Are the pro break-in people concluding that suspension and surround wear is always a good thing?

Not on all drivers. But a competent designer knows how & how much it happens and designs for that. Ref my previous comment about spider designer specifying up to 1500 hrs for his spiders to break in before it meets its target parameters.

dave

Sy,

I think that what you are looking at is a change in compliance of the suspension and not a change in impedance.

Can't have one without the other- if the compliance changes, so will the impedance curve. A complex impedance curve will also show up a raft of other effects, including changes in the surround which will not be reflected in the resonance frequency and Q, changes in speed and dispersion of sound in the cone, changes in basket stiffness, changes in the adhesives, settling of ferrofluid... It's an extremely versatile and informative measurement.

Techbiker,

I didn't say that the sound of a broken in suspension is necessarily better than a speaker when originally assembled. But it will change and that is not a question in my mind. The physical parameters shift over time and that should not be a question. Perhaps in a mid-range driver you wouldn't want any extra low frequency response as it could muddy the sound but I have never seen anyone complain because a bass speaker got to a lower fs cutoff point...

Your analogy of a motor or engine wearing out would be a very different process than what we are talking about here. We don't have any bearings to wear out or surfaces to rub against each other. That is the point of making sure a speaker does not buzz or rub in the gap. You have two moving membranes in the surround and the spider. They do not necessarily wear out like the engine in your car or bike. It is more like looking at the back of a mid 60's Mustang and how they will look like the trunk is full of moonshine or something. The rear springs go soft and the car sits down. In a speaker the cone will retain its neutral position unless you are using it mounted vertically instead of horizontally. Then you can worry in a down-firing speaker, as the spider gets soft the weight of the cone will cause the voicecoil position to change and this is not good. The voicecoil will no longer be centered in the middle of the magnetic gap, you will have trouble with a loss of excursion as this happens.

I didn't say that the sound of a broken in suspension is necessarily better than a speaker when originally assembled. But it will change and that is not a question in my mind. The physical parameters shift over time and that should not be a question. Perhaps in a mid-range driver you wouldn't want any extra low frequency response as it could muddy the sound but I have never seen anyone complain because a bass speaker got to a lower fs cutoff point...

Your analogy of a motor or engine wearing out would be a very different process than what we are talking about here. We don't have any bearings to wear out or surfaces to rub against each other. That is the point of making sure a speaker does not buzz or rub in the gap. You have two moving membranes in the surround and the spider. They do not necessarily wear out like the engine in your car or bike. It is more like looking at the back of a mid 60's Mustang and how they will look like the trunk is full of moonshine or something. The rear springs go soft and the car sits down. In a speaker the cone will retain its neutral position unless you are using it mounted vertically instead of horizontally. Then you can worry in a down-firing speaker, as the spider gets soft the weight of the cone will cause the voicecoil position to change and this is not good. The voicecoil will no longer be centered in the middle of the magnetic gap, you will have trouble with a loss of excursion as this happens.

@ XRK : thanks.

Knowing what I'm messing with, I was always very careful to take care of their hearing.

They have learnt the lesson so well (get out of the room when Dad tests something), that they also carry out with them my Daughter's Guinea Pig which sometimes "visits" me.

I always let masochistic Musicians alone while testing at high volume, using the time for a well deserved cup of Coffee or Tea.

Back to Acoustics, never used FLAC or other modern Codecs, but will try them.

I have a little ZOOM recorder which has helped me many times, always record "Raw" of course, will experiment a little.

As of Break-in, we are talking about something made of paper, after all.

Ok, also impregnated cloth, another fiber based material.

All I can say now is: compare a new, just opened book (or magazine) to an already read one.

Just one reading and you can already notice a difference.

And a much loved and reread many times book?

Set it standing on its edge and it will open on your favorite pages, all by itself

Same thing happens to speaker paper and treated cloth fibers, they somewhat "unattach" from each other, the structure becomes measurably less rigid, damping increases and Q lowers.

Mass and such do not change, of course.

Knowing what I'm messing with, I was always very careful to take care of their hearing.

They have learnt the lesson so well (get out of the room when Dad tests something), that they also carry out with them my Daughter's Guinea Pig which sometimes "visits" me.

I always let masochistic Musicians alone while testing at high volume, using the time for a well deserved cup of Coffee or Tea.

Back to Acoustics, never used FLAC or other modern Codecs, but will try them.

I have a little ZOOM recorder which has helped me many times, always record "Raw" of course, will experiment a little.

As of Break-in, we are talking about something made of paper, after all.

Ok, also impregnated cloth, another fiber based material.

All I can say now is: compare a new, just opened book (or magazine) to an already read one.

Just one reading and you can already notice a difference.

And a much loved and reread many times book?

