I mounted the cables side by side instead of on top of each other to reduce the capacitance slightly

The construction was simple:

1) Attach double sided tape to grip liner

2) Attach foil inductor to double sided tape. The CFAC inductor has a polyester film inbetween the layers of foil. I used this as a top insulator for the foil. The foil is therefore in direct contact with the adhesive on one side. I read some stuff about oxidisation problems when copper comes into contact with adhesive due to chlorine leakage. I will have to wait and see.....

3)Trim excess double sided tape and grip liner

The construction was simple:

1) Attach double sided tape to grip liner

2) Attach foil inductor to double sided tape. The CFAC inductor has a polyester film inbetween the layers of foil. I used this as a top insulator for the foil. The foil is therefore in direct contact with the adhesive on one side. I read some stuff about oxidisation problems when copper comes into contact with adhesive due to chlorine leakage. I will have to wait and see.....

3)Trim excess double sided tape and grip liner

Attachments

I've been planning on making a pair of speaker cables the same way. I bought a 1mH Alpha Core Inductor but am having trouble finding the right insulator. I like the idea of using a single sided tape and just sandwiching each conductor between it, so I've been looking at 3M's product line.

They have a real nice and strong Polyurethane Tape made specifically for Abrasion, erosion, scratch, puncture, and impact resistance. It's only downfall is the very high price and the availability. Most of the line comes in around $60-$150 USD.

3M™ Polyurethane Long-Term Protective Tapes

They also have some nice Polyester Tape that could also work but much of it is thin and may not keep the wire from being stretched, bent, etc.

3M™ Polyester Film Tapes

I'm going to have pictures of my progress up pretty soon.

- Brian

They have a real nice and strong Polyurethane Tape made specifically for Abrasion, erosion, scratch, puncture, and impact resistance. It's only downfall is the very high price and the availability. Most of the line comes in around $60-$150 USD.

3M™ Polyurethane Long-Term Protective Tapes

They also have some nice Polyester Tape that could also work but much of it is thin and may not keep the wire from being stretched, bent, etc.

3M™ Polyester Film Tapes

I'm going to have pictures of my progress up pretty soon.

- Brian

According to my references, dielectric (insulator) is not very important for speaker cables, hence I just used what I found. I too was planning on using some adhesive PTFE tape that was £50 for 10m, but the cost seemed in excess of the benefits..

See below:

http://www.audioholics.com/techtips/audioprinciples/interconnects/CableDielectricAbsorption.html

and

http://www.tnt-audio.com/clinica/spkcbl_e.html

Note that dielectric is very important for interconnects (not speaker cable) due to the high terminating impedance. I am planning on making some interconnects from thin wall PFTE tube and foil, such that the foil only just touches the tube.

See below:

http://www.audioholics.com/techtips/audioprinciples/interconnects/CableDielectricAbsorption.html

and

http://www.tnt-audio.com/clinica/spkcbl_e.html

Note that dielectric is very important for interconnects (not speaker cable) due to the high terminating impedance. I am planning on making some interconnects from thin wall PFTE tube and foil, such that the foil only just touches the tube.

Hello,

as far as I know, the famous flat cables made by Allan Wright (www.vacuumstate.com) are insulated with TESA-FILM - the German brand name for an adhesive tape. At least some of his cable kits are said to use such tape.

I think that the dielectric is very important with flat cables due to the large surface which is in contact with the dielectric...

But that is just my theoretical point of view, up to now no real experience.

Good luck

as far as I know, the famous flat cables made by Allan Wright (www.vacuumstate.com) are insulated with TESA-FILM - the German brand name for an adhesive tape. At least some of his cable kits are said to use such tape.

I think that the dielectric is very important with flat cables due to the large surface which is in contact with the dielectric...

But that is just my theoretical point of view, up to now no real experience.

Good luck

If you read the article above regarding dielectric absortion, you will see that is not a very important factor wrt speaker cables

My tape was cloth, which being fabric has a very low DA, I'm not sure what the effect of adhesive is, it is not a subject much discussed

Tesa is just the name of a tape manufacturer like 3M, they make all different types of tape

My tape was cloth, which being fabric has a very low DA, I'm not sure what the effect of adhesive is, it is not a subject much discussed

Tesa is just the name of a tape manufacturer like 3M, they make all different types of tape

One of the biggest reasons that I was researching into the 3M tapes was their strength. I want to create a cable that is tightly laminated with a strong "plastic" insulator that will keep the cable from easily being damaged from normal use. All of us could probably buy some transparent packaging tape and use that on both side of the foil but give it a month and they would look like a wrinkled piece of newspaper.

The stronger tapes should keep the foil from bending for the most part and stop it from creasing.

I would comment about the dielectric properties but i've got a lack of knowledge to that respect.

I guess either way some of those rolls of tape are way to expensive for most of us, including myself.

The stronger tapes should keep the foil from bending for the most part and stop it from creasing.

I would comment about the dielectric properties but i've got a lack of knowledge to that respect.

I guess either way some of those rolls of tape are way to expensive for most of us, including myself.

Hello;

I constructed three sets of silver foil speaker cables approx. 2 years ago the first set was for myself the other two sets for friends.

I used double sided carpet tape with both + and- leads on oposite sides covered with crystal clear packing tape .

Silver foil is .003 x 1in.

These cables are amazing ( although they do need about 500 hours break in) they beat the crap out of every other cables that I have heard....

out of every other cables that I have heard....

I have seen zero signs of oxidation.

