Oslon only took it as far as the sphere. An eggshape or even better

Is that Oslon that Mork was invoking ?

Attachments

I'd like something like the Undefinition 'Sunflower' in its layout: open baffle top end and sealed bass cabinet. But with a rounded smooth-edged cabinet, perhaps tapered like an obelisk (picture a very tapered egg).

https://sites.google.com/site/undefinition/diy-sunflowers

https://sites.google.com/site/undefinition/diy-sunflowers

This solution would probably suit the most people. If you could optionally include a [baffle with] standard cutout (e.g. for 6" and 1") that might increase the appeal, for people with no tools.I AM simply looking for input on the SHAPE and SIZE of whatever is made.

Should it be a small, conventional general-purpose BOX with removable front and possibly rear baffles that the user would then supply when they build it up for their own project?

This would appeal to a more dedicated builder / nerd ...but that sort of person is also likely to email you 18 times with questions and then decide to build it themselves. What Boden said is exactly how I'd do it (I'd use something cheap and discardable for my spheres - like fishbowls from a $2 shop).Should it be something that is not easy to make by the DIYer like a spherical enclosure for a midrange and tweeter that would sit on top of another cabinet [...]

As I understand it, the internal cavities are made by polystyrene fillers/cut-to-shape- blocks, that are melted away once the walls have hardened.

It should not to be too hard to do it yourself.

Last edited:

I have not read the whole thread but 40 yrs ago in Oz a local retailer in Melbourne marketed a concrete three way enclosure (IB) that was about 70-80 litres internal volume and he included polystyrene balls from a "bean bag" in the concrete mix. This reduced the weight somewhat. They used 12" Philips based three-way drivers.

They sold a few.

Cheers Jonathan

They sold a few.

Cheers Jonathan

A variety of fillers are available to lower density- microspheres are probably wasteful from a cost perspective- they're the best but most expensive for density reduction- we don't need the last 10% on that one piece of the puzzle, cheap fillers work quite well (and it's not a performance affecting issue). It's concrete after all.

MBSE

See attached PDF file.

Polished Chrome Bracket later.

WHG

Ah, interesting. So assuming we can describe this loosely as an "egg" shape, where on the surface do you thing would the drivers best be located? On the larger round end or on the "side" with the larger driver towards the larger end and the smaller (e.g. tweeter) towards the smaller end?

One issue that comes along with any enclosure that doesn't have any flat surfaces is how to stand it up as a loudspeaker. Your "egg" or my "sphere" will roll away unless there is a stand included that cradles it or some portion of it, or there are three of four struts cast into it that can be used to stand it up on top of something... any thoughts on that?

See attached PDF file.

Polished Chrome Bracket later.

WHG

Attachments

See attached PDF file.

Polished Chrome Bracket later.

WHG

I don't think that is a very good shape at all, frankly. It's hardly spherical or even bi-sphereical because of the large cut for the drivers. I think that the cut will defeat the advantages of the "sphere" in terms of smooth baffle step transition.

You probably need to make the sphere much larger in radius than the largest driver in order to not disturb its gradually curved diffraction edge. This means you need something on the order of at least a 20" diameter sphere for a 5" midwoofer and tweeter. This is not an insignificant volume or size to make or ship, and you are not likely to find an off-the-shelf "globe" of that size either. This kind of project will be left for later.

With such a large diameter/volume sphere one should be able to get effective internal standing wave suppression with lots of fill without having to resort to a tapered rear tube like B&W. It would also make sense to put the sphere on top of a stand with an 18 woofer below, which keeps the drivers close together and would make a nice 3-way speaker. The woofer would operate below 150-200Hz where the 5" driver can no longer provide enough excursion to keep up. With such a low crossover frequency between woofer and midwoofer, the position of the woofer below the sphere is not a problem.

Last edited:

The Egg-Shaped Enclosure Model is not Idiot Proof!

