Hi guys, I am very glad I found this site and maybe some help.

This is my first post .

I have this Crown XLS 602 which has given me the same problem two times.

The first time, I took it to a Crown registered dealer and fixed exactly a year ago. There is not too much that she is doing but playing my music at home running a mini studio, two hours tops.

This time, the same cracking noise. I am asked to shell close to 400 dollars to the same dealer for the same problem and this is so not happening.

They estimated that it will take 8 transistors each in/out, but that was done last year.

This is my dilemma, I have the skills to trouble shoot a laptop mother board and fix my own car, and have used a oscilloscope in a lab setting and this amp has been unplugged for days just in case.

I am sure there must be a write up of the procedure to replace the 16 transistor on this site. Any help either way will surely be appreciated.

Thanks!

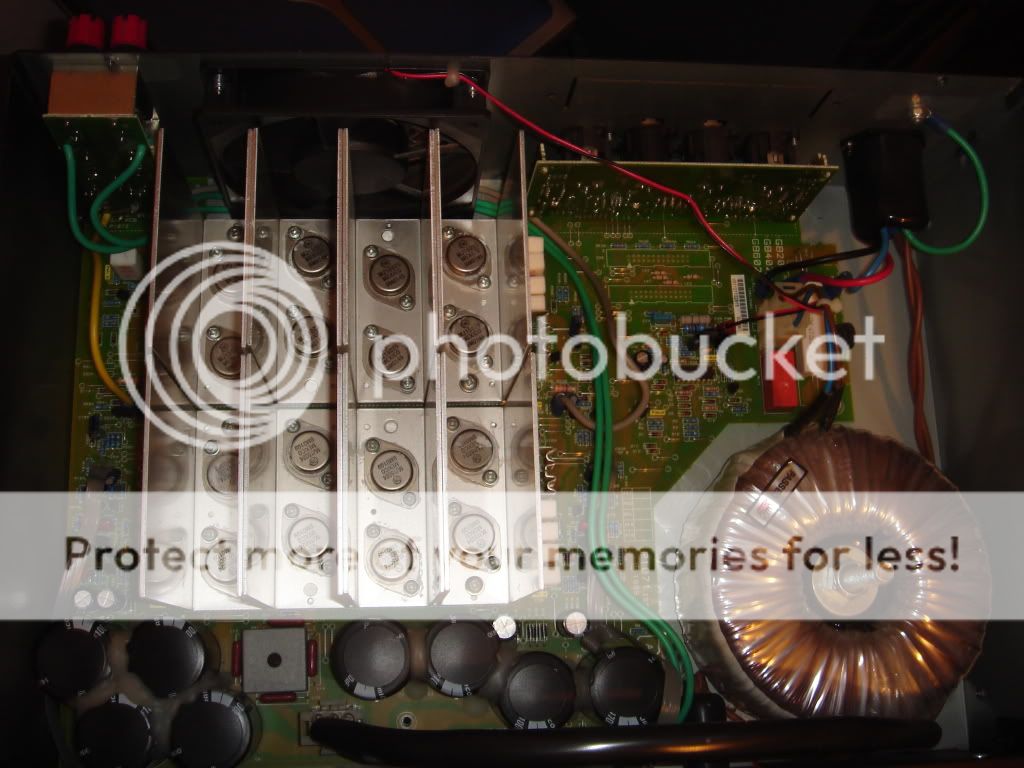

