I'm about to start making a pair of celestion TF1525e speaker boxes (https://celestion.com/wp-content/uploads/2019/10/188.pdf) and was wondering if anyone had attempted making these before and had any specific tips on making them, or if anyone had more general advice on speaker cab construction.

For the panels, I'm going to get them cut on a cnc machine to keep the edges nice and straight. I'm either going to use the recommended 15mm birch plywood, or an alternative to birch as its quite expensive at the moment. To secure the panels together I was thinking of using wood glue and countersunk screws to increase the grip between the panels (is this nesacery or will just standard brad nails work instead?). I'm going to leave the finish as exposed wood instead of painting so will need to apply some hard wearing varnish on them so that they don't get banged up as easily. I might look to make some stands for them as well as this is the recommend positioning for them (but I might also jsut use them on a table depends how lazy I'm feeling).

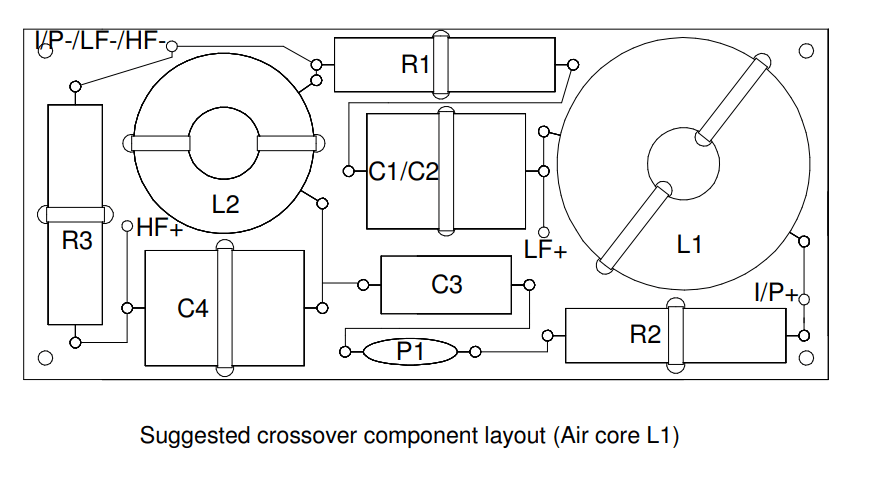

For making the crossover I'm going to use the plan shown on the link above, although one part of it has confused me a little. On the design C1 and C2 are shown next to each other but with a "/" in between. Does this mean that the values are interchangeable or will I need two capacitors for the low pass filter? Also on the diagram for C2 the value is in uH instead of uF, I'm guessing this is just a typo though and I'm just going to use a uF value instead. For the inductors I haven't really been able to find ones of the exact values so I may have to buy some larger ones and uncoil them to get the right value, does anyone have any experience of doing this and know how to get the best results? I've also drafted up a components list of what I'll need for the crossover:

LF:

L1: https://www.bluearan.co.uk/index.php?id=CNVACLD180 - potentially use a core from willys hifi -https://willys-hifi.com/

C1: https://willys-hifi.com/products/mkp-polypropylene-hifi-crossover-capacitor-10uf-250v

C2: https://willys-hifi.com/products/mkp-polypropylene-hifi-crossover-capacitor-2-2uf-250v

R1: https://uk.farnell.com/arcol/hs25-1r-j/resistor-wirewound-1ohm-5-axial/dp/2478173?st=1ohm resistor - more on https://willys-hifi.com/collections/resistors-20-watt

HF:

L2: https://www.bluearan.co.uk/index.php?id=CNVACMC072 - will need to uncoil to give desired value - potentially use a core from willys hifi -https://willys-hifi.com/

R2: 12 Ohm 20 Watt 5% Ceramic Wirewound Resistor - Willys-Hifi Ltd - more on https://willys-hifi.com/collections/resistors-20-watt

R3: Jantzen Superes 10W 100 Ohm 1% Crossover Resistor - Willys-Hifi Ltd - more on https://willys-hifi.com/collections/resistors-20-watt

C3: https://willys-hifi.com/collections...lypropylene-hifi-crossover-capacitor-1uf-250v

C4: https://willys-hifi.com/collections...propylene-hifi-crossover-capacitor-6-8uf-250v

P1: https://cpc.farnell.com/raychem-te-...-radial-1-35a/dp/FF02433?ost=1.35a+polyswitch

Please refer to the link at the top if the component acronyms don't make any sense.

