What'd you get?I just got a new guitar

The problem with the HBAC today is that transformers have gone up - didn’t you mention rumblings of a THBAC? Or an HWAC (hundred watts for minimum cost)? The Antek route is $20 for the OPT and $42 for a 100VA PT (Which has the required 6/12V heater winding included - the Triads don’t unless you are allowed to add turns per challenge rules). By the time you add sockets and pots you‘re over $100. $6 OPTs is quite attractive. Even without a formal “challenge”.

Yeah, that S.E.X. amp was the very first Bottlehead product, before it was called Bottlehead and before I was designing. Came out in 1996, and was replaced in 1997. Two 6DN7s with power triodes paralleled and small triodes in mu-follower, per monobloc. A terrible design by today's standards, but it got a lot of people started on SETs. Also a lesson in the perils of bargain parts - that vertical output was airgapped, but for only half the current used, the HF rolled off at 6kHz before feedback, and resistive losses were more than 50%.Twenty some years ago a friend brought me an SE amp kit to finish. It used a vertical output transformer from a TV set with a 6DN7 or 6EM7 tube. I believe it was called a SEX amp.

...

https://www.amazon.com/dp/B0CSLNWTQ8?What'd you get?

After watching several people play and review these on Youtube with too many good comments to be believable, I bought one. One commenter stated that he would pay the $120 just for the neck. It is made in China. The negative comments are all centered on the use of "cheap tuners" but I have no issues with mine. So far it plays better than both of my other "Strats." I have a 1980's Korean Squier that I bought new at Ace Music in Miami. It has been rebuilt due to a spontaneous rapid self disassembly one day that left me bleeding resulting in me throwing it across the room. I also have a Chinese "CovidCaster" that I got for $59 on Ebay when everyone was stuck at home playing video games or learning how to play an instrument on YouTube. The new one is the sunburst on the right.

Post #3629 here:

https://www.diyaudio.com/community/threads/what-did-you-last-repair.313739/page-182#post-7290844

The HBAC occurred when someone joined diyAudio just to hawk his amp kit. He was implying that we were wasting our time since nobody could do it better than he did. All occurred in this short thread:The problem with the HBAC today is that transformers have gone up - didn’t you mention rumblings of a THBAC? Or an HWAC (hundred watts for minimum cost)? The Antek route is $20 for the OPT and $42 for a 100VA PT (Which has the required 6/12V heater winding included - the Triads don’t unless you are allowed to add turns per challenge rules). By the time you add sockets and pots you‘re over $100. $6 OPTs is quite attractive. Even without a formal “challenge”.

https://www.diyaudio.com/community/threads/need-recommendations-for-diy-small-guitar-amp.190449/

There have been a few mentions of a new challenge, but nobody has thrown down the gauntlet yet.

The reality of the challenge, and its results are uncertain. How many of us who designed and built those amps still use them? How many used them at all after the thrill of the contest was over? If the amps did, or did not get used for a good period of time, why or why not? If the amp did not see much use, what would you do differently? I have thought about making a new guitar amp, by answering these questions, watching too many guitar amp videos on YouTube and making a list of features that I would want. I grew up playing 60's surf music, so number one is REVERB! Unfortunately the list keeps growing. Fulfilling that list for minimum cost will be an engineering design challenge in itself. It would be easy to build three different preamps and two or three different power amps and switch them in and out with relays or LDR's. See The latest iteration of the Hughes and Kettner Triamp......that is a killer amp that sells for over $4000! Too many parts and too many knobs......

The 4 tube amp that I designed for absolute minimum cost worked, it fulfilled all of the contest criteria, but it did not ROCK. Well after the contest started and the rules that allowed silicon in "supporting roles' the irritant that started the contest stated that no TUBE AMP could include ANY silicon, except in the power supply as this was how his "pure tube amp" was designed. As the contest was winding down, my engineering career was also running out of time, so all the HBAC stuff got boxed up for the eventual road trip. That box was one of a few that got damaged during the trip or a year of storage. The 4 tube amp survived but got torn apart and rebuilt into the amp I use today. A pair of added mosfets gave it the ability to ROCK and created a circuit I now call the Saturator, since even a wimpy guitar can drive it well into saturation. I have not looked up the prices, but I believe that it could be built for under $100 today. The tubes are still on the $1 list.

