The unit is a Sony TA1150 integrated that I've had since 2018. It was unwell when I bought it but it did power up and it did pass signal. I did not use it per se, just hooked up for the odd listen over a couple of years then there came a time when it stopped amplifying.

I learned some transistors failed, outputs and drivers so i replaced them with those which were recommended. I also replace the electrolyltic capacitors associated with the power supply. At that point the amplifier was working well enough to leave connected in a small "hobby room" system.

Not long ago, the pilot lamp did not light up. I did the disassembly necessary to repair that and thought it was a good time to replace all the electrolytic capacitors and that task spanned several days. When all the new electrolytic capacitors were in place, I used a 40 watt DBT to check for shorts and there were none. It went dark almost immediatly after turning on the power switch.

Since a number of components were new, I decided to check and if necessary, re-set the bias. Since the DBT went dark right away and my understanding was not to use a DBT when setting bias, the amplifier was plugged dirctly in to wall power.

As per the service manual, the target is 25mv and the left channel bias was pretty close. The right channel was nearly 60mv so I attempted to adjust that channel's bias pot.

As I rotated the pot, both 1.6A fuses blew and I noticed the telltale odor of an overheated component. Even now, I fail to see anything that shows heat damage.

My next step was replaing the fuses and turning the amp on using a DBT which went bright and stayed bright so there was now a short.

I pulled all eight output transitors, which are now four MSJ15032G and four MSJ15033G. One 15032 and one 15033 in the right channel were damaged. At that point I ordered new 1K ohm bias pots. When they arrived, I installed them and I replaced the two bad output transistors.

Again with a DBT, I turned on the power. DBT went bright, stayed bright and both fuses blew again. As a shot in the dark, I replaced all eight of the output transistors one more time on the off chance that some others were injured and would fail under load. There was no change, DBT wet bright, stayed bright and both fuses blew.

My last attempt to trouble shoot the short was to remove all eight output transistors and see what the DBT did in conjunction with a variac but that too changed nothing. DBT got bright with the variac around 50 volts. I went no further so fuses are still intact.

I am unsure at this time what to do next. My hope is that some knowedgable person here can point me towards the cause of this shorting problem. I don't particulary want to junk this amplifier, I bought it for a reason. A Sony TA1150 was the very first brand new amplifier I ever bought. That was in 1973 and I was 20 years old.

Doing the math, that makes me 71 and my intention was to make this TA1150 my final amplifier. A kind of ironic twist that only I would appreciate.

I learned some transistors failed, outputs and drivers so i replaced them with those which were recommended. I also replace the electrolyltic capacitors associated with the power supply. At that point the amplifier was working well enough to leave connected in a small "hobby room" system.

Not long ago, the pilot lamp did not light up. I did the disassembly necessary to repair that and thought it was a good time to replace all the electrolytic capacitors and that task spanned several days. When all the new electrolytic capacitors were in place, I used a 40 watt DBT to check for shorts and there were none. It went dark almost immediatly after turning on the power switch.

Since a number of components were new, I decided to check and if necessary, re-set the bias. Since the DBT went dark right away and my understanding was not to use a DBT when setting bias, the amplifier was plugged dirctly in to wall power.

As per the service manual, the target is 25mv and the left channel bias was pretty close. The right channel was nearly 60mv so I attempted to adjust that channel's bias pot.

As I rotated the pot, both 1.6A fuses blew and I noticed the telltale odor of an overheated component. Even now, I fail to see anything that shows heat damage.

My next step was replaing the fuses and turning the amp on using a DBT which went bright and stayed bright so there was now a short.

I pulled all eight output transitors, which are now four MSJ15032G and four MSJ15033G. One 15032 and one 15033 in the right channel were damaged. At that point I ordered new 1K ohm bias pots. When they arrived, I installed them and I replaced the two bad output transistors.

Again with a DBT, I turned on the power. DBT went bright, stayed bright and both fuses blew again. As a shot in the dark, I replaced all eight of the output transistors one more time on the off chance that some others were injured and would fail under load. There was no change, DBT wet bright, stayed bright and both fuses blew.

