit up into the area occupied by his Chord unit, so I'm not doing too bad.

Any ideas on any given units I might have overlooked? Of the cheap chinese variety, I'm thinking here. The Jolida is off my list, I've seen inside of it. I'm looking for s simple circuit, the Yaqin seems to have that, at the least.

YNWOAN said:

My cartridge is no longer in production but it would certainly be in the $2000+ range if it were (even second hand they sell for approx $1000). However, the price is not relevant, my point is just to say that I wouln't risk my MC if I thought there was a problem

Kiseki?

do you want me to rip it open and send some snaps? I can't even mod, but I'd love to be able to chase some of the hiss out of it.KBK said:

I just arranged to buy one of these for the requisite $285 it seems to go for. I'm looking to pick it up on Monday, on a business trip to Toronto,as the ebay seller is in the Toronto (Ontario, Canada) area.

I'm looking to find a decent chassis to start with with respects to modification.

I'm looking to start at a fairly low price ..with a decent chassis, and basic circuit...and then move it up in quality. The Yaqin is a stab in the dark.

This may end up being a modified Yaqin product for OEM base use and course...modified .., rebranded...then resale.

I'd have Yaqin make me new faceplate, of course. I'd like to use the Ming Da stuff, but it's quite expensive to start with.

Too many choices!

I've also floated around the idea of having the guys on the board cobble together a circuit and then label it on the board as 'product of the DIYAuadio.com crew', and then donate some cash to the board for each one sold. Help the board out, kinda thing. I mean, all doors are open here. I'm just trying to figure out which one to walk through.

Building one from scratch is also not something I'm looking to do right now, which a design coming from here would need take, as a route.

I'm smart enough to stick to my strength, which is modding gear, not designing circuits. Which is why I have to start with an existing product. I'd start with Ongaku level stuff..but that can be bit insulting to the designers, and not too many sales at that level.

A friend has four of the Blue Note units floating around his store, he's sending me one, it should be here tomorrow. I'm going to hack it to pieces to see what it does when it's taught to sit up and beg and bark.

According to that friend I've already pushed a modded $200 unit up into the area occupied by his Chord unit, so I'm not doing too bad.

Any ideas on any given units I might have overlooked? Of the cheap chinese variety, I'm thinking here. The Jolida is off my list, I've seen inside of it. I'm looking for s simple circuit, the Yaqin seems to have that, at the least.

My lucaschek is coming soon, but I still want to be able to hear MC through a nice tube riaa

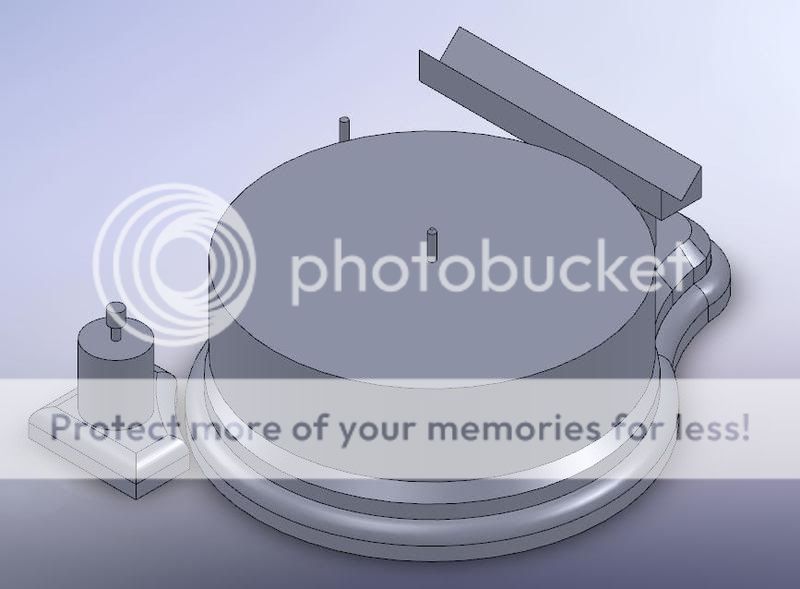

I'm seeing one serious flaw here. You might want to rethink your arm geometry.

Dougie085 said:Ok took some of what you said into consideration and redid it a bit.

Altmann stepper motor drive....

If you use Mr. Altmann's stepper motor system, it does not use a floppy drive motor. It uses a 6 wire stepper, (2 grounds), 2 +ve signals and 2 -ve signals. The signals are 90 degrees out of phase to one another, and a computer or MP3 player to provide the frequency generation and a small stereo amp to provide the voltage. Very inexpensive and very easy to implement.

I've ordered a half dozen motors, have an mp3 player (even the cheapest smallest ones will work), and have enough small amps to use for a drive. Easy to change frequencies to ensure correct correlation between motor speed and platter speed.

