few,heat shrinking the diagphram while it is attached to the stators shouldn't effect the glue gun glue ,as the glue won't be in direct contact with the hot air long enough to asorbe that much heat to loose grip.i had the same question about melting the plastic(styrene i think) grate as it was right (closest to)on the nozzle and did not cause any issues of warpping or melting of any compnents.worried about this i used o common hand held hair dry'er first and it was hot but not hot enough to tension the mylar.hope that helps. jer

heat shrinking the diagphram while it is attached to the stators shouldn't effect the glue gun glue ,as the glue won't be in direct contact with the hot air long enough to asorbe that much heat to loose grip.i

I might be able safely to apply heat to the diaphragm if I pull the stators apart so I can direct the air at the diaphragm. I'm sure, though, that if I try to blow hot air through the magnet wire stators in an effort to heat shrink the diaphragm on the other side of the wires, I'll definitely disrupt the hot melt glue joints. The copper wires are great thermal conductors, and when they warm up, the glue joints soften. I know from experience.

If I come up with a convenient way to remove one of the stators from the diaphragm perhaps heat shrinking would still be an option. It'll still make me very nervous though. Making the wire stators was enough work so that I'm not interested in risking ruining them based on a guess.

Few

understood,few,you could make small mock panel and then try it on that to see if it would work, and to see how much time it takes for something catastrophic to happen(on the mock up of course).i was going to use wires once.so i know the process it takes.let me think about that i little bit and i'll try to come up with a procedure.meanwhile i'll try to find my heat gun try some things myself. jer

Haven't read the entire thread, but I vaguely recall that polypropylene is a real PITA to glue (as is polyethylene)... Glue simply refuses to stick to it!