The larger amp was "inspired" by an "18 watt Marshall." It was damaged, but still plays sometimes. Both used series heater strings to allow for use of isolation transformers for power. The Triad N-68X that powers the 4 tube amp was about $15 at the time and the 80 VA Triad was under $20. The little guy runs a pair of 32ET5's (similar to a 6AQ5 with a 32 volt 100 mA heater), an 18FW6 (6AU6) and an 18FY6 (6AV6 Mu=100). The larger unit runs 3 X 26AQ6, and 2 X 45B5 (a 45 volt 100 mA 6CW5). It would be easy to use series heaters with TV sweep tubes, or even old radio tubes to make guitar amps with isolation transformers for power. Two 50L6's (6W6) and two 12AX7's could make for a 30 watt amp that DOES ROCK! That continuous heater current on the isolation transformer blunts the pulses from the rectifiers so that the cheap iso transformer doesn't buzz. I use a pair of voltage doublers wired out of phase to keep a symmetrical load on the transformer in quest for quietness. I call it the "way too many diodes power supply."

"Yeah, that S.E.X. amp was the very first Bottlehead product, before it was called Bottlehead and before I was designing. Came out in 1996, and was replaced in 1997. Two 6DN7s with power triodes paralleled and small triodes in mu-follower, per monobloc."

When I was a kid in the 60's I learned that you could rip the entire vertical sweep section from a TV set, lift the feedback cap and connect it to a 1/4 inch jack to make a guitar amp. They weren't half bad either. I finished that amp kit for a co-worker and we both wound up with a case of the Single Ended Fever. Mine resulted in something I called the TSE which is still around. I think my friend satisfied his fever with an amp called a "Bugle 45" but both of us used the same Electra Print OPT's.

Attachments

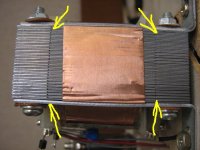

I guess those small line transformers could be made "usable" in a SE amp IF you pulled EI laminations (doable with some patience) and reinserted all E-s one way, a pack of I-s to complete the magnetic path, and a strip of printer paper between them to create a predictable gap.

Just counting on punching irregularities is too iffy for my taste.

Reassembled OT "should" be dunked in varnish to avoid it buzzing like an angry wasp nest.

You will have little bass, too low primary inductance remaining for that, but it would be "usable", not heavily distorting because of core saturation which affects all frequencies.

If somebody wants to try it, he's welcome to post results here (hint hint) 😉

I am not doing that experiment because my Religion forbids me to buy a $4 part and spend $90 or more on shipping 🙄

Just counting on punching irregularities is too iffy for my taste.

Reassembled OT "should" be dunked in varnish to avoid it buzzing like an angry wasp nest.

You will have little bass, too low primary inductance remaining for that, but it would be "usable", not heavily distorting because of core saturation which affects all frequencies.

If somebody wants to try it, he's welcome to post results here (hint hint) 😉

I am not doing that experiment because my Religion forbids me to buy a $4 part and spend $90 or more on shipping 🙄

How about a no holes barred? With the reasonable caveat that a single component cant cost >$100? So you couldnt put a JJ 6386 tube in it, as example. Goal being simply best sounding, versus something like N individually configurable, computer controlled signal paths.There have been a few mentions of a new challenge, but nobody has thrown down the gauntlet yet.

Otherwise, all the "classic" features apply; tone stack, reverb, trem, pre-post, dual rectifier - or not - being completely up to the builder's choice. Best versatility not necessarily equal to best sound.

Best sound might be tough to judge, in a text / picture / externally hosted cell phone video forum.

surely there are places you can go to get a line transformer - unless your religion also forbids you to pay $36 retail markup on a $4 part (Mine does).I am not doing that experiment because my Religion forbids me to buy a $4 part and spend $90 or more on shipping 🙄

“Acquire“ one from a ceiling speaker that came out of an office somewhere?

They are already packed that way, all Es on one side, all Is on the other.I guess those small line transformers could be made "usable" in a SE amp IF you pulled EI laminations (doable with some patience) and reinserted all E-s one way, a pack of I-s to complete the magnetic path, and a strip of printer paper between them to create a predictable gap.

Because the Is and Es don't have a perfect fit and the ends are not grinded, they do have some sort of a gap, although rather undefined.

I actually have a couple of exactly those which were shown by the o.p.