My last attempt to trouble shoot the short was to remove all eight output transistors and see what the DBT did in conjunction with a variac but that too changed nothing. DBT got bright with the variac around 50 volts. I went no further so fuses are still intact.

I am unsure at this time what to do next. My hope is that some knowedgable person here can point me towards the cause of this shorting problem. I don't particulary want to junk this amplifier, I bought it for a reason. A Sony TA1150 was the very first brand new amplifier I ever bought. That was in 1973 and I was 20 years old.

Doing the math, that makes me 71 and my intention was to make this TA1150 my final amplifier. A kind of ironic twist that only I would appreciate.

Last edited:

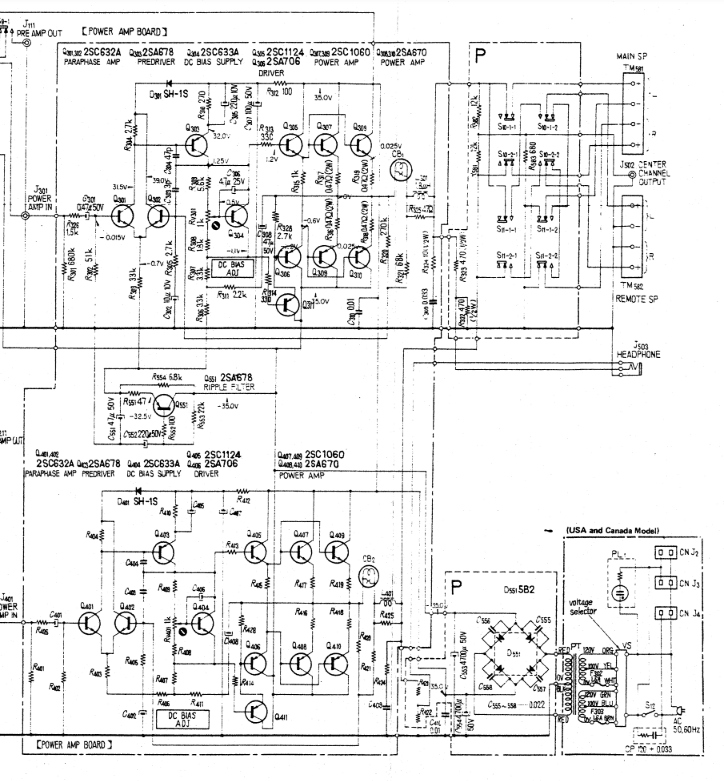

The driver transistors (three per channel, Q305, Q306, Q311, Q405, Q406, Q411) or the rectifier bridge (D551) might be damaged. Transistors and diodes usually fail shorted, so with a bit of luck you can identify any damaged components with a diode or a resistance test on an unpowered amplifier.

I just put this on my list of design errors in commercial equipment, https://www.diyaudio.com/community/threads/design-errors-in-commercial-equipment.396887/ It's good practice to connect the trimming potmeters such that the quiescent current goes to zero when the wiper contact is interrupted, but the designers connected them such that the current goes through the roof.

I just put this on my list of design errors in commercial equipment, https://www.diyaudio.com/community/threads/design-errors-in-commercial-equipment.396887/ It's good practice to connect the trimming potmeters such that the quiescent current goes to zero when the wiper contact is interrupted, but the designers connected them such that the current goes through the roof.

Last edited:

Always use some current limiting when initially setting the bias, and never connect speakers while adjusting. First set the pots to the minimum bias end (that may take a little figuring out).

Once you've figured out the rough point at which bias current starts to flow you may be able to run with full power and tweak the last bit, as the current limiting may prevent getting to the correct value.

When current limited you have to watch out for the current limit setting the bias rather than the pot - if that's the case it is not safe to restore full power.

Another trick is to replace fuses with 100 ohm resistors or so to provide moderate but limited current supplies - change to 50 ohms then 30 ohms to verify safe operation (ie have more 100 ohm resistors in parallel to check current stays under control).

