More TH work with aKaBak

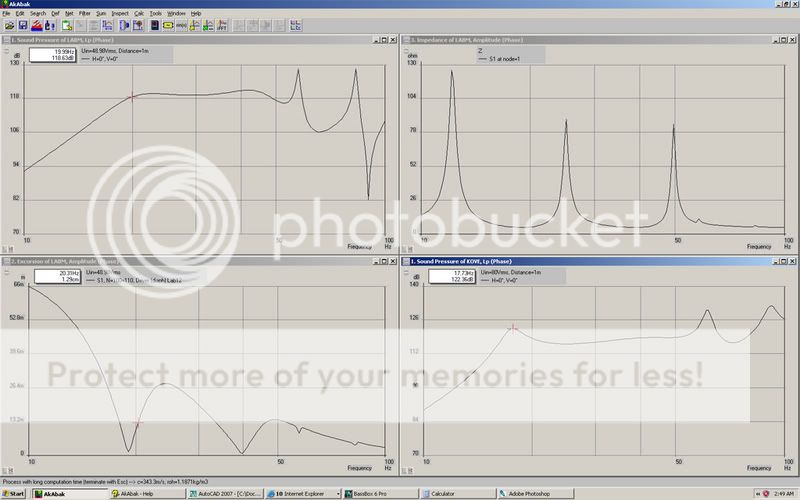

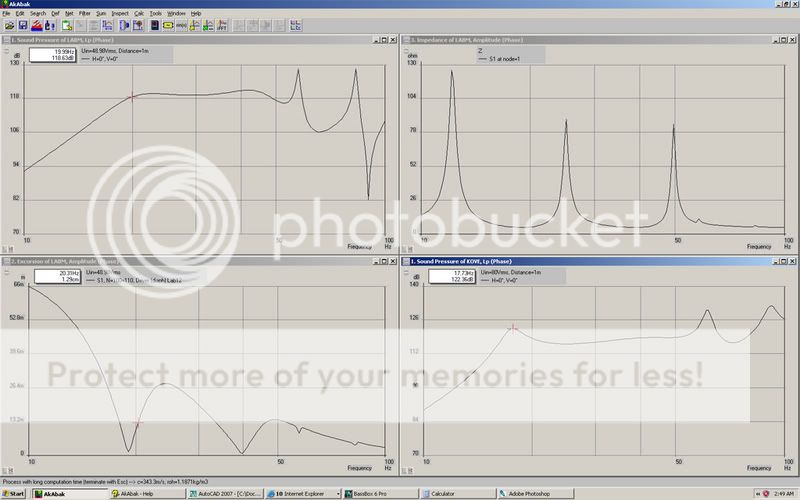

The Graph of the Lab12 at the mouth looks awfully good, too bad the Lab12 overexcurds a little too easily, There are a couple of drivers that look almost as good so far. CSS SD12, looks decent, and the TC sounds dB 500 looks OK.

Fore some reason the Kove Audio Driver models well at the 1/4 cab height Tap.

Has anyone here checked the math in the aKaBak manual around page 147? There is a pain in the *** calculation for finding the air mass of the transition of butted ducts of different "heights" but of the same depth.

At the end of the equation you are supposed to have some (XkG/m^4) relation ship. I convert all of my Values to Meters, do all of the arithmatic steps involved. The t value (depth) in the denominator Seems to have its meter ratio canceled by the resultant numerator. Roh is suppose to = 1.2kg/m^3 The final result can never be XkG/m^4 because the meter ratios cancel out and there is no extra m raise m^3 to m^4.

I've tried to ignore this fact and just see what happens when I plug the numbers in. My final Duct transition, Which only expands the Next duck by about 1" ended up with a hugh air mass of 250kg/m^4 I know this wasn't right and it really screwed up the graph so I plugged in a number that seemed rational.

I think there is an error in the butted Duct math, though I may be not catching something, about the process.

Also I'm not sure if I should treat my final segment that attatches to the TH mouth as an duct or a air mass/90degree bend.

