Hello everyone, a bit of a search around the internet has suggested this is the place to find out about building my own speakers!

I've always had a bit of a fascination with horn speakers (and have been impressed with the few that I've actually heard) and also with the concept of the fullrange driver.

After many years living in rented rooms I now have the opportunity to build something, because I'm in the process of renovating a flat I'm going to move into, and I'm thinking it would be fun to build some big(ish) horns - probably built into a wall of storage etc. I've attached a diagram showing the basic dimensions of the room they will live in.

I currently own a pair of Lowther PM6C drivers...acquired a while ago in anticipation of building my own speakers at some point but as yet unused. So I'd like to use these, but if it turns out they aren't appropriate, I can sell them and get something else instead.

Potentially each speaker could occupy a space of approx. 600mm wide by 2000mm high by 700mm deep.

There are lots of designs on the internet...but it's difficult to know where to start. I'm hoping some of you might be able to point me in the right direction at this stage.

As for my listening preferences... I'd like to build something with a fairly low reach. I don't want bass at the expense of everything else but I would definitely like it to be present. I've considered horns + subwoofer but I really like the idea of the simplicity of just two drivers and would like to stick to that if possible. At the high end... I like it to be there and sharp but it's not my no. 1 priority. I would like to make sure if possible to avoid excessive brightness or harshness in the upper midrange/top end.

Like I say, any suggestions at this point would be much appreciated.

I will post photos here if and when I start the project!

I've always had a bit of a fascination with horn speakers (and have been impressed with the few that I've actually heard) and also with the concept of the fullrange driver.

After many years living in rented rooms I now have the opportunity to build something, because I'm in the process of renovating a flat I'm going to move into, and I'm thinking it would be fun to build some big(ish) horns - probably built into a wall of storage etc. I've attached a diagram showing the basic dimensions of the room they will live in.

I currently own a pair of Lowther PM6C drivers...acquired a while ago in anticipation of building my own speakers at some point but as yet unused. So I'd like to use these, but if it turns out they aren't appropriate, I can sell them and get something else instead.

Potentially each speaker could occupy a space of approx. 600mm wide by 2000mm high by 700mm deep.

There are lots of designs on the internet...but it's difficult to know where to start. I'm hoping some of you might be able to point me in the right direction at this stage.

As for my listening preferences... I'd like to build something with a fairly low reach. I don't want bass at the expense of everything else but I would definitely like it to be present. I've considered horns + subwoofer but I really like the idea of the simplicity of just two drivers and would like to stick to that if possible. At the high end... I like it to be there and sharp but it's not my no. 1 priority. I would like to make sure if possible to avoid excessive brightness or harshness in the upper midrange/top end.

Like I say, any suggestions at this point would be much appreciated.

I will post photos here if and when I start the project!

An externally hosted image should be here but it was not working when we last tested it.

Potentially each speaker could occupy a space of approx. 600mm wide by 2000mm high by 700mm deep.

My goodness, that's a lot of working space. Quite a bit bigger than a Sachiko (340x1830x460), and they're pretty hefty cabinets. I wonder if your PM6C would be compatible...

The Spawn Family of Double Horns

edit: Hmm... the construction plans specifically mention the PM6C. I'd say go for it.

Last edited:

My goodness, that's a lot of working space. Quite a bit bigger than a Sachiko (340x1830x460), and they're pretty hefty cabinets. I wonder if your PM6C would be compatible...

The Spawn Family of Double Horns

edit: Hmm... the construction plans specifically mention the PM6C. I'd say go for it.

Thanks very much for the link - lots of designs to look at there. Did you mean the Sachiko plans mention the PM6C - I couldn't find any mention on them...?

Hello,

may be a solution would be:

TUBA, BASSTUBA,

Thanks - where would I be able to find details for these?

A couple of general questions:

1. Am I right in thinking that generally, bigger is better (especially if I want a good low frequency response)? Or are there problems that begin to appear beyond a certain size?

2. Should the size and shape of my room have any particular bearing on the design of speaker I choose?

3. I will probably end up building them from plywood, as per most designs but I also have this idea that I'd like to try and cast something from concrete... this may be wildly over-ambitious but is this something that other folk have tried / succeeded with? I'm thinking that I'd be able to make the formwork from something like dense polystyrene which would allow smooth curves and also possibly a horn that is circular in cross-section along its length. I'd probably make it in two halves that would be bolted together. Is this a completely crazy idea?

1. Am I right in thinking that generally, bigger is better (especially if I want a good low frequency response)? Or are there problems that begin to appear beyond a certain size?

