I think that takes you into something much more fundamental which is the basic enclosure design for the particular speaker. Typically the enclosure design has a great deal to do with handling of low frequencies, so it's really more a matter of what you are building, horn, sealed, bandpass, bass reflex, etc. But in general a quiet cabinet will help.

In a sealed box you may also want to add loose fill stuffing such as wool or hollow fiber dacron. Just take care that it is not in direct contact with the divers. Putting it into nylon stockings can be an easy solution to this. How much you use is often a matter of trials, listen, measure, re trial, etc until you are satisfied. If you really want to go high end you might also consider electronic high pass, and low pass filtering, with dedicated amps to each driver.

Translam wood cabinet construction with an Aluminum baffle has the potential for control of baffle diffraction, complex bracing, and resonance reduction. The forum has examples using a good router and a few pattern jigs. Even MDF cabinets look amazing.

Attachments

The underlying premise of the thread seems flawed.

1) That stuff in post one about "ultra-stiffnes" is not valid.

If weight is the limit, good plywood is just as strong as aluminium, see link.

6061-T6 Aluminum vs. Bamboo Plywood :: MakeItFrom.com

If cost is the limiting factor, good plywood is cheaper (where I am, anyway), so you can use more of it for the same cost.

2) Those "3-way super-floorstander" speakers could probably be optimised.

If you haven't already got a measurement mic and DSP and learned how to use them, I'd recommend doing that before jumping into something new.

1) That stuff in post one about "ultra-stiffnes" is not valid.

If weight is the limit, good plywood is just as strong as aluminium, see link.

6061-T6 Aluminum vs. Bamboo Plywood :: MakeItFrom.com

If cost is the limiting factor, good plywood is cheaper (where I am, anyway), so you can use more of it for the same cost.

2) Those "3-way super-floorstander" speakers could probably be optimised.

If you haven't already got a measurement mic and DSP and learned how to use them, I'd recommend doing that before jumping into something new.

I mentioned this in another thread, but you might want to check out Panzerholz

you might want to check out Panzerholz

Yea. This and similar products are about as expensive as aluminium - but have excellent damping, unlike aluminium.

damping factor values - audio qualia

In fact, Panzerholz was literally the best thing he measured, and aluminium had the worst damping.

or that there won't be any advantage over an MDF enclosure?

Scroll to the bottom of the link below. Notice that MDF and bamboo have the same density. Compare the stiffness:weight ratios. MDF is pretty bad.

MDF also has poor damping. Notice, in the damping factors link, how much better bamboo is?

For "someone like me who has a zero-compromise-mind" there is no reason to use MDF. If you can't afford Panzerholz, or bamboo, a laminate of good ply & filled resin looks like it'd offer the best of both worlds, strength and damping.

MDF vs. Bamboo Plywood :: MakeItFrom.com

As mentioned above the original design had 1" thick panels, can I keep it that way or do you think a thinner panel with internal bracing will be better?

Do both. A lot. For "ultra-stiffnes", thickness is king. If you double the wall thickness, you cube the stiffness.

Create a spreadsheet. Put the the Elastic Modulus of several materials in column A. Put the thickness of material in column B.

Set column C = [A * B * B * B]

...then fiddle with the material thickness. That will tell you roughly how thick a wall of material X has to be to match the stiffness of material Y.

A premium material, like 10mm alu plate, can be easily 'beaten' (for the same weight and much less money) by a thicker panel of cheap-but-good construction ply.

Yea. This and similar products are about as expensive as aluminium - but have excellent damping, unlike aluminium.

damping factor values - audio qualia

In fact, Panzerholz was literally the best thing he measured, and aluminium had the worst damping.

