I am a little worried that the DHT 2A3 filament will be warm long before the EL84 indirectly heated cathode is warm.

Also, I expect the 5U4G filament to warm up long before the EL84 indirectly heated cathode is warm.

That means all 475V will appear on the 2A3 grid, and slowly fall to 157 as the EL84 warms up, and the EL84 starts to draw plate current.

Thee will be Lots of 2A3 current at power-up time.

I like the circuit, but just take care to get the EL84 cathode warm first.

You might select a pair of slow warming Damper Diodes instead of the 5U4G.

Also, I expect the 5U4G filament to warm up long before the EL84 indirectly heated cathode is warm.

That means all 475V will appear on the 2A3 grid, and slowly fall to 157 as the EL84 warms up, and the EL84 starts to draw plate current.

Thee will be Lots of 2A3 current at power-up time.

I like the circuit, but just take care to get the EL84 cathode warm first.

You might select a pair of slow warming Damper Diodes instead of the 5U4G.

First of all thanks for the heads-up! This is exactly the why I posted this thread.

I'm planning to use 1200 V power Schottky silicon carbide diodes for the HV. Followed by the K&K Audio SoftStart module. (It uses a 30 second timer after which it ramps up the voltage in 2 - 3 seconds. Should be enough right? Otherwise I can lengthen the time...both for the relay and the ramp-up.

For the filaments I think I'm going for AC as shown. But I might try Rod Coleman's boards later.

I'm planning to use 1200 V power Schottky silicon carbide diodes for the HV. Followed by the K&K Audio SoftStart module. (It uses a 30 second timer after which it ramps up the voltage in 2 - 3 seconds. Should be enough right? Otherwise I can lengthen the time...both for the relay and the ramp-up.

For the filaments I think I'm going for AC as shown. But I might try Rod Coleman's boards later.

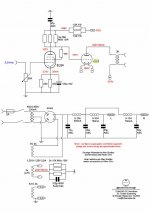

Attachments

Filaments: I think the Rod Coleman filament boards are soft start (delays full heat to filament and/or cathode). Take how long that is into account.

B+: Parts that have intrinsically correct timing may be more reliable than a circuit that drives a set of relay contacts. Depends on the exact parts, and their quality. I know some use the Damper Diodes, lower voltage drop that most 5V rectifiers, but not as low voltage drop as silicon diodes.

A completely different issue versus your thread, but applies to B+: I did have a B+ that had problems with killing 1kV diodes that should have been high enough PRV rating. There was a situation where the transformer primary was disconnected and the secondary was not loaded (no tubes in, so no filaments across the windings). I replaced the small diodes with 8A 1500V HEXFREDS. The Big Area Chips took any and all punishment that the circuit could put out.

I have written in several threads about DC filaments vs AC filaments on DHT.

My next 2A3 amp will have DC filaments or I will not build it. Period. 45 and 2A3 are really good for DC.

The 5V and 7.5V filament DHT are not quite as good with DC as 2.5V filaments. But AC on 5V and 7.5V filaments is even worse.

B+: Parts that have intrinsically correct timing may be more reliable than a circuit that drives a set of relay contacts. Depends on the exact parts, and their quality. I know some use the Damper Diodes, lower voltage drop that most 5V rectifiers, but not as low voltage drop as silicon diodes.

A completely different issue versus your thread, but applies to B+: I did have a B+ that had problems with killing 1kV diodes that should have been high enough PRV rating. There was a situation where the transformer primary was disconnected and the secondary was not loaded (no tubes in, so no filaments across the windings). I replaced the small diodes with 8A 1500V HEXFREDS. The Big Area Chips took any and all punishment that the circuit could put out.

I have written in several threads about DC filaments vs AC filaments on DHT.

My next 2A3 amp will have DC filaments or I will not build it. Period. 45 and 2A3 are really good for DC.

The 5V and 7.5V filament DHT are not quite as good with DC as 2.5V filaments. But AC on 5V and 7.5V filaments is even worse.

Good to hear! I already have Rod's boards...so they're in.45 and 2A3 are really good for DC.

I hear you. But will stubbornly use the relays I have.Parts that have intrinsically correct timing may be more reliable than a circuit that drives a set of relay contacts.