Once you've figured out the rough point at which bias current starts to flow you may be able to run with full power and tweak the last bit, as the current limiting may prevent getting to the correct value.

When current limited you have to watch out for the current limit setting the bias rather than the pot - if that's the case it is not safe to restore full power.

Another trick is to replace fuses with 100 ohm resistors or so to provide moderate but limited current supplies - change to 50 ohms then 30 ohms to verify safe operation (ie have more 100 ohm resistors in parallel to check current stays under control).

I completely agree with Marcel's observation.I just put this on my list of design errors in commercial equipment, https://www.diyaudio.com/community/threads/design-errors-in-commercial-equipment.396887/ It's good practice to connect the trimming potmeters such that the quiescent current goes to zero when the wiper contact is interrupted, but the designers connected them such that the current goes through the roof.

Replacing the bias pot would a prudent precaution. A further "bandaid"would add a 10K from wiper to the 5.6k end of the pot. If the wiper were to open, the bias spreader would pull the bias to minimum rather than toward destruction.

Also good advice from Mark.

Q305, Q306, Q311, Q405, Q406, Q411) or the rectifier bridge (D551) might be damaged.

Q301, Q302, C302, Q401, Q402 and C402

Most, if not all, of the transistors in the above positions had leads coated in black oxidation. The only way I could reliably check them was out of circuit. All of them tested OK with the means at my disposal.

I have not yet checked rectifier bridge, D551. I did do that about three years ago but cannot remember how. At that time it was OK.

C402 is brand new as are all the electrolytic caps. I did not remove it but closely examined it. Top is not distended neither is the bottom

But I did find a bad transistor kind of by accident. I unsoldered Q303 - instead of Q301 or 302. I checked it and it is faulty. The service manual describes it as "pre driver".

That transistor at position Q303 is a PNP 2SA678. My brief search for a substitute quickly led to KSA1015. I have some of those on hand so can install one at Q303 and I am inclined to do likewise at Q403.

There are several 2SA678 transistors used in this TA1050 and if I understand correctly, those transistors are a Sony product. The package is green and has a unique shape. They are also some of the transistors with legs that are totally black with oxidation.

Should all of the 2SA678 transistors be replaced with KSA1015's?

I am kind of stuck with the single turn 1K trimmers I bought for the bias adjustment pots. I sort of understand it being common practice to tie one leg to the wiper leg, But if I did that, the trimmer would only be supported by a single pin. I was able to adapt the trim pots I got to be supported by two legs. The wiper pin is not one of those. I had to run a jumper from the wiper pin through the hole in the board. So in other words, the new trimmers are connected the same way as the old trimmers.

Always use some current limiting when initially setting the bias, and never connect speakers while adjusting. First set the pots to the minimum bias end (that may take a little figuring out).

Once you've figured out the rough point at which bias current starts to flow you may be able to run with full power and tweak the last bit, as the current limiting may prevent getting to the correct value.

When current limited you have to watch out for the current limit setting the bias rather than the pot - if that's the case it is not safe to restore full power.

Another trick is to replace fuses with 100 ohm resistors or so to provide moderate but limited current supplies - change to 50 ohms then 30 ohms to verify safe operation (ie have more 100 ohm resistors in parallel to check current stays under control).

Using current limiting initially is a sensible precaution and I shall do that if/when the time comes. I will use a variac in conjunction with a DBT. My selection of resistors is not extensive and I doubt I have on hand all of the values you suggested.

Replacing the bias pot would a prudent precaution. A further "bandaid"would add a 10K from wiper to the 5.6k end of the pot. If the wiper were to open, the bias spreader would pull the bias to minimum rather than toward destruction.

The bias pots have already been replaced, They are actually 1K. Since they are brand new, I will take the chance that they will not fail in the immediate future. Following instructions in the service manual. I currently have them turned to their lowest setting.

I am fighting the urge to throw in the towel on this TA1150.