I think this post covers my basic prebuild understanding of the design and how I will execute the build, if anyone has any tips to add or things that I should be considering which I haven't mentioned then please let me know. Otherwise just wait for more posts to show progress updates on the build!

For the panels, I'm going to get them cut on a cnc machine to keep the edges nice and straight. I'm either going to use the recommended 15mm birch plywood, or an alternative to birch as its quite expensive at the moment. To secure the panels together I was thinking of using wood glue and countersunk screws to increase the grip between the panels (is this nesacery or will just standard brad nails work instead?). I'm going to leave the finish as exposed wood instead of painting so will need to apply some hard wearing varnish on them so that they don't get banged up as easily. I might look to make some stands for them as well as this is the recommend positioning for them (but I might also jsut use them on a table depends how lazy I'm feeling).

For making the crossover I'm going to use the plan shown on the link above, although one part of it has confused me a little. On the design C1 and C2 are shown next to each other but with a "/" in between. Does this mean that the values are interchangeable or will I need two capacitors for the low pass filter? Also on the diagram for C2 the value is in uH instead of uF, I'm guessing this is just a typo though and I'm just going to use a uF value instead. For the inductors I haven't really been able to find ones of the exact values so I may have to buy some larger ones and uncoil them to get the right value, does anyone have any experience of doing this and know how to get the best results? I've also drafted up a components list of what I'll need for the crossover:

LF:

L1: https://www.bluearan.co.uk/index.php?id=CNVACLD180 - potentially use a core from willys hifi -https://willys-hifi.com/

C1: https://willys-hifi.com/products/mkp-polypropylene-hifi-crossover-capacitor-10uf-250v

C2: https://willys-hifi.com/products/mkp-polypropylene-hifi-crossover-capacitor-2-2uf-250v

R1: https://uk.farnell.com/arcol/hs25-1r-j/resistor-wirewound-1ohm-5-axial/dp/2478173?st=1ohm resistor - more on https://willys-hifi.com/collections/resistors-20-watt

HF:

L2: https://www.bluearan.co.uk/index.php?id=CNVACMC072 - will need to uncoil to give desired value - potentially use a core from willys hifi -https://willys-hifi.com/

R2: 12 Ohm 20 Watt 5% Ceramic Wirewound Resistor - Willys-Hifi Ltd - more on https://willys-hifi.com/collections/resistors-20-watt

R3: Jantzen Superes 10W 100 Ohm 1% Crossover Resistor - Willys-Hifi Ltd - more on https://willys-hifi.com/collections/resistors-20-watt

C3: https://willys-hifi.com/collections...lypropylene-hifi-crossover-capacitor-1uf-250v

C4: https://willys-hifi.com/collections...propylene-hifi-crossover-capacitor-6-8uf-250v

P1: https://cpc.farnell.com/raychem-te-...-radial-1-35a/dp/FF02433?ost=1.35a+polyswitch

Please refer to the link at the top if the component acronyms don't make any sense.

I think this post covers my basic prebuild understanding of the design and how I will execute the build, if anyone has any tips to add or things that I should be considering which I haven't mentioned then please let me know. Otherwise just wait for more posts to show progress updates on the build!

