A couple more questions as I start building the cabinet:

Is there any sound quality difference with bumping the design up to 1" MDF on the front baffle? What about using 1" MDF on the entire cabinet excluding the internal baffles?

When I build the external box for the crossover do I need to add vents for cooling? I am not sure how much heat a crossover of this size would produce.

Is there any sound quality difference with bumping the design up to 1" MDF on the front baffle? What about using 1" MDF on the entire cabinet excluding the internal baffles?

When I build the external box for the crossover do I need to add vents for cooling? I am not sure how much heat a crossover of this size would produce.

As long as your internal dimensions are the same, you can make the panels as thick as you want.

You do not need to vent a passive crossover box.

These are really pretty simple to solder together. I didn't use a PCB, just ran everything point to point and stuck them on masonite with hot glue and zip ties. There is a pic on this page, post #45. Not pretty, but they work!

http://www.diyaudio.com/forums/multi-way/142615-short-thor-build-5.html

You do not need to vent a passive crossover box.

These are really pretty simple to solder together. I didn't use a PCB, just ran everything point to point and stuck them on masonite with hot glue and zip ties. There is a pic on this page, post #45. Not pretty, but they work!

http://www.diyaudio.com/forums/multi-way/142615-short-thor-build-5.html

I figured this was a better spot to ask then starting a new thread..

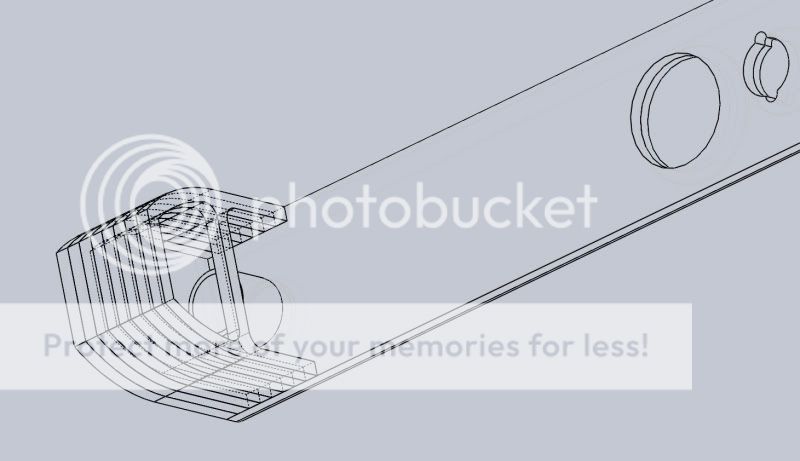

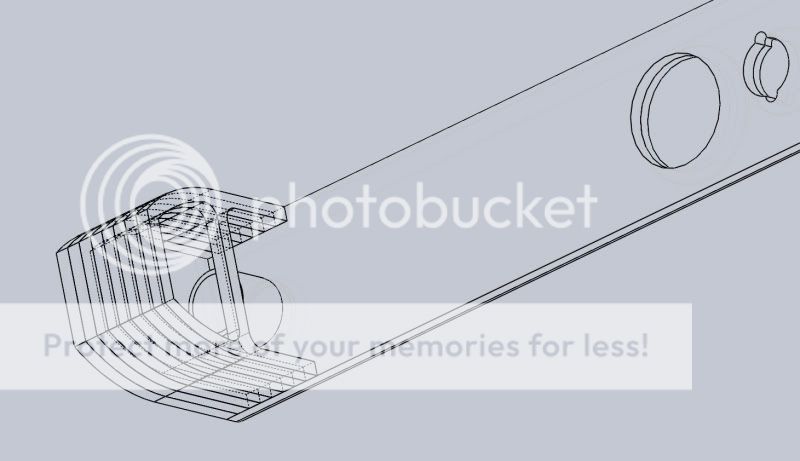

I'm working on building a curved translam version of the small thor and I'm curious about the swiss cheese baffle. How crucial is that for the brace that runs parallel with the baffle in the scottmoose drawings?

In the model I have now I can either just use braces spaced in every couple of laminates or make a slot to attach a swiss cheese type baffle.

So how crucial is it?

I'm working on building a curved translam version of the small thor and I'm curious about the swiss cheese baffle. How crucial is that for the brace that runs parallel with the baffle in the scottmoose drawings?

In the model I have now I can either just use braces spaced in every couple of laminates or make a slot to attach a swiss cheese type baffle.

So how crucial is it?

The holey driver brace in my drawings are quite important. They transfer/distribute the energy from the driver to the back of the cabinet.

Those braces you have in your image are not very effective. You'd be better off leaving them out, and installing the long vertical brace and couple the baffle to all the individual slices.

With the translam you will need thicker walls which will lead to a wider cabinet so you will need to adjust the BSC in the crossover.

I hope you are using plywood.

From a sonic POV using many layers of thin plywood and actually bending it is much more effective.

dave

Those braces you have in your image are not very effective. You'd be better off leaving them out, and installing the long vertical brace and couple the baffle to all the individual slices.

With the translam you will need thicker walls which will lead to a wider cabinet so you will need to adjust the BSC in the crossover.

I hope you are using plywood.

From a sonic POV using many layers of thin plywood and actually bending it is much more effective.

dave

Yeah Baltic Birtch Plywood and I've made sure to keep the baffle the same width.

How do you manage that... thickening the box walls toward the inside is not a good idea, the wall panels are already closer to the driver than i like.

Thanks for the input, I'll make some changes to accommodate the vertical brace. Is there any particular jedi magic that goes into the hole spacing/sizing in a swiss cheese baffle?

30-40% holes. Placement such that there is a solid path behind the driver to transfer energy. No holes so close that they will compromise rigidity. Do not place the brace in the centre.

dave

stuffing a fat Thor

I just got an unfinished pair of fat Thor's from one member. They sound great! So much detail...