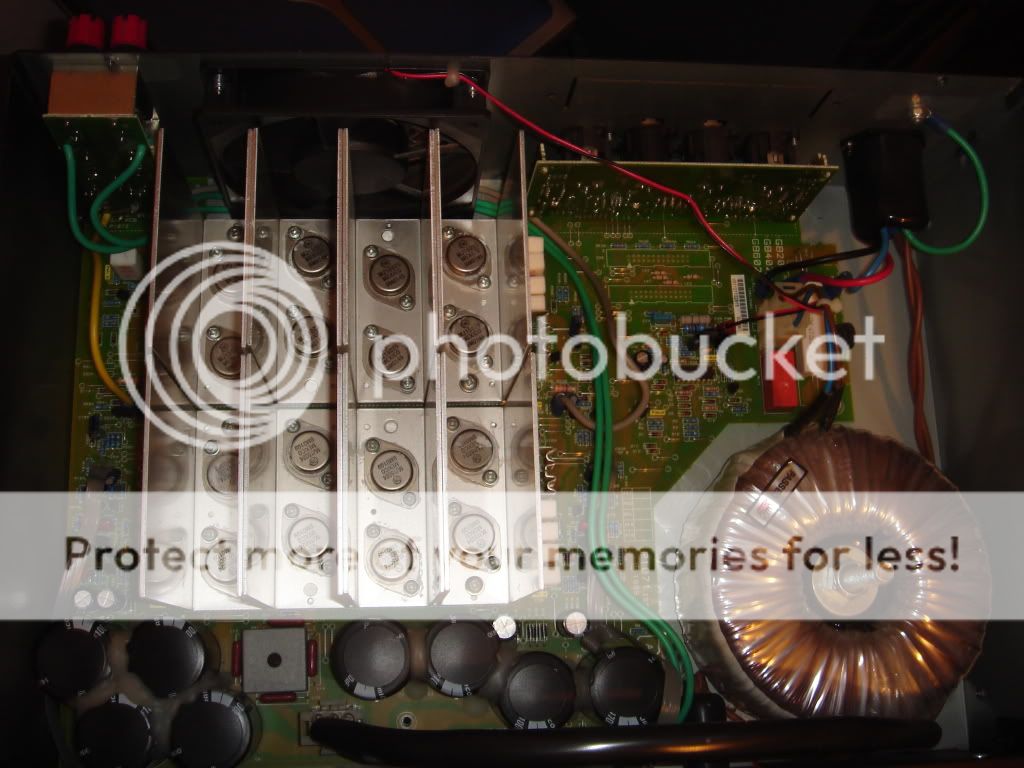

A picture is worth...

This is my first post .

I have this Crown XLS 602 which has given me the same problem two times.

The first time, I took it to a Crown registered dealer and fixed exactly a year ago. There is not too much that she is doing but playing my music at home running a mini studio, two hours tops.

This time, the same cracking noise. I am asked to shell close to 400 dollars to the same dealer for the same problem and this is so not happening.

They estimated that it will take 8 transistors each in/out, but that was done last year.

This is my dilemma, I have the skills to trouble shoot a laptop mother board and fix my own car, and have used a oscilloscope in a lab setting and this amp has been unplugged for days just in case.

I am sure there must be a write up of the procedure to replace the 16 transistor on this site. Any help either way will surely be appreciated.

Thanks!

A picture is worth...