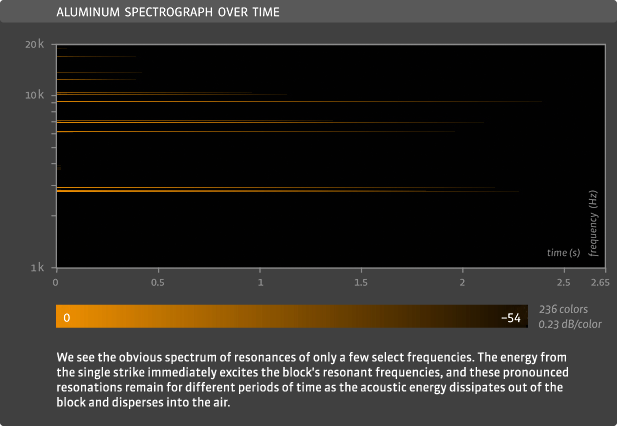

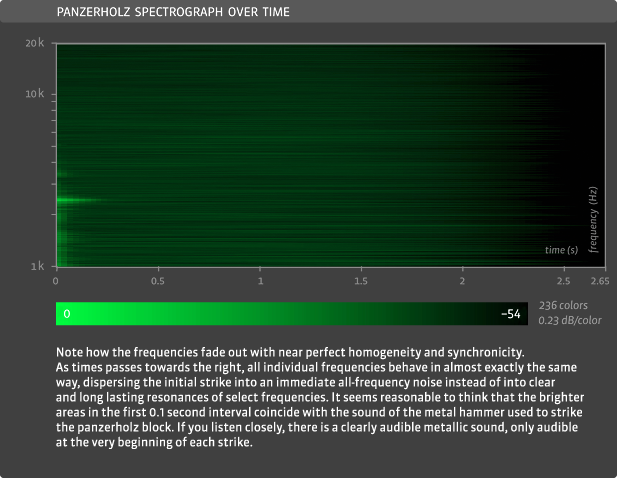

If we look at these resonances isn't it other way around ? While panzerholz resonates equally at all frequencies, aluminium has only few strips and the lowest being at around 2800Hz - up to that point it doesn't make a sound at all. If you make a two way with crossover point at 1500-2000Hz why would aluminium be a problem ?

Or maybe i don't interpret these measurements very well ?

Aluminium:

Panzerholz

I mean - Magico, Kii Three, Beolab 90, YG-Acoustics and few others make their cabinets out of pure aluminium. Is it possible that they have done it wrong - measuring very high performance everywhere ?

Last edited:

@Zvu did you get the distortion measurements of YG Acoustics / BeoLab 90? Links please

I did not for B&O. Here's some for YG: YG Acoustics Sonja 1.3 loudspeaker Measurements | Stereophile.com

How is that related to type of material used for enclosure ?

Last edited:

It's interesting to look at different materials, alum, bamboo ply, etc., however it's really the total combination of enclosure + dampening treatments that really matters. With bracing and dampening I can see no reason why alum couldn't be used for a superb bookshelf two way the poster wants to do. Other factors such as fundamentals of drivers and crossover choices, diffraction treatment, etc. are going to play a much greater role.

Or maybe i don't interpret these measurements very well ?

Honestly - I'm not sure.

I notice you linked only two images, not the website, and the site the images came from comes to exactly the opposite conclusion.

Thus, there appears to be a multiciplicity of ways that the data can be interpreted.

The Virtues of Panzerholz : An Investigation into the Acoustical Properties of Aluminum and Panzerholz

If we look at these resonances isn't it other way around ? While panzerholz resonates equally at all frequencies, aluminium has only few strips and the lowest being at around 2800Hz - up to that point it doesn't make a sound at all. If you make a two way with crossover point at 1500-2000Hz why would aluminium be a problem ?

A test block has weight Z and rings like a bell at 2800Hz and above.

If a larger test block weighed 10*Z, would that larger block ring like a bell at 280Hz and above?

Maybe. If then by comparison we take smaller block, does it ring at even higher frequency ?

I've linked the two that i can compare and hope to understand. Others don't mean much to me.

I've read the conclusion from their website but question remains if it is easier to mitigate or avoid one strong resonance or to try to deal with resonances that are lower in lewel but exist through the whole spectrum.

I've linked the two that i can compare and hope to understand. Others don't mean much to me.

I've read the conclusion from their website but question remains if it is easier to mitigate or avoid one strong resonance or to try to deal with resonances that are lower in lewel but exist through the whole spectrum.

Last edited:

Aluminum isn’t that expensive right?! I just looked up the price and it’s only €1,79/kg or $0,98/lb

A bit late in the game for me, but I would be curious to know where would one get aluminium for €1,79/kg, in quantities less than ~500kg, for example.

Locally, 6061 is €6.5/kg and 6082 is €5.5/kg...

...unless the conversation has moved away from aluminium by now.