Antone-

The Graph of the Lab12 at the mouth looks awfully good, too bad the Lab12 overexcurds a little too easily, There are a couple of drivers that look almost as good so far. CSS SD12, looks decent, and the TC sounds dB 500 looks OK.

Fore some reason the Kove Audio Driver models well at the 1/4 cab height Tap.

Has anyone here checked the math in the aKaBak manual around page 147? There is a pain in the *** calculation for finding the air mass of the transition of butted ducts of different "heights" but of the same depth.

At the end of the equation you are supposed to have some (XkG/m^4) relation ship. I convert all of my Values to Meters, do all of the arithmatic steps involved. The t value (depth) in the denominator Seems to have its meter ratio canceled by the resultant numerator. Roh is suppose to = 1.2kg/m^3 The final result can never be XkG/m^4 because the meter ratios cancel out and there is no extra m raise m^3 to m^4.

I've tried to ignore this fact and just see what happens when I plug the numbers in. My final Duct transition, Which only expands the Next duck by about 1" ended up with a hugh air mass of 250kg/m^4 I know this wasn't right and it really screwed up the graph so I plugged in a number that seemed rational.

I think there is an error in the butted Duct math, though I may be not catching something, about the process.

Also I'm not sure if I should treat my final segment that attatches to the TH mouth as an duct or a air mass/90degree bend.

Antone-

Hmm, is that air mass of a 2 dimensional slice?

I'm not sure how it relates dirrectly to my problem, as I'm not clear out of what context you arrived at that number, I don't think its a derivative of 1.2kg/(m^3). I'm sure that the number 235kg/(m^4), was eronious, as the transition was very small. t=.4149m Ha=.303606m Hb=.32161m Perhaps the final step has to be integrated to raise the m^3 to m^4?

Looking back at the Akabak instructions 60kg/m^4 is the answer for the

"Two ducts (Duct) with the same cross-section have between them a thin wall with a hole of diameter dL (Fig. 81). Let the area of the hole be much smaller than the cross-sectional area of the duct. The dimensions of the duct are also much smaller than the wavelength."

Thats a whole different equation and appears much simpler than the butted ducts of different size.

Anyhow I think I'm getting close but now I gotta buy some MDF to see how accurate my models are.

I am becoming conviced that the DTS driver is something close to the Lab 12 but perhaps with a more resistive suspension, the Ciare seems like it could be a candidate but it looks a little peaky, compared to some other drivers.

If anyone here wants to look at my aKabaK scripts or dimensions I will post them.

Antone-

I'm not sure how it relates dirrectly to my problem, as I'm not clear out of what context you arrived at that number, I don't think its a derivative of 1.2kg/(m^3). I'm sure that the number 235kg/(m^4), was eronious, as the transition was very small. t=.4149m Ha=.303606m Hb=.32161m Perhaps the final step has to be integrated to raise the m^3 to m^4?

Looking back at the Akabak instructions 60kg/m^4 is the answer for the

"Two ducts (Duct) with the same cross-section have between them a thin wall with a hole of diameter dL (Fig. 81). Let the area of the hole be much smaller than the cross-sectional area of the duct. The dimensions of the duct are also much smaller than the wavelength."

Thats a whole different equation and appears much simpler than the butted ducts of different size.

Anyhow I think I'm getting close but now I gotta buy some MDF to see how accurate my models are.

I am becoming conviced that the DTS driver is something close to the Lab 12 but perhaps with a more resistive suspension, the Ciare seems like it could be a candidate but it looks a little peaky, compared to some other drivers.

If anyone here wants to look at my aKabaK scripts or dimensions I will post them.

Antone-

I'm just gona copy and past this since its all just text.

Here is my driver at the mouth model.

Perhaps someone can comment on the accuracy of making paralell (reverse dirrection, do the akabak ducts have a directional flow?) ducts for the rear of the driver?