As pointed out somewhere else, you could make a cd of the required signals. I was criticized for making this suggestion elsewhere in this forum. If it's good enough for Mr Altmann (who makes very well reviewed gear), it's good enough for me .

.

If you use Mr. Altmann's stepper motor system, it does not use a floppy drive motor. It uses a 6 wire stepper, (2 grounds), 2 +ve signals and 2 -ve signals. The signals are 90 degrees out of phase to one another, and a computer or MP3 player to provide the frequency generation and a small stereo amp to provide the voltage. Very inexpensive and very easy to implement.

I've ordered a half dozen motors, have an mp3 player (even the cheapest smallest ones will work), and have enough small amps to use for a drive. Easy to change frequencies to ensure correct correlation between motor speed and platter speed.

As pointed out somewhere else, you could make a cd of the required signals. I was criticized for making this suggestion elsewhere in this forum. If it's good enough for Mr Altmann (who makes very well reviewed gear), it's good enough for me

did you get it already?KBK said:

I just arranged to buy one of these for the requisite $285 it seems to go for.

I'll have one for sale in a few weeks.

Re: Altmann stepper motor drive....

I want origin live advanced, maybe I should look into DIY first.

So, you just make a ten hour mp3 of sine wave?Nanook said:

As pointed out somewhere else, you could make a cd of the required signals. I was criticized for making this suggestion elsewhere in this forum. If it's good enough for Mr Altmann (who makes very well reviewed gear), it's good enough for me.

I want origin live advanced, maybe I should look into DIY first.

10 hours?

seems no LP has more than 22 minutes a side (max possible I think--but don't quote me).

I've been criticized for suggesting this approach elsewhere on this forum, but it is a simple, and "idiot-proof (although I'm in no way suggesting any here are idiots, except perhaps myself) means to an end. The beauty of this approach is that it is very easy to implement, and does not allow the speed to drift like typical DC implementations, nor is it dependent on the mains frequency. You could even use the same approach to drive a AC motor using an appropriately large amplifier.

Buy a cheap MP3 player, and record two frequencies, one for 33 1/3 rpm, and one for 45 rpm. Small adjustments can be made by re-recording the sine waves (you do need a stereo amp and one of the signals needs to be 90 degrees out of phase to the other. you will need a pulley, and also need to do a little math.

Here's the great thing: it's cheap! I just ordered a half dozen motors, including international shipping from the US (I'm Canuck) for something like USD$25 . Mp3 players are a dime a dozen (I'll use my creative Zen Nano plus or purchase an iPod shuffle ) as are amps (whether new "T-amps" , digital amps --I've found some stunning lookers for around CAD$40, or pawn shop or "boot sale" amps for less).

seems no LP has more than 22 minutes a side (max possible I think--but don't quote me).

I've been criticized for suggesting this approach elsewhere on this forum, but it is a simple, and "idiot-proof (although I'm in no way suggesting any here are idiots, except perhaps myself) means to an end. The beauty of this approach is that it is very easy to implement, and does not allow the speed to drift like typical DC implementations, nor is it dependent on the mains frequency. You could even use the same approach to drive a AC motor using an appropriately large amplifier.

Buy a cheap MP3 player, and record two frequencies, one for 33 1/3 rpm, and one for 45 rpm. Small adjustments can be made by re-recording the sine waves (you do need a stereo amp and one of the signals needs to be 90 degrees out of phase to the other. you will need a pulley, and also need to do a little math.

Here's the great thing: it's cheap! I just ordered a half dozen motors, including international shipping from the US (I'm Canuck) for something like USD$25 . Mp3 players are a dime a dozen (I'll use my creative Zen Nano plus or purchase an iPod shuffle ) as are amps (whether new "T-amps" , digital amps --I've found some stunning lookers for around CAD$40, or pawn shop or "boot sale" amps for less).

Re: 10 hours?

I'll supply my own mp3 player and amp

wanna make me one?Nanook said:seems no LP has more than 22 minutes a side (max possible I think--but don't quote me).

I've been criticized for suggesting this approach elsewhere on this forum, but it is a simple, and "idiot-proof (although I'm in no way suggesting any here are idiots, except perhaps myself) means to an end. The beauty of this approach is that it is very easy to implement, and does not allow the speed to drift like typical DC implementations, nor is it dependent on the mains frequency. You could even use the same approach to drive a AC motor using an appropriately large amplifier.

Buy a cheap MP3 player, and record two frequencies, one for 33 1/3 rpm, and one for 45 rpm. Small adjustments can be made by re-recording the sine waves (you do need a stereo amp and one of the signals needs to be 90 degrees out of phase to the other. you will need a pulley, and also need to do a little math.

Here's the great thing: it's cheap! I just ordered a half dozen motors, including international shipping from the US (I'm Canuck) for something like USD$25 . Mp3 players are a dime a dozen (I'll use my creative Zen Nano plus or purchase an iPod shuffle ) as are amps (whether new "T-amps" , digital amps --I've found some stunning lookers for around CAD$40, or pawn shop or "boot sale" amps for less).

