Ok, managed to sort out the missing parameters (WinIS pro is also useful for that)

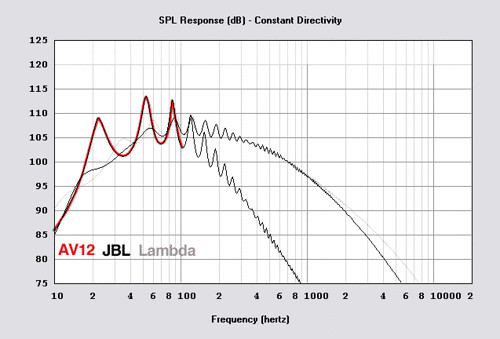

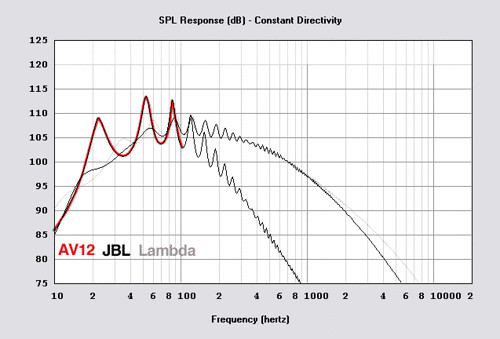

It's quite surprising how well the AV12 performs. It is actually more efficient than those larger drivers which would normally have over 10db higher efficiency. Both of the larger pro drivers meet all the recommendations for a driver except they have a large SD and they are very light at around 80g where >200g is recommended for a 12" driver.

It's quite surprising how well the AV12 performs. It is actually more efficient than those larger drivers which would normally have over 10db higher efficiency. Both of the larger pro drivers meet all the recommendations for a driver except they have a large SD and they are very light at around 80g where >200g is recommended for a 12" driver.

G'day again Paul

This is one of the better threads I've read for a while!

You should have enough power, but watch your voicecoil. Unless you drive way below cutoff, excursion should not become an issue.

This reminds me of a funny thing that happened the other day. I installed the XXLS drivers, with the help of some adapter rings, into the holes normally filled with the 15LW1401s below the Unitys in my system. (They were in separate sealed boxes of the same internal volume) I was a bothered by some distortion that was present on some tracks at moderate levels. I pulled the XXLS drivers out of their boxes for a visual. They seemed fine. Powering them up with another power amp in free air could not induce the distortion I had heard while the drivers were installed in their boxes. I re-installed the drivers and fired up the system again. Slowly increasing the level until I could just hear the distortion again. At that point I headed down stairs to have a look at the level meters on the AM1600 that was powering this pair of drivers. It's probably an understatement to say I was a little shocked to discover the amp was being driven into clipping! 800WRMS into each of these poor 12" drivers. I'm so used to very efficient speakers that this outrageous consumption of power took me completely by surprise! Had I ever driven the 15LW1401s to even 100W each, I'd have been blowing my head off. Needless to say I am delighted with the low distortion at high drive levels that these XXLS drivers show. There was not a hint of distress to just short of 1KW per driver, then it was the amp that went ugly.

AJ

Didn't measure GD. Should have but didn't reverse a driver. The sub was still very clean.

Cheers

William Cowan

This is one of the better threads I've read for a while!

You should have enough power, but watch your voicecoil. Unless you drive way below cutoff, excursion should not become an issue.

This reminds me of a funny thing that happened the other day. I installed the XXLS drivers, with the help of some adapter rings, into the holes normally filled with the 15LW1401s below the Unitys in my system. (They were in separate sealed boxes of the same internal volume) I was a bothered by some distortion that was present on some tracks at moderate levels. I pulled the XXLS drivers out of their boxes for a visual. They seemed fine. Powering them up with another power amp in free air could not induce the distortion I had heard while the drivers were installed in their boxes. I re-installed the drivers and fired up the system again. Slowly increasing the level until I could just hear the distortion again. At that point I headed down stairs to have a look at the level meters on the AM1600 that was powering this pair of drivers. It's probably an understatement to say I was a little shocked to discover the amp was being driven into clipping! 800WRMS into each of these poor 12" drivers. I'm so used to very efficient speakers that this outrageous consumption of power took me completely by surprise! Had I ever driven the 15LW1401s to even 100W each, I'd have been blowing my head off. Needless to say I am delighted with the low distortion at high drive levels that these XXLS drivers show. There was not a hint of distress to just short of 1KW per driver, then it was the amp that went ugly.