Def_Driver 'Lab12'

dD=25.28cm |Piston

fs=22Hz

Mms=146g

Cms=0.35e-3m/N

Rms=1.552Ns/m

Bl=15Tm

Qms=13.32

Qes=0.39

Re=4.29ohm

Le=1.48mH

ExpoLe=0.618

System 'S1'

Resistor 'Rg' Node=1=2 R=0.5ohm |Generator resistance

Driver 'Lab12' Def='Lab12' Node=2=0=100=110

Duct 'Du_F0' Node=100=120

dD=25.4cm Len=1.801cm

Duct 'Du_FX' Node=140=0

dD=12.979cm Len=15.646cm Visc=1

Duct 'Du_F1' Node=130=140

dD=12.979cm Len=15.646cm Visc=1

Duct 'Du_R1' Node=140=130

dD=12.979cm Len=15.646cm Visc=1

Duct 'Du_F2' Node=120=130

dD=12.979cm Len=87.046cm

Duct 'Du_R2' Node=130=120

dD=12.979cm Len=87.046cm

AcouMass 'Ma1' Node=120=150 Ma=25.34kg/m4

AcouMass 'MaR1' Node=150=120 Ma=25.34kg/m4

AcouMass 'Ma2' Node=150=160 Ma=25.34kg/m4

AcouMass 'MaR2' Node=160=150 Ma=25.34kg/m4

Duct 'Du_F3' Node=160=170

dD=17.544cm Len=1.201m

Duct 'Du_R3' Node=170=160

dD=17.544cm Len=1.201m

AcouMass 'Ma3' Node=170=180 Ma=1.008kg/m4

AcouMass 'MaR3' Node=180=170 Ma=1.008kg/m4

Duct 'Du_F4' Node=180=190

dD=25.104cm Len=35.865cm

Duct 'Du_R4' Node=190=180

dD=25.104cm Len=35.865cm

AcouMass 'Ma4' Node=190=200 Ma=10.364kg/m4

AcouMass 'MaR4' Node=200=190 Ma=10.364kg/m4

Duct 'Du_F5' Node=200=210

dD=30.225cm Len=34.084cm

Duct 'Du_R5' Node=210=200

dD=30.225cm Len=34.084cm

AcouMass 'Ma5' Node=210=220 Ma=8.207kg/m4

AcouMass 'MaR5' Node=220=210 Ma=8.207kg/m4

AcouMass 'Ma6' Node=220=230 Ma=7.851kg/m4

AcouMass 'MaR6' Node=230=220 Ma=7.851kg/m4

Duct 'Du_F6' Node=230=240

dD=31.448cm Len=35.885cm

Duct 'Du_R6' Node=240=230

dD=31.448cm Len=35.885cm

AcouMass 'Ma7' Node=240=250 Ma=9kg/m4

AcouMass 'MaR7' Node=250=240 Ma=9kg/m4

Duct 'Du_F7' Node=250=260

dD=35.672cm Len=35.885cm

Duct 'Du_R7' Node=260=250

dD=35.672cm Len=35.885cm

AcouMass 'Ma8' Node=260=280 Ma=10kg/m4

AcouMass 'MaR8' Node=280=260 Ma=10kg/m4

Duct 'Du_FR1' Node=280=270

dD=36.749cm Len=31.293cm

Duct 'Du_RFR1' Node=270=280

dD=36.749cm Len=31.293cm

Duct 'Du_FR2' Node=270=110

dD=36.749cm Len=68.913cm

Duct 'Du_RFR2' Node=110=270

dD=36.749cm Len=68.913cm

|AcouMass 'Ma9' Node=280=290 Ma=7.834kg/m4

Duct 'Du_FR3' Node=110=290

dD=36.749cm Len=25.4cm

Duct 'Du_ov' Node=290=300

dD=32.614cm Len=1.801cm

Radiator 'Rad1' Def='Du_ov' Node=300

x=0 y=0 z=0 HAngle=0 VAngle=0

"Its just a jump to the left"

Now you all can follow that right, or is it just me...

I have to take the square root of the duct area to get a ~duct diameter since its rectangular. Wouldn't it be nice if that was already an option.

So much busy work involve with aKaBak

Antone-

Here is my driver at the mouth model.

Perhaps someone can comment on the accuracy of making paralell (reverse dirrection, do the akabak ducts have a directional flow?) ducts for the rear of the driver?