I'll supply my own mp3 player and amp

planar boy...

tell me your pulley dimensions and your platter dimensions (where the belt or string or whatever will run).

a little math:

(platter circumference÷pulley circumference)× 33 1/3 (or 45 rpm) = required speed of the motor in rpm

The required speed of the motor can be recorded as a frequency, eg if R of the platter is 150 mm, and the pulley has radius r of say 1mm, then the solution is just 150/1 X 33 1/3 revs/min X 1 min/60 secs= 83.33333 Hz,,, so record a 83.33333 Hz signal using Audacity or similar for something like 25 minutes, now record a second 83.3333 signal BUT 90 degrees "behind" the first.

Stepper motors often have 6 wires; two are ground, two are coil 1 and coil 2 POSITIVE, and the other two are coil 1 and coil 2 NEGATIVE respectfully. Put the newly recorded stereo frequency of (example) 83.33333Hz into a stereo amp (in the case of DC steppers a small stereo amp will suffice , like a 10 watt T amp or whatever you can find cheap). Feed the non-delayed signal to the coil 1 wires, and the other to the coil 2 windings. Put an AC voltmeter across one channel of outputs and increase the output of the amp until you are at the rated voltage for the motor. Now the really cool thing is that you have a very inexpensive DC stepper motor acting like an asynchronous AC motor, but here's the beauty. The motors can be had for a single quid!

look

here for further information. Really quite simple and can be adapted to pretty much any turntable that has a speed problem. with a "true" AC asynchronous motor, the output voltage will need to have sufficient output to drive the motor, often in the 80 Volt range, but perhaps only a .2Amp draw--check your motor.

here's a link to Pollins in Germany , look for part number MINEBEA 55SPM25D6G.

stew

tell me your pulley dimensions and your platter dimensions (where the belt or string or whatever will run).

a little math:

(platter circumference÷pulley circumference)× 33 1/3 (or 45 rpm) = required speed of the motor in rpm

The required speed of the motor can be recorded as a frequency, eg if R of the platter is 150 mm, and the pulley has radius r of say 1mm, then the solution is just 150/1 X 33 1/3 revs/min X 1 min/60 secs= 83.33333 Hz,,, so record a 83.33333 Hz signal using Audacity or similar for something like 25 minutes, now record a second 83.3333 signal BUT 90 degrees "behind" the first.

Stepper motors often have 6 wires; two are ground, two are coil 1 and coil 2 POSITIVE, and the other two are coil 1 and coil 2 NEGATIVE respectfully. Put the newly recorded stereo frequency of (example) 83.33333Hz into a stereo amp (in the case of DC steppers a small stereo amp will suffice , like a 10 watt T amp or whatever you can find cheap). Feed the non-delayed signal to the coil 1 wires, and the other to the coil 2 windings. Put an AC voltmeter across one channel of outputs and increase the output of the amp until you are at the rated voltage for the motor. Now the really cool thing is that you have a very inexpensive DC stepper motor acting like an asynchronous AC motor, but here's the beauty. The motors can be had for a single quid!

look

here for further information. Really quite simple and can be adapted to pretty much any turntable that has a speed problem. with a "true" AC asynchronous motor, the output voltage will need to have sufficient output to drive the motor, often in the 80 Volt range, but perhaps only a .2Amp draw--check your motor.

here's a link to Pollins in Germany , look for part number MINEBEA 55SPM25D6G.

stew

I'd like to know the optimum size pulley for a rega subplatter, could probably get one turned around here somewhere.

Otherwise I could probably use stock rega pulley.

I want to find a small sinewave generator kit.

As much as I'd like to see MP3 technology "in it's place" (hahaha I love it, put the Mp3 on menial tasks in the power supply room, total demotion!)

I'd think a dedicated, small sinewave generator that does high enough voltage would have to be better and maybe even comparable in price to the said alternative. I rarely spin a whole side anyway, The repeat on the sinewave track would annoy me at least 10 times a week, if its noticeable. All mp3 players have a bit of silence between tracks in any situation.

Maybe a few don't.

And at any rate it will beat the Airpax in one category: changing to 45.

Otherwise I could probably use stock rega pulley.

I want to find a small sinewave generator kit.

As much as I'd like to see MP3 technology "in it's place" (hahaha I love it, put the Mp3 on menial tasks in the power supply room, total demotion!)

I'd think a dedicated, small sinewave generator that does high enough voltage would have to be better and maybe even comparable in price to the said alternative. I rarely spin a whole side anyway, The repeat on the sinewave track would annoy me at least 10 times a week, if its noticeable. All mp3 players have a bit of silence between tracks in any situation.

Maybe a few don't.

And at any rate it will beat the Airpax in one category: changing to 45.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- Designing a DIY TT