Need some help centering CD diaphragms.

I have a pair of 291-16K Altec compression drivers for which I have bought new GPA aluminum frams. (288 style)

Unfortunately the 291s do not have the adjustable locater pins. Just a pair of small screws. So even though the new frams came with the spider shim, they are giving me a headache getting them centered. Without the pins, the shim is no use.

I can play a 1KHz tone and look at it on FFT (Arta). As I shift the fram around, the harmonics change. Even tho I can get to a spot with low distortion, or a nice even fall-off, once I start to snug the screws the 3rd harmonic shoots up. I've tried and tried, but every time I tighten even a bit, the distortion shoots up.

Any hints or tips for doing this right. I know some of you guys have practice at this. What worked for you? Thanks!

(P.S. Also posted this on the Altec board. Will post here if the solution is found over there)

I have a pair of 291-16K Altec compression drivers for which I have bought new GPA aluminum frams. (288 style)

Unfortunately the 291s do not have the adjustable locater pins. Just a pair of small screws. So even though the new frams came with the spider shim, they are giving me a headache getting them centered. Without the pins, the shim is no use.

I can play a 1KHz tone and look at it on FFT (Arta). As I shift the fram around, the harmonics change. Even tho I can get to a spot with low distortion, or a nice even fall-off, once I start to snug the screws the 3rd harmonic shoots up. I've tried and tried, but every time I tighten even a bit, the distortion shoots up.

Any hints or tips for doing this right. I know some of you guys have practice at this. What worked for you? Thanks!

(P.S. Also posted this on the Altec board. Will post here if the solution is found over there)

Hello

Try over on Lansing Heritage as well. There are some smart reconers over there that might be able to help you. I have had problems similar to that but was always able to figure out a screw sequence that worked. I had problems with 2 particular drivers that always were a headache. Did you try calling GPA??

Good Luck

Rob

Try over on Lansing Heritage as well. There are some smart reconers over there that might be able to help you. I have had problems similar to that but was always able to figure out a screw sequence that worked. I had problems with 2 particular drivers that always were a headache. Did you try calling GPA??

Good Luck

Rob

Which direction do you think (see) the diaphragm goes when the screws are tightened?

Dose it move along the plane of top plate by the torque (twist) of screws, or move along the axis of VC (up/down)? Or both?

Flat washers help in providing a proper 'slide' between 2 twisting surfaces, so they can be secured with much less twist from the screw or hopefully pure vertical pressure is left. A very thin layer of oil between the 2 washers, or one more nylon washer in between them might be even better in this regard.

If it moves along the axis of VC, then maybe the surround of surround is pressed or distorted and make the VC get out of the gap by some degree. But is that possible?

Dose it move along the plane of top plate by the torque (twist) of screws, or move along the axis of VC (up/down)? Or both?

Flat washers help in providing a proper 'slide' between 2 twisting surfaces, so they can be secured with much less twist from the screw or hopefully pure vertical pressure is left. A very thin layer of oil between the 2 washers, or one more nylon washer in between them might be even better in this regard.

If it moves along the axis of VC, then maybe the surround of surround is pressed or distorted and make the VC get out of the gap by some degree. But is that possible?

Hey CLS. It's hard to say. And it seems to be the "last screw" that does it. All others can be tight, but the last one will cause 3rd harmonic distortion to rise when tightened. Drives me nuts!

So perhaps it's the way that the coil sits in the gap. Maybe the fram and coil need to be just slightly off level to be best placed?

I am inclined to put thread lock on that last screw and leave it just barley tight.

So perhaps it's the way that the coil sits in the gap. Maybe the fram and coil need to be just slightly off level to be best placed?

I am inclined to put thread lock on that last screw and leave it just barley tight.

barley tight.