Def_Driver 'Lab12'

dD=25.28cm |Piston

fs=22Hz

Mms=146g

Cms=0.35e-3m/N

Rms=1.552Ns/m

Bl=15Tm

Qms=13.32

Qes=0.39

Re=4.29ohm

Le=1.48mH

ExpoLe=0.618

System 'S1'

Resistor 'Rg' Node=1=2 R=0.5ohm |Generator resistance

Driver 'Lab12' Def='Lab12' Node=2=0=100=110

Duct 'Du_F0' Node=100=120

dD=25.4cm Len=1.801cm

Duct 'Du_FX' Node=140=0

dD=12.979cm Len=15.646cm Visc=1

Duct 'Du_F1' Node=130=140

dD=12.979cm Len=15.646cm Visc=1

Duct 'Du_R1' Node=140=130

dD=12.979cm Len=15.646cm Visc=1

Duct 'Du_F2' Node=120=130

dD=12.979cm Len=87.046cm

Duct 'Du_R2' Node=130=120

dD=12.979cm Len=87.046cm

AcouMass 'Ma1' Node=120=150 Ma=25.34kg/m4

AcouMass 'MaR1' Node=150=120 Ma=25.34kg/m4

AcouMass 'Ma2' Node=150=160 Ma=25.34kg/m4

AcouMass 'MaR2' Node=160=150 Ma=25.34kg/m4

Duct 'Du_F3' Node=160=170

dD=17.544cm Len=1.201m

Duct 'Du_R3' Node=170=160

dD=17.544cm Len=1.201m

AcouMass 'Ma3' Node=170=180 Ma=1.008kg/m4

AcouMass 'MaR3' Node=180=170 Ma=1.008kg/m4

Duct 'Du_F4' Node=180=190

dD=25.104cm Len=35.865cm

Duct 'Du_R4' Node=190=180

dD=25.104cm Len=35.865cm

AcouMass 'Ma4' Node=190=200 Ma=10.364kg/m4

AcouMass 'MaR4' Node=200=190 Ma=10.364kg/m4

Duct 'Du_F5' Node=200=210

dD=30.225cm Len=34.084cm

Duct 'Du_R5' Node=210=200

dD=30.225cm Len=34.084cm

AcouMass 'Ma5' Node=210=220 Ma=8.207kg/m4

AcouMass 'MaR5' Node=220=210 Ma=8.207kg/m4

AcouMass 'Ma6' Node=220=230 Ma=7.851kg/m4

AcouMass 'MaR6' Node=230=220 Ma=7.851kg/m4

Duct 'Du_F6' Node=230=240

dD=31.448cm Len=35.885cm

Duct 'Du_R6' Node=240=230

dD=31.448cm Len=35.885cm

AcouMass 'Ma7' Node=240=250 Ma=9kg/m4

AcouMass 'MaR7' Node=250=240 Ma=9kg/m4

Duct 'Du_F7' Node=250=260

dD=35.672cm Len=35.885cm

Duct 'Du_R7' Node=260=250

dD=35.672cm Len=35.885cm

AcouMass 'Ma8' Node=260=280 Ma=10kg/m4

AcouMass 'MaR8' Node=280=260 Ma=10kg/m4

Duct 'Du_FR1' Node=280=270

dD=36.749cm Len=31.293cm

Duct 'Du_RFR1' Node=270=280

dD=36.749cm Len=31.293cm

Duct 'Du_FR2' Node=270=110

dD=36.749cm Len=68.913cm

Duct 'Du_RFR2' Node=110=270

dD=36.749cm Len=68.913cm

|AcouMass 'Ma9' Node=280=290 Ma=7.834kg/m4

Duct 'Du_FR3' Node=110=290

dD=36.749cm Len=25.4cm

Duct 'Du_ov' Node=290=300

dD=32.614cm Len=1.801cm

Radiator 'Rad1' Def='Du_ov' Node=300

x=0 y=0 z=0 HAngle=0 VAngle=0

"Its just a jump to the left"

Now you all can follow that right, or is it just me...

I have to take the square root of the duct area to get a ~duct diameter since its rectangular. Wouldn't it be nice if that was already an option.