And I took some measurements:

primary turns 725 + 300 + 400 + 600 + 900

secondary turns 48 + 18 + 30

when used as p-p the CT would be 75 turns off center, 1425 : 1500, which leaves some 2nd harmonics, amp*turns could be made equal by bias adjustment, if required, or adding 75 turns of additional wire;

reflected pri impedance would be 7.5 k with 8 ohm load on 16 ohm taps

and 15 k with 8 ohm on 8 ohm tap

primary wire is 0.112mm AWG 37, 470 ohm total

secondary wire is 0.4mm AWG 26, 0.9 ohm for the total 16 ohm

primary inductance at 50V / 50 Hz excitation was 56 Hy, not so bad,

66 Hy at 100V / 50 Hz;

at 500 Hz and low excitation around 8 Hy, while leakage inductance at 500 Hz came out rather high about 100mH.

The latter may be the reason why any attempt to use gnfb from the secondary turned into hf oscillation which had to be tamed with a zobel across the primary, limiting hf response significantly.

Interestingly that was not the case when I took the feedback from the primary.

Sorento,

JMFahey,

Sorento:

1. Post #1 transformer does not have any rating for DC current.

It appears that the E's and the I's are Interleaved.

Re-stacking makes sense.

JMFahey:

2. You are correct.

All Readers of this Post:

3. In 1995 I took my Dyna Stereo 70 push pull output transformers, A470, and modified them.

Took all the Interleaved laminations out, and re-stacked them with all the E's on one side, and all the I's on the other side.

A triode Wired EL34, Single Ended, was connected with negative feedback from the 16 Ohm tap to the EL34 cathode (you have to pay attention to the phase of the primary to the 16 Ohm tap, Or you get Positive Feedback, instead of the desired negative feedback).

Quiescent DC primary current: 50mA

B+ to the top of the primary: 461V

6 Watts Output, 1kHz: 1% THD

10 Watts Output, 1kHz: 5% THD

Damping Factor: 3.8

1 kHz square wave looked excellent

Frequency Response - Full Power Bandwidth: -3dB @ 15Hz and -3dB @ 60 kHz.

Published in "Sound Practices" Issue 10 (Winter 1995)

Re-stacking the E's and I's works!

Keep in mind: The A470 has Lots of Laminations, and the design of the coil winding details are very good.

YMMV

JMFahey,

Sorento:

1. Post #1 transformer does not have any rating for DC current.

It appears that the E's and the I's are Interleaved.

Re-stacking makes sense.

JMFahey:

2. You are correct.

All Readers of this Post:

3. In 1995 I took my Dyna Stereo 70 push pull output transformers, A470, and modified them.

Took all the Interleaved laminations out, and re-stacked them with all the E's on one side, and all the I's on the other side.

A triode Wired EL34, Single Ended, was connected with negative feedback from the 16 Ohm tap to the EL34 cathode (you have to pay attention to the phase of the primary to the 16 Ohm tap, Or you get Positive Feedback, instead of the desired negative feedback).

Quiescent DC primary current: 50mA

B+ to the top of the primary: 461V

6 Watts Output, 1kHz: 1% THD

10 Watts Output, 1kHz: 5% THD

Damping Factor: 3.8

1 kHz square wave looked excellent

Frequency Response - Full Power Bandwidth: -3dB @ 15Hz and -3dB @ 60 kHz.

Published in "Sound Practices" Issue 10 (Winter 1995)

Re-stacking the E's and I's works!

Keep in mind: The A470 has Lots of Laminations, and the design of the coil winding details are very good.

YMMV

The old 4 tube 4 watt guitar amp has been sleeping for a month or so. Today's testing did not go as planned. The amp fired up normally, worked for a few minutes, then the volume dropped and a fizzy crackling distortion appeared. The distortion vanished and the volume returned when I put my hand near one of the output tubes. Oscillation is the most likely, and only suspect, but there are no high Gm tubes used, and a complete retubing made no difference. This amp and its predecessor have been super stable, so likely something died or broke. The amp was dropped a couple years ago but the only obvious damage was the broken plastic faceplate. Now, I'm not sure which HBAC amp to rip into first.

In reality I just plug the guitar cable into the Focusrite, call up a neat amp and cabinet sim in TH-U and play through headphones most of the time.

