You could do something like this guy did:

This thread: http://www.hometheatershack.com/forums/diy-speakers/21448-build-dc-gold-n7r-steel-enclosure.html

This thread: http://www.hometheatershack.com/forums/diy-speakers/21448-build-dc-gold-n7r-steel-enclosure.html

Critofur

thanks for the link to the steel enclosures, very interesting read. This article was espescially interesting, I never would have guessed that speaker decoupling would have made such a large difference. Looks like I'm in need of some sorbthane!

With the baffle being isolated from the ceramic enclosure via liquid nails, and the driver being isolated from the baffle via sorbthane how much difference does baffle material make? Specifically I've been debating two different materials for the baffle. MDF, as it's cheap and easy to shape into a smooth curve. I'm also considering using some white oak that I have laying around from building shelves in our gallery. The white oak would be harder to shape, but it seems like it would be more rigid. Also issues people have of solid hard woods cracking would not be a problem as it has a little room to move due to liquid nails and sorbthane. Any thought? I'm leaning toward the white oak as I already have it laying around. Seems like a waste though as I'll probably end up smoothing the outside with something (drywall compound, fiberglass resin, ??) to get the transition from the ceramic enclosure to the wood baffle to be perfect. Hate to put all that work into planning down/shaping good wood just to end up painting it.

any insights suggestions welcome

thanks

Joe

thanks for the link to the steel enclosures, very interesting read. This article was espescially interesting, I never would have guessed that speaker decoupling would have made such a large difference. Looks like I'm in need of some sorbthane!

With the baffle being isolated from the ceramic enclosure via liquid nails, and the driver being isolated from the baffle via sorbthane how much difference does baffle material make? Specifically I've been debating two different materials for the baffle. MDF, as it's cheap and easy to shape into a smooth curve. I'm also considering using some white oak that I have laying around from building shelves in our gallery. The white oak would be harder to shape, but it seems like it would be more rigid. Also issues people have of solid hard woods cracking would not be a problem as it has a little room to move due to liquid nails and sorbthane. Any thought? I'm leaning toward the white oak as I already have it laying around. Seems like a waste though as I'll probably end up smoothing the outside with something (drywall compound, fiberglass resin, ??) to get the transition from the ceramic enclosure to the wood baffle to be perfect. Hate to put all that work into planning down/shaping good wood just to end up painting it.

any insights suggestions welcome

thanks

Joe

How big of a baffle? If it's only like a 1" wide ring then I wouldn't worry? Seems to me it depends on what aesthetic you prefer. If you could just make the oak rings slightly overhang then sand them smooth and flush?

MDF is not terrible, as far as enclosure material choices go, I guess, but regardless, if you're just making a small portion of the cabinet out of it, it's hardly relevant. Will you glaze the ceramic?

I would definately use something to dampen the ceramic walls.

Hmm - I'm not sure if I would say that the decoupling makes a "large" difference - at least - not large relative to other factors. I guess it's just once you reach a certain level of performance, gaining that last 10% is 1,000% harder.

MDF is not terrible, as far as enclosure material choices go, I guess, but regardless, if you're just making a small portion of the cabinet out of it, it's hardly relevant. Will you glaze the ceramic?

I would definately use something to dampen the ceramic walls.

Hmm - I'm not sure if I would say that the decoupling makes a "large" difference - at least - not large relative to other factors. I guess it's just once you reach a certain level of performance, gaining that last 10% is 1,000% harder.

The linked article is indeed interesting. Thanks for the link. I think they've misinterpreted figure 5 (the coupled system rings longer because the resonance frequency is lower, not because of a difference in Q) but the paper is interesting nonetheless. I certainly agree that decoupling the driver from the enclosure makes good sense because it reduces the vibrations excited in the cabinet walls, but I still feel more comfortable finding a way to hold the drivers rigidly in place, perhaps by mounting them by their magnets, rather than leaving them quasi-free-floating. In order for the diaphragms motion to track the signal, the driver chassis/magnet needs to be stationary.

I agree with critofur that given the amount of baffle you're going to be using, the differences between the stiffness and damping of various common materials (plywood, mdf, hardwood) are not going to be a big deal. I also agree that damping the ceramic walls makes sense but it would be interesting to see whether measurements support that assertion.

