I purchased the "Battery Life Saver" perhaps more than a decade ago, off ebay from the OEM as a "cosmetic second". I dare say it works. having brought back its money's worth of lead acid batteries from going completely useless. Last night, I connected it (along with the "brick" charger) to my 24V lawnmower whose batteries are losing capacity - and went to bed. During the night, it burned emitting magic smoke and oozing a quite noxous brown oil that I cant quite get the smell off my hands (see pic). A potentially more dangerous situation than smelling up things out in the garage and my person.

I called the place which is still in business and offered to send it back for FA. They offered 10% off of a new unit, which is ~$100+. There was no reason for it to fail, as it's rated for use up to 36V. It's potted as I assume they dont want you to discover "how it works" easily.

I'm not sure I want to buy another unit. I'm an engineer, I have a function generator and I know how to drive a FET to sink current pulses. The OEM touts "Square Wave Technology" - I know what a square wave is. When it was working, I never bothered to assess the frequency, the duty cycle, not the current amplitude of whatever it does when you connect it to a battery.

So my question to the anyone here is, if I wanted to replicate this thing using my function generator along with a FET and a couple resistors, what would be the FG setup for frequency and duty cycle, also the current pulse amplitude? Just wondering if anyone knows offhand. Thanks!

I called the place which is still in business and offered to send it back for FA. They offered 10% off of a new unit, which is ~$100+. There was no reason for it to fail, as it's rated for use up to 36V. It's potted as I assume they dont want you to discover "how it works" easily.

I'm not sure I want to buy another unit. I'm an engineer, I have a function generator and I know how to drive a FET to sink current pulses. The OEM touts "Square Wave Technology" - I know what a square wave is. When it was working, I never bothered to assess the frequency, the duty cycle, not the current amplitude of whatever it does when you connect it to a battery.

So my question to the anyone here is, if I wanted to replicate this thing using my function generator along with a FET and a couple resistors, what would be the FG setup for frequency and duty cycle, also the current pulse amplitude? Just wondering if anyone knows offhand. Thanks!

There are sites about off grid citizens, and battery maintenance.

There was a desulphator, for which I got the parts and left unfinished, to revive sulphated batteries, and many other things to get the best life out of batteries.

Many of them are DIY, and have published the circuits on the net.

Take a look, might be useful.

There was a desulphator, for which I got the parts and left unfinished, to revive sulphated batteries, and many other things to get the best life out of batteries.

Many of them are DIY, and have published the circuits on the net.

Take a look, might be useful.

