The other factors : https://www.youtube.com/watch?v=dAPP-pg1-YI

(Nordhavn 76, built around your corner, and offered for sale at a little over $5.5m, 2 years old when it burnt down completely till it sank)

(Nordhavn 76, built around your corner, and offered for sale at a little over $5.5m, 2 years old when it burnt down completely till it sank)

Just had a look.Q max cutters are available from RS Components and Farnell etc. They are the industry standard for those without a Fly Press. They come in all sizes, here is an example of a hydraulic type. there are manual ones as well. Have a look;

The hydraulic aspect caught my fancy, maybe they adapted a car lifting hydraulic pump or something (I thought: what a cool, DIY idea

They suggest a "hobby type/DIY" hydraulic press .... for 721 GBP

http://uk.rs-online.com/web/p/machi...245522677633D4E4F4E45267573743D36303532323326

OUCH !!!!!!!!!

yeahThe other factors :

dock queens stupidity is probably the main factor in most marine fires. whether the hull remain floating is only a consolation prize

Last edited:

The ones you twist down manually with a wrench are about $20 to $30

For the highest return on those bucks, punch a hole in a couple of steel scrap pieces, and clamp those stacked to the top (cutting) side before wrenching the final act.

(aka mimic a real punch/die set of 25 times that rate, see e.g. Anchor Daily)

The mind and the finger, both wonderful things, but sometimes have difficulty communicating.

Die Sets - Custom Die Sets, Standard Die Sets, Cast Die Sets - Anchor Danly

Die Sets - Custom Die Sets, Standard Die Sets, Cast Die Sets - Anchor Danly

DMG MORI Lasertec 65 .

had to look that up..

'3d printer' and mill in one.

DAMN!!

2kw laser diode

How does the steel help then?For the highest return on those bucks, punch a hole in a couple of steel scrap pieces, and clamp those stacked to the top (cutting) side before wrenching the final act.

(aka mimic a real punch/die set of 25 times that rate, see e.g. Anchor Daily)

Sent from my GT-I9505 using Tapatalk

Think of push-cutting a slice from a wedding cake, or one from a gingercake.

A sharp knife will go through the wedding cake like proverbial butter.

The same knife will elastically deform the gingercake, the top will be compressed before the knife will start to go through the cake.

Now vision that the gingercake is clamped firmly between two rigid surfaces/shelves on other side of the cutting line.

When the knife pushes on the surface, the material of the gingercake has nowhere to go, it will deform less before the knife will go through it.

With a chassis punch, the die is the plate the cake is on, the punch is the knife you push through the yummy material.

Secondly, a cake does not deform plastically, but metal does.

When the pressure of the knife exceeds the elasticity maximum, the molecules start to slide off/over eachother.

By the time the knife/punch has gone through most of the material, the pressure in the remaining uncut part exceeds the maximum stress, and it will rip off.

You can see that all around you, sand has a critical angle beyond which it will break/slide off, surface of a broken bone will look identical to breaking a piece of chalk. (I studied physical geography, and walked around in a white coat plus badge)

Carpaccio is made by freezing a roll of meat before cutting it, otherwise it would deform under the knife of a meat slicer, and the last bit would tear off before the rotating knife can go through it.

Punched metal shows where it was elastic when it was cut, where it was plastic, also at which point/position it ripped off.

With serial punching, this can be influenced by the speed the metal is cut at, the force, and by clamping it.

Metal slides through a punch mold, then clamped in position, then the punch cuts it.

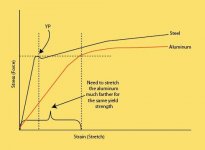

With a chassis punch, the punching speed is very slow, your material is aluminum and very elastic.

By clamping it with steel on the cutting side, you'll get a cleaner surface of the cut. Use lubricant !

(I have hands with lovely scars and early signs of osteoarthritis from hundreds of hours of punch/press work, professional disease. Same as Keith Richards, but far fewer quid. Should have gone to tech university sooner. )

)

A sharp knife will go through the wedding cake like proverbial butter.

The same knife will elastically deform the gingercake, the top will be compressed before the knife will start to go through the cake.

Now vision that the gingercake is clamped firmly between two rigid surfaces/shelves on other side of the cutting line.

When the knife pushes on the surface, the material of the gingercake has nowhere to go, it will deform less before the knife will go through it.

With a chassis punch, the die is the plate the cake is on, the punch is the knife you push through the yummy material.

Secondly, a cake does not deform plastically, but metal does.

When the pressure of the knife exceeds the elasticity maximum, the molecules start to slide off/over eachother.

By the time the knife/punch has gone through most of the material, the pressure in the remaining uncut part exceeds the maximum stress, and it will rip off.

You can see that all around you, sand has a critical angle beyond which it will break/slide off, surface of a broken bone will look identical to breaking a piece of chalk. (I studied physical geography, and walked around in a white coat plus badge)

Carpaccio is made by freezing a roll of meat before cutting it, otherwise it would deform under the knife of a meat slicer, and the last bit would tear off before the rotating knife can go through it.

Punched metal shows where it was elastic when it was cut, where it was plastic, also at which point/position it ripped off.

With serial punching, this can be influenced by the speed the metal is cut at, the force, and by clamping it.

Metal slides through a punch mold, then clamped in position, then the punch cuts it.

With a chassis punch, the punching speed is very slow, your material is aluminum and very elastic.

By clamping it with steel on the cutting side, you'll get a cleaner surface of the cut. Use lubricant !

(I have hands with lovely scars and early signs of osteoarthritis from hundreds of hours of punch/press work, professional disease. Same as Keith Richards, but far fewer quid. Should have gone to tech university sooner.

)

)Attachments

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Design & Build

- Construction Tips

- Cutting neat holes in anodized aluminum