I'm looking forward to seeing the enclosures come out of the kiln. Should be very cool!

Few

I agree with critofur that given the amount of baffle you're going to be using, the differences between the stiffness and damping of various common materials (plywood, mdf, hardwood) are not going to be a big deal. I also agree that damping the ceramic walls makes sense but it would be interesting to see whether measurements support that assertion.

I'm looking forward to seeing the enclosures come out of the kiln. Should be very cool!

Few

How big of a baffle? If it's only like a 1" wide ring then I wouldn't worry? Seems to me it depends on what aesthetic you prefer. If you could just make the oak rings slightly overhang then sand them smooth and flush?

Will you glaze the ceramic?

I would definately use something to dampen the ceramic walls.

Yeah the baffle will probably only be 2" wide at the most. I'll probably use the hardwood for the baffles... just feels higher quality (and it would be one less thing to buy). I will most likely paint them none the less. One pair of enclosures is glazed and the other pair I left unglazed and put right in front on the firebox so they will be glazed with wood ash/embers assuming I don't break them during the firing. I'll probably paint the baffles flat black to match the speaker frame.

I certainly agree that decoupling the driver from the enclosure makes good sense because it reduces the vibrations excited in the cabinet walls, but I still feel more comfortable finding a way to hold the drivers rigidly in place, perhaps by mounting them by their magnets, rather than leaving them quasi-free-floating. In order for the diaphragms motion to track the signal, the driver chassis/magnet needs to be stationary.

I also agree that damping the ceramic walls makes sense but it would be interesting to see whether measurements support that assertion.

I'm looking forward to seeing the enclosures come out of the kiln. Should be very cool!

Few

Few I'm with you about holding the driver rigidly in place so it can better track the signal. I just can't work my head around a reasonable way to decouple the driver from the cabinet and also hold it rigidly. I would rather not alter the drivers just for this cabinet (as in I don't want to glue anything onto the magnet to hold it in place), as I would still like the option of trying them in front loaded horns at some point in the future if I like.

As far as dampening the enclosure (not entirely sure I need it, but I guess it can't hurt) maybe something like this? I couldn't imagine trying to put any kind of rigid material on the walls... way to many curves.

Well off to the kiln. Assuming everything goes well the firing should be done Friday night. I'll unload Monday and post pictures then.

Joe

Few I'm with you about holding the driver rigidly in place so it can better track the signal. I just can't work my head around a reasonable way to decouple the driver from the cabinet and also hold it rigidly.

There are two problems arising from mounting a driver to the baffle.

The first is that the baffle has to be rigid enough to prevent it flexing from the driver forces. The second is that the driver basket has to be rigid enough to prevent resonances due to the motor force. Remember that the motor is in the magnet assembly, like a weight suspended on two coupled springs - the basket and the baffle.

You can avoid both of these issues by clamping the magnet rigidly to the cabinet. Put a ring of foam seal around the opening in the baffle and adjust the driver position until it partly compresses the foam.

If the magnet mount is done properly, with braces that distribute the load to the walls of the enclosure, the majority of the magnet reaction will be coupled to the walls along their strongest axis (front to back) instead of as a bending force on the baffle.

Speakers with ferrite magnets are easy to mount - take a look at a picture of a set of mediaeval stocks for a clue.

Speakers with ferrite magnets are easy to mount - take a look at a picture of a set of mediaeval stocks for a clue.

You just have to do it in a way that does not create a big relective surface imediately behind the driver

dave

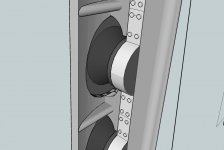

My thinking mirrors that of Don Hills. In the speakers I'm working on (open baffle) I'm going to use a soft gasket between the drivers and the front baffle, and then mount the speaker rigidly, via their magnets, to a rear spine designed to be stiff in the direction of the speaker's motion. I don't want to permanently modify the speakers in order to do the mounting so I'm going to build "stocks" of the kind Don mentioned, except made of aluminum. They'll clamp around the magnets and bolt to the rear spine. Here's a SketchUp rendition showing the woofer array from the rear. The "spine" is the vertical member on the right, and the curved front baffle is on the left. I hope the picture is self-explanatory but I've been thinking about those speakers for so long I can no longer think objectively about them.