Until you pick drivers, set [Rs] and [Rl], and address driver alignment/mounting specifics, you do not have a design to critique.

WHG

I don't think that is a very good shape at all, frankly. It's hardly spherical or even bi-sphereical because of the large cut for the drivers. I think that the cut will defeat the advantages of the "sphere" in terms of smooth baffle step transition.

You probably need to make the sphere much larger in radius than the largest driver in order to not disturb its gradually curved diffraction edge. This means you need something on the order of at least a 20" diameter sphere for a 5" midwoofer and tweeter. This is not an insignificant volume or size to make or ship, and you are not likely to find an off-the-shelf "globe" of that size either. This kind of project will be left for later.

With such a large diameter/volume sphere one should be able to get effective internal standing wave suppression with lots of fill without having to resort to a tapered rear tube like B&W. It would also make sense to put the sphere on top of a stand with an 18 woofer below, which keeps the drivers close together and would make a nice 3-way speaker. The woofer would operate below 150-200Hz where the 5" driver can no longer provide enough excursion to keep up. With such a low crossover frequency between woofer and midwoofer, the position of the woofer below the sphere is not a problem.

Until you pick drivers, set [Rs] and [Rl], and address driver alignment/mounting specifics, you do not have a design to critique.

WHG

Target to Shoot At

Also "Egg-Nest" Design for Stand. WHG

MunroSonic EGG150 Monitoring System | Overview ? MunroSonic

Also "Egg-Nest" Design for Stand. WHG

MunroSonic EGG150 Monitoring System | Overview ? MunroSonic

Attachments

Why?

The example (EGG 150) demonstrates excellent performance in a small package for the egg enclosure shape and it will not be a 'heavy lift' if cast in concrete or terrazzo even if up-scaled to accommodate an 8" or 10" bass driver. WHG

An egg shaped mini speaker is not the direction I plan to go.

The example (EGG 150) demonstrates excellent performance in a small package for the egg enclosure shape and it will not be a 'heavy lift' if cast in concrete or terrazzo even if up-scaled to accommodate an 8" or 10" bass driver. WHG

The example (EGG 150) demonstrates excellent performance in a small package for the egg enclosure shape and ...

Um, exactly how did you draw that conclusion???