Hi Few,

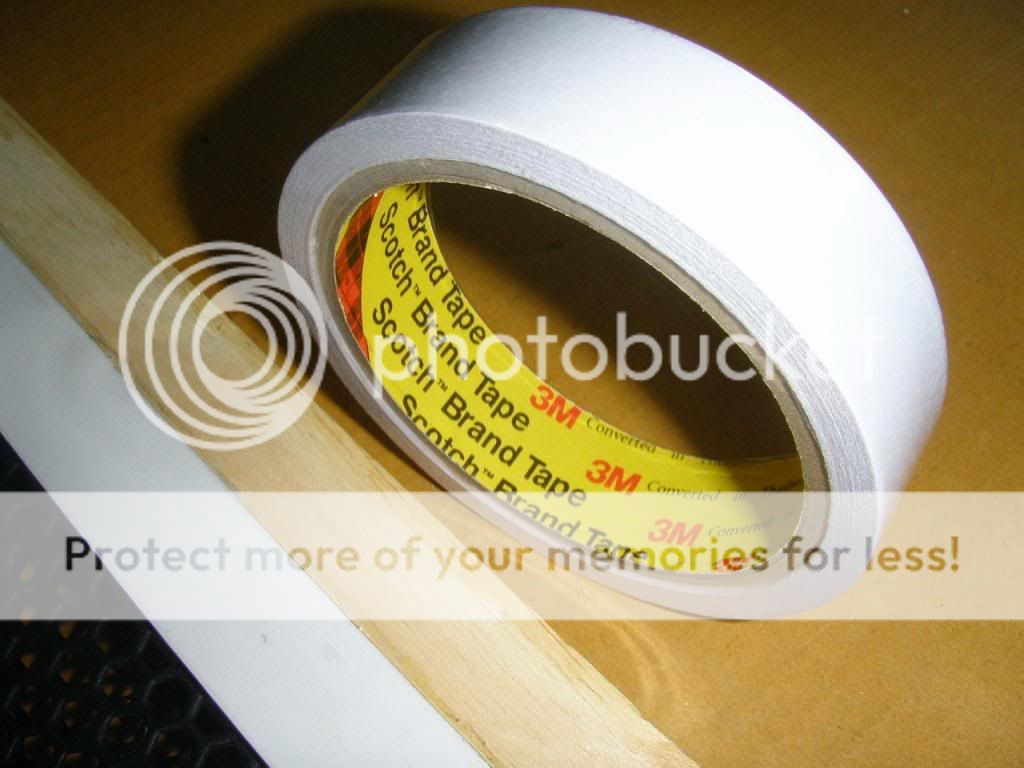

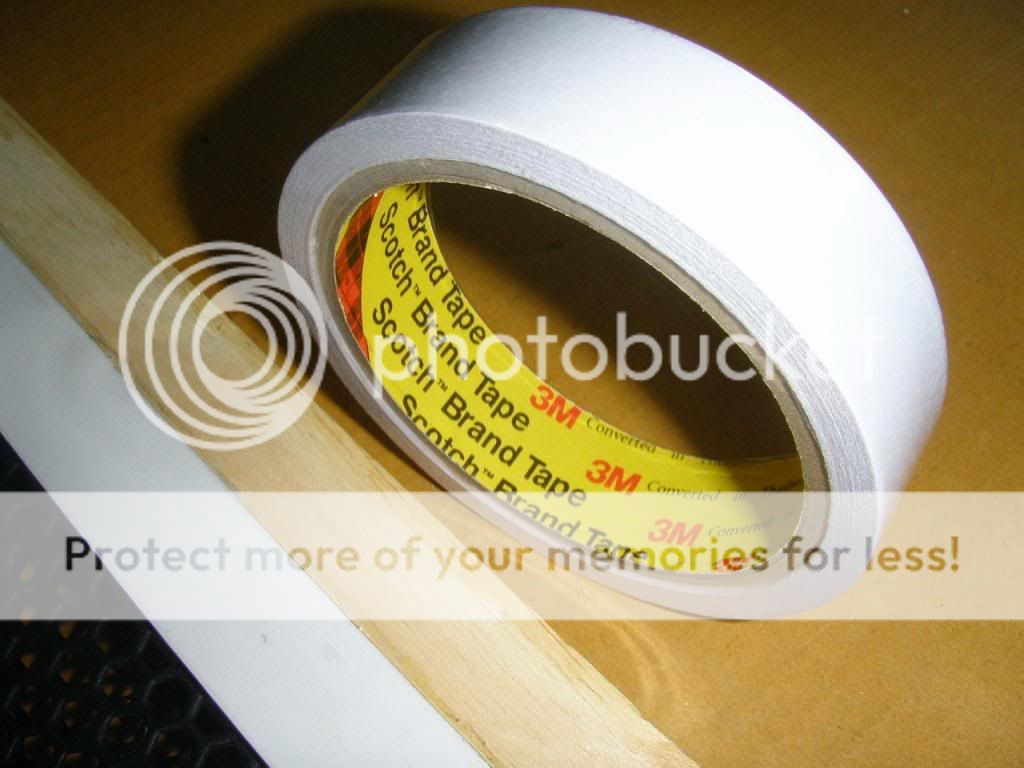

I use a thin double sided tape from 3 M to glue my diaphragm to the spacer. It works very well. It might just make your life a lot easier.

Wachara C.

I use a thin double sided tape from 3 M to glue my diaphragm to the spacer. It works very well. It might just make your life a lot easier.

Wachara C.

Wachara:

Does the tape "flex" som or do you find the bond stator-tape-film stable?

I tries to use Tesa duble sided sticky tape with PVC-spacers, but foud it to flex to much due to the tape!

/R

Does the tape "flex" som or do you find the bond stator-tape-film stable?

I tries to use Tesa duble sided sticky tape with PVC-spacers, but foud it to flex to much due to the tape!

/R

Hi SM7UYJ,

I do not understand your question well. I only use this tape to glue the Mylar film to the spacer. The tape is not good for bonding the spacer to the stator. I have tried to tension Mylar film up to 2 kg plus heat treatment. And so far it is good.

Wachara C.

I do not understand your question well. I only use this tape to glue the Mylar film to the spacer. The tape is not good for bonding the spacer to the stator. I have tried to tension Mylar film up to 2 kg plus heat treatment. And so far it is good.

Wachara C.

few,can you post some pictures of your stators and also what is the wire diameter that you are using? jer

There are some photos here. I'm using double-build nylon-coated 24 gauge magnet wire with a percent open area of around 45%.

I'm testing my theory that it makes more sense to use fine wires and low percentage open area than large percentage open area and an extra acoustically resistive layer (such as felt) to damp resonances.

Few

I'm testing my theory that it makes more sense to use fine wires and low percentage open area than large percentage open area and an extra acoustically resistive layer (such as felt) to damp resonances.

Few

i agree with using a finer wire as i think it creates a higher density static field per area.i haven't had a chance to find my heat gun yet.by looking at the pics i see your concern,having used heat on all my diagphrams i still don't think the glue will have enough time to heat up enough to lose grip.however that is alot of work to risk destroying.you should be able to tighten up the mylar rather quickly and you could do it in intervals and sections allowing things to cool in between. it makes know difference to the mylar as long as all of the surface is eventualy heat treated otherwise wachara C.'s idea is a very good alternitive or use something sturdier for your frames.i also thought of using cold packs but that would risk bending the wire.but how about using a second blower following along with the heat gun, to cool the wires, as it is moving.or what about brushing some epoxy over the glue/wire bond to give extra protection from the heat and too asure a secure bond to the frame.

Last edited:

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Planars & Exotics

- Attaching ESL spacers to stators?