Perhaps you could make "stocks" that sprout radially from the magnets and attach to the inner surfaces of your ceramic enclosures.

Few

Perhaps you could make "stocks" that sprout radially from the magnets and attach to the inner surfaces of your ceramic enclosures.

Few

Attachments

I like the rear spine idea. In a closed cabinet, the spine could be attached to the rear panel. It would perform dual duty as a panel brace.

Something i've been advocating (in a slightly similar form) for sometime.

dave

Well the firing is all done. Unfortunately one of the fostex enclosures did get broken (I assume the tangband enclosures are fine, though I couldn't see them during the firing). Not the worst thing in the world, I'm joining a friend in a firing mid-April, so it won't be too long of a wait for version 2.0 to come out. This will also give me more time to digest all the ideas that have been presented here.

These discussions of driver isolation and rigid mounting of drivers via there magnets is not something I've given all that much careful consideration to before. Few your design of rigid mounting to a spline behind the baffle makes complete sense and I can see how there could be quite a substantial improvement from this approach especially in an open baffle situation where the unsupported baffle can easily be excited.

However I'm trying to wrap my head around how these idea are best applied to the ceramic enclosures. Say it were possible to make the ceramic enclosure so that the drivers could be mounted directly to the enclosure with out the need for a wooden baffle. If this was the case I don't think a scheme of mounting the driver via a clamp that attached itself to the walls of the enclosure would offer any significant improvement. I can see why as Don suggested mounting the magnet to the side wall of a wooden enclosure could offer real benifits, as the front baffle will not transfer all the energy from the driver back into the side walls. However with these ceramic enclosures, assuming the driver is mounted rigidly to the front of the enclosure, it seems as though the energy can be transfered fairly well back to the side walls. Mainly due to the fact that the enclosures are monolithic structures with a single gentle curve from the front baffle to the side walls. Am I making any sense? I know a lot of you spend your time outside of audio endeavors doing scientific and mathmatical work, while I simply turn mud into stone though burning a lot of wood. So I accept that maybe I'm just missing something. However leaving aside the issue of the drivers frame flexing (which doesn't seem like a large issue with a 4" driver with a cast frame) I'm starting to think that maybe finding a way to rigidly mount the driver directly to the ceramic enclosure is best.

Lots to think about, and my heads still a little foggy from lack of sleep during the firing. I'm always interested in hearing peoples thoughts opinions. I'll post pictures after we get everything out of the kiln Monday.

Joe

These discussions of driver isolation and rigid mounting of drivers via there magnets is not something I've given all that much careful consideration to before. Few your design of rigid mounting to a spline behind the baffle makes complete sense and I can see how there could be quite a substantial improvement from this approach especially in an open baffle situation where the unsupported baffle can easily be excited.

However I'm trying to wrap my head around how these idea are best applied to the ceramic enclosures. Say it were possible to make the ceramic enclosure so that the drivers could be mounted directly to the enclosure with out the need for a wooden baffle. If this was the case I don't think a scheme of mounting the driver via a clamp that attached itself to the walls of the enclosure would offer any significant improvement. I can see why as Don suggested mounting the magnet to the side wall of a wooden enclosure could offer real benifits, as the front baffle will not transfer all the energy from the driver back into the side walls. However with these ceramic enclosures, assuming the driver is mounted rigidly to the front of the enclosure, it seems as though the energy can be transfered fairly well back to the side walls. Mainly due to the fact that the enclosures are monolithic structures with a single gentle curve from the front baffle to the side walls. Am I making any sense? I know a lot of you spend your time outside of audio endeavors doing scientific and mathmatical work, while I simply turn mud into stone though burning a lot of wood. So I accept that maybe I'm just missing something. However leaving aside the issue of the drivers frame flexing (which doesn't seem like a large issue with a 4" driver with a cast frame) I'm starting to think that maybe finding a way to rigidly mount the driver directly to the ceramic enclosure is best.

Lots to think about, and my heads still a little foggy from lack of sleep during the firing. I'm always interested in hearing peoples thoughts opinions. I'll post pictures after we get everything out of the kiln Monday.