So much busy work involve with aKaBak

Antone-

It probably would help if I labled each section, so that others could follow it.

I was just doing things as fast as I could, which was turbo slow style.

Basically its just ducts followed by its lable, its connecting points (nodes), and diameter and length.

The other stuff is equivalent air masses, hopefully representing, transitions and bends. also connected by nodes.

Antone-

I was just doing things as fast as I could, which was turbo slow style.

Basically its just ducts followed by its lable, its connecting points (nodes), and diameter and length.

The other stuff is equivalent air masses, hopefully representing, transitions and bends. also connected by nodes.

Antone-

Greets!

All I addressed was what I understood to be your concerns with the result of this formula: Mal = (1.2 Kg/m^3)/2 cm = 60 Kg/m^4, so I plugged it into MathCad and got the results I posted, which seemed to confirm your own results that the m^4 part of the answer was wrong. Frankly, it doesn't make any sense to me, seems like you'd want to convert the diameter to an area first, but like I said, I'm math challenged and may be missing something that's embedded in one of the more complex equations.

GM

All I addressed was what I understood to be your concerns with the result of this formula: Mal = (1.2 Kg/m^3)/2 cm = 60 Kg/m^4, so I plugged it into MathCad and got the results I posted, which seemed to confirm your own results that the m^4 part of the answer was wrong. Frankly, it doesn't make any sense to me, seems like you'd want to convert the diameter to an area first, but like I said, I'm math challenged and may be missing something that's embedded in one of the more complex equations.

GM

Oh GM

You may want to check the order of operations you used in math cad.

It may have seen ((1.2kg/m^3)/2)*cm That would lower it to m^2

It should be (1.2kg/m^3)/(2cm) which should be

(1.2kg/(m^3*2cm)) which would end up with m^4.

I think.

of cours with the other equation you end up with.

(1.2kg/(m^3*pi*(some meters))*(some more meters)

The (1/m)*m cancels out so you can't get to m^4 with the equation for butted ducts.

I could be missing one of my arithmatic steps though. I'll go Harrass my step dad he's a Math/Physics major.

Antone-

You may want to check the order of operations you used in math cad.

It may have seen ((1.2kg/m^3)/2)*cm That would lower it to m^2

It should be (1.2kg/m^3)/(2cm) which should be

(1.2kg/(m^3*2cm)) which would end up with m^4.

I think.

of cours with the other equation you end up with.

(1.2kg/(m^3*pi*(some meters))*(some more meters)

The (1/m)*m cancels out so you can't get to m^4 with the equation for butted ducts.

I could be missing one of my arithmatic steps though. I'll go Harrass my step dad he's a Math/Physics major.

Antone-

hey Antone - how difficult does it look for you to model this form? what does it take to get the aperture, etc? - would aperture be a series of ducts? Freddy

An externally hosted image should be here but it was not working when we last tested it.

Hello All,

First post, and just questions...

Antone,

Great that you posted the script.

Is it possible for you to post the script with 1/4 tap?

You mention that the Kove driver models well, which model?

I would love to see your drawing of where the different nodes are.

Keep up the good work.

Thanks/

///Anders.

First post, and just questions...

Antone,

Great that you posted the script.

Is it possible for you to post the script with 1/4 tap?

You mention that the Kove driver models well, which model?

I would love to see your drawing of where the different nodes are.

Keep up the good work.

Thanks/

///Anders.

Heres my revised eddition, with my butted duct air mass calculations corrected.

With the Kove.

It was a discontuned model that parts express was selling off ZD4 or something like that.

I can't really Varify the TS parameters. I did my own measures of the driver at some point and I think this may be off. Their web site gives minimal Ts info.

Someone at somepoint attempted to take the Ts Parameters and plugged them into Bass box pro. I'm using those values but it has to be wrong as it says Re 1.5ohm's Z=8ohms.

I did try tweaking so that Re was the series coil value 6.6, and see if bass box gives reasonable calculations.