Set it standing on its edge and it will open on your favorite pages, all by itself

Same thing happens to speaker paper and treated cloth fibers, they somewhat "unattach" from each other, the structure becomes measurably less rigid, damping increases and Q lowers.

Mass and such do not change, of course.

JMFahey,

I use the Zoom too. Works great and even has raw mode as you mentioned: 24 bit @ 96 khz sampling. The files get huge fast and would have to be dropped in a server with link rather than posting directly. But honestly, if the sound difference is too small to be picked up with mp3, it probably belongs in the realm of the 33rd FFT coefficient (indiscernable limits) with regards to human hearing. I like your analogy with paper books which utilize paper, thread, cloth, and glue for construction - same materials as speaker driver suspensions.

(indiscernable limits) with regards to human hearing. I like your analogy with paper books which utilize paper, thread, cloth, and glue for construction - same materials as speaker driver suspensions.

I use the Zoom too. Works great and even has raw mode as you mentioned: 24 bit @ 96 khz sampling. The files get huge fast and would have to be dropped in a server with link rather than posting directly. But honestly, if the sound difference is too small to be picked up with mp3, it probably belongs in the realm of the 33rd FFT coefficient

Last edited:

Pano,

I have some of my own loudspeakers that I built up. I also have some that have many hours on them and are definitely broken in to say the least. I will have to set up my test equipment and test the T/S measurements and see what I can prove. Would you be satisfied as these are not commercially available devices?

I have some of my own loudspeakers that I built up. I also have some that have many hours on them and are definitely broken in to say the least. I will have to set up my test equipment and test the T/S measurements and see what I can prove. Would you be satisfied as these are not commercially available devices?

For Example

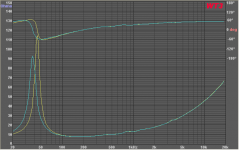

Just digging thru some old files I found this. An 18" P.Audio woofer new, and after a 12 hour break in and cool down. Doesn't prove much, but does show a change in Fs and impedance peak.

I'm sure other folks here can find as good or better.

Just digging thru some old files I found this. An 18" P.Audio woofer new, and after a 12 hour break in and cool down. Doesn't prove much, but does show a change in Fs and impedance peak.

I'm sure other folks here can find as good or better.

Attachments

Just digging thru some old files I found this. An 18" P.Audio woofer new, and after a 12 hour break in and cool down. Doesn't prove much, but does show a change in Fs and impedance peak.

Note that a comparison of 2 sets of T/S parameters to be valid they need to be taken by the same kit, with the same levels, the same humidity, temperature and barometric pressure.

dave

Pano,

It seems like you have just presented your own proof of what we have been saying. What besides this would you want to see. The Thiel-Small values do change and so does the fs value. And you are only talking a fairly short break-in period. Are we arguing for argument sake here or what? Dependent on the spider selected by the designer you will have different amounts of this shift. If you started with one of the very soft spiders to begin with and one with fairly flat spider ripples you may see much less shift that a very rigid and deep spider that will have a greater shift do to the change being greater.

ps. I would have no reason to fudge the numbers, and I would expect some of you to comment on the unusual T/S values that I know my device has. The Vas is rather high in my design. I can't recall the exact figure right now but it does force a rather large box to work with the speaker. I think my box is about 1 1/3 Cubic foot for a 6 1/2" device. I am using this from 36hz to 2.5khz. I use a 4th order L/R filter as the top end just keeps going.

It seems like you have just presented your own proof of what we have been saying. What besides this would you want to see. The Thiel-Small values do change and so does the fs value. And you are only talking a fairly short break-in period. Are we arguing for argument sake here or what? Dependent on the spider selected by the designer you will have different amounts of this shift. If you started with one of the very soft spiders to begin with and one with fairly flat spider ripples you may see much less shift that a very rigid and deep spider that will have a greater shift do to the change being greater.

ps. I would have no reason to fudge the numbers, and I would expect some of you to comment on the unusual T/S values that I know my device has. The Vas is rather high in my design. I can't recall the exact figure right now but it does force a rather large box to work with the speaker. I think my box is about 1 1/3 Cubic foot for a 6 1/2" device. I am using this from 36hz to 2.5khz. I use a 4th order L/R filter as the top end just keeps going.

Agreed. In this case they were, as much as possible..... they need to be taken by the same kit, with the same levels, the same humidity, temperature and barometric pressure.

That's the crux of the matter, I have presented something other than just chat. Does it prove the woofers sound better? No. For that we would need more elaborate tests.It seems like you have just presented your own proof of what we have been saying.

Frequency response, a plot of harmonics, maybe a CSD or waterfall plot, a well controlled listening test. Any or all of those things would go a long way.What besides this would you want to see.

As I stated in post #2, I do hear speaker break-in. I've even measured some changes in resonances. But it would be nice to have more complete objective data, simply because this is something that is easy to mistake. If it's easy to mistake, then it's easy to deny or criticize. Right?