AJ

Didn't measure GD. Should have but didn't reverse a driver. The sub was still very clean.

Cheers

William Cowan

Attachments

William, I'm a twit! I was trying to come up with a way to mount drivers push pull, and didn't think of the simple solution you used there with just one driver reversed!

If this does get beyond prototype, then I'll either build two installed under the floor, or one with push pull drivers. The beauty of this is that I can put them anywhere in the room (almost), hence have the freedom to get the best room interaction. Of course, the beauty of push pull is that it's possible to mount them so that their forces also cancel, which is welcomed in a box of this size - anything to keep vibration down without having to brace, make the box thicker and use more expensive materials. The difficulty is getting that to work with this type of box - a bit complex to pull it off, and quite awkward. I need to find out first if it's worthwhile.

What sorts of dimensions do you have with that XXLS tapped horn?

Have you by any chance tried it with push pull?

Do you know what the efficiency with 1w is? Hornresp seems to show very high efficiency.

I'm also curious to know if you have been able to trick hornresp into modelling something like what you actually measure?

If this does get beyond prototype, then I'll either build two installed under the floor, or one with push pull drivers. The beauty of this is that I can put them anywhere in the room (almost), hence have the freedom to get the best room interaction. Of course, the beauty of push pull is that it's possible to mount them so that their forces also cancel, which is welcomed in a box of this size - anything to keep vibration down without having to brace, make the box thicker and use more expensive materials. The difficulty is getting that to work with this type of box - a bit complex to pull it off, and quite awkward. I need to find out first if it's worthwhile.

What sorts of dimensions do you have with that XXLS tapped horn?

Have you by any chance tried it with push pull?

Do you know what the efficiency with 1w is? Hornresp seems to show very high efficiency.

I'm also curious to know if you have been able to trick hornresp into modelling something like what you actually measure?

G'day again Paul

That horn is XLS, 830500. The XXLS drivers are in sealed boxes in my Unity system at the moment (covering 20-300Hz). I will try them in the 30Hz tapped horn some time in the next few weeks (Pending time) The timber in the big horn has since gone into other projects.

Reversing one of the drivers in the dual driver horn will not give a reduction of vibration. It will only serve to reduce even order distortion products. I guess you'd need to do a one up two back type deal to put the drivers in a clamshell front to back type arrangement.

The different tapped horns I measured were between 95 and 100dB/W/M.

No luck with an accurate model in Horn Response, but the guesstimates give you a pretty good idea.

Outside dimensions of the big tapped horn are 2250 by 450 by 515. All material is 25mm. Taper is shallow, under 1.5:1.

Cheers

William Cowan

That horn is XLS, 830500. The XXLS drivers are in sealed boxes in my Unity system at the moment (covering 20-300Hz). I will try them in the 30Hz tapped horn some time in the next few weeks (Pending time) The timber in the big horn has since gone into other projects.

Reversing one of the drivers in the dual driver horn will not give a reduction of vibration. It will only serve to reduce even order distortion products. I guess you'd need to do a one up two back type deal to put the drivers in a clamshell front to back type arrangement.

The different tapped horns I measured were between 95 and 100dB/W/M.

No luck with an accurate model in Horn Response, but the guesstimates give you a pretty good idea.

Outside dimensions of the big tapped horn are 2250 by 450 by 515. All material is 25mm. Taper is shallow, under 1.5:1.