2. Should the size and shape of my room have any particular bearing on the design of speaker I choose?

3. I will probably end up building them from plywood, as per most designs but I also have this idea that I'd like to try and cast something from concrete... this may be wildly over-ambitious but is this something that other folk have tried / succeeded with? I'm thinking that I'd be able to make the formwork from something like dense polystyrene which would allow smooth curves and also possibly a horn that is circular in cross-section along its length. I'd probably make it in two halves that would be bolted together. Is this a completely crazy idea?

A couple of general questions:

3. I will probably end up building them from plywood, as per most designs but I also have this idea that I'd like to try and cast something from concrete... this may be wildly over-ambitious but is this something that other folk have tried / succeeded with? I'm thinking that I'd be able to make the formwork from something like dense polystyrene which would allow smooth curves and also possibly a horn that is circular in cross-section along its length. I'd probably make it in two halves that would be bolted together. Is this a completely crazy idea?

Being only one and a half sets of speakers from being a newbie myself, I suggest you go with an established design out of plywood.

If you do something complex, immovable and not at all adjustable out of concrete, you have to get everything just right the first time and re-dos are a PITA.

Besides, the first time(s), it won't be perfect, so give yourself a break and start simple, established and enjoy the process of learning enough so that you can safely pour concrete in the future.

A good simple start could be a BIB. you could pick your driver based on the space available. I did a BIB with the Fostex 208EZ and it is big and sounds great. Easy first build with excellent results and with the right driver, enough bass, which is important, a room the shape of yours may eat some lower frequencies.

Did you mean the Sachiko plans mention the PM6C - I couldn't find any mention on them...?

How curious. Version 1v0 (dated 23-03-07?) of the drawings had a note near the bottom of page two. The current package 1v01 (dated 22-03-09?) has some changes, and the mention of Lowthers is no longer there. I think that part of the drawing got snipped because it contained some response plots that tended to cause more confusion than clarity. Regardless, I suspect the design is still valid for the Lowthers. Perhaps Scott Lindgren can chime in.

If you are to build them, definitely use the newer drawing package. I seem to recall there are some important corrections in it, especially with regards to the wedge deflector.

I also have this idea that I'd like to try and cast something from concrete... this may be wildly over-ambitious but is this something that other folk have tried / succeeded with? I'm thinking that I'd be able to make the formwork from something like dense polystyrene which would allow smooth curves and also possibly a horn that is circular in cross-section along its length. I'd probably make it in two halves that would be bolted together. Is this a completely crazy idea?

It's been done here before. Search long and hard, and you should find the thread. The builder used some kind of styrofoam for the casting, poured the cement, then used a solvent to remove the foam. I'm sure it was messy and most likely bad for the environment. He managed to build one but never completed a pair. I'd stick with wood. If you pour a solid block of concrete to the dimensions you've described earlier, you're dealing with over 2.2 tons per cabinet. Even recognizing that some fraction is going to be empty space (60%?) it's still going to be incredibly heavy.

edit: Here's the thread with the concrete horn -

http://www.diyaudio.com/forums/full-range/145924-tqwt-concrete-cabinet-attempt-building-thread.html

Last edited:

Here you get feedback, plan, measurement, may be take goo.. translate if you need:

tuba

tubamess

tubaFB

tubaplan

basstuba

basstubamess

basstubaFB

basstubaplan

tuba

tubamess

tubaFB

tubaplan

basstuba

basstubamess

basstubaFB

basstubaplan

1. Am I right in thinking that generally, bigger is better (especially if I want a good low frequency response)? Or are there problems that begin to appear beyond a certain size?

To an extent, yes, providing it's correctly designed, bigger is better. However, as horn length increases, so does group delay, thus the acoustic XO frequency from horn to direct radiation will need to drop to render it ~inaudible and / or you will need some form of digital delay on everything above that point. If this XO occurs significantly below the driver's mass corner, you will then need a short front-horn to 'fill in' the resultant dip in the response.

2. Should the size and shape of my room have any particular bearing on the design of speaker I choose?

The room dominates low down, so unless it's of ideal acoustic proportions & you've lots of treatment, then yes, you want to think about it. A lot of it is common sense though; if you want to fill a concert hall, you don't pick an LS3/5a.

3. I will probably end up building them from plywood, as per most designs but I also have this idea that I'd like to try and cast something from concrete... this may be wildly over-ambitious but is this something that other folk have tried / succeeded with? I'm thinking that I'd be able to make the formwork from something like dense polystyrene which would allow smooth curves and also possibly a horn that is circular in cross-section along its length. I'd probably make it in two halves that would be bolted together. Is this a completely crazy idea?

It's been done, but it's not especially easy. I wouldn't discourage you from it, but I'd probably consider something in wood initially, as it's quicker & simpler to ascertain whether you like the results or not. If you do, & you're feeling ambitious, you could always consider the cast concrete at a later date.