In reality I just plug the guitar cable into the Focusrite, call up a neat amp and cabinet sim in TH-U and play through headphones most of the time.

Look at the flag just besides my user name😄, I am in Argentina, 10000 km away. 😎surely there are places you can go to get a line transformer - unless your religion also forbids you to pay $36 retail markup on a $4 part (Mine does).

“Acquire“ one from a ceiling speaker that came out of an office somewhere?

And the interesting and thread related experiment applies to that particular Conrad transformer, none other.

The $36 retail markup does not apply either because Conrad transformers are not sold here at any price.

Using other brand/model line transformers may give good/bad results but that's not the point, they are all different 🤷🏻

Digging deeper, IF I ever needed 100V distributed load transformers, there is a high probability I would wind them myself, but again it would tell me nothing wrt that 10W Conrad.

By the way: looking at picture and data sheet, it actually looks quite well made .... for a PA speaker distribution transformer that is.

FWIW2: large area distributed PA is not my business, but now and then a regular Musician customer insists "hey Juan, my Father in Law - Uncle - whatever has a small Supermarket or the School I teach music at or my Church needs distributed PA", we are talking some 30-40 meters away, 50 meters tops, in that case I use strings of speakers in series, say 3-4-5 each branch, then 3-4-5 such branches converging at the amplifier location.

The amp sees a total 8 ohm load, (or 4 Ohm if twice the number of branches), no Transformers involved.

I am not only saving individual small ones but also a big one rising, say, 200W into 4 or 8 ohms to 100V for distribution 🤑

Now for a commercial installer who buys everything ready made and does not even warm up his soldering gun (all connections are made using screw terminals) the situation is different..

Thanks, it confirms my visual hunch: quite reasonable considering its intended use.They are already packed that way, all Es on one side, all Is on the other.

Because the Is and Es don't have a perfect fit and the ends are not grinded, they do have some sort of a gap, although rather undefined.

I actually have a couple of exactly those which were shown by the o.p.

And I took some measurements:

primary turns 725 + 300 + 400 + 600 + 900

secondary turns 48 + 18 + 30

when used as p-p the CT would be 75 turns off center, 1425 : 1500, which leaves some 2nd harmonics, amp*turns could be made equal by bias adjustment, if required, or adding 75 turns of additional wire;

reflected pri impedance would be 7.5 k with 8 ohm load on 16 ohm taps

and 15 k with 8 ohm on 8 ohm tap

primary wire is 0.112mm AWG 37, 470 ohm total

secondary wire is 0.4mm AWG 26, 0.9 ohm for the total 16 ohm

primary inductance at 50V / 50 Hz excitation was 56 Hy, not so bad,

66 Hy at 100V / 50 Hz;

at 500 Hz and low excitation around 8 Hy, while leakage inductance at 500 Hz came out rather high about 100mH.

The latter may be the reason why any attempt to use gnfb from the secondary turned into hf oscillation which had to be tamed with a zobel across the primary, limiting hf response significantly.

Interestingly that was not the case when I took the feedback from the primary.

I was thinking in general terms, about using whatever line output trafos you can get. I’d just buy and try the ones from PE. Duties are a little high for that in your country - they want you to buy local/home grown. Unless you get things wholesale, from a thriving industry in your country, that often comes with high prices you can’t circumvent. Here there isn’t a factory making them operating right up the road. If I had to walk into an AV install place to buy one they’d be forty bucks for the same one you get at PE, not a better one. And they would have to special order it - have one in STOCK? Not in this day and age.Look at the flag just besides my user name😄, I am in Argentina, 10000 km away. 😎

And the interesting and thread related experiment applies to that particular Conrad transformer, none other.

If you have the capability to wind, of course the dynamic changes. Here the difficulty is getting the laminations. Since I’m not an OEM they would be through the roof, and i‘d be just as well off buying off the shelf finished units as buying the PARTS. That changes when I find donor cores on the surplus market. Then I can turn what I have (or can get) into what I need. But that is hit or miss, feast or famine. I haven’t gotten a good deal on rewindable EIs since Covid. My stock is dwindling.

Thanks God we still have some local Industry because of that.

Such as laminations, enamel wire and cable.

Even plastic cores for winding.

Imported lamination and wire (there is some in the market, probably to keep local prices down) is Brazilian (so on a way "same people as us") and not Chinese which would be impossible to fight against.