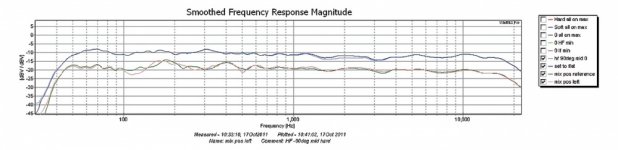

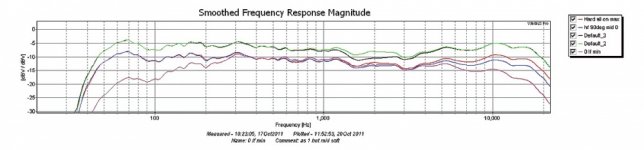

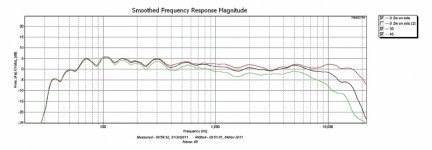

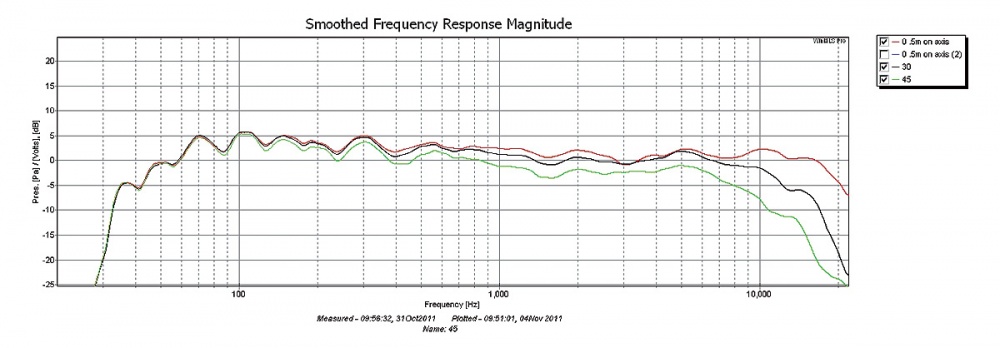

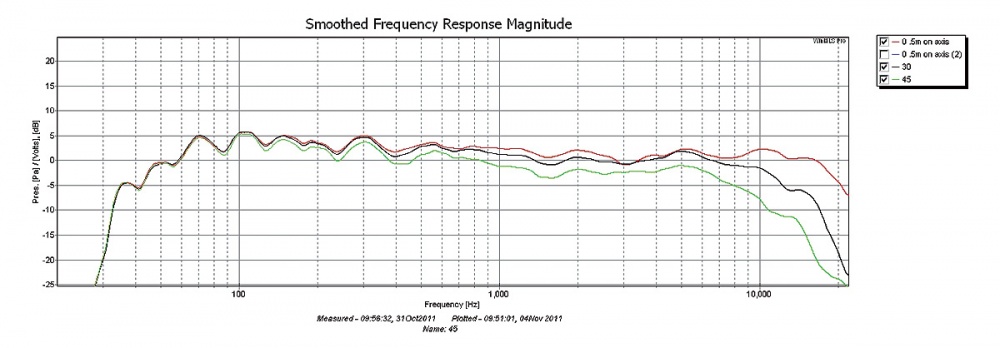

I didn't really see any evidence of 'excellent performance' in their response curves. Since they were only measured on axis they tell very little. They claim:

That's mostly some well written marketing language. To me it looks like a little 2-way with a plate amp and several tone/EQ and level adjustment options. What is so special about that? Why are there even tone controls like these if this is supposed to be a reference for mixing???The Egg 150 is naturally neutral in its frequency response. This is mainly a result of the acoustically optimal enclosure

and the choice of small drivers with almost perfectly controlled directivity.

Are there other measurements that might reveal more about the performance?

You are correct in that a small cabinet will not be too heavy. But I would not be in favor of scaling this up for a large(r) driver(s) like an 8" or 10". As I mentioned before I would want to make the diameter of the sphere several times (at least 4-5 times) the diameter of the largest driver. For a 10" driver that means a 40" diameter sphere. That size is not at all practical. On the other hand, if you stick with a 5" driver you can use a 24" diameter sphere and you will have very little "edges" around the drivers since the curvature is large. The baffle step transition would then be very smooth. This is the direction I would go if and when I do a project like this, and it might not even be in terrazzo because I imagine it might be getting rather heavy at that size....it will not be a 'heavy lift' if cast in concrete or terrazzo even if up-scaled to accommodate an 8" or 10" bass driver. WHG

At this point we are laying plans for a couple of conventional rectangular boxes with removable baffles in a small to medium size. If that proves successful we can consider moving on to more complicated (and expensive) shapes.

The model I gave you ...

Yes! See attachments.

... is a tool to be used, not a master to be served. Modify geometry slightly to meet your mission.

Ugh! Acoustical Sacrifice!

WHG

Um, exactly how did you draw that conclusion???

I didn't really see any evidence of 'excellent performance' in their response curves. Since they were only measured on axis they tell very little. They claim:

That's mostly some well written marketing language. To me it looks like a little 2-way with a plate amp and several tone/EQ and level adjustment options. What is so special about that? Why are there even tone controls like these if this is supposed to be a reference for mixing???

Are there other measurements that might reveal more about the performance?

Yes! See attachments.