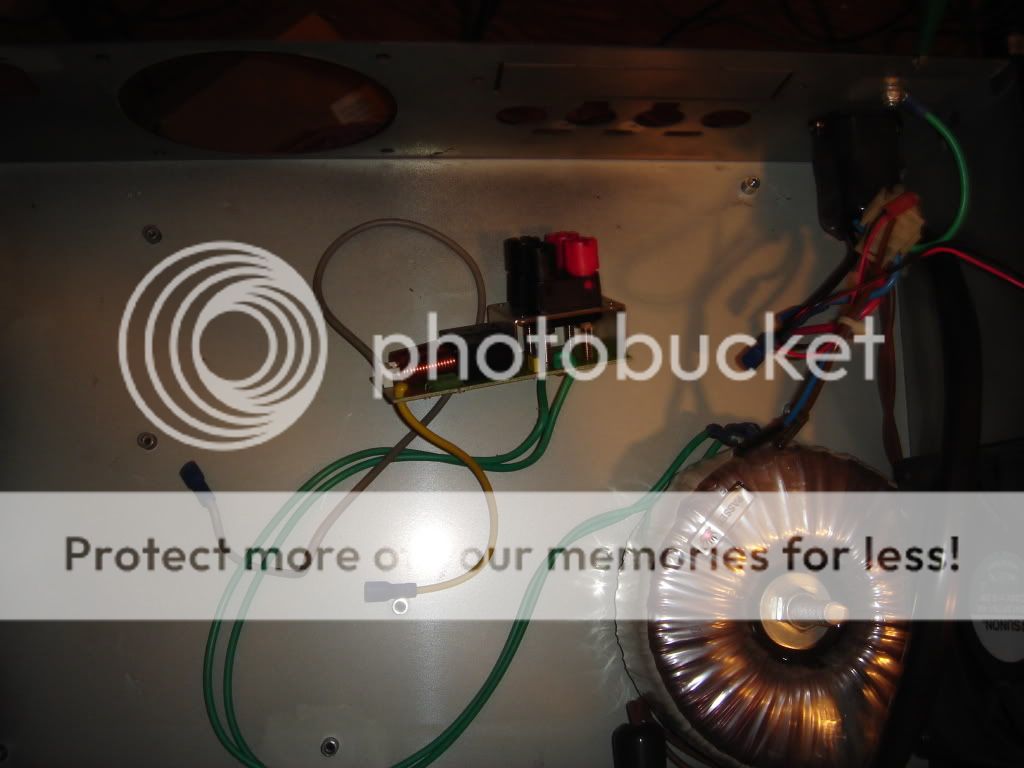

It has been a day and I have had at least 20 visitors and no response. As can be seen at the bottom, there is a screw missing from this new amp as it left the tech shop registered by Crown. The first time it went it was in excellent condition, actually brand new, the last time fair.The more it goes there, the more scratches it received, the more reason I need to fix this myself with or without help. Thanks!

For a starter, does the cracking noise occur when there is no signal, when the level settings are altered, when music is played (normal volume) or when it is played loudly? Including some more information like this will help others to help you.

As well as that, I'd advise to check the board closely for any capacitors that appear to be bulging/leaking, any burnt/heat scorched components or areas of the board and if you really want to, check the solder side of the board for any dry joints. When doing this, please bear in mind that those capacitors at the bottom may still hold a charge which could give you (at most) a bit of a shock if you happened to come into contact with them.

As well as that, I'd advise to check the board closely for any capacitors that appear to be bulging/leaking, any burnt/heat scorched components or areas of the board and if you really want to, check the solder side of the board for any dry joints. When doing this, please bear in mind that those capacitors at the bottom may still hold a charge which could give you (at most) a bit of a shock if you happened to come into contact with them.

the above advice is correct ....you probably have a car with a flat tire and you are looking for an engine replacement ...that is bad practice

output transistors at least under the way you describe things cannot be responsible for such a problem ... output transistors either work or simply are shorted resulting blown fuses protection circuits activated and so on .

Be advised now this is a forum from very happy friendly and helpful people .... that means that from the 20 people that read your post most of them understood that either you are a nb or an amateur which is absolutely no problem cause each and everyone of us has already been there but the problem is that ...

even if someone is willing to help you there is a serious "language " problem and things said are probably not easy for you to understand .

Finally you need to use the advise given so far and we will hear from you again i think ....

cracling sound might occur from

--- bad soldering ....

--- faulty output relay

--- and a dirty pot

--- check the soldering

--- tick the relay with a screw driver while operating ...if crackles come up you got it !!!

--- spray the pots with some contact cleaner or de-oxidizer

kind regards sakis

output transistors at least under the way you describe things cannot be responsible for such a problem ... output transistors either work or simply are shorted resulting blown fuses protection circuits activated and so on .

Be advised now this is a forum from very happy friendly and helpful people .... that means that from the 20 people that read your post most of them understood that either you are a nb or an amateur which is absolutely no problem cause each and everyone of us has already been there but the problem is that ...

even if someone is willing to help you there is a serious "language " problem and things said are probably not easy for you to understand .

Finally you need to use the advise given so far and we will hear from you again i think ....

cracling sound might occur from

--- bad soldering ....

--- faulty output relay

--- and a dirty pot

--- check the soldering

--- tick the relay with a screw driver while operating ...if crackles come up you got it !!!

--- spray the pots with some contact cleaner or de-oxidizer

kind regards sakis

I only check diy once a day. SS amps is mostly design, which I don't do, repair shows up more in PA amps (which this is) under live sound. You can check for bad solder joints if you can operate it with the case off, by poking at the components with a plastic stick and listening. A dead ball point pen (stick) comes to mine- no metal. You can also spray circuit cooler on things but that is more expensive. You can also just look for "dry" solder joints, or crystalized looking ones. Reheating usually works, but sometimes you have to add a little solder. I use rosin core lead-tin solder, 22 to 28 gauge. I use a Weller WP25 iron with a 7/32" screwdriver tip (extra). Don't use conductive tools with the power on, and take all jewelry off while working around it, you don't want a bad burn from your ring or anything.

For a starter, does the cracking noise occur when there is no signal, when the level settings are altered, when music is played (normal volume) or when it is played loudly? Including some more information like this will help others to help you.

As well as that, I'd advise to check the board closely for any capacitors that appear to be bulging/leaking, any burnt/heat scorched components or areas of the board and if you really want to, check the solder side of the board for any dry joints. When doing this, please bear in mind that those capacitors at the bottom may still hold a charge which could give you (at most) a bit of a shock if you happened to come into contact with them.