Being only one and a half sets of speakers from being a newbie myself, I suggest you go with an established design out of plywood.

If you do something complex, immovable and not at all adjustable out of concrete, you have to get everything just right the first time and re-dos are a PITA.

Besides, the first time(s), it won't be perfect, so give yourself a break and start simple, established and enjoy the process of learning enough so that you can safely pour concrete in the future.

A good simple start could be a BIB. you could pick your driver based on the space available. I did a BIB with the Fostex 208EZ and it is big and sounds great. Easy first build with excellent results and with the right driver, enough bass, which is important, a room the shape of yours may eat some lower frequencies.

Thanks - I've just had a look at the BIB stuff. Your point about starting with something relatively easy is a perfectly valid one of course, although I'm wanting to be a bit ambitious with this because I won't necessarily have the time or opportunity to repeat the process in the near future!

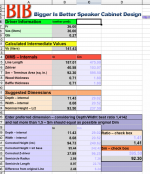

I plugged the Lowther PM6C specs into the calculator on the BIB site by the way... assuming I got the specs right (different sources seem to disagree on them) it suggested a 2.4m high cabinet which is pretty big! (see below)

Can anyone comment on the advantages of building a more complex design (for example the Spawn double horns linked to earlier) compared to something like the BIB design (assuming I build both competently of course)?

Attachments

How curious. Version 1v0 (dated 23-03-07?) of the drawings had a note near the bottom of page two. The current package 1v01 (dated 22-03-09?) has some changes, and the mention of Lowthers is no longer there. I think that part of the drawing got snipped because it contained some response plots that tended to cause more confusion than clarity. Regardless, I suspect the design is still valid for the Lowthers. Perhaps Scott Lindgren can chime in.

If you are to build them, definitely use the newer drawing package. I seem to recall there are some important corrections in it, especially with regards to the wedge deflector.

It's been done here before. Search long and hard, and you should find the thread. The builder used some kind of styrofoam for the casting, poured the cement, then used a solvent to remove the foam. I'm sure it was messy and most likely bad for the environment. He managed to build one but never completed a pair. I'd stick with wood. If you pour a solid block of concrete to the dimensions you've described earlier, you're dealing with over 2.2 tons per cabinet. Even recognizing that some fraction is going to be empty space (60%?) it's still going to be incredibly heavy.

edit: Here's the thread with the concrete horn -

http://www.diyaudio.com/forums/full-range/145924-tqwt-concrete-cabinet-attempt-building-thread.html

Here you get feedback, plan, measurement, may be take goo.. translate if you need:

tuba

tubamess

tubaFB

tubaplan

basstuba

basstubamess

basstubaFB

basstubaplan

To an extent, yes, providing it's correctly designed, bigger is better. However, as horn length increases, so does group delay, thus the acoustic XO frequency from horn to direct radiation will need to drop to render it ~inaudible and / or you will need some form of digital delay on everything above that point. If this XO occurs significantly below the driver's mass corner, you will then need a short front-horn to 'fill in' the resultant dip in the response.

The room dominates low down, so unless it's of ideal acoustic proportions & you've lots of treatment, then yes, you want to think about it. A lot of it is common sense though; if you want to fill a concert hall, you don't pick an LS3/5a.

It's been done, but it's not especially easy. I wouldn't discourage you from it, but I'd probably consider something in wood initially, as it's quicker & simpler to ascertain whether you like the results or not. If you do, & you're feeling ambitious, you could always consider the cast concrete at a later date.

Thanks all for your comments.

One thing to consider is that with horns built in, you have zero options for tweaking the position or toe-in to get the best response. Special consideration is also needed for the 2 pi loading.

dave

Sure. I will probably construct them in such a way that I can rotate them to some degree, possibly even build them before finishing off the surrounding cupboards etc so I can tweak the position a bit before fixing it.

What is the 2 pi loading?

2 pi is radiating into a 1/2 sphere (2pi steriradians).

But actually with the floor (and ceiling) playing a roll 1pi steriradians might be closer.

Sachiko for instance is designed to be out from a wall, so you might find excessive bass gain (not a bad thing as long as you have a way to turn it down)

dave

But actually with the floor (and ceiling) playing a roll 1pi steriradians might be closer.

Sachiko for instance is designed to be out from a wall, so you might find excessive bass gain (not a bad thing as long as you have a way to turn it down)

dave

2 pi is radiating into a 1/2 sphere (2pi steriradians).

But actually with the floor (and ceiling) playing a roll 1pi steriradians might be closer.

Sachiko for instance is designed to be out from a wall, so you might find excessive bass gain (not a bad thing as long as you have a way to turn it down)

dave

Ok, I think I sort of understand what you are talking about...