Cheers

William Cowan

When I mentioned the more complicated push pull I meant a clamshell labhorn type mounting, except with one driver inverted, hence as you know, reduced distortion and vibration. As you can imagine, much more complex to build. If I go beyond prototype then I'll see if I can come up with something along those lines.

Did you form any conclusions when it comes to throat to mouth ratios and compression ratios?

Did you discover any particular and significant impact of changing throat to mouth ratio?

Did you find that 25mm ply is adequate without bracing?

Did you form any conclusions when it comes to throat to mouth ratios and compression ratios?

Did you discover any particular and significant impact of changing throat to mouth ratio?

Did you find that 25mm ply is adequate without bracing?

G'day again

One path up, two back or the other way around will give you an easy to build clam shell.

#2 Umm...See below

#3 Yep, Hornresponse will show the changes I saw.

#4 Yep, for testing at least. (The pressure didn't rip any boxes apart, and the panels did not vibrate too much)

Cheers

Wiliam Cowan

One path up, two back or the other way around will give you an easy to build clam shell.

#2 Umm...See below

#3 Yep, Hornresponse will show the changes I saw.

#4 Yep, for testing at least. (The pressure didn't rip any boxes apart, and the panels did not vibrate too much)

Cheers

Wiliam Cowan

One path up, two back or the other way around will give you an easy to build clam shell.

Could you elaborate, I don't quite follow!

Paul

Your drawing is better.

Since this is a new idea, perhaps I should patent it!?$

My design just requires one more internal baffle, which adds bracing. External size is only increased by the thickness of that baffle (25mm). A horizontal brace between the two drivers would probably help.

During the free air testing of the XXLS driver I thought had failed, I had it sitting on it's magnet and playing high level sinewave through it. The driver was almost bouncing off the floor! The carpet has a 9mm or so pile and the driver frame was moving up and down about 6mm at times. Cancelling vibration between opposing drivers has got to help.

The carpet has a 9mm or so pile and the driver frame was moving up and down about 6mm at times. Cancelling vibration between opposing drivers has got to help.

Have a good weekend.

Cheers

William Cowan

Your drawing is better.

Since this is a new idea, perhaps I should patent it!?$

My design just requires one more internal baffle, which adds bracing. External size is only increased by the thickness of that baffle (25mm). A horizontal brace between the two drivers would probably help.

During the free air testing of the XXLS driver I thought had failed, I had it sitting on it's magnet and playing high level sinewave through it. The driver was almost bouncing off the floor!

The carpet has a 9mm or so pile and the driver frame was moving up and down about 6mm at times. Cancelling vibration between opposing drivers has got to help.

The carpet has a 9mm or so pile and the driver frame was moving up and down about 6mm at times. Cancelling vibration between opposing drivers has got to help.Have a good weekend.

Cheers

William Cowan

(I tried to attach moray's refenced patent, but the file was too big)

Hi Paul

So I don’t build up expectations and later find I can’t fit one in, what would be the external dimensions of the current config, if built as a settled design rather than a prototype, for 10/ 12/ 15 inch drivers?

Or even to see if I could fit one in my lounge room as well

Thanks

Hi Paul

So I don’t build up expectations and later find I can’t fit one in, what would be the external dimensions of the current config, if built as a settled design rather than a prototype, for 10/ 12/ 15 inch drivers?

Or even to see if I could fit one in my lounge room as well

Thanks

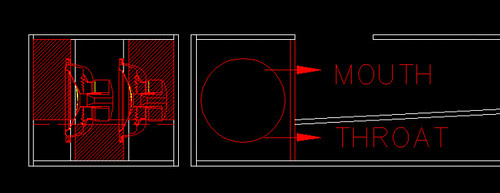

Top drawing is 2250 x 515 and bottom drawing is 2250 x 436. Mounting plate shown hatched is 430mm square and the opening in which it fits is 450 x 450 - enough to fit any 15" driver. Hatched blue circle shows the cutout required for the PHL driver, hence the baffle hole shown there will be cut for this or for the biggest 15" that anyone is bringing. So in short, any 15" driver should fit.