Joe

Yes, you're making a lot of sense. Your small "baffle" is more integral to an inherently stronger structure than an open baffle consisting of a large, flat, unsupported panel. Mount the driver rigidly and be done with it. If you must, and it might help mitigate energy transfer, use a gasket and nylon bolts or elastomeric cement instead of metal bolts. I suspect you'll have more trouble with ringing of the ceramic walls than you will with flexing of such a small baffle. Dynamat or similar compound could prove useful.

Peace,

Tom E

Peace,

Tom E

Well here are the finished enclosures after firing. I don't think I'll keep these ones though. Neither of them have a very smooth curve to where the baffle would meet the ceramic enclosure. I'm not sure how I manged to miss that little bauble while it was still on the wheel.... Either way I've got another firing coming up mid April so we'll give it another go.

As chance would have it I came across a piece of corian this past weekend. It certainly does seem like a viable option for a front baffle. The piece I saw was around 1/2" thick and seemed very stiff. Right now I'm thinking of using corian or something similar for the front baffle so I can rigidly attach it to the enclosure. Using oak for a front baffle I would have to use a flexible adhesive (liquid nails) to account for the movement of the wood with changes in the humidity.

So I'm thinking rigidly couple the front baffle then I can test rigidly attaching the driver vs decoupling the driver with sorbthane. Sorry guys, I just can't wrap my head around a rigid coupling system using "stocks" on the rear magnet.

Joe

As chance would have it I came across a piece of corian this past weekend. It certainly does seem like a viable option for a front baffle. The piece I saw was around 1/2" thick and seemed very stiff. Right now I'm thinking of using corian or something similar for the front baffle so I can rigidly attach it to the enclosure. Using oak for a front baffle I would have to use a flexible adhesive (liquid nails) to account for the movement of the wood with changes in the humidity.

So I'm thinking rigidly couple the front baffle then I can test rigidly attaching the driver vs decoupling the driver with sorbthane. Sorry guys, I just can't wrap my head around a rigid coupling system using "stocks" on the rear magnet.

Joe

Attachments

I'll give you a big thumbs up on the WAF, Joe. I'd be much happier if our speakers looked that rather than unfinished surfboards.

As to the attachment, I think people got carried away talking to each other. You're not going to have the typical problems with panel resonances. Corian sounds like a great idea, you might be able to get cast off pieces from a kitchen builder that were cutouts for sinks. (I don't think they make them ALL into cutting boards.)

As to the attachment, I think people got carried away talking to each other. You're not going to have the typical problems with panel resonances. Corian sounds like a great idea, you might be able to get cast off pieces from a kitchen builder that were cutouts for sinks. (I don't think they make them ALL into cutting boards.)

I think the fired enclosures look great! Nice work.

No doubt I've missed the obvious while following and participating in this thread, but why again do you need a separate "baffle?" Why not select a shape and size for the opening such that you can simply mount the driver directly to the ceramic? If it's difficult to predict precisely the final dimensions of the fired piece, could you leave a flat surface that you could mount the driver to? I'm imagining one of your graceful shapes with a clean cut at the big-hole end. You could use removable caulking to hold the driver in place; you wouldn't necessarily need a material that can accept screws. The whole add-a-baffle process seems unnecessarily complex and I see more disadvantages than advantages. Sorry if I'm missing something that should be obvious.

Few

No doubt I've missed the obvious while following and participating in this thread, but why again do you need a separate "baffle?" Why not select a shape and size for the opening such that you can simply mount the driver directly to the ceramic? If it's difficult to predict precisely the final dimensions of the fired piece, could you leave a flat surface that you could mount the driver to? I'm imagining one of your graceful shapes with a clean cut at the big-hole end. You could use removable caulking to hold the driver in place; you wouldn't necessarily need a material that can accept screws. The whole add-a-baffle process seems unnecessarily complex and I see more disadvantages than advantages. Sorry if I'm missing something that should be obvious.

Few

I think the fired enclosures look great! Nice work.

No doubt I've missed the obvious while following and participating in this thread, but why again do you need a separate "baffle?" Why not select a shape and size for the opening such that you can simply mount the driver directly to the ceramic? If it's difficult to predict precisely the final dimensions of the fired piece, could you leave a flat surface that you could mount the driver to? I'm imagining one of your graceful shapes with a clean cut at the big-hole end. You could use removable caulking to hold the driver in place; you wouldn't necessarily need a material that can accept screws. The whole add-a-baffle process seems unnecessarily complex and I see more disadvantages than advantages. Sorry if I'm missing something that should be obvious.