You are correct in that a small cabinet will not be too heavy. But I would not be in favor of scaling this up for a large(r) driver(s) like an 8" or 10". As I mentioned before I would want to make the diameter of the sphere several times (at least 4-5 times) the diameter of the largest driver. For a 10" driver that means a 40" diameter sphere. That size is not at all practical. On the other hand, if you stick with a 5" driver you can use a 24" diameter sphere and you will have very little "edges" around the drivers since the curvature is large. The baffle step transition would then be very smooth. This is the direction I would go if and when I do a project like this, and it might not even be in terrazzo because I imagine it might be getting rather heavy at that size.

... is a tool to be used, not a master to be served. Modify geometry slightly to meet your mission.

At this point we are laying plans for a couple of conventional rectangular boxes with removable baffles in a small to medium size. If that proves successful we can consider moving on to more complicated (and expensive) shapes.

Ugh! Acoustical Sacrifice!

WHG

Attachments

Only this one is the off axis responses:Yes! See attachments.

... is a tool to be used, not a master to be served. Modify geometry slightly to meet your mission.

WHG

The other egg speaker images are just providing examples of the effect of EQ settings. But thanks, I did not see the off axis response curves. Looks pretty good except maybe around 3k-5k Hz.

I will take your advice under advisement.

Regarding:

I'm not forcing you to buy anything here... so there is no need for you to sacrifice your ideals. A rectangular box that is easy for the DIYer to use is definitely a better place to start than an egg or sphere shaped speaker. Since it's very general purpose it can be adapted to fit whatever the DIY desires to do with it.Ugh! Acoustical Sacrifice!

Only this one is the off axis responses:

The other egg speaker images are just providing examples of the effect of EQ settings. But thanks, I did not see the off axis response curves. Looks pretty good except maybe around 3k-5k Hz.

I will take your advice under advisement.

Regarding:

I'm not forcing you to buy anything here... so there is no need for you to sacrifice your ideals. A rectangular box that is easy for the DIYer to use is definitely a better place to start than an egg or sphere shaped speaker. Since it's very general purpose it can be adapted to fit whatever the DIY desires to do with it.

Just gave you a total design package example.

I am in the market for some low diffraction enclosures, fabricated to my design only. WHG

A couple things-

1) Cool!

2) I'd have metal threaded inserts in the material for baffle mounting, and have the baffle inset with a large roundover made of the cast material

3) Damping will matter, as hard materials like these will tend to ring.

I disagree with #3, and don't think that these will ring. Concrete walls make a very good sound barrier, as they do not get excited, nor transmit sound.

Remember this is not really about the material (concrete) being better than aluminum or whatever. It's more about the amazingly beautiful surface finish of the terrazzo material ......

Here's an example of a well finished spherical concrete loudspeaker. Sophera - Sophera Sphere 1

I got to see and listen to these earlier this year. They look spectacular, and didn't sound too bad either. If I knew anything about moulding concrete I'd be making a pair to play around with.

Graham.

Sorry Graham, I do mot want to sound harsh, but that is definitely not an example of a well finished sphere. It lacks the most import property of a well designed sphere, that is an ultra smooth transition from driver to enclosure. Basically there should be no flat surface surrounding the driver(s).

From the looks of it, the Sophera has a "hard" transition from a flat baffle to the sphere.

Eelco

From the looks of it, the Sophera has a "hard" transition from a flat baffle to the sphere.

Eelco

Eelco,

I was using the word "finish" to refer to the surface finish of the concrete, a common usage in my language. The manufacturer has arrived at a successful process with no defects and a very nice shiny surface. I agree that the design doesn't look sensible, for a number of reasons, but nevertheless they did not sound too bad.

Graham.

I was using the word "finish" to refer to the surface finish of the concrete, a common usage in my language. The manufacturer has arrived at a successful process with no defects and a very nice shiny surface. I agree that the design doesn't look sensible, for a number of reasons, but nevertheless they did not sound too bad.

Graham.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Custom Concrete Speaker Cabinets