I'm going to have to build this thing out of 3 sheets, no way around it. I had hoped for 2, but it's obviously not going to happen.

Are any of your drivers in pairs? I'll probably make the second baffle to suit the AV12 without mounting plate.

I'll be interested to see the impact of one vs two drivers. In the next 1-2 weeks my Rythmik Direct Servo kit is coming, not only would I like to try it tapped, but it could also be a good reference sub to compare them all against, being a servo sub. One thing I want to test is if a horn can actually get a conventional driver to compare with a servo sub. Rob Wells commented that his lab horns are very similar to servo subs, except at much higher output. This is what first really got my attention about bass horns.

I'm going to have to build this thing out of 3 sheets, no way around it. I had hoped for 2, but it's obviously not going to happen.

Are any of your drivers in pairs? I'll probably make the second baffle to suit the AV12 without mounting plate.

I'll be interested to see the impact of one vs two drivers. In the next 1-2 weeks my Rythmik Direct Servo kit is coming, not only would I like to try it tapped, but it could also be a good reference sub to compare them all against, being a servo sub. One thing I want to test is if a horn can actually get a conventional driver to compare with a servo sub. Rob Wells commented that his lab horns are very similar to servo subs, except at much higher output. This is what first really got my attention about bass horns.

I would strongly recommend against using the Rythmik in a TH without consulting with Brian. My guess is that he will not recommend it either. The TH will certainly give much greater output, but there is also evidence that points towards phase distortion possibly being audible a very low frequencies and mainly at very low frequecies. I have not yet seen Gedlee AES paper so I suppose the jury is still out. I however, cannot imagine how a pair of sealed Rythmik Servo 15's would not supply sufficient low frequency output for music (or even HT for that matter) unless the room was extremely large.

The SQ is superb for music with the sealed (recommended by Brian) enclosures (low GD). I'm not saying it is because of the low GD, but having low amounts certainly can't be hurting the performance.

Keep in mind this GD is inherent in the system before XO.

Now of course if you need 120db @ 25hz at the listening position, TH's do have their appeal .

.

cheers,

AJ

The SQ is superb for music with the sealed (recommended by Brian) enclosures (low GD). I'm not saying it is because of the low GD, but having low amounts certainly can't be hurting the performance.

Keep in mind this GD is inherent in the system before XO.

Now of course if you need 120db @ 25hz at the listening position, TH's do have their appeal

cheers,

AJ

Why ask for an opinion on whether something will work when you can simply try it and find out for yourself?

I doubt I'll keep the Rythmik drivers in a tapped horn, more likely dipole or a large horn, or perhaps more short term a sealed box. This is about experimentation first and foremost. It won't be a failure unless we learn nothing. If I come out th e other end wanting to actually use a tapped horn, then that's a bonus. If not I'll re-use the MDF for something better.

If I do use the Rythmik, then I'll see if I can get a custom made servo board. Apparently only the frequency response is required.

The paper does look interesting. Geddes has done some very interesting work in the field of perception of distortion.

I doubt I'll keep the Rythmik drivers in a tapped horn, more likely dipole or a large horn, or perhaps more short term a sealed box. This is about experimentation first and foremost. It won't be a failure unless we learn nothing. If I come out th e other end wanting to actually use a tapped horn, then that's a bonus. If not I'll re-use the MDF for something better.

If I do use the Rythmik, then I'll see if I can get a custom made servo board. Apparently only the frequency response is required.

The paper does look interesting. Geddes has done some very interesting work in the field of perception of distortion.

Hi Paul,

Finally got some time to read and think about this a little.

Not attempting to pour any “cold water”, just to understand better:

Post 1 –

“With the correct driver, the result is that the response is flat and the dips are filled in”

How confident can we be of this (or if the measured response ended up close to the sims), how easy would it be to flatten the sharp notches?