Def_Driver 'Lab12'

Meas_DiPole

dD=27.07cm |Piston

fs=34Hz

Mms=239.8g

Cms=0.0914e-3m/N

Rms=9.612Ns/m

Bl=29.45Tm

Qms=5.33

Qes=.39

Vas=.043m3

Re=6.667ohm

Le=2.5mH

ExpoLe=0.618

System 'S1'

Resistor 'Rg' Node=1=2 R=0.5ohm |Generator resistance

Driver 'Lab12' Def='Lab12' Node=2=0=100=110

Duct 'Du_F0' Node=100=120

dD=25.4cm Len=1.801cm

Duct 'Du_FX' Node=120=0

dD=12.979cm Len=15.646cm Visc=1

Duct 'Du_F1' Node=120=130

dD=12.979cm Len=15.646cm Visc=1

Duct 'Du_R1' Node=130=120

dD=12.979cm Len=15.646cm Visc=1

Duct 'Du_F2' Node=130=140

dD=12.979cm Len=87.046cm

Duct 'Du_R2' Node=140=130

dD=12.979cm Len=87.046cm

AcouMass 'Ma1' Node=140=150 Ma=25.34kg/m4

AcouMass 'MaR1' Node=150=140 Ma=25.34kg/m4

AcouMass 'Ma2' Node=150=160 Ma=25.34kg/m4

AcouMass 'MaR2' Node=160=150 Ma=25.34kg/m4

Duct 'Du_F3' Node=160=170

dD=17.544cm Len=1.201m

Duct 'Du_R3' Node=170=160

dD=17.544cm Len=1.201m

AcouMass 'Ma3' Node=170=180 Ma=.375667kg/m4

AcouMass 'MaR3' Node=180=170 Ma=.375667kg/m4

Duct 'Du_F4' Node=180=190

dD=25.104cm Len=35.865cm

Duct 'Du_R4' Node=190=180

dD=25.104cm Len=35.865cm

AcouMass 'Ma4' Node=190=200 Ma=.138kg/m4

AcouMass 'MaR4' Node=200=190 Ma=.138kg/m4

Duct 'Du_F5' Node=200=210

dD=30.225cm Len=34.084cm

Duct 'Du_R5' Node=210=200

dD=30.225cm Len=34.084cm

AcouMass 'Ma5' Node=210=220 Ma=8.207kg/m4

AcouMass 'MaR5' Node=220=210 Ma=8.207kg/m4

AcouMass 'Ma6' Node=220=230 Ma=7.851kg/m4

AcouMass 'MaR6' Node=230=220 Ma=7.851kg/m4

Duct 'Du_F6' Node=230=240

dD=31.448cm Len=35.885cm

Duct 'Du_R6' Node=240=230

dD=31.448cm Len=35.885cm

AcouMass 'Ma7' Node=240=250 Ma=.0748kg/m4

AcouMass 'MaR7' Node=250=240 Ma=.0748kg/m4

Duct 'Du_F7' Node=250=260

dD=35.672cm Len=35.885cm

Duct 'Du_R7' Node=260=250

dD=35.672cm Len=35.885cm

AcouMass 'Ma8' Node=260=280 Ma=.0405kg/m4

AcouMass 'MaR8' Node=280=260 Ma=.0405kg/m4

Duct 'Du_FR1' Node=110=270

dD=36.749cm Len=31.293cm

Duct 'Du_FR2' Node=270=280

dD=36.749cm Len=68.913cm

AcouMass 'Ma9' Node=280=290 Ma=7.834kg/m4

Duct 'Du_FR3' Node=280=290

dD=36.749cm Len=25.4cm

Duct 'Du_ov' Node=290=300

dD=32.614cm Len=1.801cm

Radiator 'Rad1' Def='Du_ov' Node=300

x=0 y=0 z=0 HAngle=0 VAngle=0

See how that looks to you

Antone-

With the Kove.

It was a discontuned model that parts express was selling off ZD4 or something like that.

I can't really Varify the TS parameters. I did my own measures of the driver at some point and I think this may be off. Their web site gives minimal Ts info.

Someone at somepoint attempted to take the Ts Parameters and plugged them into Bass box pro. I'm using those values but it has to be wrong as it says Re 1.5ohm's Z=8ohms.