Last edited:

I am actually planning separate transformers for B+ and heaters/filaments.I would run separate transformers for B+ and heaters/filaments. Then use the relay to switch the primary of the B+ transformer, do not switch B+ itself as the relay was not designed for that. 450V+ is way too much to safely switch with 250VAC rated relays.

Because the K&K circuit I have ....also has a slow ramp up section...I'll just use switches...and will use the relay/slow ramp-up for another project.

do not switch B+ itself as the relay was not designed for that. 450V+ is way too much to safely switch with 250VAC rated relays.

A little snippet from K&K Audio website though on the relay:

The same PC mount power relay is used in both circuits and is rated for a hefty 8 amps. These relays have been used for years in products switching B+ voltages as high as 550V with no problems.

Last edited:

Finally started on this amp again. The plate choke paint was chipped off in some arease...so I just did a respray.

Pic with shrouds off the plate choke Magnequest FS-100 PC /60mA (around 125H). With output transformer (TFA 2004 Jr) next to it and a 6p1p as size reference.

Pic with shrouds off the plate choke Magnequest FS-100 PC /60mA (around 125H). With output transformer (TFA 2004 Jr) next to it and a 6p1p as size reference.

Attachments

Last edited:

Nice work. Looking good.

For the startup, have you decided what to do?

I've dealt with a DC PP amp, with SS PS so B+ was immediate.

Well despite all my attempts (diode grid/cathode, etc..), I could not guarantee that there won't be a period in which the power tubes are unbiased (so runaway current in the OT), as it is totally dependent of the driver tube. Because of the DC nature, the tubes are tied together. It works well with one tube, use another one, and it won't start as nicely as expected.

So I had to build a time delay in my PS circuitry. It now works all the time, and I set the delay at 45 seconds to be on the safe side. I did not have a problem so far after 2 years.

I hope it helps.

For the startup, have you decided what to do?

I've dealt with a DC PP amp, with SS PS so B+ was immediate.

Well despite all my attempts (diode grid/cathode, etc..), I could not guarantee that there won't be a period in which the power tubes are unbiased (so runaway current in the OT), as it is totally dependent of the driver tube. Because of the DC nature, the tubes are tied together. It works well with one tube, use another one, and it won't start as nicely as expected.

So I had to build a time delay in my PS circuitry. It now works all the time, and I set the delay at 45 seconds to be on the safe side. I did not have a problem so far after 2 years.

I hope it helps.

Member

Joined 2009

Paid Member

These dc amps scare folk BUT remember that you have at least some cushion from the large cathode resistor. This resistor is shown as dropping 200V in normal operation. If the 2a3 grid were inadequately biassed and the anode current were to double to 120mA you’d then be dropping 400V across the cathode resistor leaving only 50V across the tube. Depending on your rectifier this increased current draw would likely drop the supply rail and you’d have even less across the tube. So it becomes a bit self-protected.

Delaying B+ until everything is hot may not be too kind an option either because it may result in a large current spike to charge up the cathode bypass capacitor.

In the end, the simple solution might be to leave all well alone, no fancy delays or relays are needed anywhere in this amplifier. And many such dc-coupled amplifiers like this have been built as such e.g. Fi 2A3.

I’d suggest try it with ac filaments first to see how much of an issue it is. The 2A3 has relatively low heater voltage and some versions of this tube have a filament designed to minimize hum, e.f. the JJ 2A3-40 is run by some folk on a.c. without even a hum pot. Simple, reliable.

Delaying B+ until everything is hot may not be too kind an option either because it may result in a large current spike to charge up the cathode bypass capacitor.

In the end, the simple solution might be to leave all well alone, no fancy delays or relays are needed anywhere in this amplifier. And many such dc-coupled amplifiers like this have been built as such e.g. Fi 2A3.

I’d suggest try it with ac filaments first to see how much of an issue it is. The 2A3 has relatively low heater voltage and some versions of this tube have a filament designed to minimize hum, e.f. the JJ 2A3-40 is run by some folk on a.c. without even a hum pot. Simple, reliable.

Last edited:

Thanks!Nice work. Looking good.

Yes. 6AX4 damper diodes.For the startup, have you decided what to do?

- Home

- Amplifiers

- Tubes / Valves

- Building parafeed EL84 DC 2A3 amp