Hi William,

On that note, what distance from the mouth were your measurements taken at?

Post 15 –

The PHL sims a smoother response than the AV-12, so curious why its suspected the AV12 will work out best?

“The kappa is very similar to the PHL except that it has a peak at the bottom end due to the much stronger magnet”

The BL of the Kappa Pro 12 is 17.3, the XLS 17.6, JBL 2035 and the AV-12 BL is 16.

The PHL 5320 is an ‘outlier’ in this group at 23.4. Not clear on this possible correlation?

Mounting

Is it possible to mount the drivers per Planet 10’s Push-push in post 2 www.diyaudio.com/forums/showthread.php?s=&threadid=96902&highlight= to cancel the drivers’ Newtonian motion, and still be a tapped horn?

“Top drawing is 2250 x 515 and bottom drawing is 2250 x 436”.

Both liveable, IMHO

All my drivers are pairs, though how many will we have time to test, maybe we need a weekend?

Cheers

Finally got some time to read and think about this a little.

Not attempting to pour any “cold water”, just to understand better:

Post 1 –

“With the correct driver, the result is that the response is flat and the dips are filled in”

How confident can we be of this (or if the measured response ended up close to the sims), how easy would it be to flatten the sharp notches?

Hi William,

On that note, what distance from the mouth were your measurements taken at?

Post 15 –

The PHL sims a smoother response than the AV-12, so curious why its suspected the AV12 will work out best?

“The kappa is very similar to the PHL except that it has a peak at the bottom end due to the much stronger magnet”

The BL of the Kappa Pro 12 is 17.3, the XLS 17.6, JBL 2035 and the AV-12 BL is 16.

The PHL 5320 is an ‘outlier’ in this group at 23.4. Not clear on this possible correlation?

Mounting

Is it possible to mount the drivers per Planet 10’s Push-push in post 2 www.diyaudio.com/forums/showthread.php?s=&threadid=96902&highlight= to cancel the drivers’ Newtonian motion, and still be a tapped horn?

“Top drawing is 2250 x 515 and bottom drawing is 2250 x 436”.

Both liveable, IMHO

All my drivers are pairs, though how many will we have time to test, maybe we need a weekend?

Cheers

G'day Rick, my latest version is like version 3 linked in the other thread. It's not practical to face the magnets together in this example, and I think it's best to get distortion reduction as well.

About how confident, the unknown is the drivers in question, not the concept of the tapped horn itself. William shows measurements to demonstrate it works.

I'm just speculating about which will work best. Kind of like guessing which horse will win melbourne cup.

What I am looking for though is two peaks and a dip - if there is no dip then it's not going to get filled in and then you have early rolloff and less efficiency down at the tuning point.

But we will find out when we actually measure it.

I'll allow for two drivers of each, but I just wonder if two 15s will be too much SD, but who knows. I'll allow for it anyway.

Comparing the drivers I was talking about the hornresp SPL chart, not their parameters.

If the response in reality works out like those charts, then no chance of eq, we are counting on it working out much better as hornresp isn't really set up to model it all.

About how confident, the unknown is the drivers in question, not the concept of the tapped horn itself. William shows measurements to demonstrate it works.

I'm just speculating about which will work best. Kind of like guessing which horse will win melbourne cup.

What I am looking for though is two peaks and a dip - if there is no dip then it's not going to get filled in and then you have early rolloff and less efficiency down at the tuning point.

But we will find out when we actually measure it.

I'll allow for two drivers of each, but I just wonder if two 15s will be too much SD, but who knows. I'll allow for it anyway.

Comparing the drivers I was talking about the hornresp SPL chart, not their parameters.

If the response in reality works out like those charts, then no chance of eq, we are counting on it working out much better as hornresp isn't really set up to model it all.

- Home

- Loudspeakers

- Subwoofers

- Collaborative Tapped horn project