Q303, a 2SA678 (described as, pre-driver on the schematic) was defective and I replaced it with a KSA1015. For symetry's sake, I did likewise at Q403.

Now, the DBT behaves properly as in goes dark almost immediatly after amplifier power is switched on.

RV301 and RV401 are brand new single turn trimmer pots that I installed several days ago.

I can adjust RV301 to exactly 25mv, the target voltage according to the service manual. RV401 however, does not alter the bias voltage at all. My meter displays (-)25.5 volts (not mv) regardless of whether I rotate RV401 or leave it alone.

Any posibility that someone here can offer a suggestion on what I should look at?

EDIT: I see on the schematic, (-)35 volts indicated leaving the power supply. When I obtained the (-)25 volts it was when the DBT was engaged. Might this voltage figure actually be (-)35 volts if the DBT was not in place?

If so, then would my assumption be correct that some component in the voltage pathway to RV401 is faulty?

Q303, a 2SA678 (described as, pre-driver on the schematic) was defective and I replaced it with a KSA1015. For symetry's sake, I did likewise at Q403.

Now, the DBT behaves properly as in goes dark almost immediatly after amplifier power is switched on.

RV301 and RV401 are brand new single turn trimmer pots that I installed several days ago.

I can adjust RV301 to exactly 25mv, the target voltage according to the service manual. RV401 however, does not alter the bias voltage at all. My meter displays (-)25.5 volts (not mv) regardless of whether I rotate RV401 or leave it alone.

Any posibility that someone here can offer a suggestion on what I should look at?

EDIT: I see on the schematic, (-)35 volts indicated leaving the power supply. When I obtained the (-)25 volts it was when the DBT was engaged. Might this voltage figure actually be (-)35 volts if the DBT was not in place?

If so, then would my assumption be correct that some component in the voltage pathway to RV401 is faulty?

Last edited:

Voltages around Q303 and Q304 (in the defective channel) would be a good starting point.what I should look at?

Don't do that. It's a simple design so I'm sure we can get it working.I am fighting the urge to throw in the towel on this TA1150.

Where are you measuring -25 V?

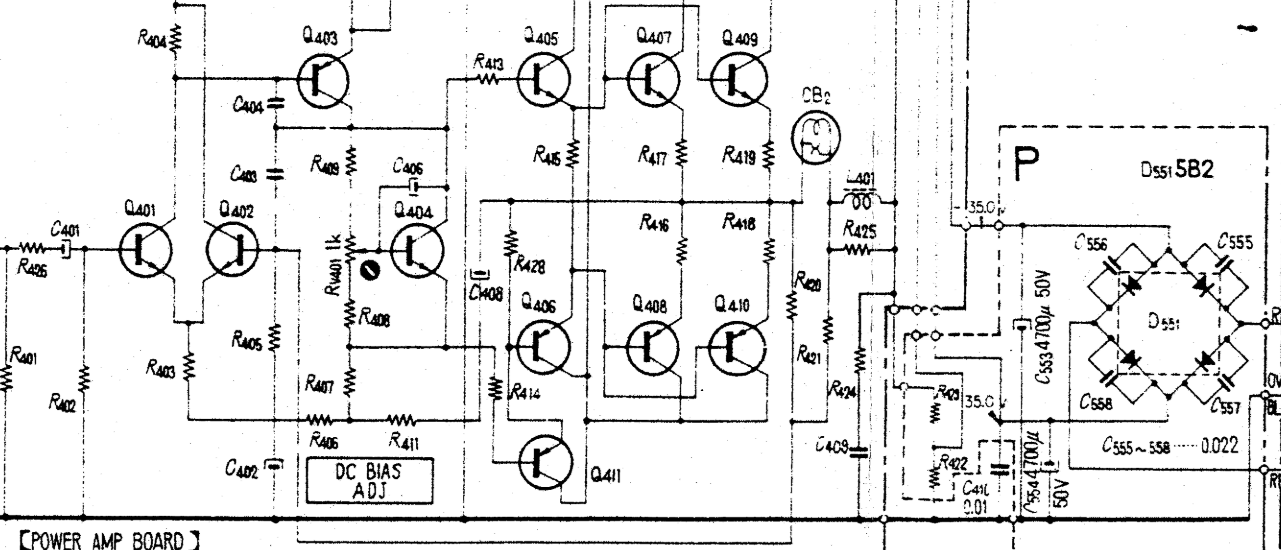

If turning R401 does noting I'd look at Q404, the drivers, and output stage.