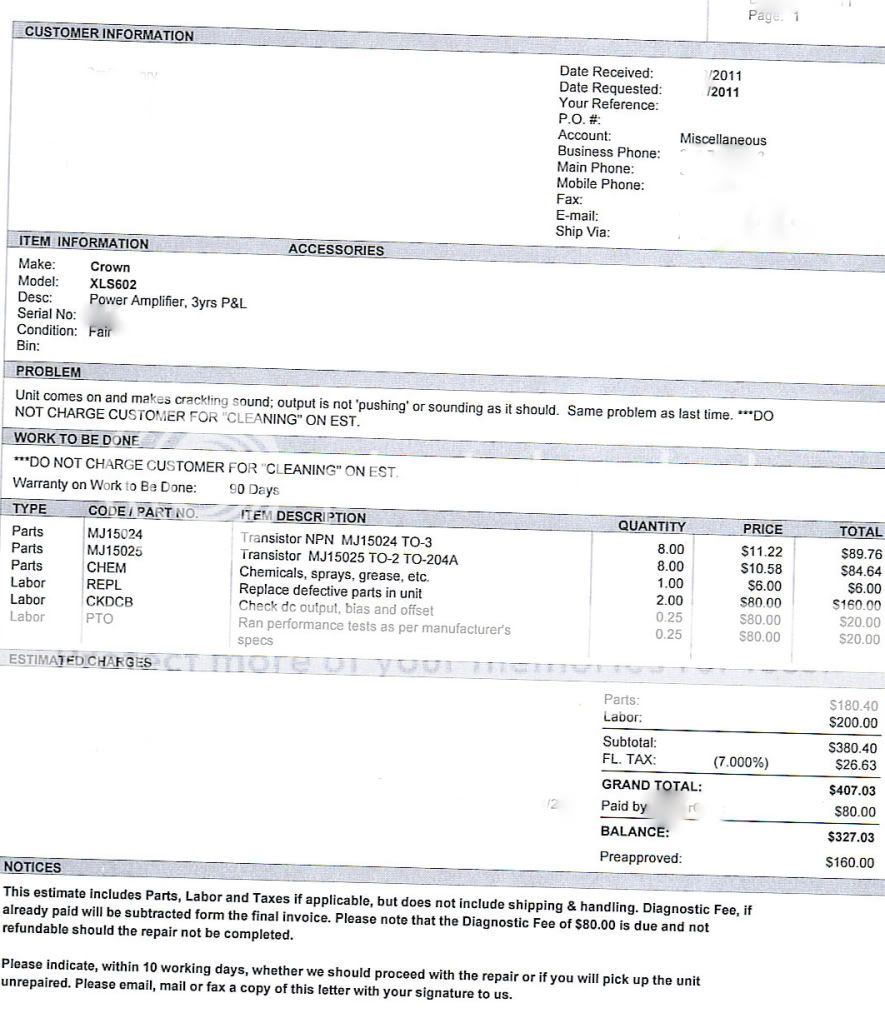

Thanks for responding! The crackling noise starts at boot up (buzz sound) and as the music plays, it reacts as if it is a blown speaker regardless of volume unable to come to grip with the request. I have gotten a 407.03 dollar estimate from the Crown registered dealer and they have already replaced the same 16 transistors after diagnosis, unless they are lying to the customer.

Last edited:

Thanks for the response Sakis!the above advice is correct ....you probably have a car with a flat tire and you are looking for an engine replacement ...that is bad practice

output transistors at least under the way you describe things cannot be responsible for such a problem ... output transistors either work or simply are shorted resulting blown fuses protection circuits activated and so on .

Be advised now this is a forum from very happy friendly and helpful people .... that means that from the 20 people that read your post most of them understood that either you are a nb or an amateur which is absolutely no problem cause each and everyone of us has already been there but the problem is that ...

even if someone is willing to help you there is a serious "language " problem and things said are probably not easy for you to understand .

Finally you need to use the advise given so far and we will hear from you again i think ....

cracling sound might occur from

--- bad soldering ....

--- faulty output relay

--- and a dirty pot

--- check the soldering

--- tick the relay with a screw driver while operating ...if crackles come up you got it !!!

--- spray the pots with some contact cleaner or de-oxidizer

kind regards sakis

I may be a nb at this site but belong to many other forums for my exotic car and other hobbies. You may be confusing being anxious to find some help, weary of avoidance of liability and hence not getting a quick response with language problems. Nothing to fear from here. :

The Crown authorized dealer has already charged me 80 dollars for the diagnosis, did not put all the washers back in and missing a screw not counting the many scratches that they alone created. This is a new amp that was serviced the first time last year by the same dealer for the same reason. Everything looks clean. Please don't put me in a shoe I can not wear. Cheers!