I did try tweaking so that Re was the series coil value 6.6, and see if bass box gives reasonable calculations.

Def_Driver 'Lab12'

Meas_DiPole

dD=27.07cm |Piston

fs=34Hz

Mms=239.8g

Cms=0.0914e-3m/N

Rms=9.612Ns/m

Bl=29.45Tm

Qms=5.33

Qes=.39

Vas=.043m3

Re=6.667ohm

Le=2.5mH

ExpoLe=0.618

System 'S1'

Resistor 'Rg' Node=1=2 R=0.5ohm |Generator resistance

Driver 'Lab12' Def='Lab12' Node=2=0=100=110

Duct 'Du_F0' Node=100=120

dD=25.4cm Len=1.801cm

Duct 'Du_FX' Node=120=0

dD=12.979cm Len=15.646cm Visc=1

Duct 'Du_F1' Node=120=130

dD=12.979cm Len=15.646cm Visc=1

Duct 'Du_R1' Node=130=120

dD=12.979cm Len=15.646cm Visc=1

Duct 'Du_F2' Node=130=140

dD=12.979cm Len=87.046cm

Duct 'Du_R2' Node=140=130

dD=12.979cm Len=87.046cm

AcouMass 'Ma1' Node=140=150 Ma=25.34kg/m4

AcouMass 'MaR1' Node=150=140 Ma=25.34kg/m4

AcouMass 'Ma2' Node=150=160 Ma=25.34kg/m4

AcouMass 'MaR2' Node=160=150 Ma=25.34kg/m4

Duct 'Du_F3' Node=160=170

dD=17.544cm Len=1.201m

Duct 'Du_R3' Node=170=160

dD=17.544cm Len=1.201m

AcouMass 'Ma3' Node=170=180 Ma=.375667kg/m4

AcouMass 'MaR3' Node=180=170 Ma=.375667kg/m4

Duct 'Du_F4' Node=180=190

dD=25.104cm Len=35.865cm

Duct 'Du_R4' Node=190=180

dD=25.104cm Len=35.865cm

AcouMass 'Ma4' Node=190=200 Ma=.138kg/m4

AcouMass 'MaR4' Node=200=190 Ma=.138kg/m4

Duct 'Du_F5' Node=200=210

dD=30.225cm Len=34.084cm

Duct 'Du_R5' Node=210=200

dD=30.225cm Len=34.084cm

AcouMass 'Ma5' Node=210=220 Ma=8.207kg/m4

AcouMass 'MaR5' Node=220=210 Ma=8.207kg/m4

AcouMass 'Ma6' Node=220=230 Ma=7.851kg/m4

AcouMass 'MaR6' Node=230=220 Ma=7.851kg/m4

Duct 'Du_F6' Node=230=240

dD=31.448cm Len=35.885cm

Duct 'Du_R6' Node=240=230

dD=31.448cm Len=35.885cm

AcouMass 'Ma7' Node=240=250 Ma=.0748kg/m4

AcouMass 'MaR7' Node=250=240 Ma=.0748kg/m4

Duct 'Du_F7' Node=250=260

dD=35.672cm Len=35.885cm

Duct 'Du_R7' Node=260=250

dD=35.672cm Len=35.885cm

AcouMass 'Ma8' Node=260=280 Ma=.0405kg/m4

AcouMass 'MaR8' Node=280=260 Ma=.0405kg/m4

Duct 'Du_FR1' Node=110=270

dD=36.749cm Len=31.293cm

Duct 'Du_FR2' Node=270=280

dD=36.749cm Len=68.913cm

AcouMass 'Ma9' Node=280=290 Ma=7.834kg/m4

Duct 'Du_FR3' Node=280=290

dD=36.749cm Len=25.4cm

Duct 'Du_ov' Node=290=300

dD=32.614cm Len=1.801cm

Radiator 'Rad1' Def='Du_ov' Node=300

x=0 y=0 z=0 HAngle=0 VAngle=0

See how that looks to you

Antone-

Antone, speaking as someone who downloaded Akabak, stared blindly at the manual for two days, and then gave up, is there any chance you could start a new thread documenting your experiences? I would love to learn how to use it properly, but I just can't get my head around how to translate a speaker and driver into script form.