I think the point is if you have the budget for it and like the aesthetics of aluminum and the tools and skills to build with it, you can make a speaker box, just like you could any number of other materials. In any event that is not going to be the decisive factor in whether you have a great speaker or not.

Their website disagrees:Magico, for instance, doesn't use damping - only braces:

"By damping the high Q resonance via elaborate constrained layer damping we have eliminated all energy storage and audible resonance from our enclosure."

Magico Loudspeakers | Enclosures

This seems like an odd point / straw man.Maybe. If then by comparison we take smaller block, does it ring at even higher frequency ?

At the risk of being obvious, a complete speaker will be heavier than the test block, not lighter.

The magico website shows a resonance in the 'aluminium only' (presumably undamped) enclosure that is below 1000Hz.

Locally, 6061 is €6.5/kg and 6082 is €5.5/kg...

And what matters for a builder is what you can get in sheet form, locally.

When I was material shopping, I put my options in a spreadsheet, and calculated price by volume (cubic metre), e.g.

Veneered birch $4,128.09

I added Permali (18mm) and Alu (10mm) to the list.

Aluminium $23,606.25

Permali $22,694.44

These are a bit steep, compared to what I actually acquired:

F27 ply $1,889.80

Bamboo Strand Woven $9,711.81

I got the ply because it is cheap and the F27 grade is about 50% stronger than the typically recommended (birch or marine) ply. The bamboo is for surface cosmetics & hardness, as well as having machining and acoustic properties that are a bit ahead of regular ply.

Their website disagrees:

"By damping the high Q resonance via elaborate constrained layer damping we have eliminated all energy storage and audible resonance from our enclosure."

Magico Loudspeakers | Enclosures

They use damping - i got the wrong impression from the photos i found on the web of what it looks like inside.

Their website also disagrees about aluminium being a bad material for loudspeaker cabinets - kinda confirming my view.

"MAGICO has pioneered the use of aluminum in loudspeakers design. We built our first aluminum enclosure back in 1994 and have never looked back. Extremely stiff yet easy to damp, a properly designed aluminum enclosure is the ideal platform for high-performance loudspeakers. So inert, the enclosures have no discernible coloration of their own-allowing the drivers to operate with the utmost clarity and dynamics."

...This seems like an odd point / straw man.

At the risk of being obvious, a complete speaker will be heavier than the test block, not lighter.

What does this have to do with anything ? Loudspeaker will have differently shaped aluminium, thinner (possibly curved?) braced walls than block from the test - all of that affects resonance.

Sheet of aluminium 2cm x 100cm x 200cm is around 340 euros here. Not too much if you're making high end speakers and certainly doable for standmount or floorstanding loudspeaker.

Last edited:

Their website also disagrees about aluminium being a bad material for loudspeaker cabinets - kinda confirming my view.

I said alu is expensive and has poor damping (ringing).

The Magico website says:

"costly to implement"

AND

"a sharpened Q of the resonance results in an audible ring."

That doesn't look like at all like disagreement.

As for the implementation:

"Extremely stiff yet easy to damp"

"elaborate constrained layer damping"

They seem to be claiming two opposing things here. If it's easy, why make it elaborate - other than to justify high prices? I think the real answer is that you can't really trust advertising copy.

My understanding is that any light structure can be damped with a relatively light mass.

e.g. a drummer can damp a cymbal by grabbing a small portion of it between their fingers.

...and the Magico thing, well braced aluminium, gets a light structure that's very strong.

But this strength:weight is not unique to aluminium and other metals. Regular plywood is equivalent. Other humble materials are stronger.

Spruce-pine-fir vs. 6008 Aluminum :: MakeItFrom.com

Many humble materials would also cost less and can be assembled with more easily obtained tools.

A text block X resonates at 2800Hz (and above)What does this have to do with anything ?

A heavier test block would resonate lower. A lighter test block would resonate higher.

Almost any speaker will be heavier than X. Some of it's resonances will therefore be lower that 2800Hz.

The Magico website supports this.

Sheet of aluminium 2cm x 100cm x 200cm is around 340 euros here. Not too much if you're making high end speakers and certainly doable for standmount or floorstanding loudspeaker.

That's remarkably cheap compared to prices in Australia! Particularly considering that most of it is mined here.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Aluminum enclosure for 2-way bookshelf?