Those who believe that speaker break-in makes a significant difference want to slam the nay-sayers. But don't the nay-sayers deserve some proof?

Pano,

I understand what you are saying. Myself I don't expect a significant change in much except for the fs shift lower. I wouldn't expect much in the higher frequencies myself as I don't see the mechanism for that to happen. I haven't looked at that much so I could be mistaken. I'll have to break out my Clio setup and do some looking. I am using a dedicated Earthworks preamp and instrumentation mic. I set the levels to the typical 1 watt level and also check at one meter from the cone. I could also check at higher power levels to see what is happening at higher levels. The voicecoil is rated for 150 watts continuous power level.

I understand what you are saying. Myself I don't expect a significant change in much except for the fs shift lower. I wouldn't expect much in the higher frequencies myself as I don't see the mechanism for that to happen. I haven't looked at that much so I could be mistaken. I'll have to break out my Clio setup and do some looking. I am using a dedicated Earthworks preamp and instrumentation mic. I set the levels to the typical 1 watt level and also check at one meter from the cone. I could also check at higher power levels to see what is happening at higher levels. The voicecoil is rated for 150 watts continuous power level.

Pano,

I'll do some testing and we can post it where you think that it would do the most good. Not sure why you would want to start a new thread though. Are we going to try and answer this so we can put the discussion to bed on whether or not a break-in period should be expected in any new speaker design. I for one think that you need to do that, especially if you are trying to use the T/S parameters for a box design. Using the numbers from a fresh driver without breaking it in is going to give less than optimum results. I wish that I had a current device so I could compare the numbers as published verses a broken in device and see how they correlate.

I'll do some testing and we can post it where you think that it would do the most good. Not sure why you would want to start a new thread though. Are we going to try and answer this so we can put the discussion to bed on whether or not a break-in period should be expected in any new speaker design. I for one think that you need to do that, especially if you are trying to use the T/S parameters for a box design. Using the numbers from a fresh driver without breaking it in is going to give less than optimum results. I wish that I had a current device so I could compare the numbers as published verses a broken in device and see how they correlate.

I commend the efforts of those of you who will attempt to quantify all of this.

I do believe that it will confirm what I already intuit as the truth, and the initial gist of this thread will no longer seem nearly as hare-brained or controversial as some have concluded.

My EL70eN have come a long way in the last 50 or 60 hours. I'd say the bulk of the obvious improvements have happened already. Still, I expect Fs to drop a bit more, for that last little bit of oomph and grace in the bottom end that I know they are capable of.

I do believe that it will confirm what I already intuit as the truth, and the initial gist of this thread will no longer seem nearly as hare-brained or controversial as some have concluded.

My EL70eN have come a long way in the last 50 or 60 hours. I'd say the bulk of the obvious improvements have happened already. Still, I expect Fs to drop a bit more, for that last little bit of oomph and grace in the bottom end that I know they are capable of.

Cogitech,

I knew from the beginning that your premise was correct, it was just the naysayers will always argue without some proof to confirm what you were already hearing being true. Any manufacturer would confirm what you thought, that is a normal process of loudspeaker design. I know at first I questioned this premise myself. I thought what could change? Then I was shown what was going on and what was causing the changes. I do have the advantage of having done much scientific product and materials development. I can't tell you how many products I have worked on developing something that others said was not possible. I worked on solar panel construction and development, touch screen technology and composites development that happened over 20 years ago now. Most projects that I took on were the ones that I was told could not be done. Doing what has already been done is just simply repeating a proven process. I still consult in composites applications that I did years ago that are still very much unknown to most engineers. The problem with most engineers is they are trained to not take chances, to develop products that are based on known information. I aim to break the rules and create things that aren't a me to product. But those rules do not include the laws of physics, they will always hold true, but how you apply them is the trick.

I knew from the beginning that your premise was correct, it was just the naysayers will always argue without some proof to confirm what you were already hearing being true. Any manufacturer would confirm what you thought, that is a normal process of loudspeaker design. I know at first I questioned this premise myself. I thought what could change? Then I was shown what was going on and what was causing the changes. I do have the advantage of having done much scientific product and materials development. I can't tell you how many products I have worked on developing something that others said was not possible. I worked on solar panel construction and development, touch screen technology and composites development that happened over 20 years ago now. Most projects that I took on were the ones that I was told could not be done. Doing what has already been done is just simply repeating a proven process. I still consult in composites applications that I did years ago that are still very much unknown to most engineers. The problem with most engineers is they are trained to not take chances, to develop products that are based on known information. I aim to break the rules and create things that aren't a me to product. But those rules do not include the laws of physics, they will always hold true, but how you apply them is the trick.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- Break-in is Real