Few

ummmmm...... well to be honest I didn't even consider that as an option. First off what could you use to effectively couple the driver to the enclosure? I'm not aware of something that is both strong enough and removable. The only thing I can think of that would be referred to as "removable caulk" would be rope caulk which doesn't seem like it would have enough holding power (keeping in mind that although I'm just mounting a 4" driver I'm trying to get all the wrinkles worked out with the thought of building one for a 6" or 8" prosound driver later on). It sounds like you have something in mind though. In which case I'm all ears.

I guess the only other reason to add a baffle is to get the last couple inches to be a perfect curve to meet the driver (which could be recessed). I guess the driver could be "recessed" by building up a layer instead of recessing a ring in a baffle. I actually have some two part epoxy that is easily colored which I've used to patch cracked pots before.

So I'm all ears as to your thoughts as to how to do this without an added baffle.

Joe

Elegant, Beautiful

Again - I'm floored by a gathering of talent in this online community. Enclosure panels of various thicknesses, without planes facing each other, are best not to have them want to vibrate at any one note. These have infinite thicknesses and interior angles!

I second the point about layers of different densities and elasticities. I have HDF LF cabinets that are lined inside with sheet lead, held on by tile adhesive. The constrained layer effect is like weights on a spring, knuckle-knocking sounds changed from a single note to a more pink, wider frequency sound. The lead can even be worked with heat to form into the interior, thanks to the heat-proof ceramic. No grinding, and keep it one piece and use low heat so as not to poison yourself.

They're going to sound great!

I have a niece who is an art teacher and can thow a mean vase. I'm curious about shaping the enclosure and leaving a boss on the front, then firing, then having a shop machine a mounting baffle with holes for rubber wellnuts, into which the screws would go. Naturally a nice gasket on the freshly machined recess...

Again - I'm floored by a gathering of talent in this online community. Enclosure panels of various thicknesses, without planes facing each other, are best not to have them want to vibrate at any one note. These have infinite thicknesses and interior angles!

I second the point about layers of different densities and elasticities. I have HDF LF cabinets that are lined inside with sheet lead, held on by tile adhesive. The constrained layer effect is like weights on a spring, knuckle-knocking sounds changed from a single note to a more pink, wider frequency sound. The lead can even be worked with heat to form into the interior, thanks to the heat-proof ceramic. No grinding, and keep it one piece and use low heat so as not to poison yourself.

They're going to sound great!

I have a niece who is an art teacher and can thow a mean vase. I'm curious about shaping the enclosure and leaving a boss on the front, then firing, then having a shop machine a mounting baffle with holes for rubber wellnuts, into which the screws would go. Naturally a nice gasket on the freshly machined recess...

knuckle-knocking sounds changed from a single note to a more pink, wider frequency sound

It goes from the single note, to the wider with the addition of the lead? (ie hi Q to low Q)... what happens to the frequency?

dave

paulfx

Thanks for the kind words. I got my first pottery apprenticeship right outside Cary NC (Pittsboro), and I have quite a few good pottery friends down there.... small world.

As far as machining a baffle onto the enclosure after they are fired.... maybe you have some experience with this, but that would definately scare me. I've broken a few pots just grinding the bottom of pots where the glaze ran down a little too far. I couldn't imagine trying to cut a hole for a baffle. If this is something you have experience with though I would be curious to hear more, as that would be the perfect solution. Pottery is quite big in your area, and maybe there is someone around there who could do it...

Joe

Thanks for the kind words. I got my first pottery apprenticeship right outside Cary NC (Pittsboro), and I have quite a few good pottery friends down there.... small world.

As far as machining a baffle onto the enclosure after they are fired.... maybe you have some experience with this, but that would definately scare me. I've broken a few pots just grinding the bottom of pots where the glaze ran down a little too far. I couldn't imagine trying to cut a hole for a baffle. If this is something you have experience with though I would be curious to hear more, as that would be the perfect solution. Pottery is quite big in your area, and maybe there is someone around there who could do it...

Joe

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Ceramic speaker enclosures