Does that mean we are going to run out of beer? Sorry pano, couldn't resist.

you do not want to make all three screws "tight" by tightening one at a time. You need to do the same trick that is used on things like engine heads and other things where the stresses need to be even. So, tighten slowly, rotate around the diaphragm if there are only three screws. For 5, use a star pattern, etc...

this might help.

_-_-bear

this might help.

_-_-bear

Yep, tried that. Used a star pattern. Even got them almost tight and tapped the edge of the fram (plastic rim) into place. But if I try to tighten, things change for the worse.

But here's the rub (excuse the pun). No 2 measurements show me the same thing. :-/

Single sine and swept are different. I'll try to post some of these later. According to the swept or stepped sines, 1K is not my problem area. 3K-5K is.

But here's the rub (excuse the pun). No 2 measurements show me the same thing. :-/

Single sine and swept are different. I'll try to post some of these later. According to the swept or stepped sines, 1K is not my problem area. 3K-5K is.

I'm confused.

How many inch pounds of torque on the diaphram mounting are we talking? It seems to me that if you have two of three screws tight then you aren't changing the concentricity of anything with the last screw except by any existing warpage angle. If the shim you mention is the sort of shim I think it is then it is critical to get the coil height placed correctly relative to gap length. A "shoots up" 3rd harmonic is interesting enough. It seems like that might occur in a relative sense, far as second harmonic becoming cancelled when things are perfectly balanced. It would be cool to see your graphs, and also to know the solution to the problem.

How many inch pounds of torque on the diaphram mounting are we talking? It seems to me that if you have two of three screws tight then you aren't changing the concentricity of anything with the last screw except by any existing warpage angle. If the shim you mention is the sort of shim I think it is then it is critical to get the coil height placed correctly relative to gap length. A "shoots up" 3rd harmonic is interesting enough. It seems like that might occur in a relative sense, far as second harmonic becoming cancelled when things are perfectly balanced. It would be cool to see your graphs, and also to know the solution to the problem.

Sorry Bear. I did not mean "number 2" I meant "no two measurements" show the same thing. Tho there are trends. I'm working on that now.

Andrew, don't know the torque, hope I don't have to resort to an inch pound wrench! But it's not a bad idea....

Let's see what I can come up with as far as graphs and stuff.

Andrew, don't know the torque, hope I don't have to resort to an inch pound wrench! But it's not a bad idea....

Let's see what I can come up with as far as graphs and stuff.

Measurements.

OK, some measurements and graphs.

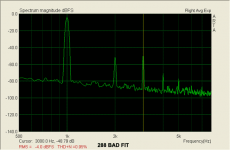

The first is an FFT of a 1KHz tone after all screws are tight. Fundamental is at -6.5dB. You can see that H3 is slightly higher than H2. Without all the screws tight, H3 is 6-8dB below H2. (Unfortunately I don't have a shot of that - will redo).

I want the lowest distortion possible, but also want the harmonics to drop off at about 6dB each, relative to the next lower order harmonic. That way they are masked and can't be heard. Definitely don't won't a rise in H3 or H5.