Again, thanks for responding.

Last edited:

Thanks Indianajo! Advice well taken. It looks like the system needs to be contained in its complete environment before it is turned on as per specs, so I will not chanced powering it on any other way. By the way, the only foreign (un-computerized) soldering that was done was by the authorized dealer.I only check diy once a day. SS amps is mostly design, which I don't do, repair shows up more in PA amps (which this is) under live sound. You can check for bad solder joints if you can operate it with the case off, by poking at the components with a plastic stick and listening. A dead ball point pen (stick) comes to mine- no metal. You can also spray circuit cooler on things but that is more expensive. You can also just look for "dry" solder joints, or crystalized looking ones. Reheating usually works, but sometimes you have to add a little solder. I use rosin core lead-tin solder, 22 to 28 gauge. I use a Weller WP25 iron with a 7/32" screwdriver tip (extra). Don't use conductive tools with the power on, and take all jewelry off while working around it, you don't want a bad burn from your ring or anything.

This is the step I am in right now;! Please do not try this at home.

Last edited:

I know Frank, but think of all the glory I will endure if a fleabay product gets it back running for $32 and some soldering time.You can replace the amplifier for less than the cost of repair.

0-if the "crackling" is not happening randomly but all the time then it should be easy

1-does the unit smell when operating ?

2-monitor the supplies (with your scope) and any relay control signals

3-check the power resistances or diodes on the power transistor emitters (?)

4-listen to the output of the pre-amplifier with an headphone (solder wires)

5-report

1-does the unit smell when operating ?

2-monitor the supplies (with your scope) and any relay control signals

3-check the power resistances or diodes on the power transistor emitters (?)

4-listen to the output of the pre-amplifier with an headphone (solder wires)

5-report

Replacing all the outputs to cure crackling noises makes zero sense. IMO, the service people are clueless, or the amp design has some very unusual issues that only they know about. I just fixed a Peavey with many problems, including a crackling problem. It was a bad ground connection in an IDC connector where the panel input board attached to the main circuit board. I've also had crackling problems when small signal transistors were going bad. The plastic rod, a certain amount of shaking and banging and some freeze mist might be your best place to start. I'd put most of my money on a mechanical issue like connectors or bad solder joints, but save a little to wager on the odd semiconductor failure. Use bright lights and a powerful magnifier as well.

0-if the "crackling" is not happening randomly but all the time then it should be easy

1-does the unit smell when operating ?

2-monitor the supplies (with your scope) and any relay control signals

3-check the power resistances or diodes on the power transistor emitters (?)

4-listen to the output of the pre-amplifier with an headphone (solder wires)

5-report

Replacing all the outputs to cure crackling noises makes zero sense. IMO, the service people are clueless, or the amp design has some very unusual issues that only they know about. I just fixed a Peavey with many problems, including a crackling problem. It was a bad ground connection in an IDC connector where the panel input board attached to the main circuit board. I've also had crackling problems when small signal transistors were going bad. The plastic rod, a certain amount of shaking and banging and some freeze mist might be your best place to start. I'd put most of my money on a mechanical issue like connectors or bad solder joints, but save a little to wager on the odd semiconductor failure. Use bright lights and a powerful magnifier as well.

Thanks for responding Pierreohm and Conrad

The unit still has its new condition smell and looks like it is new as can be seen in the picture. It has never moved from my house but twice to the same authorized Crown repair dealer. It has been pampered except when it reached their shop. All the more reason that I would rather set it on fire than bring it back.

I don't have a scope. I have a Digital Multimeter.

Output pre-amplifier no problem with a headphone.

As I said in the previous posts, this is the second time they pin pointed to the transistors and now that I have the mother board exposed, I can see the soldering done by human. I don't know if you are able to see the excess thermal compound residue left all over some of the transistors.

Let us assume that, because they were recommended by the Crown Official Site, they know what they are doing, let me post the estimate for everyone to see the diagnosis.

I may have not explained the symptom properly.

When the power is put on, it makes this buzz sound as if a jack is bad. When the musics comes on, it sounds like a blown speaker unable to handle volume on both channels. I can hear the music, but with some kind of interference and not providing the juice required.

I have read that once a few of the transistors go bad, all of them need to be tossed eventually they lose their integrity over time. These were changed before by them for the same symptom supposedly. Does it that sound like the function of the transistors. Please take a look at the estimate and what they were about to change. The discoloration of the last open my wallet surgery.