Leave the dim bulb tester in place until you can get the amp to bias up properly.

Tom

My meter displays (-)25.5 volts (not mv) regardless of whether I rotate RV401 or leave it alone.

If you are measuring using the method in the manual from speaker output to the test point and you are reading 25 volts then it appears the emitter resistor in question has to be open circuit and the output transistor in question could also be faulty.

Set the bias preset to the end that gives minimum bias current until this is fixed and always use the DBT. The DBT will lower supply voltages.

I'm not sure I'd go as far as de-soldering everything, but the thought of just replacing all the silicon has certainly crossed my mind as well. Once all the silicon has been removed most of the resistors will be floating at one end so they can be checked with an ohmmeter.

Tom

Tom

I have seen open resistors that visually show no sign of damage. I an earlier post overheating smell was mentioned - after that I would trust no resistor in the neighbourhoodthe thought of just replacing all the silicon

Sure. I'm not suggesting that you don't check the resistors at all. I'm suggesting that you don't have to remove them to check them once the silicon is out of the amp. If you go through the trouble of removing all the resistors from the board you might as well replace them. Resistors are cheap.

If the -25 V bias is measured from the speaker output terminal to the emitters of the output devices, it wouldn't surprise me if some output devices are shorted and the emitter resistors blown. That could be the cause of the smell too. Easy to check with an ohmmeter.

Tom

If the -25 V bias is measured from the speaker output terminal to the emitters of the output devices, it wouldn't surprise me if some output devices are shorted and the emitter resistors blown. That could be the cause of the smell too. Easy to check with an ohmmeter.

Tom

RV401 is unlikely to have any effect upon DCV on output. If RV401 trims the collector-emitter voltage observed across Q404, the bias spreader is probably working. Adjust very cautiously just to confirm activity, and return to minimum.I can adjust RV301 to exactly 25mv, the target voltage according to the service manual. RV401 however, does not alter the bias voltage at all. My meter displays (-)25.5 volts (not mv) regardless of whether I rotate RV401 or leave it alone.

My favorite technique for troubleshooting when there's large erroneous bias is to write out a description of expected behavior, and then measure in circuit for departures from expectation. For example, in this circumstance:

With -25V at output, (probably stuck at negative rail), bias presented at base of Q402 should be much more negative than bias at base of Q401.

Therefore Q402 should be cutoff, Q401 should be conducting.

Current in Q401 should cause conduction in Q403, which should cause voltage drop across R410.

Collector of Q403 should be pulled toward positive rail. Bias spreader and all output devices should swing toward positive rail.

Feedback from output should be attempting to pull bias at base at base of Q402 to more positive voltage.

However, probing with a meter or scope should reveal a circuit node where reality doesn't follow the above description. With luck, the defective part is nearby.

Voltages around Q303 and Q304 (in the defective channel) would be a good starting point.

I followed that suggestion and measured voltages with DBT engaged at Q303 and Q304:

Q303

E 29.9V - schematic 32V

C 1.21V - schematic 1.25V

B 28.27V - schematic 31.5V

Q304

E (-)1.79V - schematic (-)1.1V (printing not clear)

C 0.78V - schematic 1.25V

B (-)1.4V - schematic 0.5V

For comparison, I measured the same voltages on the affected channel:

Q403

E 27.5V - schematic 32V

C (-)28.5V - schematic 1.25V

B 30.45V - schematic 31.5V

Q404

E (-)28.5V - schematic (-)1.1V (printing not clear)

C (-)28.3V - schematic 1.25V

B (-)27.7V - schematic 0.5V

I examined the foil side of the board and thought I discovered a defect. A foil trace pad at Q404 looked to be partially lifted so I resoldered it. Unfortunately it made no difference to allowing bias current to be adjusted.