The original builder never reached a conclusion on how to stuff the cabinets properly for best sound. That's now my task... One of the side panels is still open, so experimentation is relatively easy. Any recommendation on how to properly stuff the fat Thor's? The cabinets are very well build and braced.

Once I can seal the cabinets, I can start finishing them...

Thanks in advance for any help!

I just got an unfinished pair of fat Thor's from one member. They sound great! So much detail...

The original builder never reached a conclusion on how to stuff the cabinets properly for best sound. That's now my task... One of the side panels is still open, so experimentation is relatively easy. Any recommendation on how to properly stuff the fat Thor's? The cabinets are very well build and braced.

Once I can seal the cabinets, I can start finishing them...

Thanks in advance for any help!

Excellent thread !!!! plenty of info on TL.

Is it possible to build a fat THOR using budget minded drivers like vifa P17WJ & D25Ag3506?

Regards,

Anil

No,

They won't be Thors, or sound like them either.

Ron

I just got an unfinished pair of fat Thor's from one member. They sound great! So much detail...

The original builder never reached a conclusion on how to stuff the cabinets properly for best sound. That's now my task... One of the side panels is still open, so experimentation is relatively easy. Any recommendation on how to properly stuff the fat Thor's? The cabinets are very well build and braced.

Once I can seal the cabinets, I can start finishing them...

Thanks in advance for any help!

Julien,

What type of stuffing are you going to use? Not sure if it really matters.

Stuff the upper portions behind the drivers, to a medium full capacity. With the Fat Thors, you should have Tons of Bass. Keep the lower portion of the speakers open, don't obstruct the port.

You'll love the Thors.

Show us some Pics!!!

Ron

E

Is it possible to build a fat THOR using budget minded drivers like vifa P17WJ & D25Ag3506?

As Renron says it won't be a Thor, but it is certainly possible to build a speaker with these drivers inspired by the Thor. Scott & I have, under the custom design by donation scheme, come up with a Fat & a Short equivalent for P17.

Email if interested.

dave

Julien,

What type of stuffing are you going to use? Not sure if it really matters.

Stuff the upper portions behind the drivers, to a medium full capacity. With the Fat Thors, you should have Tons of Bass. Keep the lower portion of the speakers open, don't obstruct the port.

You'll love the Thors.

Show us some Pics!!!

Ron

Thank you for the tip Ron! I'll try that.

Right now only the bottom of the first "chamber" is stuffed. The stuffing is that synthetic stuff that came with the kit. Any options to that? Natural fibers perhaps...

It sounds good, but I feel the sound could be more open. In my basement bass is very tight, but shy. I have to move it to the living room at some point, but I'd like to enclose the crossovers first. Probably a wood or metal box...

Julien

Julien,

What is the first chamber? diagram or photo even better. Synthetic is just fine, I used long haired wool and it sticks to everything and won't stay put. LOL, when I crank up the volume it sometimes blows the stuffing out the port. Poof. I've used synthetic since and for the $$$ difference, it's not worth it. IMO. Wally World pillows $1.99.

As far as the sound being more open, these drivers are tight. They WILL need at least 50 hours break in time, and the sound will change, be patient. 80 hours is when they open fully. Stuff the upper area(s), Close'em up, and put on FM music medium loud and walk away for a few days. You'll be shocked.

Ron

What is the first chamber? diagram or photo even better. Synthetic is just fine, I used long haired wool and it sticks to everything and won't stay put. LOL, when I crank up the volume it sometimes blows the stuffing out the port. Poof. I've used synthetic since and for the $$$ difference, it's not worth it. IMO. Wally World pillows $1.99.

As far as the sound being more open, these drivers are tight. They WILL need at least 50 hours break in time, and the sound will change, be patient. 80 hours is when they open fully. Stuff the upper area(s), Close'em up, and put on FM music medium loud and walk away for a few days. You'll be shocked.

Ron

Thanks Ron!

I'll take some picture when I get back home.

The first "chamber" is the bottom front area of the cabinets.

The speakers haven't been used for months so they probably need a few days of break in. This morning, it already sounded much better than yesterday. It has be on 24/7 since I put the parts together...

I'll move the stuffing around as you recommended.

Any links on how to finish MDF properly? I was thinking about painting the cabinets in white with a lacker finish using one of those small hand paint spray machines. And the base would be wood, also lacquered.

Julien

I'll take some picture when I get back home.

The first "chamber" is the bottom front area of the cabinets.

The speakers haven't been used for months so they probably need a few days of break in. This morning, it already sounded much better than yesterday. It has be on 24/7 since I put the parts together...

I'll move the stuffing around as you recommended.

Any links on how to finish MDF properly? I was thinking about painting the cabinets in white with a lacker finish using one of those small hand paint spray machines. And the base would be wood, also lacquered.

Julien

Were the speaker in use prior to you buying them? If so then they're broken in by now.

Moving the stuffing will help with the Bass reproduction.

MDF finishing is a can of worms in itself. Start with sanding them down with 220 and then a light coat, or 2 or 3 of Dewaxed Shellac. Let dry and have a go at whatever top coat you prefer. There is a wonderful LONG thread (aren't they all) on how to achieve a Piano Black finish. Warning; lots of work and very messy.

Ron

Moving the stuffing will help with the Bass reproduction.

MDF finishing is a can of worms in itself. Start with sanding them down with 220 and then a light coat, or 2 or 3 of Dewaxed Shellac. Let dry and have a go at whatever top coat you prefer. There is a wonderful LONG thread (aren't they all) on how to achieve a Piano Black finish. Warning; lots of work and very messy.

Ron

- Home

- Loudspeakers

- Multi-Way

- Clarity on Seas Thor Kit