Thanks!

Last edited:

Power transistors usually fail shorted, so the amp would blow fuses/breakers or activate some sort of limiting. That's not your symptom. Small signal and passive components can do anything- that's where I'd be looking. In all honesty, they're charging some markup on the transistors, but their labor rate is quite fair. Considering unpacking, setup and cleanup, it takes me about a full day to sort out and document an amplifier if it has subtle problems and if I'm being as thorough as I like to be. That's why many things aren't worth fixing- labor is too high. Factory authorized service is good unless it isn't. You might want to consider a skilled tech someplace else.

BTW, transistors don't "lose their integrity". You put 'em on a curve tracer and they're either good or not.

(I notice the condition is marked "fair" which doesn't seem quite fair if it was perfect when they got it the first time.)

BTW, transistors don't "lose their integrity". You put 'em on a curve tracer and they're either good or not.

(I notice the condition is marked "fair" which doesn't seem quite fair if it was perfect when they got it the first time.)

Last edited:

6-can you tell us the AC voltage on all the DC supplies and grounds, that should give an idea of the ripple.

7-idle, are the bjts getting hot ?

8-do the headphone test (solder) further down the power path, stop when you find something suspicious

9-sure any kind of protection is not triggering and degrading the sound?

like Conrad Hoffman said triple check the input stage

7-idle, are the bjts getting hot ?

8-do the headphone test (solder) further down the power path, stop when you find something suspicious

9-sure any kind of protection is not triggering and degrading the sound?

like Conrad Hoffman said triple check the input stage

Not spotted it in the above posts, but a manual is here if needed,

Free Manuals User / Service / Schematics for Download | HiFi Engine

I agree it doesn't sound like an output transistor failing... they don't fail like that but other types can and do go intermitent but that would be more like a catestrophic failure and result in intermitently high DC offsets. Little caps can be a problem but I'm afraid we are just guessing.

With a lack of test gear/scope it may be a bit ambitious to undertake DIY repair as any mishaps could be costly.

Free Manuals User / Service / Schematics for Download | HiFi Engine

I agree it doesn't sound like an output transistor failing... they don't fail like that but other types can and do go intermitent but that would be more like a catestrophic failure and result in intermitently high DC offsets. Little caps can be a problem but I'm afraid we are just guessing.

With a lack of test gear/scope it may be a bit ambitious to undertake DIY repair as any mishaps could be costly.

How much for MJ15024/4!!!!!

They seem to have diagnosed without seeing the unit and are charging you maybe 10x cost on those transistors. They haven't a clue, and don't let them touch it. If you were in UK I would have pointed you in the direction of Lee Basham as that amplifier used to be the C Audio GB602. You could try posting on SpeakerPlans.com - they might know a service tech nearer you to help you out.

They seem to have diagnosed without seeing the unit and are charging you maybe 10x cost on those transistors. They haven't a clue, and don't let them touch it. If you were in UK I would have pointed you in the direction of Lee Basham as that amplifier used to be the C Audio GB602. You could try posting on SpeakerPlans.com - they might know a service tech nearer you to help you out.

I'm nowhere near some of the guys here when it comes to engineering experience, however I have a lot of experience talking with Crown customer support. Just call support and ask for Kevin Gring. He'll have a bunch of helpful tips that will enable you to walk through the whole thing until you get the amp repaired.

I know that it sounds crazy, but I spoke with him for about half an hour a day for over a week and we were eventually able to narrow down the problem to one section of the circuitry and then a particular bad resistor (my Comtech 400 was producing very garbled audio)! Before starting, I was an amplifier nub.

At least for me, Crown offered unlimited free support even though I purchased my amplifier from Ebay.

Good luck!

By the way, you can find the schematic, etc here:

Discontinued Amplifier Products

I know that it sounds crazy, but I spoke with him for about half an hour a day for over a week and we were eventually able to narrow down the problem to one section of the circuitry and then a particular bad resistor (my Comtech 400 was producing very garbled audio)! Before starting, I was an amplifier nub.

At least for me, Crown offered unlimited free support even though I purchased my amplifier from Ebay.

Good luck!

By the way, you can find the schematic, etc here:

Discontinued Amplifier Products

Just out of curiosity why didn't you sent the amp to Indiana? Crown factory service is better than many I've dealt with . I send dozens of amps to them every year and they are always fair and honest. They will often even fix design issues that go out as service bulletins for no charge on parts.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Solid State

- Crown XLS 602