When you say it needs to be taken into consideration, do you mean choice of speaker design, or alterations to a chosen design... or something else?

So, a year and a bit on, I am resurrecting this thread because I am getting closer to the point where I can start building these.

A question though - I had been thinking of building the "Sachiko" from the Frugelhorn website (part of the "Spawn" family), however, I've just had a look now, and there no longer seems to be a "Sachiko" design there.

I'm guessing these are updated designs? Is anyone able to help me with the question of whether Lowther PM6Cs would work with any of the current designs? Or would I be better to use one of the older ones? As per the post below, from earlier in the thread, it seemed to be the case that an earlier iteration of the design had been tested with Lowthers.

A question though - I had been thinking of building the "Sachiko" from the Frugelhorn website (part of the "Spawn" family), however, I've just had a look now, and there no longer seems to be a "Sachiko" design there.

I'm guessing these are updated designs? Is anyone able to help me with the question of whether Lowther PM6Cs would work with any of the current designs? Or would I be better to use one of the older ones? As per the post below, from earlier in the thread, it seemed to be the case that an earlier iteration of the design had been tested with Lowthers.

How curious. Version 1v0 (dated 23-03-07?) of the drawings had a note near the bottom of page two. The current package 1v01 (dated 22-03-09?) has some changes, and the mention of Lowthers is no longer there. I think that part of the drawing got snipped because it contained some response plots that tended to cause more confusion than clarity. Regardless, I suspect the design is still valid for the Lowthers. Perhaps Scott Lindgren can chime in.

Happened to notice this thread...

Imo, with the Lowther drivers you have to deal with the inherent aspects of that driver. Generalized solutions are not going to work well.

The basic response of the driver is more or less a response that gently droops from a mid point in the frequency range down to either end.

Many people have tried to augment the lower frequency section, and to produce "real bass".

It's problematic, the solutions vary in effectiveness.

I think that MJK's solution is to use his TQWT design but with an electrical network to flatten the response, at the expense of sensitivity.

The various front horn designs seek to augment the lower freq range via the horn. The back horn seeks to augment the lowest freq response.

Oh, while thinking of it, looking at ur earlier sketch it seems that corner placement facing down the long way in the room might be a good option to consider.

Depending on how much effort and time you want to put into the speakers, I'd suggest that you might want to start with the following:

- a basic FFT (freeware or low cost ware) speaker measurement set up for your laptop or PC, with a low cost, or home made (Linkwitz site) WM-61 Panasonic capsule.

- a very very basic and simple enclosure to get familiar with the driver and it's characteristics. probably a large face (bigger is better) not too deep, internally absorptive box.

- the box can be sized according to the T/S parameters and the results from a basic freeware or shareware box simulation program. you can decide sealed or ported to start.

This is just to get you measuring and listening to the drivers in short order... maybe even a used commercial enclosure of the right size with a bit of MDF cut to fit over a 15" or 12" dia speaker hole will suffice.

First listen, then measure, then you will have a basis for knowing what you want or need to do.

that's my advice...

_-_-bear

PS. if ur not using the Lowther, then your project has no limitations, anything is possible !

Imo, with the Lowther drivers you have to deal with the inherent aspects of that driver. Generalized solutions are not going to work well.

The basic response of the driver is more or less a response that gently droops from a mid point in the frequency range down to either end.

Many people have tried to augment the lower frequency section, and to produce "real bass".

It's problematic, the solutions vary in effectiveness.

I think that MJK's solution is to use his TQWT design but with an electrical network to flatten the response, at the expense of sensitivity.

The various front horn designs seek to augment the lower freq range via the horn. The back horn seeks to augment the lowest freq response.

Oh, while thinking of it, looking at ur earlier sketch it seems that corner placement facing down the long way in the room might be a good option to consider.

Depending on how much effort and time you want to put into the speakers, I'd suggest that you might want to start with the following:

- a basic FFT (freeware or low cost ware) speaker measurement set up for your laptop or PC, with a low cost, or home made (Linkwitz site) WM-61 Panasonic capsule.

- a very very basic and simple enclosure to get familiar with the driver and it's characteristics. probably a large face (bigger is better) not too deep, internally absorptive box.

- the box can be sized according to the T/S parameters and the results from a basic freeware or shareware box simulation program. you can decide sealed or ported to start.

This is just to get you measuring and listening to the drivers in short order... maybe even a used commercial enclosure of the right size with a bit of MDF cut to fit over a 15" or 12" dia speaker hole will suffice.

First listen, then measure, then you will have a basis for knowing what you want or need to do.

that's my advice...

_-_-bear

PS. if ur not using the Lowther, then your project has no limitations, anything is possible !

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- Building a fullrange horn - any advice for a newbie?