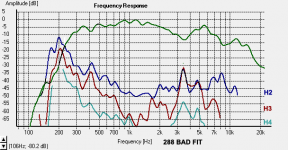

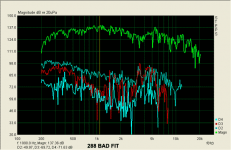

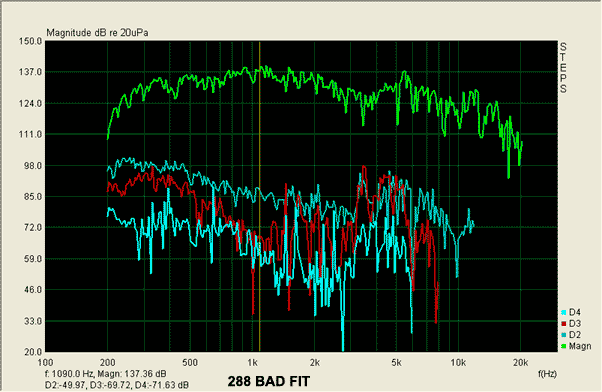

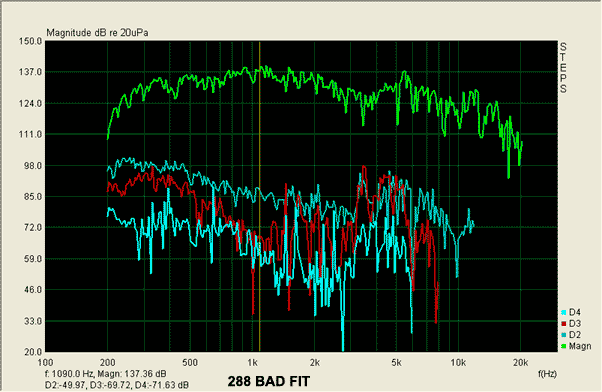

But here is the trouble. Using a stepped or swept sine, things don't look the same. HOLMImpulse and STEPS do NOT show a predominate H3 @ 1Khz. They both do show big trouble from 3-5KHz.

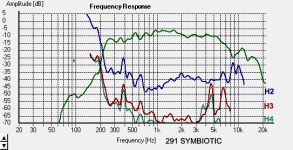

For reference, the last graph is the Altec symbiotic fram that came in the driver. Don't know if it's a factory install.

Not sure what to make of all this, but will keep working at it.

OK, some measurements and graphs.

The first is an FFT of a 1KHz tone after all screws are tight. Fundamental is at -6.5dB. You can see that H3 is slightly higher than H2. Without all the screws tight, H3 is 6-8dB below H2. (Unfortunately I don't have a shot of that - will redo).

I want the lowest distortion possible, but also want the harmonics to drop off at about 6dB each, relative to the next lower order harmonic. That way they are masked and can't be heard. Definitely don't won't a rise in H3 or H5.

But here is the trouble. Using a stepped or swept sine, things don't look the same. HOLMImpulse and STEPS do NOT show a predominate H3 @ 1Khz. They both do show big trouble from 3-5KHz.

For reference, the last graph is the Altec symbiotic fram that came in the driver. Don't know if it's a factory install.

Not sure what to make of all this, but will keep working at it.

Attachments

Not to Rub it in , but ;

Pano,

( for the archives )

- I expect a healthy 288 with a proper fitting diaphragm to measure something like this ( this is my best performing 288-8K on a small Emilar , radial-type horn ) ;

- Note the db spread between the various distortion products / which you've mentioned that you'd like to accomplish due to the inherent masking effects .

As opposed to this ( your bad fit ) ;

- I know these plots were obtained using different measuring conditions ( horns , levels, scales / even the type of distortions displayed ) but still, the general trend looks pretty clear ( IMO ) .

<> cheers

Pano,

( for the archives )

- I expect a healthy 288 with a proper fitting diaphragm to measure something like this ( this is my best performing 288-8K on a small Emilar , radial-type horn ) ;

- Note the db spread between the various distortion products / which you've mentioned that you'd like to accomplish due to the inherent masking effects .

An externally hosted image should be here but it was not working when we last tested it.

As opposed to this ( your bad fit ) ;

- I know these plots were obtained using different measuring conditions ( horns , levels, scales / even the type of distortions displayed ) but still, the general trend looks pretty clear ( IMO ) .

<> cheers

Last edited:

Earl - thanks. I quite agree. Your 288 looks a lot better. The only thing mine has going for it is better low end extension. But it's a bigger horn, so it would.

So I think I'll work on centering the fram with a 3KHz tone. Since that seems to be the big problem area, that's where I'll work. Wish me luck!

So I think I'll work on centering the fram with a 3KHz tone. Since that seems to be the big problem area, that's where I'll work. Wish me luck!

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Centering compression driver 'frams by tone.