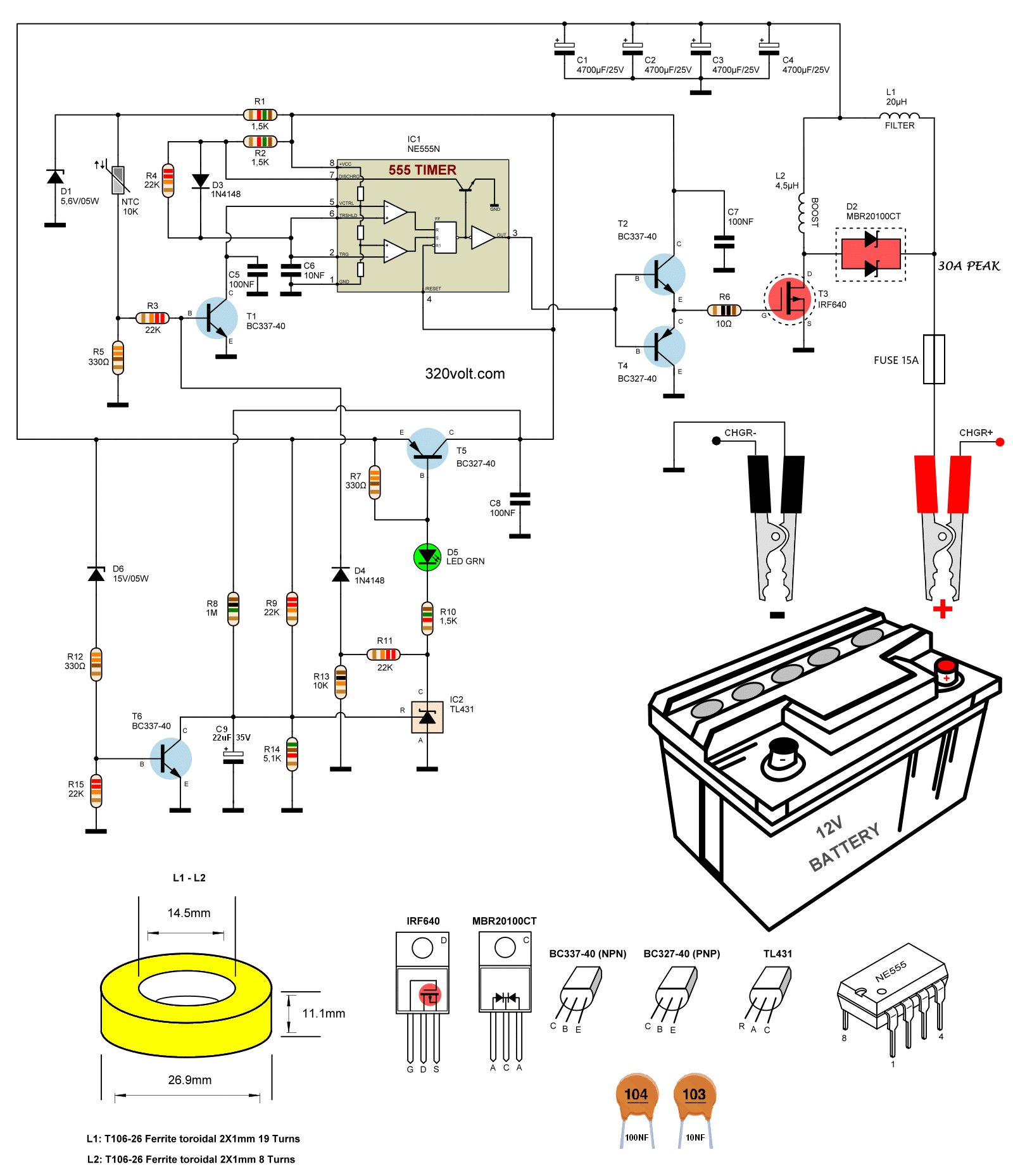

This is with IRF540 Mosfet:

https://320volt.com/en/battery-desulfator-circuit/

"battery desulfator schematic" as the search term gets many results.

Avoid the ones where the coils are hard to get.

https://320volt.com/en/battery-desulfator-circuit/

"battery desulfator schematic" as the search term gets many results.

Avoid the ones where the coils are hard to get.

I did build one very similar to the schematics presented above using 555 timer and IRFZ44 as the main switcher but it's only 55 Vds and I have a memory the voltage spikes mine produced was more than that, maybe up to 70 Volt, the FET lived for a while but eventually died although it didn't get particularly hot, I ran mine at as high frequency as possible by checking with a scope to get the max surge out of the flyback inductor, I think it was maybe up to 5 kHZ but my inductor had too high inductance which set the upper frequency limit, can't really remember as it was so long time ago. I think maybe one can run at much higher frequencies as the point is to let the voltage spike penetrate through the sulfate and break it up, and the faster the repetition the faster the desulfate process goes I would think.

If that is the case, I wonder if you could just blast music into the battery for a month - capacitively coupled of course. A class D amp as battery charger? I see a pair of outputs sitting at 13V above ground, for a mono amp driven by 26V of PSU.Mains frequency harmonics will go through the battery.

Today, I just finished something very similar to the Zapper MK3, above. I drive the fet with one of my function generators, got as best I could dig up with the relative coil values, getting it that the larger inductor blocks the flyback pulse so most of it goes into the battery. (I have a 0.27 ohm in my fets source, so I can see the current waveform; hopefully what I'm looking at is the smaller inductor "charging"...). It's putting a positive going spike 40V above the 24V dc value; I'm trying to do both batteries at once. Heatsink isnt even warm, guess I can sleep tonight with it on.

When I got the two 18AH batteries, they'd easily do both front and back sections of our small lawn with no power loss. Last time I used it, performance starts dying after just one section - I have to recharge to finish the job. We'll see if things improve over the summer.

When I got the two 18AH batteries, they'd easily do both front and back sections of our small lawn with no power loss. Last time I used it, performance starts dying after just one section - I have to recharge to finish the job. We'll see if things improve over the summer.

Break them open if needed, check electrolyte level, if they are sealed lead acid batteries.

You can pry the top off, inside there will be some sort of lid for each cell.

They are ordinary car batteries with baffles to prevent electrolyte loss.

Use distilled water, as usual, to top up.

And use them right side up, sideways or upside down are not recommended, even though the literature says so, you will expose the cell connectors and plates to air.

You can pry the top off, inside there will be some sort of lid for each cell.

They are ordinary car batteries with baffles to prevent electrolyte loss.

Use distilled water, as usual, to top up.

And use them right side up, sideways or upside down are not recommended, even though the literature says so, you will expose the cell connectors and plates to air.

On closer inspection, the parts lists don't give detailed specs for the inductors, but luckily the pictures in the EPE article show Jaycar part numbers:

LF1322, 1.0mH, DCR: 0.74 Ohms, Wire Dia: 0.8mm

LF1310: 0.22mH, DCR: 0.3 Ohms, Wire Dia: 0.8mm

0.8 mm is close to 21 gauge

And, here's the site for the original design from Home Power magazine (link found in NareshBrd's pdf), with some alternative circuits and PC board layouts:

https://web.archive.org/web/20070928044215/http://shaka.com/~kalepa/desulf.htm

Air core coils are not mandatory, just low resistance, and reasonably close to the correct inductance.

