Stuey said:Guys, regarding your general comments about blade depth and general saw use, I have to stress here that I'm no novice in using a circular saw.

Stu

That was at least not my point anyway, but there's a lot of people reading these threads, and I have been more than amazed and closed to horrified sometimes of some the suggestions and solutions that creep up around here....

Some are really

and some are really

and some are really

- even for old geezers....

- even for old geezers.... MJL21193 said:

As odd as it seems, radial arm saws are used the way sandyhooker says - pulled toward your through the work. This applies to aluminum cut on a radial arm saw also

John, radial arm saws are used both push and pull. If you are attempting to pull, you'd best know what you are doing, use an anti-climb blade and make sure your insurance is up to date. This is not for the uninitiated. If you are using as a push, there are virtually no problems if you clamp the work down.

(Though I would NEVER use this saw to cut aluminum). Using it the other way (pushing it through the work) is dangerous... [/B]

Aluminum is fine on a radial saw but I would never, repeat never try it in pull mode.

John, I have spent a number of years in aluminum fabrication and I am having trouble reading what you are typing.

MJL21193 said:Like any dangerous tool, the radial arm saw has a some learning attached - the blade needs to be the correct type (low angle for less agressive cutting) and shouldn't be used by someone who isn't familiar with it's operation.

If done correctly, cutting aluminum sheet with a circular saw when the sheet is clamped down and using a sharp carbide METAL cutting blade in the saw is more safe than using a tablesaw.

I agree with the first point.

I think the second point is up to the operator. A table saw is not that dangerous but I must admit I still a lot of persons standing behind the stock rather than beside, not using a feeder stick, no gloves, no ear protection, no goggles and removing the guard.

Cal Weldon said:

John, radial arm saws are used both push and pull. If you are attempting to pull, you'd best know what you are doing, use an anti-climb blade and make sure your insurance is up to date. This is not for the uninitiated. If you are using as a push, there are virtually no problems if you clamp the work down.

Aluminum is fine on a radial saw but I would never, repeat never try it in pull mode.

John, I have spent a number of years in aluminum fabrication and I am having trouble reading what you are typing.

Cal, A quick search of radial arm saw safety on google will confirm what I'm saying. I learned it from my father (and also in trade school) long ago, have been using these saws for nearly 30 years.

To crosscut on a radial arm saw you pull the blade through the work - this is not an option. To push through runs the risk of the blade grabbing the work and forcing it up. Your advice on this matter is not only wrong, it's dangerous. Clamping the workpiece down to attempt a push through cut is ridiculous.

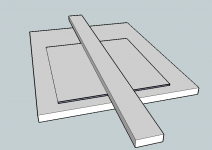

Maybe a quick sketchup drawing will clarify what I'm saying about using the hand held circular saw to cut sheet aluminum. Below is the drawing - on the bottom is the scrap plywood or MDF, above that ( smaller) is the aluminum sheet and on top is the strip of plywood that will act as the fence or guide for the saw. This is clamped down on both ends. Clear?

Attachments

Where's that? I get out there occasionally and could use a couple of panels like that.Minion said:The metal shop by my house will sell me and cut to size a 19in x4in x1/16in Aluminum plate for $6 ...... it"s probably cheaper if you allreay have the aluminum plate .....

Originally posted by MJL

Maybe a quick sketchup drawing will clarify what I'm saying about using the hand held circular saw to cut sheet aluminum. Below is the drawing - on the bottom is the scrap plywood or MDF, above that ( smaller) is the aluminum sheet and on top is the strip of plywood that will act as the fence or guide for the saw. This is clamped down on both ends. Clear?

That's exactly what I meant way back in my first post, only the 2 guides were to be bricklayer's profiles, which are 1" square steel tubing. This is what I do with wood for speakers and it works very accurately if set up properly.

Chrisb, two things to note - the offcuts were from a CNC water jet cutting shop and that's all they do. Yes, they could do it, but it's 10km away and they need to fit these small jobs in between their larger programmed ones. I don't like to interrupt them as they kindly give me aluminium offcuts for almost nothing. The other thing is that, as mentioned above, this thread was more for the long term, so I could use the method on a number of projects. So while I could easily go to a metal shop a couple of kays away, I'd rather get a setup I could use at home.

Cheers

Stuey

Stuey said:An update; the local sheet metal shop cut them with their guillotine in literally two minutes. Worth it for sure...minimal filing required as well.

Stuey

And don't forget, you still got 9 fingers

Magura

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Design & Build

- Parts

- Cutting aluminium, again...