In fact, there used to be a Law against importing "small Transformers" , so typical 9-12 VAC 200 to 500mA were swept from the market allowing many small commercial winders to fill that niche.

Wholly unrestricted "free trade and Globalism" actually destroy local Industry and Jobs.

Same with speakers, cheapest Celestion (G12L50) is U$106 retail, G12T75 U$160, V30 >U$200, standard Eminence >U$145, so I can comfortably sell mine for U$80-85 which is fine.

Otherwise it would be impossible

Such as laminations, enamel wire and cable.

Even plastic cores for winding.

Imported lamination and wire (there is some in the market, probably to keep local prices down) is Brazilian (so on a way "same people as us") and not Chinese which would be impossible to fight against.

In fact, there used to be a Law against importing "small Transformers" , so typical 9-12 VAC 200 to 500mA were swept from the market allowing many small commercial winders to fill that niche.

Wholly unrestricted "free trade and Globalism" actually destroy local Industry and Jobs.

Same with speakers, cheapest Celestion (G12L50) is U$106 retail, G12T75 U$160, V30 >U$200, standard Eminence >U$145, so I can comfortably sell mine for U$80-85 which is fine.

Otherwise it would be impossible

Unfortunately the laminations are stacked on such a way that you can't really do that.I guess those small line transformers could be made "usable" in a SE amp IF you pulled EI laminations (doable with some patience) and reinserted all E-s one way, a pack of I-s to complete the magnetic path, and a strip of printer paper between them to create a predictable gap.

Just counting on punching irregularities is too iffy for my taste.

Reassembled OT "should" be dunked in varnish to avoid it buzzing like an angry wasp nest.

You will have little bass, too low primary inductance remaining for that, but it would be "usable", not heavily distorting because of core saturation which affects all frequencies.

If somebody wants to try it, he's welcome to post results here (hint hint) 😉

I am not doing that experiment because my Religion forbids me to buy a $4 part and spend $90 or more on shipping 🙄

I have actually a bunch of these Conrad Ela 100 transformers.

They perform actually pretty decent, obviously not like the best and lowest distortion etc

I have to check the inductances again, but even those aren't so bad.

I am planning to do a little line audio transformer competition.

But right off the bat these do better than like the Visaton TR10.16.

This has mostly to do with the symmetry of the primary windings.

If I have some time this weekend or so, I can share some more information (I think I already promised that 😄😄)

Although there is no air gap, in practice most transformers can handle a little bit of DC current.

Often with reduced performance.

In this case I wouldn't expect much, definitely not enough for an EL84.

Btw, it's either inflation or people at Conrad have been paying attention.

But these used to sell for just 5 bucks only a few years ago

If they were interleaved, I'd expect to see those tell-tale lines where E meets I every other time.1. Post #1 transformer does not have any rating for DC current.

It appears that the E's and the I's are Interleaved.

Like in the 2nd picture from a PP transformer.

But not so in the Conrad ... both sides the same, and both welds are on top ...

Attachments

Occam's razor says "the simpler explanation is the proper one" 😄I am amazed at the Air gapped laminations.

Perhaps it was made for a solid state drive with DC current and with lower primary voltages;

versus higher plate voltages?

I guess cost is the answer 😎

It is much faster (i.e. "cheaper") to grab a proper height stack (say 20-22 mm) of E lamination out of the box and insert them "all at once" in the already wound plastic bobbin, then grab same height of I lamination, put it in place to complete the magnetic path, press them momentarily with a quick clamp and run an electric welding bead across the joint on each side.

I estimate some 45 seconds per transformer.

While interleaving is slow, might take 2 or more minutes.

In this high volume cutthroat pricing market that is a huge difference.

There is a lamination insertion machine, my supplier has one for his "small transformer" manufacturing, but:

* It costs some money and takes significant bench space.

" You must load stacks of E and I lamination in hoppers at both sides.

* It does not fill the bobbin; it inserts, say, 95% of bobbin capacity but then you must insert the last 4 or 5 Es by hand and using s small hammer and then add missing Is.

In practice you need one machine per core size 😱

You can set it up for a different EI size but it involves partial disassembly and reassembly with the new separation, also new hoppers, half a morning job.

You'd better have a 100+ transformer order to justify that.

- Home

- Amplifiers

- Tubes / Valves

- Audio transformer for small tube projects?