The foil traces on this amp are quite fragile. I had done some transistor replacement about 3 years ago and quite likely loosened the bonding on some solder pads without realizing it. I do not know how much more component removal and replacement they can stand. At present, I alread had to jumper a couple of solder points.

To clarify what "tools" I have to work with, there is a old Weller variable temp soldering station with a small point tip, a 5A variac, a DBT and a <$100 Exotech DMM For de-soldering I use 1.5mm copper braid solder wick.

I am shocked, I suppose, that one small nudge of a bias trim pot caused this big of a problem. As mentioned, I had done a fair bit of component replacing already - output transistors, driver transistors, bias transistors and all of the electrolytic capacitors. At that point, the amp was working.

Had I not attempted to lower the bias voltage on that one channel from 60mv or so to 25mv, it would likely be still working.

I bet the wiper to the bias pot lifted and that caused the high bias current. That's a design flaw.

With V(B) > V(E) Q403 should be completely off. So something is causing Q403's collector to be pulled to the negative rail. I wonder if Q411 has turned to slag.

You may want to invest in a solder sucker. Jonard DP-200 is my favourite: https://www.digikey.ca/en/products/detail/jonard-tools/DP-200/243485

Tom

With V(B) > V(E) Q403 should be completely off. So something is causing Q403's collector to be pulled to the negative rail. I wonder if Q411 has turned to slag.

You may want to invest in a solder sucker. Jonard DP-200 is my favourite: https://www.digikey.ca/en/products/detail/jonard-tools/DP-200/243485

Tom

And likely most the problem.

Huge DC offset seen is likely that second gain stage/ vbe multiplier.

Something is open or shorted.

Current source is basic bootstrap R407/ 406 / R408

check them.

Cap C48

Basically anything in the line since Q403 / 406

showing negative voltages where they shouldnt be.

Since turning a bad pot caused the problem could

also be hidden open tracks or if electrolytic have leaked

and damaged the tracks.

So C402 , 406 , 408 look like electros

and could have damaged the board

or have pins pulled out that is not visible.

basically sounds like something open or shorted

in second gain stage and huge DC offset

and yes the pot was wired in non ideal manner

from the start, any whoopsie doo or open circuit

would blast the outputs. Not your fault for the most part.

Design error.

Can also recheck your new pot install connections

or lifted traces.

Huge DC offset seen is likely that second gain stage/ vbe multiplier.

Something is open or shorted.

Current source is basic bootstrap R407/ 406 / R408

check them.

Cap C48

Basically anything in the line since Q403 / 406

showing negative voltages where they shouldnt be.

Since turning a bad pot caused the problem could

also be hidden open tracks or if electrolytic have leaked

and damaged the tracks.

So C402 , 406 , 408 look like electros

and could have damaged the board

or have pins pulled out that is not visible.

basically sounds like something open or shorted

in second gain stage and huge DC offset

and yes the pot was wired in non ideal manner

from the start, any whoopsie doo or open circuit

would blast the outputs. Not your fault for the most part.

Design error.

Can also recheck your new pot install connections

or lifted traces.

Q403

E 27.5V - schematic 32V

C (-)28.5V - schematic 1.25V

B 30.45V - schematic 31.5V

Your reported Q403 base voltage is 30.45 V, and emitter is 27.5V. That's about 3V of reverse bias on Q403 b-e junction, which suggests it's not conducting any current. You should reconfirm these measurements. A more direct measurement is to look at voltage drop across R410 as indication of Q403 current flow. Just looking at schematic, how can Q403 emitter voltage be lower than base? If true, where/how is the current flowing? Something very odd. No current in Q403 could help explain negative voltages seen at bias spreader and output.

- Home

- Amplifiers

- Solid State

- Adjusting an old bias pot did some damage and I am unsure how to proceed