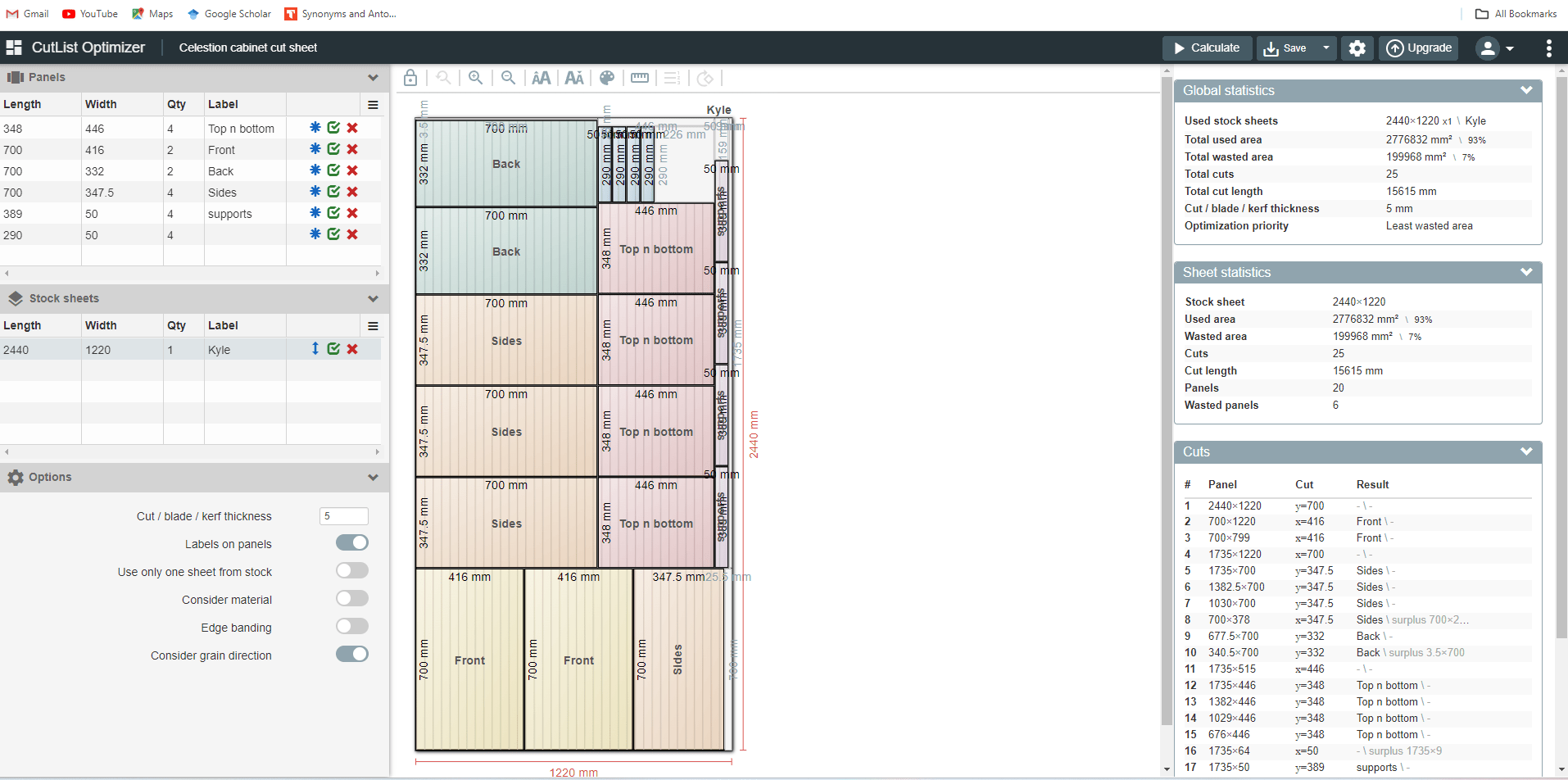

I've got a cutting list now which took a bit of calculating to figure out but has been confirmed as the correct measurements by the guys at celestion. Two of these cabs will fit pretty nicely into an 8 x 4 ft sheet (with some spare material)

I should be getting the panels cut sometime next week and then I'll be starting construction. I wanted to get peoples opinions on using biscuit or domino joints to secure the box together. I wanted to just use glue and screws but I'm not going to be painting the cabs and don't really like the look of exposed screws so something hidden like a domino seems to be the best solution, let me know your thoughts though!

I should be getting the panels cut sometime next week and then I'll be starting construction. I wanted to get peoples opinions on using biscuit or domino joints to secure the box together. I wanted to just use glue and screws but I'm not going to be painting the cabs and don't really like the look of exposed screws so something hidden like a domino seems to be the best solution, let me know your thoughts though!

I've also ordered all the electrical components for the crossover so will be making those next week as well, any pointers on how to join multiple wires to one terminal? As the bellow layout shows they recommend that all of the negative wires are joined together in the top left of the board, but this will mean joining 3 sections of around 17 gauge wire to a very thin component lead from resistors 1 and 3. I've seen people soldering these connections together, some using junction boxes and some using wire nut strips. What would be the best way to do this to get a reliable connection that won't fail and cause the speakers to break?