And there's another desulfator here, near the bottom of the page:

http://www.w5usj.com/batterytoolkit.html

using Jameco ferrite core coils,

371979 1mH 1.3A, 0.4 ohm

387268 220uH 5.8A, 0.054 ohm

LF1322, 1.0mH, DCR: 0.74 Ohms, Wire Dia: 0.8mm

LF1310: 0.22mH, DCR: 0.3 Ohms, Wire Dia: 0.8mm

0.8 mm is close to 21 gauge

And, here's the site for the original design from Home Power magazine (link found in NareshBrd's pdf), with some alternative circuits and PC board layouts:

https://web.archive.org/web/20070928044215/http://shaka.com/~kalepa/desulf.htm

Air core coils are not mandatory, just low resistance, and reasonably close to the correct inductance.

And there's another desulfator here, near the bottom of the page:

http://www.w5usj.com/batterytoolkit.html

using Jameco ferrite core coils,

371979 1mH 1.3A, 0.4 ohm

387268 220uH 5.8A, 0.054 ohm

Last edited:

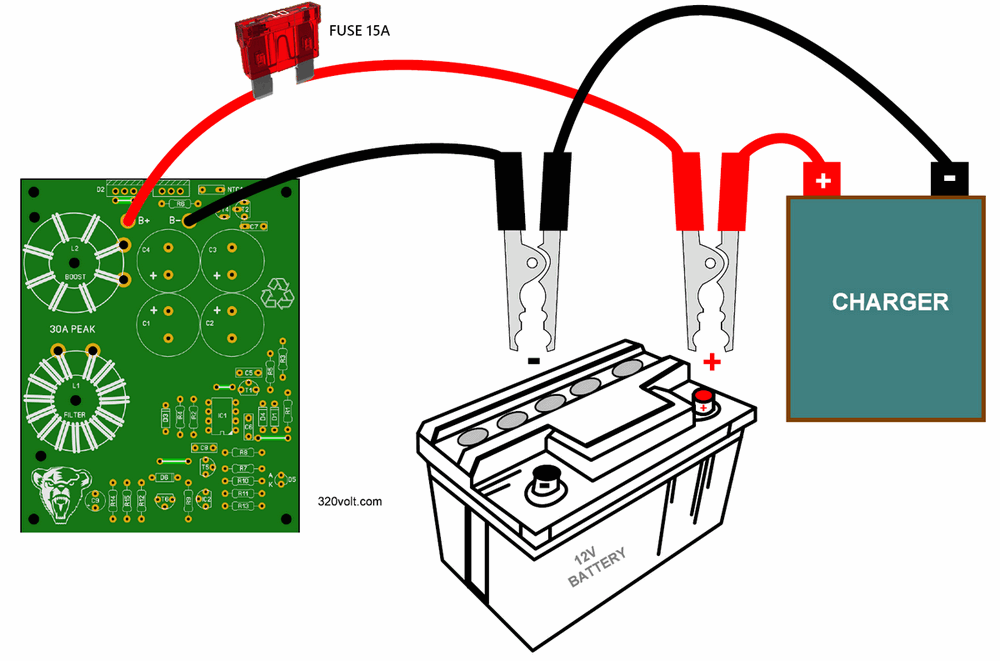

Hello, it works.

The long test has begun. Results of the first day. (This is just a simple time test.)

The process will take a month, now everything is fine. Green light appears

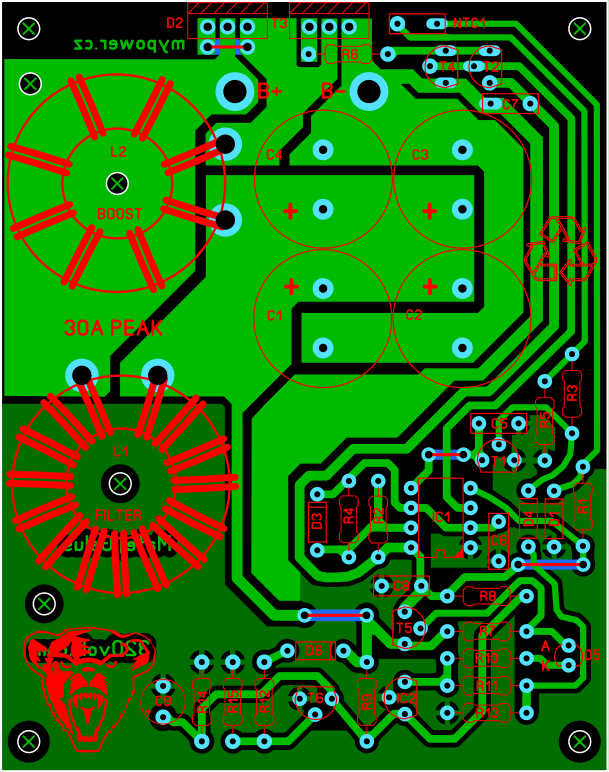

source: http://wiki.mypower.cz/desulfator

The long test has begun. Results of the first day. (This is just a simple time test.)

- Fully charged expired battery (12v 60ah)

- A 10 A load was connected, after 40 minutes the battery voltage became 10 V

- The battery was recharged and connected to the desulfation circuit (1 day in total)

- A 10A load was reconnected. After 95 minutes, the battery voltage becomes 10V.

The process will take a month, now everything is fine. Green light appears

source: http://wiki.mypower.cz/desulfator

Attachments

- Home

- General Interest

- Everything Else

- Battery Life Saver