Regards.

Craig.

I constructed three sets of silver foil speaker cables approx. 2 years ago the first set was for myself the other two sets for friends.

I used double sided carpet tape with both + and- leads on oposite sides covered with crystal clear packing tape .

Silver foil is .003 x 1in.

These cables are amazing ( although they do need about 500 hours break in) they beat the crap

out of every other cables that I have heard....

out of every other cables that I have heard....I have seen zero signs of oxidation.

Regards.

Craig.

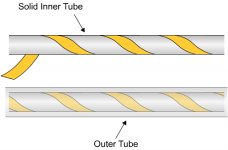

What do you all think about this idea? It uses no adhesives but it may be a little too much work when compared to the tape method.

How about using a solid insulating tube and spiraling the copper foil down the length. Than inserting that into a larger insulating tube. My drawing is kind of crude but you all should get the point. Thanks

How about using a solid insulating tube and spiraling the copper foil down the length. Than inserting that into a larger insulating tube. My drawing is kind of crude but you all should get the point. Thanks

Attachments

Good idea!!!

I'll have to give that one a try. I could think that the only real downfall would be the fact that you need quite a bit more foil to make a decent length of cable. I wonder how much length is wrapped into my 14 gauge 1mH inductor. I guess I'll find out soon enough. The thing is at least 2.5 inches in diameter.

I'll have to give that one a try. I could think that the only real downfall would be the fact that you need quite a bit more foil to make a decent length of cable. I wonder how much length is wrapped into my 14 gauge 1mH inductor. I guess I'll find out soon enough. The thing is at least 2.5 inches in diameter.

Oxidation

Even if you happen to get oxidation, it is not the problem for silver that it is for copper. Silver oxide is a conductor where copper oxide is not. Sealing copper from the environment is most important. Silver oxide just doesn't look as good as polished silver.

rentiap said:Hello;

I constructed three sets of silver foil speaker cables approx. 2 years ago the first set was for myself the other two sets for friends.

These cables are amazing ( although they do need about 500 hours break in) ....

I have seen zero signs of oxidation.

Craig.

Even if you happen to get oxidation, it is not the problem for silver that it is for copper. Silver oxide is a conductor where copper oxide is not. Sealing copper from the environment is most important. Silver oxide just doesn't look as good as polished silver.

Hi,

True...

What makes silver look tarnished isn't so much the oxygen but sulphursulphate and sulphides. That's AgSO2 and Ag2S IIRC.

Either way, if the silver is pure enough it will hardly show any sign of contamination even after years unless you happen to live in a very humid climate.

Naturally, you'd still want to use some sort of insulator to avoid short circuits...

Cheers,

Silver oxide is a conductor where copper oxide is not.

True...

What makes silver look tarnished isn't so much the oxygen but sulphursulphate and sulphides. That's AgSO2 and Ag2S IIRC.

Either way, if the silver is pure enough it will hardly show any sign of contamination even after years unless you happen to live in a very humid climate.

Naturally, you'd still want to use some sort of insulator to avoid short circuits...

Cheers,

Copper pipe? Like you use for plumbing? That could make for some really high current capability, if slightly limited routing possibilities...fdegrove said:Hi,

Has anyone tried hollow solid conductors, crossed or not crossed over, for speaker cables?

Cheers,

Hi,

Yeah....They're throwing in a free toilet seat for every twenty yards bought.

Nah, I was refering to a coaxial type of cable with solid round shield where only that shield is used as a conductor: it's more or less the same as a flat conductor...

Well, not really, but just so you know I'm not talking plumbers stuff...

In the broadcast industry it's often called "hard line".

Cheers,

Copper pipe? Like you use for plumbing? That could make for some really high current capability, if slightly limited routing possibilities...

Yeah....They're throwing in a free toilet seat for every twenty yards bought.

Nah, I was refering to a coaxial type of cable with solid round shield where only that shield is used as a conductor: it's more or less the same as a flat conductor...

Well, not really, but just so you know I'm not talking plumbers stuff...

In the broadcast industry it's often called "hard line".

Cheers,

Sounds like the coax we use for radio transmitters, hollow core copper centre stood off a hollow core outer with telfon inserts every couple of feet. Effectively an air dielectric. A 1 7/8" will handle 5 kw at RF frequencies, at audio frequencies it will probably handle more than you neighbours and power grid can take. If that's not enough I've seen 12" diameter. WAF = 0 but imagine the bragging rights!

Hi everyone,

I made some foil type cables a few yrs ago. I used, I think it is, mylar

insulated type made for HF transformers, switch-mode stuff.

I have no idea about the pricetag cause I got it from the junkbox at work.

But looking for transformer type foil you should be able to find a huge

selection of widths and thickness etc.

I also believe that the cap is not as much an issue as inductance.

Therefore i just put them flat together with ordinary adhesive tape.

Packing tape is quite good but watch out on the sharp edges so you don't get shorts, maybe use 2 layers.

/ Mattias

I made some foil type cables a few yrs ago. I used, I think it is, mylar

insulated type made for HF transformers, switch-mode stuff.

I have no idea about the pricetag cause I got it from the junkbox at work.

But looking for transformer type foil you should be able to find a huge

selection of widths and thickness etc.

I also believe that the cap is not as much an issue as inductance.

Therefore i just put them flat together with ordinary adhesive tape.

Packing tape is quite good but watch out on the sharp edges so you don't get shorts, maybe use 2 layers.

/ Mattias

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Copper foil speaker cables