Ohh I left both of those active.

I'm not sure how to treat the final section before the mouth,

as a duct or an air mass.

In the script I posted both are acting in paralell right now which I think is technically incorrect.

AcouMass 'Ma9' Node=280=290 Ma=7.834kg/m4

Duct 'Du_FR3' Node=280=290

dD=36.749cm Len=25.4cm

put a | in front of the Duct our acouMass to remove it from the model.

Antone-

I'm not sure how to treat the final section before the mouth,

as a duct or an air mass.

In the script I posted both are acting in paralell right now which I think is technically incorrect.

AcouMass 'Ma9' Node=280=290 Ma=7.834kg/m4

Duct 'Du_FR3' Node=280=290

dD=36.749cm Len=25.4cm

put a | in front of the Duct our acouMass to remove it from the model.

Antone-

pinkmouse said:Antone, speaking as someone who downloaded Akabak, stared blindly at the manual for two days, and then gave up, is there any chance you could start a new thread documenting your experiences? I would love to learn how to use it properly, but I just can't get my head around how to translate a speaker and driver into script form.

This is how it works, you have to draw out your equivalent schematic first. That way you know what entities your box is made of, and flow paths, node/junctions etc.

I guess theres Three steps.

Know your enclosure (dims), and driver values.

Determine schematic.

Start building the script based on your schematic.

If I start playing with stuff other than the tapped horn approach I will start The Chronicals of aKaBak thread.

Looking at that bandpass enclosure around page 64 of the manual and the schematic really helped me figure out how to start.

I didn't get it a first glance but I wasn't willing to read the whole manual, because I'm lazy that way.

I'm not sure what else to say but, draw your schematic out, lable each entity and node appropriately.

Good luck

Antone-

freddi said:a schematic diagram with labeled ducts of the tapped-horn would be helpful too.

simple examples of sealed, bass reflex and bandpass would be good for discussion

(how would one create Karlson aperture and slanted baffle?)

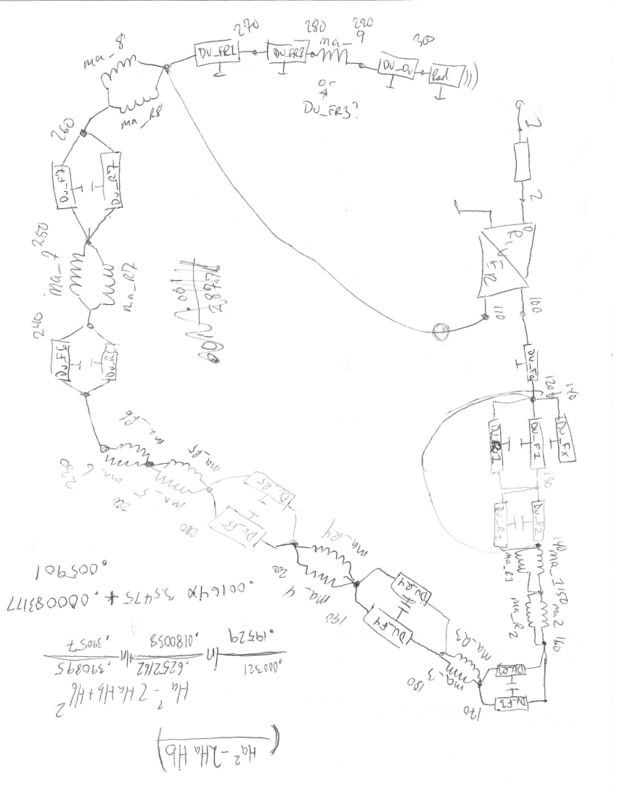

This is my good and sloppy Th Layout that I did.

I don't have time to lay it out in cad.

The jumper between 120 and 140 is for moving the driver to the mouth just ignor it. You have to break some node connections to actually get it to happen right.

Antone-

- Home

- Loudspeakers

- Subwoofers

- Collaborative Tapped horn project